Professional Documents

Culture Documents

1.5.3.1.10 Paper (2011) - SPE-0911-0086-JPT 3D Geomechanical Modeling Optimizes Drilling

Uploaded by

capl930Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.5.3.1.10 Paper (2011) - SPE-0911-0086-JPT 3D Geomechanical Modeling Optimizes Drilling

Uploaded by

capl930Copyright:

Available Formats

DRILLING MANAGEMENT

3D Geomechanical Modeling Optimizes Drilling

in the Llanos Orientales Basin, Colombia

Drilling in tectonically active areas Suria fields in that every well has shown with a mud weight lower than the

involves nonproductive time (NPT) clear evidence of wellbore instability, fracture gradient was a clear indication

related to wellbore-stability problems as modest-to-severe hole enlargement that the stress regime in the field has

that are very difficult to predict with- and related problems such as tight hole a maximum horizontal stress that is

out a clear understanding of the local- and stuck pipe. In extreme situations, higher than the vertical (overburden)

and regional-stress magnitude and some wells with high inclinations had stress. Also, significant horizontal-stress

orientation and their effect on well- to be sidetracked to reach target depth, anisotropy must be present.

bore trajectory. To optimize drilling not allowing wireline-logging tools to A comprehensive analysis of all image

by eliminating the wellbore-instability be run. data available for the project resulted in

NPT, a 3D geomechanical model was To understand such a challenging very good information to constrain the

built that integrates the geological drilling scenario and to make appropri- direction and magnitude of horizontal

structural model with relevant well ate changes in drilling practice to reduce stresses. The first step in building the

information such as wireline-logging the NPT, a 3D geomechanical model geomechanical model was to compute

data and drilling reports. A new drill- was built by use of structural geologi- the vertical stress SV. The main sources

ing campaign used the 3D model for cal description and information from of data used were density and sonic

wellbore-stability analysis, and the more than 40 wells drilled in the area. logs. Because the wells have an over-

results showed that the associated Wireline-logging and borehole-image gauged condition, the best combination

geomechanical risks to drill the wells data and daily drilling reports were of density and pseudodensity was used

have been addressed properly, with a sources of information to constrain the to calculate the overburden. One of the

much better drilling experience. orientation and magnitude of local in- most critical, and most important, steps

situ stresses and pore pressure. The rock was to constrain the pore-pressure pro-

Introduction mechanical properties were calculated file. It is not uncommon to determine

The Llanos Orientales basin, in the by use of logging-based equations cali- pore-pressure profiles in uplifted areas,

northern Andes of Colombia, is affect- brated with laboratory-test results. such as the Andes foothills, by use of

ed by light but complex deformation. trend-line methods. The main mistake

Wellbore stability is a concern in the 1D Geomechanical Models with these methods is misunderstand-

area, and it is part of well planning. Individual 1D models for wells in the ing applicability (reliable results are

Ecopetrol S.A. has dealt with this prob- project were very useful in understand- generated only when the overpressure-

lem for the last 20 years in the Apiay- ing lateral variation across the area of generating mechanism is subcompac-

interest and in confirming features that tion). Manipulating the fitting expo-

This article, written by Senior Technology might exist in one formation but not in nents only forces a value for overpres-

Editor Dennis Denney, contains high- another. Because the area has many geo- sure that seems to be the main cause of

lights of paper SPE 138752, Drilling logical faults, an important aspect was instability problems; however, it can be

Optimization Using 3D Geomechanical selecting and analyzing wells close to extremely dangerous if the rock is not

Modeling in the Llanos Orientales Basin, and far away from the main geological overpressured, as is the case with the

Colombia, by Ewerton Araujo, SPE, faults. This work verified whether the Leon formation in the area studied in

and Rene Alcalde, GeoMechanics current stress state contributed to reac- this project.

