Professional Documents

Culture Documents

One Ways Slab Design To BS 8110-1997

Uploaded by

Gihan ChathurangaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

One Ways Slab Design To BS 8110-1997

Uploaded by

Gihan ChathurangaCopyright:

Available Formats

Basic Structural Element Design to BS 8110-1:1997

1.0 Slab Design

1.1 One Way Spanning Slab Design

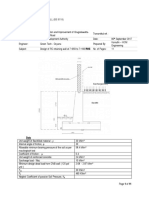

Figure 1.1: General Arrangement

Edifice Consultants Pvt.Ltd Page 1

Basic Structural Element Design to BS 8110-1:1997

Reference Calculation Out Put

Design of One Way Spanning Slab

Cover to Reinforcement

BS 8110- For durability requirements: Assume mild exposure conditions.

1:1997 Nominal Cover required is 20mm.

Table 3.3

BS 8110- For fire requirements: Assume 2 hour fire resistance

1:1997 Nominal Cover required is 25mm

Table 3.4

Hence Select a cover of 25mm. Cover 25mm

Slab load evaluation

Assume 125mm thick slab.

Self weight of the slab = 0.125 24 = 3kN/m 2

Finishes = 1kN/m 2

Total Dead Load (gk ) = 3 + 1 = 4kN/m 2

BS 6399:Part 1

Imposed load (qk ) = 3kN/m 2

= 1.4g + 1.6q n = 10.4kN/m2

k k

Hence Design load (n) = 1.4 4 + 1.6 3

= 10.4kN/m2

ly = 7425mm

lx = 3225mm

ly 7425

= = 2.3 > 2

lx 3225

Hence Slab Panel is one way spanning slab.

Edifice Consultants Pvt.Ltd Page 2

Basic Structural Element Design to BS 8110-1:1997

Reference Calculation Out Put

According to Table 3.12 of BS 8110-1:1997 maximum sagging moment

is at the middle of end span and maximum support moment is at first

interior support and in both case maximum bending moment is

0.086FL

Consider a 1m wide strip of the Slab.

F = 10.4 3.225 = 33.54kN/m

Maximum moment = 0.086FL = 0.086 33.54 3.225 = 9.30kNm/m

Assume T10 is to be used as main reinforcement.

Effective depth (d)

10

d = 125 25 = 95mm

2

M 9.30 106

K= = = 0.034 < 0.156

fcubd2 30 1000 952

Hence section can be designed as a singly reinforced section.

K

z = 0.5 + 0.25 d

0.9

0.034

z = 0.5 + 0.25 d = 0.96d > 0.95d

0.9

Hence Area of reinforcement required ,

M 9.30 106 mm2

A s,req = = = 235

0.87fy Z 0.95 460 0.95 95 m

Table 3.25 Checks for minimum area of reinforcement

100As,min

= 0.13

bh

0.13 1000 125 mm2

A s,min = = 162.5

100 m

Provide T10 @ 200mm C/C

Edifice Consultants Pvt.Ltd Page 3

Basic Structural Element Design to BS 8110-1:1997

Reference Calculation Out Put

mm2 T10 @ 200 B1

A s,provided = 393

m

Checks for maximum spacing

Clause Maximum spacing is lesser of 3 times effective depth or 750mm.

3.12.11.2.7 3d = 3 95 = 285mm

Hence provided spacing of 200mm is satisfactory.

Distribution Steel

Distribution steel needs to satisfy the minimum area of reinforcement

requirement.

0.13 1000 125 mm2

A s,min = = 162.5

100 m

Hence provide T10 @ 300mm C/C.

mm2

A s,provided = 262

m

Maximum spacing is lesser of 3 times effective depth or 750mm.

3d = 3 95 = 285mm

Hence provided spacing of T10 @ 300mm spacing is satisfactory T10@ 300 B2

Checks for Deflection

For deflection check end span slab panel is critical.

Span =3225mm

Table 3.9 For simply supported slab panel

Span

Basic = 20

Effective Depth

For a Continuous slab panel

Span

Basic = 26

Effective Depth

Edifice Consultants Pvt.Ltd Page 4

Basic Structural Element Design to BS 8110-1:1997

Reference Calculation Out Put

In an end slab panel one edge is simply supported and the other end is

continuous. Hence,

Span 20 + 26

Basic = 2 = 23

Effective Depth

Span 3225

Actual = 95 = 33.94

Effective Depth

Span Span

Allowable = Basic F1 F2

Effective Depth Effective Depth

F1 Modificati on Factor for Tension Reinforcem ent

F2 Modificati on Factor for Compressi o n Reinforcem ent

2 A s,req 1

fs = fy

3 A s,pro b

b = 1

2 235 1

fs = 460 = 183.38N/mm2

3 393 1

M 9.30 106

= = 1.03

bd2 1000 952

(477 fs ) (477 183.38)

F1 = 0.55 + = 0.55 + = 1.82 < 2

M 120(0.9 + 1.03)

120(0.9 + 2 )

bd

No Compression reinforcement is provided.

