Professional Documents

Culture Documents

HES3350 Machine Design Semester 1 2012 Assignment 1 Compound Reverted Gear Train Design PDF

Uploaded by

risirarocksOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HES3350 Machine Design Semester 1 2012 Assignment 1 Compound Reverted Gear Train Design PDF

Uploaded by

risirarocksCopyright:

Available Formats

SWINBURNE UNIVERSITY OF TECHNOLOGY (SARAWAK CAMPUS)

FACULTY OF ENGINEERING AND INDUSTRIAL SCIENCE

HES3350 Machine Design

Semester 1, 2012

Assignment 1: Compound Reverted Gear Train Design

By

Group No. 9

Stephen Bong Pi Yiing (4209168)

Kueh Min Hui (4209974)

Mohd Azmudin Bin Isa @ Danial (4209028)

Jimmy Huong How Lee (4209761)

Lecturer: Dr. Soon Kok Heng

Due Date: 30th March 2012 (Thursday), 4 pm

Assignment 1: Compound Reverted Gear Train Design Group No. 9

TABLE OF CONTENTS

PAGE

ABSTRACT 3

1. OBJECTIVE 4

2. INTRODUCTION 4

3. MAIN CONTENT 5

3.1 Parameters and Schematic Diagram for Compound Reverted Gear Train 5

3.2 Calculation of Number of Teeth for Gear 1, 2, 3, and 4 5-8

3.3 Calculation of Speed of the Intermediate & Output Shafts 9

3.4 Calculation of the Torques Generated for the Input, Intermediate and Output Shafts 10

4. DISCUSSION 11

4.1 The Indispensability of Two Stage Compound Gear Train 11

4.2 Gear Interference 12-14

4.3 Compound Reverted Gear Train and the Benefits or Application of It 15-16

4.4 Gear Reduction Ratio 16

5. CONCLUSION 17

6. REFERENCES 18

HES3350 Machine Design, Semester 1, 2012 Page 2 of 18

Assignment 1: Compound Reverted Gear Train Design Group No. 9

ABSTRACT

The primary intention of this assignment is to determine the number of teeth for gear 1, 2, 3, and 4

utilized in a two-stage reduction gear train which serve as a speed reducer in a machine which is

powered by an electric motor. The calculations in this report have reviewed that torques generated as a

result of rotational motion of shafts and gears are inversely proportional to the angular velocities.

Therefore, as the rotary motion is transmitted through the double reduction gear train, the reduction in

velocities has results in an upsurge of torque generated. The indispensability of the utilization of double

reduction gear train, gear interference, the advantages and applications of double reduction gear train,

and the gear reduction ratio are discussed in this report as well. Apart from that, double reduction gear

train has been extensively employed in wide range of engineering application which ranges from a can

opener to an aircraft carries.

HES3350 Machine Design, Semester 1, 2012 Page 3 of 18

Assignment 1: Compound Reverted Gear Train Design Group No. 9

1. OBJECTIVE

The primary intention of this assignment is to determine the number of teeth for gear 1, 2, 3, and 4 of a

compound reverted gear train which plays as a role of speed reducer in a machine which is powered by

an electric motor as shown in Fig. 1 below. Apart from that, the computations of speeds and torques

generated for input, intermediate and output shafts as a result of the rotary motion of the gears are also

the purposes of this assignment.

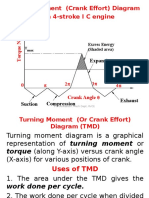

Fig. 1: A machine which is powered by an electric motor

2. INTRODUCTION

With the statistics and parameters provided such as the input and output speeds, the pressure angle, the

module of the double-reduction gear train, and the power to be delivered in order to drive the motor; we

are required to calculate the number of teeth for gear 1, 2, 3, and 4. The number of teeth for all the four

gears are computed based on the prerequisites stated which are the axes of the driver and driven shafts

are co-axial (inline of the output and input shafts) (see Fig. 2 below), and the minimum package size of

the double-reduction gear train. In addition, the determination of the speeds and torques generated for

input, intermediate and output shafts as a result of the rotational motion produced by the gears are

incorporated in this report as well.

Fig. 2: Compound Reverted Gear Train (J. K. Brar & R. K. Bansal, 2004)

Since this assignment by all means, cannot be tantamount to a real life design project as most of the

calculations in the design of the compound reverted gear train are based on theoretical equations and

appropriate assumptions such as the surfaces in contact are frictionless and therefore there has no

power losses through the transmission. By neglecting the power losses due to friction, we only centralize

our design based on the number of teeth of all the four gears, and the speed and torques generated for

the input, intermediate and output shafts.