International; Darwin Mateus, SPE, tivation of the faults, which can affect Throughout the Leon formation, the

Instituto Colombiano del Petroleo; Fermn wellbore stability when drilling nearby sonic and resistivity logs deviate from

Fernandez-Ibaez, Judith Sheridan, or when crossing them. An extensive the normal-compaction trend, but the

Chris Ward, SPE, Martin Brudy, and analysis of available image data was density log does not. The reason is that

Jose Alvarellos, SPE, GeoMechanics performed to identify drilling-induced the sonic and resistivity logs measure

International; and Luz Yamile Ordonez failures (i.e., breakouts and fractures) at conductivity properties and these logs

and Felipe Cardona, Ecopetrol S.A., the borehole wall, which was very useful are affected by natural fractures that

prepared for the 2010 SPE Latin American information to constrain the orientation exist in the rock before drilling or even

& Caribbean Petroleum Engineering Con- and magnitude of in-situ stresses. A by microfractures generated by shearing

ference, Lima, Peru, 13 December. The drilling-induced fracture that was gen- (borehole collapse). Density, however,

paper has not been peer reviewed. erated in a near-vertical well drilled is an index property of the rock and is

For a limited time, the full-length paper is available free to SPE members at www.jptonline.org.

86 JPT SEPTEMBER 2011

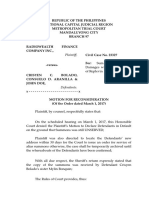

Density Overburden Sv

Lithology

Pore pressure

Structural

model

Stress model

Mechanical

properties

Water tight SHmax azimuth SHmax azimuth

model

Sonic

Image data SHmax

Stratigraphic ESR

model SHmin

QC

Grid Populating

Wellbore

Well data Seismic Fault seal stability

Fig. 13D-Geomechanical-model workflow. QC=quality control, ESR=effective-stress ratio.

Register Now

www.spe.org/atce/2011

Follow ATCE at www.JPTOnline.org

Society of Petroleum Engineers

beginning 30 October 2011.

JPT SEPTEMBER 2011 87

not affected much by the presence of Fig. 1 was followed to build the 3D the wellbore stability can be addressed

fractures. To constrain the minimum- geomechanical model. A combination by loading the well survey into the 3D

horizontal-stress SHmin magnitude, all of the geological-structural model and cubes and then extracting the input

fracturing tests were analyzed including well data was the basic source used to data along the well path that are needed

leakoff tests, formation-integrity tests, build the model. For wellbore-stability for the analysis. The analysis enables

minifracs, and hydraulic-fracturing tests. analysis, the most-troubling forma- determining safe mud-weight windows

This method provided a lower bound, tions (e.g., Leon formation) received a to drill the well, and it pinpoints criti-

given by the closure-pressure values in higher level of discretization (number cal depths that are prone to instabil-

the hydraulic-fracturing tests, that was of elements) in the grid to capture criti- ity. One of the main outcomes of the

used as a safety margin when preventing cal variations in the unconfined com- wellbore-stability analysis was that the

lost circulation. The rock mechanical pressive strength (UCS), for example. mud weight that was recommended by

properties were calculated by calibrating Thereafter, the wireline-log data from the model was in very good agreement

published log-based strength-parameter each offset well were imported honor- with the actual mud weight used to drill

correlations with laboratory-test values. ing individual geological formations, a new well in the area. The mud weight

The last step of building the 1D geo- which ensure that well data are popu- was selected with no advice from the

mechanical model was estimating of lated properly into the 3D model, tak- 3D geomechanical model because the

maximum-horizontal-stress SHmax mag- ing into account formation-depth and project was just beginning. However,

nitude. The Brazilian tests carried out by -thickness variation across the field. the well was drilled in less than half the

the Instituto Colombiano del Petroleo After log data from all the wells were average time required to drill previous

were available and used to constrain the imported, a geostatistical approach was wells in the area. Comparing the results

tensile strength of the rocks. By combin- used to populate the grid and obtain a of the project with the drilling experi-

ing those data with the stress-polygon 3D description of data, such as sonic ence of that well verified that the mud

theory and tensile fractures observed in and density. It was possible to use weight used was in very good agree-

the image data, it was possible to obtain seismic data as cokriging data to help ment with that recommended by the

a range for SHmax magnitude. populate the grid and capture lateral 3D geomechanical model and wellbore-

variations, mainly in regions where well stability analysis, confirming that most