Hence F2 = 1

Span Span

Allowable = Basic F1 F2

Effective Depth Effective Depth

Span

Allowable = 23 1.82 1 = 41.86

Effective Depth

Span Span

Allowable > Actual

Effective Depth Effective Depth

Hence deflection check is satisfied Deflection Ok

Edifice Consultants Pvt.Ltd Page 5

Basic Structural Element Design to BS 8110-1:1997

Reference Calculation Out Put

Checks for Shear

Clause Shear is critical at first interior support.

3.4.5.2

0.6F = 0.6 33.54 = 20.12N/mm2

Clause Maximum possible shear , lesser of Maximum shear

3.4.5.2 0.8 fcu or 5N/mm2 Ok

0.8 fcu = 0.8 30 = 4.38N/mm2

Clause V 20.12 103

v= = = 0.21N/mm2 < 4N/mm2

3.4.5.2 bvd 1000 95

Hence applied shear stress is less tan maximum allowable.

Table 3.8 1 1 1

100As 3 400 4 1 fcu 3

v c = 0.79

b v d d m 25

100As 100 393

= = 0.413 < 3

b v d 1000 95

1 1

400 4 400 4

d = 95 = 1.43 > 1

m = 1.25

1

1 1 30 3

v c = 0.79 [0.413] 3 1.43 = 0.72N/mm2

1.25 25

v < vc

Hence shear check is satisfied. Shear is Ok

Edifice Consultants Pvt.Ltd Page 6

You might also like

- BasicStainedGlassMakingLookInsidetheBook PDFDocument10 pagesBasicStainedGlassMakingLookInsidetheBook PDFComan Eduard100% (2)

- Two Way Design Slab To BS 8110Document6 pagesTwo Way Design Slab To BS 8110Gihan Chathuranga100% (18)

- Strip Footing Design ExampleDocument6 pagesStrip Footing Design ExampleMthokozisi Mbiba100% (2)

- RCD Course Work PDFDocument60 pagesRCD Course Work PDFSaciid LaafaNo ratings yet

- Design in Reinforced Concrete To BS 8110 1Document66 pagesDesign in Reinforced Concrete To BS 8110 1paul macharia100% (13)

- Design of Beams To BS 8110Document14 pagesDesign of Beams To BS 8110Kasun Karunaratne99% (76)

- Examples Design Reinforced Concrete Buildings Bs8110 PDFDocument2 pagesExamples Design Reinforced Concrete Buildings Bs8110 PDFDanielle59% (17)

- Staircase Design To BS 8110-1:1997Document9 pagesStaircase Design To BS 8110-1:1997Gihan Chathuranga100% (9)

- Design of RC Retaining Wall (BS 8110) )Document11 pagesDesign of RC Retaining Wall (BS 8110) )Chiran Semasinghe100% (3)

- Structural Design Report 2017.12.25Document27 pagesStructural Design Report 2017.12.25Gihan ChathurangaNo ratings yet

- BS 8110 PART 3 1985 - Design Charts For Singly Reinforcement Beam, Doubly Reinforcement Beam & Rectangular ColumnsDocument62 pagesBS 8110 PART 3 1985 - Design Charts For Singly Reinforcement Beam, Doubly Reinforcement Beam & Rectangular ColumnsJacky Tiong100% (1)

- Deflection Check (Beams BS 8110)Document2 pagesDeflection Check (Beams BS 8110)dhanya1995No ratings yet

- Structural Design Report 07.06.2016Document22 pagesStructural Design Report 07.06.2016Gihan ChathurangaNo ratings yet

- Structural Design Report 07.06.2016Document22 pagesStructural Design Report 07.06.2016Gihan ChathurangaNo ratings yet

- Slab DesignDocument87 pagesSlab Designshamen amarasekaraNo ratings yet

- Design Detail To Bs 8110 1997Document32 pagesDesign Detail To Bs 8110 1997Duke Thibbotuwawa0% (2)