HES3350 Machine Design, Semester 1, 2012 Page 4 of 18

Assignment 1: Compound Reverted Gear Train Design Group No. 9

3. MAIN CONTENT

3.1 Parameters and Schematic Diagram for Compound Reverted Gear Train

The schematic diagram for the compound reverted gear train is shown in Fig. 3 below:

Fig. 3: Schematic of compound reverted gear train

The parameters given are tabulated in Table 1 below:

Power to Be Delivered (kW) 27.5

Input Speed (rpm) 1200

Output Speed (rpm) 50

Pressure Angle (Deg.) 25

Module (mm) 6

Table 1: Parameters given

3.2 Calculations of Number of Teeth for Gear 1, 2, 3, 4

The speed ratio of the double-reduction gear train utilized in this machine is given by:

a a b d d d d N N

= = 2 4 = 2 4 = 2 4

c b c d1 d 3 d1d 3 N1 N 3

where a = Input Speed

b = Speed of Intermediate Shaft

c = Output Speed

d1 = Diameter of Gear 1

d2 = Diameter of Gear 2

d3 = Diameter of Gear 3

d4 = Diameter of Gear 4

N1 = Number of Teeth for Gear 1

N2 = Number of Teeth for Gear 2

N3 = Number of Teeth for Gear 3

N4 = Number of Teeth for Gear 4

Based on the information given, the speed ratio of the double-reduction gear train can be computed as

follows:

a N 2 N 4 1200 rpm

= = = 24

c N1 N 3 50 rpm

HES3350 Machine Design, Semester 1, 2012 Page 5 of 18

Assignment 1: Compound Reverted Gear Train Design Group No. 9

Therefore,

N2 N4

= 24 Eq. [1]

N1 N 3

Given that the module, m, of the gear train is 6, thus,

d d d N d

m= = 1 = 2 =6 2 = 2 =6 Eq. [2]

N N1 N 2 N 1 d1

By substituting Eq. [2] into Eq. [1] gives:

N2 N4 N N

= 24 6 4 = 24 4 = 4 N 4 = 4 N 3 Eq. [3]

N1 N 3 N3 N3

In order to make the axes of the driver and driven shafts become collinear (Inline input and output

shafts), the center distance between gear 1 and gear 2 should be equal to the center distance between

gear 3 and gear 4.

d1 + d 2 d 3 + d 4

c1 2 = c34 = d1 + d 2 = d 3 + d 4 Eq. [4]

2 2

Since m = d/N or d = mN, hence Eq. [4] above becomes:

mN 1 + mN 2 = mN 3 + mN 4 Eq. [5]

Since the module of the entire gear train is similar, Eq. [5] can be reduced to:

N1 + N 2 = N 3 + N 4 Eq. [6]

The smallest number of teeth, Np, on a spur pinion or gear without interference is given by

Np =

(

2 m + m 2 + (1 + 2m ) sin 2 ) Eq. [7]

(1 + 2m )sin 2

By substituting the data given (m = 6 mm and = 25) into Eq. [7] yields:

Np =

{

2 6 + 6 2 + [1 + 2(6 )]sin 2 (25) }

= 10.71 11

[1 + 2(6)]sin 2 (25)

Let Np = N1 = 11, from Eq. [2],

N2

= 6 N 2 = 6 N1 = 6(11) = 66

N1

Since N4 = 4N3, and substituting N1 = 11 and N2 = 66 into Eq. [6] gives:

11 + 66 = N 3 + 4 N 3 77 = 5 N 3 N 3 = 15.4

Since the number of teeth of gear must be an integer, therefore, N3 = 15.4 cannot be accepted. Thus, in

order to obtain an integer number of teeth, trial and error method had been selected.

HES3350 Machine Design, Semester 1, 2012 Page 6 of 18

Assignment 1: Compound Reverted Gear Train Design Group No. 9

Since the minimum number of teeth for one of the gear in the compound reverted gear train is Np = 11,

hence the integer number of teeth utilized in the trial and error method should be greater than 11 in order

to avoid interference of gears.

By trial and error,

1st Trial (N1 = 12) From Eq. [2] N2 = 6N1 = 6(12) = 72

Since N1 + N2 = N3 + N4, and N4 = 4N3, therefore,

12 + 72 = N3 + 4N3

84 = 5N3

N3 = 16.8 (Not accepted)

2nd Trial (N1 = 13) From Eq. [2] N2 = 6N1 = 6(13) = 78

Since N1 + N2 = N3 + N4, and N4 = 4N3, therefore,

13 + 78 = N3 + 4N3

91 = 5N3

N3 = 18.2 (Not accepted)

3rd Trial (N1 = 14) From Eq. [2] N2 = 6N1 = 6(14) = 84

Since N1 + N2 = N3 + N4, and N4 = 4N3, therefore,

14 + 84 = N3 + 4N3

98 = 5N3

N3 = 19.6 (Not accepted)

4th Trial (N1 = 15) From Eq. [2] N2 = 6N1 = 6(15) = 90

Since N1 + N2 = N3 + N4, and N4 = 4N3, therefore,

15 + 90 = N3 + 4N3

105 = 5N3

N3 = 21 (Accepted)

Based on the calculations from the 1st Trial to the 4th Trial, N1 = 15 is the 1st integer number of teeth for

gear 1 which can results in an integer number of teeth for gear 3 which is N3 = 21. Thus, N1 = 15 is

acceptable.

With N1 = 15, we know that N3 = 21, N4 can be computed by using Eq. [3]:

N4 = 4N3 = 4(21) = 84

Thus, on the basis of the calculations above and the prerequisites stated, the number of teeth for gear 1,

2, 3, 4 are N1 = 15, N2 = 90, N3 = 21, and N4 = 84.

HES3350 Machine Design, Semester 1, 2012 Page 7 of 18

Assignment 1: Compound Reverted Gear Train Design Group No. 9

Based on the number of teeth computed for gear 1, 2, 3 & 4, a double-reduction gear train is sketched by

using SolidWorks and shown in Fig. 4 below.