3D Geomechanical Model information was not abundant. To qual- of the NPT experienced in the past was

After individual 1D geomechanical ity control the 3D-grid population with related mostly to geomechanics.

models were ready for each of the cor- log data, a comparison was made of

relation wells, the workflow shown in synthetic density and sonic information Conclusions

with real data from two wells that were The 3D geomechanical model applied

not used to populate the grid. Results to wellbore-stability analysis in the

showed that the geostatistical approach Apiay-Suria area showed the following.

used to populate the 3D grid achieved The stress regime is strike-slip with

a very high reliability to reproduce real the maximum horizontal stress much

data expected at any new well location higher than the overburden.

across the studied area. Following the The main wellbore instability

same geostatistical approach, the rock mechanism in the area is the high stress

mechanical and elastic properties were contrast rather than pore pressure,

populated into the 3D volume along which showed signs of overpressure at

with properties such as maximum-stress some depths.

orientation from the image analysis. Because of the complex geological

Then, the vertical stress (overburden) history of the basin, pore-pressure esti-

was calculated by integrating the 3D mation by use of normal compaction-

density cube with depth. Because sub- trend lines was not straightforward.

compaction was not the driving mecha- The mud weight used in past wells

nism of overpressure generation in the was too low, leading to severe hole

area, the 3D pore pressure also was cal- instability, mainly when drilling the

culated by use of geostatistical methods weak shales in the lithological column.

for the individual pore-pressure pro- Wells drilled in the direction of the

files from the correlation wells, always minimum horizontal stress required

honoring the different formations in the highest mud weights to maintain

Now Available the lithological column. Eventually, the

horizontal stresses were calculated by

borehole stability.

The mud weight recommended by

use of effective-stress ratios. In this man- the 3D geomechanical model and the

Download the free JPT app to read

ner, a 3D distribution of every prop- wellbore-stability analysis was in very

current and past print issues. erty of the geomechanical model was good agreement with the actual mud

obtained (e.g., the rock UCS). weight used to drill a recent well in

Search Journal of Petroleum half of the time required for other wells

Technology in the Apple AppStore. Wellbore-Stability Analysis drilled in the area, which is the best indi-

The 3D geomechanical model will be cation that most of NPT was associated

used to plan future well trajectories, and with borehole-instability problems. JPT

88 JPT SEPTEMBER 2011

You might also like

- Paper Basin LlanoDocument12 pagesPaper Basin LlanojimmymorelosNo ratings yet

- A Geomechanical Approach To Reduce Drilling Time: ARMA 12-155Document7 pagesA Geomechanical Approach To Reduce Drilling Time: ARMA 12-155Julian RamírezNo ratings yet

- Iterative 3D Geomechanical Modeling To Determine Distribution and Impact of Stresses in Deepwater Gulf of Mexico Subsalt and Near-Salt EnvironmentsDocument13 pagesIterative 3D Geomechanical Modeling To Determine Distribution and Impact of Stresses in Deepwater Gulf of Mexico Subsalt and Near-Salt EnvironmentsCAMILO ANDRES BOHORQUEZ ESPARZANo ratings yet

- Research SummaryDocument18 pagesResearch SummaryOttawa CanadaNo ratings yet

- SPE 142022 The Role of Geomechanics in Diagnosing Drilling Hazards and Providing Solutions To The Northern Iraq FieldsDocument11 pagesSPE 142022 The Role of Geomechanics in Diagnosing Drilling Hazards and Providing Solutions To The Northern Iraq FieldsAnkit SharmaNo ratings yet

- Can Seismic Inversion Be Used For GeomecDocument6 pagesCan Seismic Inversion Be Used For GeomecMartin RylanceNo ratings yet

- GEOMECHANICAL WELLBORE STABILITY MODELINGDocument18 pagesGEOMECHANICAL WELLBORE STABILITY MODELINGcamel 125No ratings yet

- Borehole GeophysicsDocument4 pagesBorehole Geophysicsfaten adelNo ratings yet

- Mô Hình Địa Cơ - Thầy Lân & Thầy TùngDocument11 pagesMô Hình Địa Cơ - Thầy Lân & Thầy TùngNguyen Cao KyNo ratings yet