- Design of Continuous Beam and Slab Footing Using BS 8110-1:1997Document8 pagesDesign of Continuous Beam and Slab Footing Using BS 8110-1:1997Ubani Obinna Ranks80% (5)

- Tower Crane Foundation Design 24.07.2016Document11 pagesTower Crane Foundation Design 24.07.2016Gihan Chathuranga92% (13)

- Tower Crane Foundation Design 24.07.2016Document11 pagesTower Crane Foundation Design 24.07.2016Gihan Chathuranga92% (13)

- Design of Column For Axial Loads and BendingDocument6 pagesDesign of Column For Axial Loads and BendingGihan ChathurangaNo ratings yet

- RC Column Design BS8110Document5 pagesRC Column Design BS8110dantevariasNo ratings yet

- RC Beam Torsion Design (BS8110)Document2 pagesRC Beam Torsion Design (BS8110)Osarieme Osakue100% (3)

- Unit 8 (SERVICEABILITY LIMIT STATE (SLS) )Document26 pagesUnit 8 (SERVICEABILITY LIMIT STATE (SLS) )Zara Nabilah100% (2)

- Beam Design To BS 8110Document14 pagesBeam Design To BS 8110Gihan Chathuranga60% (5)

- Structural Design Report Rev 02 24.01.2018Document51 pagesStructural Design Report Rev 02 24.01.2018Gihan ChathurangaNo ratings yet

- Structural Design Report Rev 02 24.01.2018Document51 pagesStructural Design Report Rev 02 24.01.2018Gihan ChathurangaNo ratings yet

- Technical Info Wireless Internet Service Provider (WISP)Document6 pagesTechnical Info Wireless Internet Service Provider (WISP)Ton HerNo ratings yet

- LECTURE NOTE 01 - RCC DesignDocument14 pagesLECTURE NOTE 01 - RCC DesignMohamed AbdNo ratings yet

- Design of BeamsDocument19 pagesDesign of BeamssnsatyanarayanaNo ratings yet

- Minimum Edge Distances As Identified in BS 5950Document1 pageMinimum Edge Distances As Identified in BS 5950Jagdish DhanuskarNo ratings yet

- Unit 13 (DESIGN OF SHORT BRACED COLUMNS)Document21 pagesUnit 13 (DESIGN OF SHORT BRACED COLUMNS)Zara Nabilah80% (15)

- PAB 831 Industrial Concrete Products: Perunding BaktiDocument1 pagePAB 831 Industrial Concrete Products: Perunding Baktitini871100% (1)

- Pad Footing BS8110Document1 pagePad Footing BS8110Mer Din75% (4)

- Staircase Design To BS 8110Document5 pagesStaircase Design To BS 8110Alma M. LaraNo ratings yet

- Unbraced Short Column Design To BS 8110Document8 pagesUnbraced Short Column Design To BS 8110Gihan Chathuranga100% (3)

- Flat Slab Design ExampleDocument5 pagesFlat Slab Design ExampleKong SooYit58% (12)

- Slab Design To BS 8110Document11 pagesSlab Design To BS 8110Samuel Antobam100% (2)

- Column Design To Bs8110 TemplateDocument6 pagesColumn Design To Bs8110 TemplateMitra Rampersad100% (9)

- Unit 6 (DESIGN OF REINFORCED CONCRETE CONTINUOUS BEAMS)Document26 pagesUnit 6 (DESIGN OF REINFORCED CONCRETE CONTINUOUS BEAMS)Zara Nabilah90% (30)

- Hollow Pot DesignDocument4 pagesHollow Pot Designgaza man100% (1)

- 05.08.2009 - Cable Trench SectionsDocument22 pages05.08.2009 - Cable Trench SectionsandyhrNo ratings yet

- Consultation Sheet: Design DataDocument15 pagesConsultation Sheet: Design DatamichaelNo ratings yet

- Column Design Bs 8110 PDFDocument2 pagesColumn Design Bs 8110 PDFAlexis60% (5)

- Resistance Moment Calculations (Columns BS 8110)Document3 pagesResistance Moment Calculations (Columns BS 8110)dhanya1995100% (2)

- Reinforced Concrete Design BS 8110Document15 pagesReinforced Concrete Design BS 8110Kutty Mansoor75% (4)

- Unit 7 (DESIGN DETAILS OF BEAMS)Document35 pagesUnit 7 (DESIGN DETAILS OF BEAMS)Zara Nabilah94% (16)