Fig. 4: Drawing of gears in the double-reduction gear train with N1 = 15, N2 = 90, N3 = 21, and N4 = 84 by

using SolidWorks

HES3350 Machine Design, Semester 1, 2012 Page 8 of 18

Assignment 1: Compound Reverted Gear Train Design Group No. 9

3.3 Calculations of the Speeds of the Intermediate and Output Shafts

Since the module is constant throughout the entire compound reverted gear train, thus,

d1 d d d

m= = 2 = 3 = 4

N1 N 2 N 3 N 4

With the number of teeth for all the four gears known, the diameter of each gear can be computed as

follows:

d1 = mN1 = (6)(15) = 90 mm

d 2 = mN 2 = (6)(90) = 540 mm

d 3 = mN 3 = (6 )(21) = 126 mm

d 4 = mN 4 = (6)(84) = 504 mm

Based on the diameter of each gear computed above, the center distance for gear 1 and gear 2, and

gear 3 and gear 4 are calculated as follows:

d 1 + d 2 90 mm + 540 mm

c1 2 = = = 315 mm

2 2

d 3 + d 4 126 mm + 504 mm

c 3 4 = = = 315 mm

2 2

On account of c1 2 = c3 4, therefore, the condition of inline input and output shafts is accomplished.

The gear ratio of gear 1 and gear 2 is given by:

d 2 a

g r ,1 2 = =

d1 b

With d1 = 90 mm, d2 = 540 mm, and a = 1200 rpm, the speed of the intermediate shaft, b, can be

obtained as follows:

d1

= 1200 rpm

90

b = a = 200 rpm

d2 540

Therefore, the speeds for the input, intermediate, and output shafts are a = 1200 rpm, b = 200 rpm,

and c = 50 rpm respectively.

HES3350 Machine Design, Semester 1, 2012 Page 9 of 18

Assignment 1: Compound Reverted Gear Train Design Group No. 9

3.4 Calculations of the Torques Generated for the Input, Intermediate and Output Shafts

Since there has no power loss throughout the entire transmission, thus the only parameters which

influence the torque generated as a result of gears rotate is the speed of each shafts. The torque

generated can be computed by utilizing the relation of power and torque, W& = T .

Based on the information given and calculations above, we know that

= 27.5 kW

a = 1200 rpm

b = 200 rpm

c = 50 rpm

The torques for the input, intermediate and output shafts are computed as follows:

W& 27.5 10 3 W

Ta = = = 218.84 N m

a rev 1 min 2 rad

1200

min 60 s 1 rev

W& 27.5 10 3 W

Tb = = = 1313.03 N m

b rev 1 min 2 rad

200

min 60 s 1 rev

W& 27.5 10 3 W

Tc = = = 5252.11 N m

c rev 1 min 2 rad

50

min 60 s 1 rev

HES3350 Machine Design, Semester 1, 2012 Page 10 of 18

Assignment 1: Compound Reverted Gear Train Design Group No. 9

4. DISCUSSION

4.1 The Indispensability of Two Stage Compound Gear Train

Gear trains are extensively applicable in wide range of engineering applications such as all varieties of

mechanisms and machines which ranged from a can opener to aircraft carries. Gear trains will usually

be utilized whenever a variation in velocity or torque of a rotating device is required (Norton, R. L., 2004,

p. 462). According to Norton, R. L. (2004), a gear train can be interpreted as any collection of two or

more meshing gears for the purpose of power transmission from one shaft to another (Gupta, J. K. &

Khurmi, R. S., 2000, p. 412). A gear train may encompass of spur gears, bevel gears, or spiral gears,

depending on how much speeds and power output to be generated. Distinct arrangement of gears and

wheels will results in different types of gear trains such as simple gear train, compound gear train,

reverted gear train, and epicyclic gear train.

Norton, R. L. (2004) states that a compound gear train is one in which at least one shaft carries more

than one gear. The arrangement of gears and wheels in a compound gear train is either a parallel or

series-parallel arrangement, rather than the pure series connections of the simple gear train. Fig. 5

below shows a two stage compound gear train which consists of four gears and two of which, gear 3 and

gear 4, are regularized on the same shaft and therefore have the same angular velocity.

Fig. 5: A two stage compound gear train (Norton, R. L., 2004, p. 484)

Although the idle gears utilized in simple gear train do not influence the speed ratio of the entire system,

nevertheless these gears are beneficial in bridging over the space between the driver (gear 2) and the

driven (gear 5). Whenever the offset between the driver and the driven has to be bridged over by

intermediate gears and a great speed ratio is demanded simultaneously, and then the dominant position

of intermediate gears (gear 3 & 4 see Fig. 4 above) is intensified by furnishing compound gears on the

intermediate shaft. In contrast with simple gear train, a much larger speed reduction will occurred as a

result of a compound gear train being utilized. If a simple gear train is utilized in order to provide a large

reduction in angular velocity, the size of the large gear has to be very huge. Generally for a speed

reduction ratio which exceeds the ratio of 7 to 1, the utilization of a simple gear train is not convenient,

and a compound gear train is employed. Based on the calculations in Section 4.2 above, the speed ratio

computed from the given parameters is 24 to 1 which exceeds 7 to 1, therefore, the application of a two-

stage compound gear train is necessary (Gupta, J. K. & Khurmi, R. S., 2000, p. 414-416).