- Journal of Petroleum Science and EngineeringDocument12 pagesJournal of Petroleum Science and EngineeringNguyen The DucNo ratings yet

- Deep Shaft Sinking Limestone, Mudstone, HaliteDocument11 pagesDeep Shaft Sinking Limestone, Mudstone, HalitebithcassNo ratings yet

- Zoback Abu Dhabi SPWLADocument64 pagesZoback Abu Dhabi SPWLAJairo CortesNo ratings yet

- Deep and High Stress Mining - Deformation and SeismicityDocument15 pagesDeep and High Stress Mining - Deformation and SeismicityJugurtha MassinissaNo ratings yet

- AADE 12 FTCE 37 - HilgedickDocument7 pagesAADE 12 FTCE 37 - HilgedickNabaa M. Al-KhazrajiNo ratings yet

- Otc 22364 MSDocument13 pagesOtc 22364 MSLucas NunesNo ratings yet

- Alshamali2015 PDFDocument17 pagesAlshamali2015 PDFarief_7No ratings yet

- Comparison of Simplified and Detailed Analyses For Assessment of Dynamic Displacement of A Centerline Tailings DamDocument14 pagesComparison of Simplified and Detailed Analyses For Assessment of Dynamic Displacement of A Centerline Tailings DamCristian Omar Erazo CastilloNo ratings yet

- International Journal of Rock Mechanics and Mining SciencesDocument10 pagesInternational Journal of Rock Mechanics and Mining SciencesheydaripostNo ratings yet

- Numerical Model For Shaley Rock - TDD - Lake Ontario - FLACDocument13 pagesNumerical Model For Shaley Rock - TDD - Lake Ontario - FLACchucho stewartNo ratings yet

- Jember University - Reservoir Data Analysis - Reservoir Mapping - DiscussionDocument7 pagesJember University - Reservoir Data Analysis - Reservoir Mapping - DiscussionUNI KIKINo ratings yet

- Geomechanical Wellbore Stability ModelingDocument18 pagesGeomechanical Wellbore Stability ModelingAndreea AndrNo ratings yet

- Numerical Simulation of Parallel Hole Cut Blasting With Uncharged HolesDocument6 pagesNumerical Simulation of Parallel Hole Cut Blasting With Uncharged HolesVassilis PentheroudakisNo ratings yet

- M Ferdaos Mostapa - 2017 - The Versatility of Integrating 3D Seismic Transformations and Well Log Data For Carbonate Complex Reservoir Modelling1Document7 pagesM Ferdaos Mostapa - 2017 - The Versatility of Integrating 3D Seismic Transformations and Well Log Data For Carbonate Complex Reservoir Modelling1Muhammad Ferdaos Bin MostapaNo ratings yet

- Core Quality - Quantification of Coring-Induced Rock AlterationDocument19 pagesCore Quality - Quantification of Coring-Induced Rock AlterationYiwei LiNo ratings yet

- Stability analysis of a 3D rock wedge in an arch dam abutmentDocument82 pagesStability analysis of a 3D rock wedge in an arch dam abutmentFilip OrdanovskiNo ratings yet

- Mantilla 2015Document9 pagesMantilla 2015Baiq MaulindaNo ratings yet

- Epfl TH3523Document228 pagesEpfl TH3523וויסאם חטארNo ratings yet

- Geomechanics, Ecd Management and Rss To Manage Drilling in Carbonate Rocks (Mature Field)Document13 pagesGeomechanics, Ecd Management and Rss To Manage Drilling in Carbonate Rocks (Mature Field)energibkisbcNo ratings yet

- Sakurai 1997 PDFDocument8 pagesSakurai 1997 PDFMatiasNavarroQuilodránNo ratings yet

- GSP - 731 - 1 PrintedDocument32 pagesGSP - 731 - 1 Printedademola adelakunNo ratings yet

- Prediction of Rock Mechanical Parameters For Hydrocarbon Reservoirs Using Different Artificial Intelligence TechniquesDocument11 pagesPrediction of Rock Mechanical Parameters For Hydrocarbon Reservoirs Using Different Artificial Intelligence TechniquesfelipeNo ratings yet

