Professional Documents

Culture Documents

Apm-4 5T

Uploaded by

elsadwihermiatiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Apm-4 5T

Uploaded by

elsadwihermiatiCopyright:

Available Formats

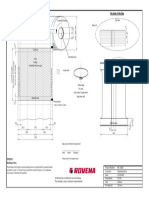

PARAPET WALL DETAIL EDGE DETAIL

TECHNICAL SCHEDULE Coping

Joint cover, 4" to

6" wide, set in

elastomeric sealant

Metal fascia, gravel stop with

low raised edge or plain drip

Modified bitumen

or asphalt

edge without raised lip. bleed out

10' max. length at edge

each piece 1/2" wide gap (4" min. flange width) 93-106

between pieces Prime flange top & bottom Revised March 2007

Bitumen

APM-4.5T ROLLSARE 1 METER WIDE AND 25.58 FEET IN LENGTH. Exterior plywood on

cleat or tapered

Modified bitumen bleed out

sealant under

FLASHING ROLLS ARE AVAILABLE IN HALF AND QUARTER WIDTHS. blocking to

provide slope

Fasteners, approx.

24" o.c. at coping metal flange

and 8" o.c. at 1-1/2" 3"

Solid wood base flashing 3" BITEC

blocking membrane

APPROVALS UL (R13231) BITEC M.B. base

1/2"

edge strip

flashing, up and

Exterior siding, over wall BITEC

brick, etc.

SOFTENING POINT (ASTM D-36) 302F (150C) Bitumen bleed out Continuous

cleat

field membrane

turned down over

Cant strip, securely edge w/opt.

BITUMEN-POLYMER WATERPROOFING MEMBRANE,

nailed or set in BITEC M.B. surfacing or coating

REINFORCEMENT spunbond polyester fabric bitumen membrane with opt.

surfacing or coating Wood blocking,

Fasteners 3" o.c.,

Wood blocking, secured with

staggered as shown

MADE FROM SELECT APP AND DISTILLED BITUMEN,

secured with Fiberglass approp. fasteners,

PENETRATION (ASTM D5) 30 dmm @ 25C approp. fasteners, base sheet match ins.

thickness Base sheet or modified

match ins. thickness bitumen base as required,

REINFORCED WITH SPUNBOND POLYESTER FABRIC.

Base sheet stop at the outside edge

Wood framed wall or M.B. Roof insulation

SLIDE (UNI-8202) <1 mm construction shown base as required

Steel deck

of wood blocking

COLD FLEXIBILITY (UNI-8202) passed +5F (-15C) BITEC APM-4.5T is a torch properties giving the compos- APM-4.5T incorporates a

applied, mineral surfaced, modi- ite membrane similar mechani- smooth and even application

WATER TIGHTNESS (CGSB 37-GP-56M) passed ROOF DRAIN DETAIL Strainer

VENT PIPE DETAIL fied bitumen waterproofing cal characteristics in all angu- of polyethylene film to prevent

Optional M.B. seal around

lead flashing,

primed Clamping ring

Roll lead flashing

1" down

all pipe penetrations membrane composed of care- lar directions in relation to the blocking of rolls and to provide

DYNAMIC PUNCTURE (CGSB 37-GP-56M) passed M.B. target

into the pipe Set lead flange in fully selected asphalts (bitu- membrane surface. Spunbond a smooth, acceptable torching

M.B. sealant. Prime

flashing with opt. flange top & bottom men) having superior modifying polyester fabric imparts the fol- surface. Polyethylene burn-off

surfacing or before stripping.

STATIC PUNCTURE (CGSB 37-GP-56M) passed coating 4" min. flange width characteristics, blended with lowing properties to the com- film is contained on the torch-

Bit. bleed out high quality polypropylene res- posite membrane: able face of the roll. The poly-

TENSILE STRENGTH (ASTM D-412) MD = 100 lbf/in XMD = 70 lbf/in Modified bitumen target ins. APM-4.5T is reinforced with

Opt. lead flashing over the field High flexibility ethylene burn-off film acts as a

flashing, primed membrane joints spunbond polyester fabric. APM-

4.5T waterproofing membrane Puncture resistance sight indicator for the applica-

ELONGATION (ASTM D412) MD = 50% XMD = 55% Taper BITEC 4"

insulation M.B. field

memb. with

Bitumen bleed out

yields the following performance High elongation tor in determining the proper

24" to drain

LOAD STRAIN PRODUCT (CGSB 37-GP-56M) MD = 44,482 n XMD = 34,251 n

opt. surfacing Plumbing BITEC M.B. field

characteristics: flow needed to insure adequate

or coating vent stack membrane with

opt. surfacing

Mechanical strength bonding of plies and seams.