HES3350 Machine Design, Semester 1, 2012 Page 11 of 18

Assignment 1: Compound Reverted Gear Train Design Group No. 9

4.2 Gear Interference

In order to interpret the theories of interference and undercutting of gears in details, it is significance to

have a proper comprehending on each of the nomenclature of involute gear teeth. The nomenclature of

involute gear teeth is shown in Fig. 6 below.

Fig. 6: Nomenclature of involute gear teeth (Juvinall, R. C. & Marshek, K. M., 2012, p. 596)

HES3350 Machine Design, Semester 1, 2012 Page 12 of 18

Assignment 1: Compound Reverted Gear Train Design Group No. 9

According to Norton, R. L., (2004), the contact ratio of a pair of gears, mp, can be defined as the average

number of teeth in contact at any instant and it can be expressed mathematically as:

Z

mp =

pb

where Z is the length of action; Z = (r p + a p ) (rp cos ) +

2 2

(r

g + a g ) (rg cos ) C sin

2 2

d

pb is the base pitch, pb = p c cos , p c =

N

A contact ratio of 1, for example, implies that one tooth is leaving contact just as the next is beginning

contact. This is objectionable as some unwanted circumstances such as oscillations in velocity, vibration,

and noise will occurred if there are miscalculations in the analysis and design of tooth spacing. Apart

from that, there is also a high possibility for bending to occurred due to the applied loads at the tip of the

tooth. Therefore, the contact ratio which falls between the ranges of 1.2 to 1.6 has usually selected and

employed in the design of spur gears as the utilization of higher contact ratio will increase the possibility

of load sharing among the teeth. Gears with contact ratios which exceed 2 are often referred to as high-

contact ratio gears and there are always in perpetuity less than two pairs of teeth in contact. The

selection and utilization of high contact ratio gears is often being the first priority in most of the

applications where long term operations are required. In the design of high-contact ratio gears, detailed

analysis should always take into account and considerations as the tooth dedendum region might

experience a higher bending stresses due to higher dynamic loading subjected. Apart from that, the

distress of the tooth surfaces might be occurred due to higher sliding in tooth contact (Brown, T. H. &

Rothbart, H., 2006; Norton, R. L., 2004, p. 474).

Generally, the involute curve is only defined beyond the base circle, but in some state of affairs, the

dedendum will be large enough to broaden below the base circle or the addendum circles extends

beyond the tangent points A and B (see Fig. 7 below) which are called interference points (Juvinall, R. C.

& Marshek, K. M., 2006, p. 601). This will lead to the portion of tooth below the base circle will not be an

involute and will intervene with the tip of the tooth on the mating gear (Norton, R. L., 2004, p. 472). This

non-conjugate action is referred to as gear interference. If a standard gear sharper is utilized to cut the

gear, interference will occurred between the cutting tool and the portion of tooth below the base circle as

well. As a result, the interfering material will be cut away and results in an undercut tooth as shown in

Fig. 8 below. When the interfered materials had been removed due to undercutting and the maximum

shear and bending from the tooth loaded as a cantilever beam both happen in this portion, the tooth will

be weaken and lead to early tooth failure.

Interference and undercutting can be forestalled by refrain from utilizing gears with little number of teeth

as the number of teeth is decreased for a regularized diameter gear, the size of the teeth must be large

enough in order drive the other gear. As the driver gear rotates to some point, the dedendum will exceed

the radial distance between the base circle and the pitch circle, and thus result in gear interference

(Norton, R. L., 2004, p. 472).

HES3350 Machine Design, Semester 1, 2012 Page 13 of 18

Assignment 1: Compound Reverted Gear Train Design Group No. 9

Fig. 7: Interference in the action of gear teeth (Interference is on flank of pinion during approach action

and flank of gear during recess action) (Brown, T. H. & Rothbart, H., 2006)

Fig. 8: Interference and undercutting of teeth below the base circle (Norton, R. L., 2004)

HES3350 Machine Design, Semester 1, 2012 Page 14 of 18

Assignment 1: Compound Reverted Gear Train Design Group No. 9

4.3 Compound Reverted Gear Train and The Benefits or Applications of It

The distinction between compound gear train and compound reverted gear train is that the locations of

input and output shafts are different. For such compound gear train, in which the input and output shafts

are not coincident, is called a non-reverted compound gear train. On the contrary, a compound gear train

can be referred as a compound reverted gear train if the input and output shafts are in exact alignment

(output shaft concentric with the input shaft) (see Fig. 9 below). The design and analysis of a compound

reverted gear train is furthermore complicated as compared to compound gear train due appended

constraint and restriction which is the center distances of each stage must be equal.

Fig. 9: A compound reverted gear train (Norton, R. L., 2004, p. 487)

Molian, S. (1982) listed that one of the advantage of the utilization of compound reverted gear train is the

amount of power to be transmitted can be increased by a train of given overall size. Compound reverted

gear trains are extensively employed in manual automotive transmission to offer user-selectable ratios

between the engine and the drive wheels for torque multiplication. These gearboxes generally

encompass of four forward speeds and one reverse as shown in Fig. 10 below.

Based on Fig. 10 below, the input shaft is located on the top left corner of the gearbox and the input gear

is always in mesh with the leftmost counter-gear on the countershaft at the bottom. This countershaft has

several counter-gears integral with it and each of which meshes with a distinct output gear which is

freewheeling on the output shaft. The output shaft of the five-speed gearbox is concentric with the input

shaft and they are linked by means of the counter-gears on the countershaft (Norton, R. L., 2004, p.