- SPE/IADC 125614 Improving Drilling Efficiency Through Wellbore Stability Analysis in The Gulf of Suez, EgyptDocument24 pagesSPE/IADC 125614 Improving Drilling Efficiency Through Wellbore Stability Analysis in The Gulf of Suez, EgyptAmr HegazyNo ratings yet

- Horizontal Well in UAEDocument16 pagesHorizontal Well in UAEsajjad moradiNo ratings yet

- 04-19-26 Sedmak DTZSB2021Document8 pages04-19-26 Sedmak DTZSB2021LudiNo ratings yet

- Computer Simulation of Ground Behaviour and Rock Bolt InteractionDocument8 pagesComputer Simulation of Ground Behaviour and Rock Bolt InteractionRudhy Andry TanjungNo ratings yet

- GeomechanicalDocument10 pagesGeomechanicalenergibkisbcNo ratings yet

- 1988 WongKaiser PerformanceevaluationDocument21 pages1988 WongKaiser PerformanceevaluationThejaswiniNo ratings yet

- Nhess 9 451 2009Document8 pagesNhess 9 451 2009reza.khrmiNo ratings yet

- Measuring Stress in Rock MassesDocument5 pagesMeasuring Stress in Rock MassesShivendra KumarNo ratings yet

- (2013 Chandra Et Al.) Improving Reservoir Characterization and Simulation With Near-Wellbore ModelingDocument11 pages(2013 Chandra Et Al.) Improving Reservoir Characterization and Simulation With Near-Wellbore ModelingAiwarikiaarNo ratings yet

- A Review of Recent Experience in Modeling of Caving - Mark BoardDocument11 pagesA Review of Recent Experience in Modeling of Caving - Mark BoardFajar SariandiNo ratings yet

- The Q-Slope Method For Rock Slope EngineeringDocument17 pagesThe Q-Slope Method For Rock Slope EngineeringThiago MarquesNo ratings yet

- Plexity of Pore Pressure and Stress Analyses in Mahakam Median Axis of The Lower Kutai Basin, Kalimantan, Indonesia.Document14 pagesPlexity of Pore Pressure and Stress Analyses in Mahakam Median Axis of The Lower Kutai Basin, Kalimantan, Indonesia.Herry SuhartomoNo ratings yet

- Geomechanical Model and Wellbore Stability Analysis Utilizing Acoustic Impedance and Reflection Coefficient in A Carbonate ReservoirDocument27 pagesGeomechanical Model and Wellbore Stability Analysis Utilizing Acoustic Impedance and Reflection Coefficient in A Carbonate ReservoirDaniel Mauricio Rojas CaroNo ratings yet

- In Situ Stress Measurement Techniques 18th Dec.Document16 pagesIn Situ Stress Measurement Techniques 18th Dec.Chandrani PrasadNo ratings yet

- Fully Coupled 3D Deformation and Hydrogeology Simulation of An Open Pit Slope in Arctic ConditionsDocument12 pagesFully Coupled 3D Deformation and Hydrogeology Simulation of An Open Pit Slope in Arctic ConditionsAnonymous PdzpkUNo ratings yet

- Hydraulic FracturingDocument3 pagesHydraulic FracturingTarek TarkanNo ratings yet

- 2018 Geomechanics in Petroleum Industry - Join Workshop D1 PDFDocument68 pages2018 Geomechanics in Petroleum Industry - Join Workshop D1 PDFarifaiehusniNo ratings yet

- Sand PredictionDocument10 pagesSand PredictionJAJANo ratings yet

- Ajahet Al2020Document9 pagesAjahet Al2020Adryan MarstyaNo ratings yet

- 2D Numerical Analysis of Hydraulic Fracturing in Heterogeneous Geo-Materials - 2009 - c49 PDFDocument11 pages2D Numerical Analysis of Hydraulic Fracturing in Heterogeneous Geo-Materials - 2009 - c49 PDFMoataz Hesham SolimanNo ratings yet