Deck clamp

40" x 40"

Treated wood

blocking

or coating Impermeable to water Fatigue resistance

THICKNESS 4.5 mm smooth surface After installation of the roof-

M.B. collar

BITEC smooth

surface M.B. Low temp flexibility Tear strength

Note: Min. 30" sq., 21/2 to 4 lb. sealed to roof collar membrane. ing membrane is complete,

ROLL WEIGHT, APPROX. 92 lbs lead flashing set on MB membrane in drain flange Thermally stable Deterioration resistance

MB sealant. Prime top surface before stripping.

Membrane plies and lead flashing extend under

M.B. sealant Base sheet or the surface may be coated

clamping ring. Stripping membrane extends 4" Base sheet or M.B. base

as required

Excellent adhesion Dimensional stability with a BITECAPPROVED ROOF

COVERAGE, INSTALLED APPROX. 75 ft2 beyond edge of flashing sheet, but not modified bitumen base Note:

beyond the edge of sump. as required Sheet lead minimum of 21/2 lbs. per foot. Resistant to acids and The mineral surface pro- COATING to increase the overall

most bases reflectivity of the system and/or

TOTAL SURFACE AREA, APPROX. 86.4 ft2 tects the membrane from age-

Puncture resistant ing caused from heat and ultra fire rating. BITEC recommends

DISTRIBUTED BY: APPROVALS: MEMBER OF: Excellent workability violet radiation. Most mineral that a period of at least 45 days

All Information is given in good vidual requirements of each con- at the date of warranty issuance, elapse before roof coatings are

Longevity surfacings yield sufficiently high

faith, but normal tolerances of tract. In consideration of the many and any addendums thereto. Under Factory amounts of solar reflectivity to applied. This will effectively allow

manufacture and testing will apply. factors involved, BITEC cannot be no circumstances will BITEC be held Mutual NATIONAL

ROOFING Spunbond polyester fabric, realized some energy savings, the membrane to cure and

BITEC reserves the right to improve held responsible for the application liable for any damage, whether per- System CONTRACTORS

ASSOCIATION

used as a reinforcement in APM- depending on building construc- accept the roof coating.

and change its products at any of its products and for conditions sonal injury or property damage, 4.5T has isotropic mechanical

A SS I F I ED tion and use. Some heat absorp-

time without prior notice or advice. beyond its control. All claims filed which occur during or after the CL Membrane for Roofing Systems

The use of BITEC products is deter- against BITEC warranties will be application of the membrane. U L Classified By

Underwriters Laboratories, Inc.

tion values are given below, cal-

culated on the basis of an ideal

mined by local conditions and indi- subject to the provisions set forth

R-13231

As to an external fire exposure only

49S8

black surface as being 100%:

PACKAGING

Ideal Black 100% Palletized units contain 20

rolls of APM-4.5T waterproofing

Bituminous Surface 94%

membrane. Each unit is shrink

Gray Mineral 85% wrapped in a special polyethyl-

For more information concerning this and other fine BITEC products, Tan Mineral 57% ene bag for stability. BITEC rec-

CALL 1-800-535-8597 Visit our web site at www.bi-tec.com

White Mineral 30%

ommends that units of material

Manufacturers of Advanced Technology Waterproofing Membranes be single stacked.

Ask for Manager, Technical Services P.O. Box 497 No. 2 Industrial Park Drive Morrilton, Arkansas 72110 Fax (501) 354-3019 Phone 1-800-535-8597

If the membrane is loose laid, DAMAGE. to prevent water ponding at the POSITIVE DRAINAGE AS: ROOF to prevent water ponding at DECK BECOMES DEVOID OF WATER

an area of 40" each side of the SPECIFICATION: drain rim. Base ply should be DECK BECOMES DEVOID OF WATER SPECIFICATION: rim. Base ply should be evenly WITHIN 72 HOURS AFTER LIQUID

APPLICATION SAFETY

end lap should be fully bonded to

the roof surface. APM-4.5T.1 evenly trimmed with the drain

flange, followed with a 40 x

WITHIN 72 HOURS AFTER LIQUID

PRECIPITATION HAS OCCURRED. APM-4.5T.2 trimmed with the drain flange,

followed with a 40" x 40" heat

PRECIPITATION HAS OCCURRED.

BITEC WILL NOT BE RESPONSIBLE

NON-NAILABLE DECK 40 heat welded collar of BITEC BITEC WILL NOT BE RESPONSIBLE NAILABLE DECK welded collar of BITEC APS-4T. FOR MEMBRANE DAMAGE AS A

Depending on the type of BITEC APP MEMBRANES THE CONTRACTOR APS-4T. This collar must extend FOR MEMBRANE DAMAGE AS A This collar must extend into and RESULT OF INADEQUATE ROOF

roof, APM-4.5T can be either MAY NOT BE INSTALLED IN HOT

It is the contractors respon- into and be fully adhered to the RESULT OF INADEQUATE ROOF be fully adhered to the interior DECK DRAINAGE.