504).

Apart from the utilization of compound reverted gear train in manual automobile transmission, it is also

employed in wide range of engineering and industrial applications such as lathe back gears, industrial

speed reducers, and mechanical watches and clocks in which the minute and hour hand shafts are

concentric (Gupta, J. K. & Khurmi, R. S., 2000, p. 419).

HES3350 Machine Design, Semester 1, 2012 Page 15 of 18

Assignment 1: Compound Reverted Gear Train Design Group No. 9

Fig. 10: 5-Speed gearbox

4.4 Gear Reduction Ratio

Gear reduction ratio is a proportion that used to describes the ratio of angular velocities between the

input shaft and the output shaft. The angular velocity of the gear can be reduced by utilizing a pair of

gear with a reduction ratio of 2 to 1 as the pinion would have to complete 2 revolutions in order to drive

the gear to complete 1 revolution of rotational motion (Brett Buzz Dawson, 2002; Pauline, G., 2012).

From the equation which relates power and torque, = T or T = /, it can easily be seen that the

torque generated is inversely proportional to the angular velocity of the gears. Therefore, a double-

reduction gear train has been selected in order to minimize the angular velocity so that a larger torque

and power output can be generated.

HES3350 Machine Design, Semester 1, 2012 Page 16 of 18

Assignment 1: Compound Reverted Gear Train Design Group No. 9

5. CONCLUSION

Through this assignment, our knowledge on the design and analysis of gear mechanism had improved

immensely. Based on the parameters provided, we had computed the number of teeth for gear 1, 2, 3,

and 4 in the two-stage reduction gear train in conjunction with the pre-requisite stated. Apart from that,

according to the calculations in Section 3.3 and 3.4, we had found that the reduction in angular velocities

due to the transmission of rotary motion from gear 1 to gear 2, and gear 3 to gear 4 has leads to an

upsurge in torques generated. According to the relation of power and torque, it can be clearly shows that

the torque generated is inversely proportional to the angular velocity. Besides, since the velocity ratio

computed in Section 4.2 is 24 to 1 which exceeds the general velocity ratio of simple gear train,

therefore, the application of a two-stage compound gear train is indispensable.

In this report, a two-stage reduction gear train which encompasses of gear 1, 2, 3, and 4 with their

respective number of teeth had designed. Based on the theoretical analysis of gear tooth, it had been

proven mathematically that the gear train has the capability to furnish ample amount of torques so that

the electric motor can be driven perfectly. But there are some other factors and parameters which had

been neglected due to the assumptions made and have the possibility to influence the overall

performance and mechanical efficiency of the entire gear train exists in the authentic design of two-stage

compound gear train.

As a verdict, double reduction gear train has been extensively employed in wide range of engineering

and industrial applications as a large amount of power can be transmitted by a train of given overall size.

And this will leads to an upsurge of performance and mechanical efficiency of the machine.

HES3350 Machine Design, Semester 1, 2012 Page 17 of 18

Assignment 1: Compound Reverted Gear Train Design Group No. 9

6. REFERENCES

Brett Buzz Dawson, 2002, Understanding Gear Reduction, Team DaVinci Robotics, viewed on 28

March, 2012.

< http://www.teamdavinci.com/understanding_gear_reduction.htm>

Brown, T. H. & Rothbart, H., 2006, Mechanical Design Handbook, Measurement, Analysis, and Control

of Dynamic Systems CONTRIBUTORS, McGraw-Hill Companies, Inc., New York.

Hamrock, B. J., Schmid, S. R., and Jacobson, Bo. O., 2005, FUNDAMENTALS OF MACHINE

ELEMENTS, 2nd ed., McGraw-Hill Companies, Inc., Anvenue of the Americas, New York.

Juvinall, R. C. and Marshek, K. M., 2012, Machine Component Design, 5th ed., John Wiley & Sons Inc.

Khurmi, R. S. and Gupta, J. K., 2000, Theory of Machines, S. Chand & Company Ltd, India.

Molian, S., Mechanism design An introductory text, 1982, Cambridge University Press

Norton, R. L., 2004, DESIGN OF MACHINERY An Introduction to the Synthesis and Analysis of

Mechanism and Machines, 3rd ed., McGraw-Hill Education (Asia), Singapore.

Pauline Gill, 2012, How to Calculate Reduction Ratio, eHow, viewed on 28 March, 2012.

<http://www.ehow.com/how_6602288_calculate-reduction-ratio.html#ixzz1qX0fsT7u>

HES3350 Machine Design, Semester 1, 2012 Page 18 of 18

You might also like

- Optimization of Process Parameters in Drilling of Glass Fiber Reinforced Epoxy Resin Composites Using Taguchi MethodDocument6 pagesOptimization of Process Parameters in Drilling of Glass Fiber Reinforced Epoxy Resin Composites Using Taguchi MethodInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Main Spindle Motor Selection: 9/30/2018 Aruna Kumar.p 1Document19 pagesMain Spindle Motor Selection: 9/30/2018 Aruna Kumar.p 1srinivas murthyNo ratings yet

- Agricultural Engineering-Farm Machinery: Sources of Farm PowerDocument17 pagesAgricultural Engineering-Farm Machinery: Sources of Farm PowerGladys Ruth PaypaNo ratings yet