- Chang_2019_IOP_Conf._Ser.__Earth_Environ._Sci._242_062030Document14 pagesChang_2019_IOP_Conf._Ser.__Earth_Environ._Sci._242_062030Slavoljub IlicNo ratings yet

- Minim and Maks Horizontal StressDocument23 pagesMinim and Maks Horizontal StressenergibkisbcNo ratings yet

- Spwla 1988 yDocument25 pagesSpwla 1988 yAinash ShabdirovaNo ratings yet

- 01 SainsburyDocument16 pages01 SainsburyAlagu RamNo ratings yet

- Multidisciplinary and Integrated Methodology For Deepwater Thin Bed Reservoirs CharacterizationDocument16 pagesMultidisciplinary and Integrated Methodology For Deepwater Thin Bed Reservoirs CharacterizationDody Pratama GintingNo ratings yet

- Geomechanical Modeling of An Anisotropic Formation - Bakken Case StudyDocument23 pagesGeomechanical Modeling of An Anisotropic Formation - Bakken Case StudyMalek AbesNo ratings yet

- SPE-187682-MS Successful Hydraulic Fracturing Techniques in Shallow Unconsolidated Heavy Oil SandstonesDocument6 pagesSPE-187682-MS Successful Hydraulic Fracturing Techniques in Shallow Unconsolidated Heavy Oil SandstonesAndre YudhistiraNo ratings yet

- Impact of Formation Damage On Sand Production in Deep Eocene Reservoirs, Lake Maracaibo, VenezuelaDocument7 pagesImpact of Formation Damage On Sand Production in Deep Eocene Reservoirs, Lake Maracaibo, VenezuelaLok Bahadur RanaNo ratings yet

- Seabed Seismic Techniques: QC and Data Processing KeysFrom EverandSeabed Seismic Techniques: QC and Data Processing KeysRating: 5 out of 5 stars5/5 (2)

- Hercules Production Solutions Catalog PDFDocument28 pagesHercules Production Solutions Catalog PDFPedro Antonio Mejia SuarezNo ratings yet

- 1.5.5.2.8 Paper (2004) - Arma-04-616 A New Geomechanics Process Reduces OperationalDocument11 pages1.5.5.2.8 Paper (2004) - Arma-04-616 A New Geomechanics Process Reduces Operationalcapl930No ratings yet

- Stability Analysis of Borehole Wall Using ABAQUSDocument6 pagesStability Analysis of Borehole Wall Using ABAQUScapl930No ratings yet

- 1.5.3.2.4 Paper (2002) - SPE-78975-MS Geomechanics and Wellbore Stability Design of An Offshore Horizontal Well, North SeaDocument14 pages1.5.3.2.4 Paper (2002) - SPE-78975-MS Geomechanics and Wellbore Stability Design of An Offshore Horizontal Well, North Seacapl930No ratings yet

- Drilling Geomechanics Services PsDocument2 pagesDrilling Geomechanics Services Pscapl930No ratings yet

- SPE 0114 0091 JPT Uncertainty Evaluation of Wellbore Stability Model PredictionsDocument2 pagesSPE 0114 0091 JPT Uncertainty Evaluation of Wellbore Stability Model Predictionscapl930No ratings yet

- 1.5.2.5.2 Paper (2013) - SPE-165392-MS Characterizations On Geomechanical Properties of Colorado Shale BasedDocument9 pages1.5.2.5.2 Paper (2013) - SPE-165392-MS Characterizations On Geomechanical Properties of Colorado Shale Basedcapl930No ratings yet

- 1.5.3.3.1 Paper 2007 - SPE-107474-MS Borehole Stability (Geomechanics) Modeling and Drilling Optimization PracticesDocument9 pages1.5.3.3.1 Paper 2007 - SPE-107474-MS Borehole Stability (Geomechanics) Modeling and Drilling Optimization Practicescapl930No ratings yet

- 1.5.3.7.2 Paper Aapg (2011) - Drilling Optimization Using Mechanical Earth Model....Document12 pages1.5.3.7.2 Paper Aapg (2011) - Drilling Optimization Using Mechanical Earth Model....capl930No ratings yet