fully adhered, spot or partially ROOFING ASPHALT, COLD PROCESS If plans or specifications If plans or specifications

sibility to observe all fire pre- interior of the drain flange and DECK DRAINAGE. of the drain flange and interior

adhered, or loose laid. BITEC ADHESIVES OR BY MECHANICAL require installation of a modified require installation of a modified

interior surface. The APM-4.5T surface. The APM-4T membrane SEC. 8.00 FINAL SURFACING

ATTACHMENT. vention policies and practices, bitumen membrane system over SEC. 8.00 FINAL SURFACING bitumen membrane system over

specifications applicable to this membrane shall be fully adhered shall be fully adhered to the base

to train, instruct and warn a non-nailable deck apply this a nailable deck apply this specifi- As an option, any BITEC

product should be consulted to BITEC APP MEMBRANES to the base ply, APS-4T flashing As an option, any ply, APS-4T flashing collar and

employees on the use of torch- specification (APM-4.5T.1). cation (APM-4.5T.2). APPROVED ROOF COATING can

determine which system should ARE NOT RECOMMENDED FOR collar and extend into the drain. B I T E C A P P R O V E D R O O F extend into the drain. Clamp ring

ing equipment. Follow OSHA and be applied to the finished mem-

be employed. When applying USE OVER COAL TAR OR PITCH Apply this system using the Clamp ring should be installed COATING can be applied to the Apply this system using the shall be installed while the mem-

NRCA provisions for fire protec- brane system.

the membrane, the polyethylene ROOFS UNLESS THE EXISTING appropriate BITEC approved and tightened while the mem- finished membrane system. appropriate BITEC approved base brane is still hot. A 4 Ib. Iead or

DECK IS SEPARATED FROM THE tion, including but not limited brane is hot. A 4 lb. Iead or 16 16 oz. copper flashing is optional BITEC RECOMMENDS THAT

burn-off film should always be base flashing, metal flashing BlTEC RECOMMENDS THAT flashing, metal flashing or wall

BITEC MEMBRANE BY A MIN. 12" to those listed in OSHA 1962., oz. copper flashing is option- between the collar and the APM- A PERIOD OF AT LEAST 45 DAYS

down facing the roof deck. Prior or wall covering as specified in A PERIOD OF AT LEAST 45 DAYS covering as specified in the most

THICK, MECHANICALLY ATTACHED 150., 151., 153., 1191-110 al between the collar and the 4.5T field membrane. APS-4T ELAPSE BEFORE ROOF COATING IS

to application, the membrane the most current edition of the ELAPSE BEFORE ROOF COATING IS current edition of the BITEC

RECOVER BOARD. BITEC DOES which apply to torch applica- APM-4.5T field membrane. Roofing Material Specification collar should extend 4 inches APPLIED. (ROOF COATING MAY BE

should be unrolled completely, BITEC Roofing Material Spec APPLIED. (ROOF COATING MAY BE

NOT ALLOW THE USE OF PLASTIC tion. The contractor should be APS-4T collar should extend and Details publication. beyond the lead or copper flash- NECESSARY TO COMPLY WITH U.L.

aligned and set before the actual ification and Details publication. NECESSARY TO COMPLY WITH U.L.

ROOFER'S CEMENT WITH ANY OF familiar with NFPA 58 Standard 4" beyond the lead or copper ing. OR F.M. SYSTEM REQUIREMENTS.)

heat welding of the membrane OR F.M. SYSTEM REQUIREMENTS.) SEC. 1.00 INSULATION

ITS MEMBRANES. for the Storage and Handling SEC. 1.00 INSULATION flashing.

occurs. The membrane should SEC. 6.00 PIPE FLASHING BITEC WILL NOT COVER

of Liquefied Petroleum Gas The following insulations are SEC. 6.00 PIPE FLASHING BITEC WILL NOT COVER The following insulations are

then be rolled up half way, leav- AS WITH ANY ROOFING MEMBRANE DAMAGE OR

P R O J E C T, G O O D R O O F I N G and any other appropriate pub- acceptable for use with APM- MEMBRANE DAMAGE OR acceptable for use with APM- Where penetrations occur in FAILURE OF ANY ROOF SYSTEM,

ing the other half fully extended. Where penetrations occur in

PRACTICES SHOULD ALWAYS BE lications of the National LP Gas 4.5T: FAILURE OF ANY ROOF SYSTEM, 4.5T: the roof surface a collar of APS- RESULTINGFROMCOATINGS FROM

(This will insure that the mem- the roof surface a collar of APS- R E S U LT I N G F R O M C O AT I N G S 4T should be installed over the

FOLLOWED. CONSULT THE BITEC Association. ANOTHER MANUFACTURER.

brane will remain aligned during PERLITE 4T should be installed over the FROM ANOTHER MANUFACTURER. PERLITE base ply extending a minimum

the heat welding process.) SPECIFICATION AND DETAILS BOOK

FIRE DEPARTMENT GLASS FIBER base ply extending a minimum of GLASS FIBER 4" beyond the flanges. A metal