- A Review Paper On Drilling GlassDocument8 pagesA Review Paper On Drilling GlassAdelina RomanNo ratings yet

- c07 Catia v5r15 Transformation FeaturesDocument32 pagesc07 Catia v5r15 Transformation FeaturesNayefGhazaliNo ratings yet

- Design and Analysis of Crankshaft With Different CompositeDocument9 pagesDesign and Analysis of Crankshaft With Different CompositeSAI CHARANNo ratings yet

- Short Question Bank CADDocument3 pagesShort Question Bank CADnravin5No ratings yet

- Clutches and BrakesDocument77 pagesClutches and BrakesKaushikUpadyaNo ratings yet

- Sample Question Paper Mechanical Engineering MeasurementsDocument4 pagesSample Question Paper Mechanical Engineering MeasurementsAbhishek SakatNo ratings yet

- Assignments Machine Tool DesignDocument7 pagesAssignments Machine Tool Designabdullah 3mar abou reashaNo ratings yet

- CAD important questions and tipsDocument5 pagesCAD important questions and tipsjeroldscdNo ratings yet

- CH 14Document13 pagesCH 14mssaber77No ratings yet

- Design Bevel Gears for EquipmentDocument9 pagesDesign Bevel Gears for EquipmentMarkHualdaNo ratings yet

- Chapter09 (Shaft)Document70 pagesChapter09 (Shaft)Ganesh DongreNo ratings yet

- Compartive Evaluation Electrostatic Vs Power Mist BlowerDocument8 pagesCompartive Evaluation Electrostatic Vs Power Mist BlowerAnkushNo ratings yet

- Power Point Slides Lecture12Document15 pagesPower Point Slides Lecture12Sai KumarNo ratings yet

- Lab Report Example 2Document20 pagesLab Report Example 2MECHANICAL ENGINEERINGNo ratings yet

- Shaft DesignDocument4 pagesShaft DesignGurpinder Singh GillNo ratings yet

- 1 Cad Cam Intro PDFDocument40 pages1 Cad Cam Intro PDFWesleyNo ratings yet

- Machine Drawing - 15Me34D: Unit - 1 - Conventional RepresentationDocument22 pagesMachine Drawing - 15Me34D: Unit - 1 - Conventional Representationshreedhar sbNo ratings yet

- Relationship between angle of twist, torque, length and diameterDocument6 pagesRelationship between angle of twist, torque, length and diameterAhsan MumtazNo ratings yet

- Optimization of Process Parameters in Wire-EDM of AL6063-T6 Alloy Using Taguchi DOEDocument12 pagesOptimization of Process Parameters in Wire-EDM of AL6063-T6 Alloy Using Taguchi DOEIJRASETPublicationsNo ratings yet

- CH 3 Fa2018Document89 pagesCH 3 Fa2018Hassan AliNo ratings yet

- Design Project of ShaftDocument37 pagesDesign Project of Shaftniranjanbmazire100% (1)

- 3d PrintingDocument35 pages3d PrintingBharath BallalNo ratings yet

- Cadcam Geometric ModelingDocument31 pagesCadcam Geometric ModelingPankaj ChhabraNo ratings yet

- 2D Axisymmetric Threaded Connection: © 2011 ANSYS, Inc. July 12, 2013 1Document16 pages2D Axisymmetric Threaded Connection: © 2011 ANSYS, Inc. July 12, 2013 1minhnguyenvonhatNo ratings yet

- Vibration HW#2Document2 pagesVibration HW#2Narasimha Reddy100% (1)

- 3.2 Design Parameters and CalculationsDocument9 pages3.2 Design Parameters and CalculationsMasAmirahNo ratings yet

- Limit and Fit Data BooDocument18 pagesLimit and Fit Data Booविशाल पुडासैनीNo ratings yet

- A Major Project ON Biodiesel Production From Waste Cooking Oil (Literature and Planning)Document20 pagesA Major Project ON Biodiesel Production From Waste Cooking Oil (Literature and Planning)Ankur SemleNo ratings yet

- Stepper Motor CatalogueDocument28 pagesStepper Motor CatalogueSuvek KumarNo ratings yet

- Kinematics and Dynamics of Machinery Lab ManualDocument63 pagesKinematics and Dynamics of Machinery Lab ManualsaranNo ratings yet

- DOM Full Notes PDFDocument263 pagesDOM Full Notes PDFCHAMAN R100% (1)

- 5.2 Flanged Bolt CouplingDocument11 pages5.2 Flanged Bolt CouplingShayneBumatay0% (1)

- Design and Study of Helical Gears2Document24 pagesDesign and Study of Helical Gears2AmjathNo ratings yet

- ANNA UNIVERSITY MECHANICAL ENGINEERING SIMULATION LAB EXAMDocument5 pagesANNA UNIVERSITY MECHANICAL ENGINEERING SIMULATION LAB EXAMAsst.Prof MECH100% (1)

- Design and Static Analysis of Gearbox For A CNCDocument9 pagesDesign and Static Analysis of Gearbox For A CNCأحمد دعبسNo ratings yet

- The Beginners Guide To Powder Metal GearsDocument3 pagesThe Beginners Guide To Powder Metal GearsBakkiya Raj100% (1)