- 1.5.3.6.1 Paper (2001) - Spe-69490-Ms Horizontal Underbalanced Drilling in Northeast Brazil A FieldDocument8 pages1.5.3.6.1 Paper (2001) - Spe-69490-Ms Horizontal Underbalanced Drilling in Northeast Brazil A Fieldcapl930No ratings yet

- Cap 17 Well Costing - Libro Well Engineering and ConsDocument32 pagesCap 17 Well Costing - Libro Well Engineering and Conscapl9300% (1)

- Spe/Lsrm 47272 An Investigation of Leak-Off Test Data For Estimating (N-Situ Stress Magnitudes: Application To A Basinwide Study in The North SeaDocument9 pagesSpe/Lsrm 47272 An Investigation of Leak-Off Test Data For Estimating (N-Situ Stress Magnitudes: Application To A Basinwide Study in The North Seacapl930No ratings yet

- Envolvente (Solo HCS)Document1 pageEnvolvente (Solo HCS)capl930No ratings yet

- Spe 180059 MSDocument11 pagesSpe 180059 MScapl930No ratings yet

- Apendice A Tabla Propiedades Rocas - Libro Petroleum Related RockDocument5 pagesApendice A Tabla Propiedades Rocas - Libro Petroleum Related Rockcapl930No ratings yet

- ++SPE-27362-MS Control of Fines Migration A Key Problem in PetroleumDocument15 pages++SPE-27362-MS Control of Fines Migration A Key Problem in Petroleumcapl930No ratings yet

- Mechanical Properties and Strengths of Common Rock MaterialsDocument4 pagesMechanical Properties and Strengths of Common Rock Materialscapl930No ratings yet

- +SPE-144717-JPT (Pore Pressure and Wellbore Stability) 2012Document4 pages+SPE-144717-JPT (Pore Pressure and Wellbore Stability) 2012capl930No ratings yet

- DialogoDocument1 pageDialogocapl930No ratings yet

- Resume NDocument3 pagesResume Ncapl930No ratings yet

- Present Perfect-Reading ComprehensionDocument2 pagesPresent Perfect-Reading Comprehensioncapl930No ratings yet

- Effect of A Partially Communicating Fault On Transient Pressure Beh-ViorDocument9 pagesEffect of A Partially Communicating Fault On Transient Pressure Beh-Viorcapl930No ratings yet

- Cap02-3.03 SP 2-5 2-10.p1Document1 pageCap02-3.03 SP 2-5 2-10.p1Nes SuarezNo ratings yet

- ScotlandDocument1 pageScotlandcapl930No ratings yet

- 03 SP 2-5 2-10.p2Document1 page03 SP 2-5 2-10.p2capl930No ratings yet

- +SPE-128384-MS Quantitative Theory For Fines Migration and Formation DamageDocument22 pages+SPE-128384-MS Quantitative Theory For Fines Migration and Formation Damagecapl930No ratings yet

- You Finish The Exam in 30 Minutes (Or Less) : Have ToDocument1 pageYou Finish The Exam in 30 Minutes (Or Less) : Have Tocapl930No ratings yet

- X e X E: .SR.':.,., - .SR.':.,.Document1 pageX e X E: .SR.':.,., - .SR.':.,.capl930No ratings yet

- Syllabus and Schedule Instructor: Prof. Mark ZobackDocument2 pagesSyllabus and Schedule Instructor: Prof. Mark Zobackcapl930No ratings yet

- Comparative Summary of 5 Learning TheoriesDocument2 pagesComparative Summary of 5 Learning TheoriesMonique Gabrielle Nacianceno AalaNo ratings yet

- Report Daftar Penerima Kuota Telkomsel Dan Indosat 2021 FSEIDocument26 pagesReport Daftar Penerima Kuota Telkomsel Dan Indosat 2021 FSEIHafizh ZuhdaNo ratings yet

- (1964) AC 763 Help: House of Lords Chandler and OthersDocument22 pages(1964) AC 763 Help: House of Lords Chandler and OthersShehzad HaiderNo ratings yet