FOR INFORMATION GOVERNING

4" beyond the flanges. A metal ***** WARRANTIES *****

Begin torching the burn-off flashing shall be installed having

CERTAIN SYSTEMS. REGULATIONS POLYISOCYANURATE flashing shall be installed having BITEC, INC. POLYISOCYANURATE ***** WARRANTIES *****

film surface of the membrane, a continuous flange 4" minimum

The contractor should be WOOD FIBER a continuous flange 4" minimum, offers two warranties: WOOD FIBER on top of the APS-4T collar. (On BITEC, INC.

using a sweeping motion, main- offers two warranties:

familiar with all local fire codes CELLULAR GLASS on top of the APS-4T collar. (On (1) 10-YR. MATERIAL ONLY CELLULAR GLASS nailable decks, the metal flange

taining even heating. The actual TOOLS nailable decks, the metal flange

in his area. The contractor is must be nailed 3" o.c., 34" from (1) 10-YR. MATERIAL ONLY

torching motion should be done SEC. 2.00 CANTS must be nailed 3" o.c., 34" from (2) 10-YR. LIMITED INSURED SEC. 2.00 CANTS

in an L configuration, preheat- REQUIRED responsible for obtaining all nec-

the perimeter.) ROOFING WARRANTY*

the perimeter.)

(2) 10-YR. LIMITED INSURED

essary permits or certificates Flashing details, where the Flashing details, where the ALL METAL FLASHINGS MUST

ing the previously installed mem- ROOFING WARRANTY*

before any work is started. transition is from the horizon- ALL METAL FLASHINGS MUST In order to obtain warran- transition is from the horizontal BE PRIMED WITH AN ASPHALT

brane lap, then sweeping across To apply BITEC APM-4.5T tal to a vertical surface, a non- BE PRIMED WITH AN ASPHALT ty (2), which covers labor and to the vertical surface, a non- PRIMER AND ALLOWED TO In order to obtain warran-

the roll face while advancing the waterproofing membrane, the combustible cant strip must be

PERSONNEL combustible cant strip must be PRIMER AND ALLOWED TO materials, an AUTHORIZED DRY BEFORE MEMBRANE AND ty (2), which covers labor and

roll over the roof surface. As the only tools needed are: a pro- used. used.

DRY BEFORE MEMBRANE AND BITEC APPLICATOR must install FLASHINGS ARE INSTALLED. materials, an AUTHORIZED

roll is advanced, a bead of modi- pane torch having a UL certi- Proper clothing should be FLASHINGS ARE INSTALLED. the roofing system. A small war- BITEC APPLICATOR must install

fied bitumen should be seen flow- fied regulator, propane bottle, worn at all times while installing SEC. 3.00 BASE SHEET SEC. 3.00 BASE SHEET The APM-4.5T field mem-

ing from between the lap seam spatula or round nose roofer's any modified membrane. Long The APM-4.5T field mem- ranty fee is assessed if the sys- brane must be fully adhered to the roofing system. A small war-

A minimum of one ply of fiber- tem is not coated or does not A minimum of one ply of fiber-

a distance of 14 to 38" from trowel, a roofer's knife, pair of sleeve shirt, long pants, leather brane must be fully adhered to the APS-4T collar and metal ranty fee is assessed if the sys-

glass TYPE G2 base sheet must glass TYPE G2 base sheet must

the membrane edge, which is work gloves, flat soled shoes the APS-4T collar and metal have a factory installed mineral flange. All seams must be trow- tem is not coated or does not

or durable flat soled shoes and be installed over the insulation be installed over the insulation

being advanced. This flow out and an ABC dry chemical fire flange. All seams must be trow- surface. Final inspection by a eled and filled with molten modi- have a factory installed mineral

work gloves. Workmen, other or deck before the membrane is or deck before the membrane is

should be consistent and unin- extinguisher. eled and filled with molten modi- BITEC FIELD REPRESENTATIVE fied bitumen. surface. Final inspection by a

than the torch operator, should heat welded. heat welded.

terrupted. Seams which are not fied bitumen. is necessary before issuance of BITEC FIELD REPRESENTATIVE

BEFORE USING THIS be no closer than 3' from open SEC. 7.00 ROOF DECK

SEC. 4.00 FASTENERS warranty. Information regard- SEC. 4.00 FASTENERS is necessary before issuance of

fully bonded can be repaired by PRODUCT, BE CERTAIN THAT ALL flame. SEC. 7.00 ROOF DECK

Consult Factory Mutual ing BITEC warranties may Consult Factory Mutual The roof deck must be warranty. Information regard-

inserting a hot trowel between INFORMATION CONCERNING THE

Research Publications governing The roof deck must be be obtained from: MANAGER Research Publications govern- smooth, dry, clean and free of ing BITEC warranties may be

the affected seam and lightly INSTALLATION OF THIS PRODUCT

THE ROOFING CONTRACTOR AND your geographical region, or FM smooth, dry, clean and free of OFTECHNICAL SERVICES by call- ing your geographical region, or sharp projections and depres- obtained from: MANAGER

torching. Upon removal of the AND SAFETY GUIDELINES

sharp projections and depres-

HIS EMPLOYEES ARE THE KEY TO J.l.OQ3A3.AM governing BITEC ing 800-535-8597. F.M. J.l.OQ3A3.AM governing sions, and properly graded to OFTECHNICAL SERVICES by call-

hot trowel, pressure should be PERTAINING THERETO HAVE BEEN

SUCCESS REGARDING SAFETY... products and systems. sions, and properly graded to BITEC products and systems. outlets. ing 800-535-8597.