- Gear Box DesignDocument74 pagesGear Box DesignRanjib BiswasNo ratings yet

- Shaft CalculationsDocument11 pagesShaft Calculationscena3135No ratings yet

- CH 19Document11 pagesCH 19Vûmmïttî ChañðĥâñNo ratings yet

- Design of Machine ElementsDocument12 pagesDesign of Machine ElementsSai ThotaNo ratings yet

- Turning Moment Diagram & FlywheelDocument88 pagesTurning Moment Diagram & FlywheelAshishAgarwal100% (1)

- Test Code & Procedure of Power ThresherDocument8 pagesTest Code & Procedure of Power ThresherAnonymous fB9ZzVzV100% (1)

- Thermal Engineering Question BankDocument19 pagesThermal Engineering Question BankKishore RaviNo ratings yet

- Computational method for designing wind turbine bladesDocument5 pagesComputational method for designing wind turbine bladesMaurício SoaresNo ratings yet

- Creo Simulation Brochure - FinalDocument8 pagesCreo Simulation Brochure - FinalSrashmiNo ratings yet

- CC 9221 Design For ManufactureDocument2 pagesCC 9221 Design For ManufactureM.Saravana Kumar..M.ENo ratings yet

- Design of Transmission Systems Question BankDocument10 pagesDesign of Transmission Systems Question BankDesejo SozinandoNo ratings yet

- Belt Drives and Chain DrivesDocument39 pagesBelt Drives and Chain DrivesSeparatorNo ratings yet

- Design For Fatigue and Simulation of Glass Fibre Epoxy Composite Automobile Leaf SpringDocument22 pagesDesign For Fatigue and Simulation of Glass Fibre Epoxy Composite Automobile Leaf SpringjonNo ratings yet

- Design and Analysis of Spur Gear by Using Black Fiber, E-Glass Fiber and Carbon Fiber With IsopolymerDocument30 pagesDesign and Analysis of Spur Gear by Using Black Fiber, E-Glass Fiber and Carbon Fiber With Isopolymershakeel100% (1)

- 9A03401 Kinematics of MachineryDocument8 pages9A03401 Kinematics of MachinerysivabharathamurthyNo ratings yet

- Mechanical Vibrations: Vibration Isolation DesignDocument11 pagesMechanical Vibrations: Vibration Isolation DesignNABIL HUSSAINNo ratings yet

- Models - Heat.shell and Tube Heat ExchangerDocument26 pagesModels - Heat.shell and Tube Heat ExchangerLuis Esteban Vela DonosoNo ratings yet

- Gear Design and Analysis FundamentalsDocument26 pagesGear Design and Analysis FundamentalsDipakNo ratings yet

- Strength of Material Question BaksDocument33 pagesStrength of Material Question Bakssom_bs79No ratings yet

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet

- HES3350 Machine Design, Semester 1, 2012, Assignment 1 - Compound Reverted Gear Train DesignDocument18 pagesHES3350 Machine Design, Semester 1, 2012, Assignment 1 - Compound Reverted Gear Train DesignStephenPYBong100% (6)

- Industrial DesignDocument2 pagesIndustrial DesignrisirarocksNo ratings yet

- What Are The Five Design Principles To Accommodate Populations With Different Body SizesDocument3 pagesWhat Are The Five Design Principles To Accommodate Populations With Different Body SizesrisirarocksNo ratings yet

- Broschuere EMC and Power Quality Low 04Document53 pagesBroschuere EMC and Power Quality Low 04prakasa88No ratings yet

- SP (Simple Processor) SpecificationDocument4 pagesSP (Simple Processor) SpecificationrisirarocksNo ratings yet

- SpellingDocument2 pagesSpellingrisirarocksNo ratings yet

- EngineeringDocument3 pagesEngineeringrisirarocksNo ratings yet

- ReadingDocument2 pagesReadingrisirarocksNo ratings yet

- SMPS Topologies .Document30 pagesSMPS Topologies .risirarocksNo ratings yet

- Talk About A Female LeaderDocument3 pagesTalk About A Female LeaderrisirarocksNo ratings yet

- Schematic - Full Protocol Power Bank IP5358 - 2021!02!22Document1 pageSchematic - Full Protocol Power Bank IP5358 - 2021!02!22risirarocksNo ratings yet

- Tasks:: Figure 1 An Example AssemblyDocument3 pagesTasks:: Figure 1 An Example AssemblyrisirarocksNo ratings yet

- Facemill 1Document1 pageFacemill 1risirarocksNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- SpeakingDocument2 pagesSpeakingrisirarocksNo ratings yet

- What Is Lorem Ipsum?: Lorem Ipsum Is Simply Dummy Text of The Printing and Typesetting Industry. Lorem Ipsum Has BeenDocument3 pagesWhat Is Lorem Ipsum?: Lorem Ipsum Is Simply Dummy Text of The Printing and Typesetting Industry. Lorem Ipsum Has BeenrisirarocksNo ratings yet

- Talk About A Female LeaderDocument3 pagesTalk About A Female LeaderrisirarocksNo ratings yet

- Singer LankaDocument2 pagesSinger LankarisirarocksNo ratings yet

- WorkDocument1 pageWorkrisirarocksNo ratings yet

- Speaking VocabularyDocument56 pagesSpeaking VocabularyrisirarocksNo ratings yet

- Mock Exam Strategic ManagementDocument2 pagesMock Exam Strategic ManagementrisirarocksNo ratings yet