- HPLC Method for Simultaneous Determination of DrugsDocument7 pagesHPLC Method for Simultaneous Determination of DrugsWidya Dwi Arini100% (1)

- Ashida Relay Operating ManualDocument16 pagesAshida Relay Operating ManualVivek Kakkoth100% (1)

- PAG 03.1 - Determination of ResistivityDocument3 pagesPAG 03.1 - Determination of ResistivityjmsonlNo ratings yet

- The Relationship Between Dissociation and Voices: A Systematic Literature Review and Meta-AnalysisDocument52 pagesThe Relationship Between Dissociation and Voices: A Systematic Literature Review and Meta-Analysiseduardobar2000100% (1)

- 5 Job Interview Tips For IntrovertsDocument5 pages5 Job Interview Tips For IntrovertsSendhil RevuluriNo ratings yet

- Student Assessment Tasks: Tasmanian State Service Senior Executive Performance Management Plan Template 1Document77 pagesStudent Assessment Tasks: Tasmanian State Service Senior Executive Performance Management Plan Template 1Imran WaheedNo ratings yet

- SM pc300350 lc6 PDFDocument788 pagesSM pc300350 lc6 PDFGanda Praja100% (2)

- Literary Analysis Essay - Student PacketDocument11 pagesLiterary Analysis Essay - Student Packetapi-2614523120% (1)

- Motion For Reconsideration (Bolado & Aranilla)Document4 pagesMotion For Reconsideration (Bolado & Aranilla)edrynejethNo ratings yet

- Philippine Idea FileDocument64 pagesPhilippine Idea FileJerica TamayoNo ratings yet

- Evaluation Criteria LomceDocument4 pagesEvaluation Criteria LomceEnrique Delgado SeseñaNo ratings yet

- National Competency Based Teachers StandardDocument34 pagesNational Competency Based Teachers Standarddanebantilan100% (3)

- Ahmed Bahri Omar 1Document7 pagesAhmed Bahri Omar 1l3gsdNo ratings yet

- Games and Sports As Man's Cultural HeritageDocument5 pagesGames and Sports As Man's Cultural Heritagesimransabir152004No ratings yet

- Maghrib Time Nairobi - Google SearchDocument1 pageMaghrib Time Nairobi - Google SearchHanan AliNo ratings yet

- Writing Essays B1Document6 pagesWriting Essays B1Manuel Jose Arias TabaresNo ratings yet

- Pro ManualDocument67 pagesPro ManualAlan De La FuenteNo ratings yet

- 7 Ways To Shortlist The Right StocksDocument10 pages7 Ways To Shortlist The Right Stockskrana26No ratings yet

- Teresa R. Ignacio, Represented by Her Attorney-In-fact, Roberto R. Ignacio, Petitioner, V. Office of The City Treasurer of Quezon City, Et. Al.Document2 pagesTeresa R. Ignacio, Represented by Her Attorney-In-fact, Roberto R. Ignacio, Petitioner, V. Office of The City Treasurer of Quezon City, Et. Al.Pam Otic-ReyesNo ratings yet

- Sereno's Dissenting Opinion Re TruthCommDocument35 pagesSereno's Dissenting Opinion Re TruthCommGerald MagnoNo ratings yet

- Papal InfallibilityDocument6 pagesPapal InfallibilityFrancis AkalazuNo ratings yet

- Schools of PsychologyDocument30 pagesSchools of PsychologyMdl C DayritNo ratings yet

- Homework #3 - Coursera CorrectedDocument10 pagesHomework #3 - Coursera CorrectedSaravind67% (3)

- Temenoff BiomaterialsDocument0 pagesTemenoff BiomaterialsJason Chou0% (9)

- Activity 13Document13 pagesActivity 13Lielannie CarasiNo ratings yet

- Sector:: Automotive/Land Transport SectorDocument20 pagesSector:: Automotive/Land Transport SectorVedin Padilla Pedroso92% (12)

- Raa' - Tafkheem & Tarqeeq - Tajweed MeDocument11 pagesRaa' - Tafkheem & Tarqeeq - Tajweed MeClass DocumentNo ratings yet