applied to the top ply, forcing the READ AND FULLY UNDERSTOOD *Extended warranty periods are avail-

SAFETY SHOULD outlets. able, 12, 15 and 20 years.

modified bitumen to flow out the THE APPLICATION OF MODIFIED THE ROOFING CONTRACTOR, *Extended warranty periods are avail-

ALWAYS BE FIRST! SEC. 5.00 OUTLETS SEC. 5.00 OUTLETS able, 12, 15 and 20 years.

desired distance. MEMBRANES REQUIRES THE USE THE ROOFING CONTRACTOR, ARCHITECT, AND ENGINEER MUST

Drainage outlets shall be SOME SYSTEM DETAILS Drainage outlets shall be

OF EXPLOSIVE GAS AND MOLTEN ARCHITECT, ANDENGINEER MUST ALLOW FOR POSITIVE DRAINAGE

All side and end laps should ASPHALTS, WHICH IF MISHANDLED installed below the roof deck ALLOW FOR POSITIVE DRAINAGE ARE PROVIDED ON installed below the roof deck WHEN DESIGNING THE ROOF DECK SOME SYSTEM DETAILS

be a minimum of 4 inches and 6 CAN AND WILL CAUSE PERSONAL surface to permit POSITIVE WHEN DESIGNING THE ROOF DECK THE BACK PAGE. sur face to permit POSITIVE OR ROOF SYSTEM. BITEC DEFINES ARE PROVIDED ON

inches respectively. INJURY AND/OR PROPERTY DRAINAGE of the roof deck and OR ROOF SYSTEM. BITEC DEFINES DRAINAGE of the roof deck and POSITIVE DRAINAGE AS: ROOF THE BACK PAGE.

If the membrane is loose laid, DAMAGE. to prevent water ponding at the POSITIVE DRAINAGE AS: ROOF to prevent water ponding at DECK BECOMES DEVOID OF WATER

an area of 40" each side of the SPECIFICATION: drain rim. Base ply should be DECK BECOMES DEVOID OF WATER SPECIFICATION: rim. Base ply should be evenly WITHIN 72 HOURS AFTER LIQUID

APPLICATION SAFETY

end lap should be fully bonded to

the roof surface. APM-4.5T.1 evenly trimmed with the drain

flange, followed with a 40 x

WITHIN 72 HOURS AFTER LIQUID

PRECIPITATION HAS OCCURRED. APM-4.5T.2 trimmed with the drain flange,

followed with a 40" x 40" heat

PRECIPITATION HAS OCCURRED.

BITEC WILL NOT BE RESPONSIBLE

NON-NAILABLE DECK 40 heat welded collar of BITEC BITEC WILL NOT BE RESPONSIBLE NAILABLE DECK welded collar of BITEC APS-4T. FOR MEMBRANE DAMAGE AS A

Depending on the type of BITEC APP MEMBRANES THE CONTRACTOR APS-4T. This collar must extend FOR MEMBRANE DAMAGE AS A This collar must extend into and RESULT OF INADEQUATE ROOF

roof, APM-4.5T can be either MAY NOT BE INSTALLED IN HOT

It is the contractors respon- into and be fully adhered to the RESULT OF INADEQUATE ROOF be fully adhered to the interior DECK DRAINAGE.

fully adhered, spot or partially ROOFING ASPHALT, COLD PROCESS If plans or specifications If plans or specifications

sibility to observe all fire pre- interior of the drain flange and DECK DRAINAGE. of the drain flange and interior

adhered, or loose laid. BITEC ADHESIVES OR BY MECHANICAL require installation of a modified require installation of a modified

interior surface. The APM-4.5T surface. The APM-4T membrane SEC. 8.00 FINAL SURFACING

ATTACHMENT. vention policies and practices, bitumen membrane system over SEC. 8.00 FINAL SURFACING bitumen membrane system over

specifications applicable to this membrane shall be fully adhered shall be fully adhered to the base

to train, instruct and warn a non-nailable deck apply this a nailable deck apply this specifi- As an option, any BITEC

product should be consulted to BITEC APP MEMBRANES to the base ply, APS-4T flashing As an option, any ply, APS-4T flashing collar and

employees on the use of torch- specification (APM-4.5T.1). cation (APM-4.5T.2). APPROVED ROOF COATING can

determine which system should ARE NOT RECOMMENDED FOR collar and extend into the drain. B I T E C A P P R O V E D R O O F extend into the drain. Clamp ring

ing equipment. Follow OSHA and be applied to the finished mem-

be employed. When applying USE OVER COAL TAR OR PITCH Apply this system using the Clamp ring should be installed COATING can be applied to the Apply this system using the shall be installed while the mem-