- Unit 11 (DESIGN OF REINFORCED CONCRETE SLABS (RCS) )Document48 pagesUnit 11 (DESIGN OF REINFORCED CONCRETE SLABS (RCS) )Zara NabilahNo ratings yet

- Unit 14 (DESIGN OF SLENDER COLUMNS)Document33 pagesUnit 14 (DESIGN OF SLENDER COLUMNS)Zara Nabilah96% (24)

- 03 - Preliminary Member SizingDocument6 pages03 - Preliminary Member SizingAmila Liyanaarachchi0% (1)

- Hollow Pot Design WorksheetDocument7 pagesHollow Pot Design Worksheetpatrick chegeNo ratings yet

- Structural Assesment ReportDocument5 pagesStructural Assesment ReportGihan ChathurangaNo ratings yet

- Structural Assesment ReportDocument5 pagesStructural Assesment ReportGihan ChathurangaNo ratings yet

- Design For Torsion (Beams BS 8110)Document3 pagesDesign For Torsion (Beams BS 8110)dhanya1995100% (1)

- Floor ManualDocument35 pagesFloor ManualGihan ChathurangaNo ratings yet

- Hollow Pot Slabs DesignDocument4 pagesHollow Pot Slabs Designchris100% (4)

- 7.4 Slender ColumnsDocument14 pages7.4 Slender ColumnsAlfred Patrick100% (1)

- Strip Footing 3 Columns Bsi 8110 - 2Document11 pagesStrip Footing 3 Columns Bsi 8110 - 2Magdy Bakry100% (2)

- Unit 5 (DESIGN OF FLANGED BEAM: T-BEAM)Document41 pagesUnit 5 (DESIGN OF FLANGED BEAM: T-BEAM)Zara Nabilah84% (31)

- Unit 4 (DESIGN OF RECTANGULAR BEAM SECTIONS)Document37 pagesUnit 4 (DESIGN OF RECTANGULAR BEAM SECTIONS)Zara Nabilah100% (14)

- Vertical Reinforcement (Walls BS 8110)Document4 pagesVertical Reinforcement (Walls BS 8110)dhanya1995100% (1)

- HA and HB Bridge Loading ExampleDocument2 pagesHA and HB Bridge Loading ExampleMilos Bajceta86% (7)

- Design Shear Resistance (Beams - BS 8110)Document2 pagesDesign Shear Resistance (Beams - BS 8110)Lavanyan SatchithananthanNo ratings yet

- Column Design As Per BS 8110-1:1997: PHK/JSNDocument16 pagesColumn Design As Per BS 8110-1:1997: PHK/JSNJennifer Tang100% (2)

- Design Shear Resistance (Beams EC2)Document2 pagesDesign Shear Resistance (Beams EC2)dhanya1995No ratings yet

- SlabsDocument29 pagesSlabsPimpa Mwiinga100% (2)

- Lift Wall DesignDocument4 pagesLift Wall DesignBajracharya A-sub25% (4)

- RA 9266 Architecture LawDocument14 pagesRA 9266 Architecture LawPatricia Caña100% (2)

- Example 3.4 - Continuous One Way Slab-Updated 080812Document12 pagesExample 3.4 - Continuous One Way Slab-Updated 080812Muhammad Farhan Gul86% (7)

- User Instructions: Domestic Garage Door OperatorsDocument16 pagesUser Instructions: Domestic Garage Door OperatorsJack Smith100% (1)

- Unbraced Slender Column To BS 8110Document7 pagesUnbraced Slender Column To BS 8110Gihan Chathuranga67% (3)

- Unbraced Slender Column To BS 8110Document7 pagesUnbraced Slender Column To BS 8110Gihan Chathuranga67% (3)

- Unit 9 (DESIGN OF SHEAR REINFORCEMENT)Document29 pagesUnit 9 (DESIGN OF SHEAR REINFORCEMENT)Zara Nabilah76% (25)

- Thermal Comfort in The Havelis of JaisalmerDocument239 pagesThermal Comfort in The Havelis of JaisalmerManoj JangidNo ratings yet

- Manual Design of One Way Slab (Continous Slab)Document5 pagesManual Design of One Way Slab (Continous Slab)Struct Soft CentreNo ratings yet

- Steel Column Axial LoadsDocument2 pagesSteel Column Axial LoadsGihan Chathuranga100% (1)

- Disaster Management e Book PDFDocument31 pagesDisaster Management e Book PDFGihan ChathurangaNo ratings yet