- IELTS Speaking TopicsDocument8 pagesIELTS Speaking TopicsAlan Justine100% (1)

- SpeakingDocument2 pagesSpeakingrisirarocksNo ratings yet

- SpeakingDocument2 pagesSpeakingrisirarocksNo ratings yet

- 6-Week Study Plan New PDFDocument6 pages6-Week Study Plan New PDFAshwin DSNo ratings yet

- Bicycle Crank AnalysisDocument7 pagesBicycle Crank AnalysisrisirarocksNo ratings yet

- Product Description: 0.1 - 15Ghz 6-Bit Digital AttenuatorDocument11 pagesProduct Description: 0.1 - 15Ghz 6-Bit Digital AttenuatorrisirarocksNo ratings yet

- AC 2000paper517Document18 pagesAC 2000paper517dhyforNo ratings yet

- AclDocument6 pagesAclrisirarocksNo ratings yet

- Difference Between ANSI & API PumpsDocument2 pagesDifference Between ANSI & API PumpsAnonymous KpVxNXs100% (3)

- ExMotor Manual RU-EN LoresDocument35 pagesExMotor Manual RU-EN LoresMuhammad Taha KhanNo ratings yet

- Mechatronics EngineeringDocument6 pagesMechatronics EngineeringEugine BalomagaNo ratings yet

- Service Manual: Wabco Air CompressorsDocument24 pagesService Manual: Wabco Air CompressorsMuriel RembertoNo ratings yet

- Series 3600 & 4000 Geareducer ManualDocument15 pagesSeries 3600 & 4000 Geareducer ManualsoqhNo ratings yet

- Synchronous MachineDocument9 pagesSynchronous MachineAnonymous rUufA9BUNo ratings yet

- WDocument147 pagesWNelsonNo ratings yet

- S.S. W600 D450 H1000: Gas Fryer Gas FryerDocument1 pageS.S. W600 D450 H1000: Gas Fryer Gas FryerKo PhyoNo ratings yet

- Fujitsu Klima Kullanim Kilavuzu PDFDocument20 pagesFujitsu Klima Kullanim Kilavuzu PDFomeras11No ratings yet

- Workshop ManualDocument787 pagesWorkshop ManualGoran Apostolov92% (38)

- Cummins ISX Engine Harness P92-1262 E 01: Usage NoteDocument5 pagesCummins ISX Engine Harness P92-1262 E 01: Usage NoteJuan Pablo Leon RualesNo ratings yet

- Santa Fe 2010 3.5LDocument93 pagesSanta Fe 2010 3.5LCristian Alejandro Bedoya SalgadoNo ratings yet

- Manual Motor MRD 1100Document40 pagesManual Motor MRD 1100brotaccristianNo ratings yet

- HOK Work BookDocument42 pagesHOK Work BooksathishNo ratings yet

- TCM Wiring - MultronicDocument5 pagesTCM Wiring - MultronicComptadorasAutomotrices33% (3)

- Century 2000 Ddec IVDocument65 pagesCentury 2000 Ddec IVEduardo Alvarez100% (5)

- Gas Scrubber Level ControlDocument2 pagesGas Scrubber Level ControlMehdi Hajd KacemNo ratings yet

- Manual Sanyo SC-15 (M)Document4 pagesManual Sanyo SC-15 (M)Guillermo CornetNo ratings yet

- Valores Sist - Electrico-Maxxforce11,13valores Que Deve Tener El Cablado Del MaxxforceDocument2 pagesValores Sist - Electrico-Maxxforce11,13valores Que Deve Tener El Cablado Del Maxxforceoctavio hernandezNo ratings yet

- TM 5-9005 PIPE LINE EQUIPMENT SET, 1945Document31 pagesTM 5-9005 PIPE LINE EQUIPMENT SET, 1945Advocate100% (1)

- Parts catalog for GB5 coffee machine body panels and accessoriesDocument70 pagesParts catalog for GB5 coffee machine body panels and accessoriesAnatoliy RozenbljumNo ratings yet

- 2 - Revised Draft Schedule of Standard Examination of 1400HP DEMU - Report No. MP-MISC-157 - Rev-03 - Oct-2018Document51 pages2 - Revised Draft Schedule of Standard Examination of 1400HP DEMU - Report No. MP-MISC-157 - Rev-03 - Oct-2018MD AZHAR KAZMINo ratings yet

- 6h.5255-6k1080ta Engine For Power Generation 125kvaDocument118 pages6h.5255-6k1080ta Engine For Power Generation 125kvanilesh asthana67% (3)

- 4 Vacuum PumpDocument4 pages4 Vacuum PumpMithun Singh Rajput100% (1)

- HydraulicDocument380 pagesHydraulicAhmad Mubarok80% (5)

- Raleigh Maintenance HandbookDocument15 pagesRaleigh Maintenance Handbooktspinner19No ratings yet

- Harga Naik IpDocument29 pagesHarga Naik IpmomoNo ratings yet

- SH-E Pump Motor - Final - 2014Document213 pagesSH-E Pump Motor - Final - 2014Md. Nobin KhanNo ratings yet

- BELARUS-510 - Minsk Tractor Works PDFDocument3 pagesBELARUS-510 - Minsk Tractor Works PDFLAliNo ratings yet

- Shop Manual: DX140W-5 / DX160W-5Document21 pagesShop Manual: DX140W-5 / DX160W-5Manuals CE & Ag67% (3)