NRCA provisions for fire protec- brane system.

the membrane, the polyethylene ROOFS UNLESS THE EXISTING appropriate BITEC approved and tightened while the mem- finished membrane system. appropriate BITEC approved base brane is still hot. A 4 Ib. Iead or

DECK IS SEPARATED FROM THE tion, including but not limited brane is hot. A 4 lb. Iead or 16 16 oz. copper flashing is optional BITEC RECOMMENDS THAT

burn-off film should always be base flashing, metal flashing BlTEC RECOMMENDS THAT flashing, metal flashing or wall

BITEC MEMBRANE BY A MIN. 12" to those listed in OSHA 1962., oz. copper flashing is option- between the collar and the APM- A PERIOD OF AT LEAST 45 DAYS

down facing the roof deck. Prior or wall covering as specified in A PERIOD OF AT LEAST 45 DAYS covering as specified in the most

THICK, MECHANICALLY ATTACHED 150., 151., 153., 1191-110 al between the collar and the 4.5T field membrane. APS-4T ELAPSE BEFORE ROOF COATING IS

to application, the membrane the most current edition of the ELAPSE BEFORE ROOF COATING IS current edition of the BITEC

RECOVER BOARD. BITEC DOES which apply to torch applica- APM-4.5T field membrane. Roofing Material Specification collar should extend 4 inches APPLIED. (ROOF COATING MAY BE

should be unrolled completely, BITEC Roofing Material Spec APPLIED. (ROOF COATING MAY BE

NOT ALLOW THE USE OF PLASTIC tion. The contractor should be APS-4T collar should extend and Details publication. beyond the lead or copper flash- NECESSARY TO COMPLY WITH U.L.

aligned and set before the actual ification and Details publication. NECESSARY TO COMPLY WITH U.L.

ROOFER'S CEMENT WITH ANY OF familiar with NFPA 58 Standard 4" beyond the lead or copper ing. OR F.M. SYSTEM REQUIREMENTS.)

heat welding of the membrane OR F.M. SYSTEM REQUIREMENTS.) SEC. 1.00 INSULATION

ITS MEMBRANES. for the Storage and Handling SEC. 1.00 INSULATION flashing.

occurs. The membrane should SEC. 6.00 PIPE FLASHING BITEC WILL NOT COVER

of Liquefied Petroleum Gas The following insulations are SEC. 6.00 PIPE FLASHING BITEC WILL NOT COVER The following insulations are

then be rolled up half way, leav- AS WITH ANY ROOFING MEMBRANE DAMAGE OR

P R O J E C T, G O O D R O O F I N G and any other appropriate pub- acceptable for use with APM- MEMBRANE DAMAGE OR acceptable for use with APM- Where penetrations occur in FAILURE OF ANY ROOF SYSTEM,

ing the other half fully extended. Where penetrations occur in

PRACTICES SHOULD ALWAYS BE lications of the National LP Gas 4.5T: FAILURE OF ANY ROOF SYSTEM, 4.5T: the roof surface a collar of APS- RESULTINGFROMCOATINGS FROM

(This will insure that the mem- the roof surface a collar of APS- R E S U LT I N G F R O M C O AT I N G S 4T should be installed over the

FOLLOWED. CONSULT THE BITEC Association. ANOTHER MANUFACTURER.

brane will remain aligned during PERLITE 4T should be installed over the FROM ANOTHER MANUFACTURER. PERLITE base ply extending a minimum

the heat welding process.) SPECIFICATION AND DETAILS BOOK

FIRE DEPARTMENT GLASS FIBER base ply extending a minimum of GLASS FIBER 4" beyond the flanges. A metal

FOR INFORMATION GOVERNING

4" beyond the flanges. A metal ***** WARRANTIES *****

Begin torching the burn-off flashing shall be installed having

CERTAIN SYSTEMS. REGULATIONS POLYISOCYANURATE flashing shall be installed having BITEC, INC. POLYISOCYANURATE ***** WARRANTIES *****

film surface of the membrane, a continuous flange 4" minimum

The contractor should be WOOD FIBER a continuous flange 4" minimum, offers two warranties: WOOD FIBER on top of the APS-4T collar. (On BITEC, INC.

using a sweeping motion, main- offers two warranties:

familiar with all local fire codes CELLULAR GLASS on top of the APS-4T collar. (On (1) 10-YR. MATERIAL ONLY CELLULAR GLASS nailable decks, the metal flange

taining even heating. The actual TOOLS nailable decks, the metal flange

in his area. The contractor is must be nailed 3" o.c., 34" from (1) 10-YR. MATERIAL ONLY

torching motion should be done SEC. 2.00 CANTS must be nailed 3" o.c., 34" from (2) 10-YR. LIMITED INSURED SEC. 2.00 CANTS

in an L configuration, preheat- REQUIRED responsible for obtaining all nec-

the perimeter.) ROOFING WARRANTY*

the perimeter.)