- Design of A UbDocument8 pagesDesign of A UbGihan Chathuranga100% (1)

- GC 2014 16 Stu 01 PDFDocument1 pageGC 2014 16 Stu 01 PDFGihan ChathurangaNo ratings yet

- Helical Concrete Staircase - tcm45-343894Document1 pageHelical Concrete Staircase - tcm45-343894Gihan ChathurangaNo ratings yet

- Soil Investigation For Proposed New Hotel Project in BeruwalaDocument3 pagesSoil Investigation For Proposed New Hotel Project in BeruwalaGihan ChathurangaNo ratings yet

- Alluminium Section PropertiesDocument4 pagesAlluminium Section PropertiesGihan ChathurangaNo ratings yet

- Temple Architecture in IndiaDocument16 pagesTemple Architecture in IndiaKaamana SahuNo ratings yet

- Architecture (AR) III YearDocument17 pagesArchitecture (AR) III YearFiroj AnsariNo ratings yet

- Subcontractors Progress Qtys To DateDocument373 pagesSubcontractors Progress Qtys To Datearchie_728No ratings yet

- Sensornet Rs 422 Network Design Guide An LT enDocument36 pagesSensornet Rs 422 Network Design Guide An LT enschatten_3No ratings yet

- These Interview Questions Test The Knowledge of x86 Intel Architecture and 8086 Microprocessor SpecificallyDocument4 pagesThese Interview Questions Test The Knowledge of x86 Intel Architecture and 8086 Microprocessor Specificallyswathikomati7870No ratings yet

- Study of Concrete Properties by Partial ReplacementDocument18 pagesStudy of Concrete Properties by Partial ReplacementSuryaprakash Reddy EesariNo ratings yet

- Rheem Commercial R-410 15 and 20 TonDocument24 pagesRheem Commercial R-410 15 and 20 Tonjuanchocazon78No ratings yet

- Eternus dx100 s4 PDFDocument122 pagesEternus dx100 s4 PDFMartiNo ratings yet

- Wago CatalogDocument669 pagesWago CatalogElectromateNo ratings yet

- Full Report 1Document73 pagesFull Report 1Johnny BlazeNo ratings yet

- Charles Correa The New LandscapeDocument116 pagesCharles Correa The New LandscapeAshish RajadhyakshaNo ratings yet

- LaptopDocument19 pagesLaptopRaman VenkyNo ratings yet

- Armoured Csta CablesDocument5 pagesArmoured Csta CablesMd Irshad AlamNo ratings yet

- History of Archi 4 - NotesDocument2 pagesHistory of Archi 4 - Notesgelay kimNo ratings yet

- PVC Crust Foam Board Manufacture Process ControDocument1 pagePVC Crust Foam Board Manufacture Process ControFrank ZhangNo ratings yet

- Theory of Structures Assignment FinalDocument21 pagesTheory of Structures Assignment FinalManasAroraNo ratings yet

- 6 8051 IO InterfacingDocument66 pages6 8051 IO InterfacingSahilYadavNo ratings yet

- Instructions For Making The Inflatable KiteDocument15 pagesInstructions For Making The Inflatable KiteLuka NikitovicNo ratings yet

- Zoneminder Latest PDFDocument141 pagesZoneminder Latest PDFCamaras IPNo ratings yet

- Enterprise Support Utilities Group: Nonav Symantec Antivirus Corporate Edition Uninstall UtilityDocument5 pagesEnterprise Support Utilities Group: Nonav Symantec Antivirus Corporate Edition Uninstall UtilityfkrnawNo ratings yet

- Life Time Prediction of GRP Piping SystemsDocument15 pagesLife Time Prediction of GRP Piping SystemsRamon FrenchNo ratings yet

- M&E DelayDocument3 pagesM&E DelayAssem ElhajjNo ratings yet

- An Enhanced Uplink Scheduling Algorithm Based On Voice Activity For Voip Services in Ieee 802.16D/E SystemDocument3 pagesAn Enhanced Uplink Scheduling Algorithm Based On Voice Activity For Voip Services in Ieee 802.16D/E SystemTamal ChakrabortyNo ratings yet

- Absence Manager Installation and User GuideDocument27 pagesAbsence Manager Installation and User Guideigillett7030No ratings yet

- Securing Optimizing Linux DNS BIND Rc1.0Document49 pagesSecuring Optimizing Linux DNS BIND Rc1.0sidneyelagibNo ratings yet