(2) 10-YR. LIMITED INSURED

essary permits or certificates Flashing details, where the Flashing details, where the ALL METAL FLASHINGS MUST

ing the previously installed mem- ROOFING WARRANTY*

before any work is started. transition is from the horizon- ALL METAL FLASHINGS MUST In order to obtain warran- transition is from the horizontal BE PRIMED WITH AN ASPHALT

brane lap, then sweeping across To apply BITEC APM-4.5T tal to a vertical surface, a non- BE PRIMED WITH AN ASPHALT ty (2), which covers labor and to the vertical surface, a non- PRIMER AND ALLOWED TO In order to obtain warran-

the roll face while advancing the waterproofing membrane, the combustible cant strip must be

PERSONNEL combustible cant strip must be PRIMER AND ALLOWED TO materials, an AUTHORIZED DRY BEFORE MEMBRANE AND ty (2), which covers labor and

roll over the roof surface. As the only tools needed are: a pro- used. used.

DRY BEFORE MEMBRANE AND BITEC APPLICATOR must install FLASHINGS ARE INSTALLED. materials, an AUTHORIZED

roll is advanced, a bead of modi- pane torch having a UL certi- Proper clothing should be FLASHINGS ARE INSTALLED. the roofing system. A small war- BITEC APPLICATOR must install

fied bitumen should be seen flow- fied regulator, propane bottle, worn at all times while installing SEC. 3.00 BASE SHEET SEC. 3.00 BASE SHEET The APM-4.5T field mem-

ing from between the lap seam spatula or round nose roofer's any modified membrane. Long The APM-4.5T field mem- ranty fee is assessed if the sys- brane must be fully adhered to the roofing system. A small war-

A minimum of one ply of fiber- tem is not coated or does not A minimum of one ply of fiber-

a distance of 14 to 38" from trowel, a roofer's knife, pair of sleeve shirt, long pants, leather brane must be fully adhered to the APS-4T collar and metal ranty fee is assessed if the sys-

glass TYPE G2 base sheet must glass TYPE G2 base sheet must

the membrane edge, which is work gloves, flat soled shoes the APS-4T collar and metal have a factory installed mineral flange. All seams must be trow- tem is not coated or does not

or durable flat soled shoes and be installed over the insulation be installed over the insulation

being advanced. This flow out and an ABC dry chemical fire flange. All seams must be trow- surface. Final inspection by a eled and filled with molten modi- have a factory installed mineral

work gloves. Workmen, other or deck before the membrane is or deck before the membrane is

should be consistent and unin- extinguisher. eled and filled with molten modi- BITEC FIELD REPRESENTATIVE fied bitumen. surface. Final inspection by a

than the torch operator, should heat welded. heat welded.

terrupted. Seams which are not fied bitumen. is necessary before issuance of BITEC FIELD REPRESENTATIVE

BEFORE USING THIS be no closer than 3' from open SEC. 7.00 ROOF DECK

SEC. 4.00 FASTENERS warranty. Information regard- SEC. 4.00 FASTENERS is necessary before issuance of

fully bonded can be repaired by PRODUCT, BE CERTAIN THAT ALL flame. SEC. 7.00 ROOF DECK

Consult Factory Mutual ing BITEC warranties may Consult Factory Mutual The roof deck must be warranty. Information regard-

inserting a hot trowel between INFORMATION CONCERNING THE

Research Publications governing The roof deck must be be obtained from: MANAGER Research Publications govern- smooth, dry, clean and free of ing BITEC warranties may be

the affected seam and lightly INSTALLATION OF THIS PRODUCT

THE ROOFING CONTRACTOR AND your geographical region, or FM smooth, dry, clean and free of OFTECHNICAL SERVICES by call- ing your geographical region, or sharp projections and depres- obtained from: MANAGER

torching. Upon removal of the AND SAFETY GUIDELINES

sharp projections and depres-

HIS EMPLOYEES ARE THE KEY TO J.l.OQ3A3.AM governing BITEC ing 800-535-8597. F.M. J.l.OQ3A3.AM governing sions, and properly graded to OFTECHNICAL SERVICES by call-

hot trowel, pressure should be PERTAINING THERETO HAVE BEEN

SUCCESS REGARDING SAFETY... products and systems. sions, and properly graded to BITEC products and systems. outlets. ing 800-535-8597.

applied to the top ply, forcing the READ AND FULLY UNDERSTOOD *Extended warranty periods are avail-

SAFETY SHOULD outlets. able, 12, 15 and 20 years.

modified bitumen to flow out the THE APPLICATION OF MODIFIED THE ROOFING CONTRACTOR, *Extended warranty periods are avail-

ALWAYS BE FIRST! SEC. 5.00 OUTLETS SEC. 5.00 OUTLETS able, 12, 15 and 20 years.

desired distance. MEMBRANES REQUIRES THE USE THE ROOFING CONTRACTOR, ARCHITECT, AND ENGINEER MUST

Drainage outlets shall be SOME SYSTEM DETAILS Drainage outlets shall be

OF EXPLOSIVE GAS AND MOLTEN ARCHITECT, ANDENGINEER MUST ALLOW FOR POSITIVE DRAINAGE

All side and end laps should ASPHALTS, WHICH IF MISHANDLED installed below the roof deck ALLOW FOR POSITIVE DRAINAGE ARE PROVIDED ON installed below the roof deck WHEN DESIGNING THE ROOF DECK SOME SYSTEM DETAILS

be a minimum of 4 inches and 6 CAN AND WILL CAUSE PERSONAL surface to permit POSITIVE WHEN DESIGNING THE ROOF DECK THE BACK PAGE. sur face to permit POSITIVE OR ROOF SYSTEM. BITEC DEFINES ARE PROVIDED ON

inches respectively. INJURY AND/OR PROPERTY DRAINAGE of the roof deck and OR ROOF SYSTEM. BITEC DEFINES DRAINAGE of the roof deck and POSITIVE DRAINAGE AS: ROOF THE BACK PAGE.

If the membrane is loose laid, DAMAGE. to prevent water ponding at the POSITIVE DRAINAGE AS: ROOF to prevent water ponding at DECK BECOMES DEVOID OF WATER

an area of 40" each side of the SPECIFICATION: drain rim. Base ply should be DECK BECOMES DEVOID OF WATER SPECIFICATION: rim. Base ply should be evenly WITHIN 72 HOURS AFTER LIQUID

APPLICATION SAFETY

end lap should be fully bonded to

the roof surface. APM-4.5T.1 evenly trimmed with the drain

flange, followed with a 40 x

WITHIN 72 HOURS AFTER LIQUID

PRECIPITATION HAS OCCURRED. APM-4.5T.2 trimmed with the drain flange,

followed with a 40" x 40" heat

PRECIPITATION HAS OCCURRED.

BITEC WILL NOT BE RESPONSIBLE

NON-NAILABLE DECK 40 heat welded collar of BITEC BITEC WILL NOT BE RESPONSIBLE NAILABLE DECK welded collar of BITEC APS-4T. FOR MEMBRANE DAMAGE AS A

Depending on the type of BITEC APP MEMBRANES THE CONTRACTOR APS-4T. This collar must extend FOR MEMBRANE DAMAGE AS A This collar must extend into and RESULT OF INADEQUATE ROOF

roof, APM-4.5T can be either MAY NOT BE INSTALLED IN HOT

It is the contractors respon- into and be fully adhered to the RESULT OF INADEQUATE ROOF be fully adhered to the interior DECK DRAINAGE.

fully adhered, spot or partially ROOFING ASPHALT, COLD PROCESS If plans or specifications If plans or specifications

sibility to observe all fire pre- interior of the drain flange and DECK DRAINAGE. of the drain flange and interior

adhered, or loose laid. BITEC ADHESIVES OR BY MECHANICAL require installation of a modified require installation of a modified

interior surface. The APM-4.5T surface. The APM-4T membrane SEC. 8.00 FINAL SURFACING

ATTACHMENT. vention policies and practices, bitumen membrane system over SEC. 8.00 FINAL SURFACING bitumen membrane system over

specifications applicable to this membrane shall be fully adhered shall be fully adhered to the base

to train, instruct and warn a non-nailable deck apply this a nailable deck apply this specifi- As an option, any BITEC

product should be consulted to BITEC APP MEMBRANES to the base ply, APS-4T flashing As an option, any ply, APS-4T flashing collar and

employees on the use of torch- specification (APM-4.5T.1). cation (APM-4.5T.2). APPROVED ROOF COATING can

determine which system should ARE NOT RECOMMENDED FOR collar and extend into the drain. B I T E C A P P R O V E D R O O F extend into the drain. Clamp ring

ing equipment. Follow OSHA and be applied to the finished mem-

be employed. When applying USE OVER COAL TAR OR PITCH Apply this system using the Clamp ring should be installed COATING can be applied to the Apply this system using the shall be installed while the mem-

NRCA provisions for fire protec- brane system.

the membrane, the polyethylene ROOFS UNLESS THE EXISTING appropriate BITEC approved and tightened while the mem- finished membrane system. appropriate BITEC approved base brane is still hot. A 4 Ib. Iead or

DECK IS SEPARATED FROM THE tion, including but not limited brane is hot. A 4 lb. Iead or 16 16 oz. copper flashing is optional BITEC RECOMMENDS THAT

burn-off film should always be base flashing, metal flashing BlTEC RECOMMENDS THAT flashing, metal flashing or wall

BITEC MEMBRANE BY A MIN. 12" to those listed in OSHA 1962., oz. copper flashing is option- between the collar and the APM- A PERIOD OF AT LEAST 45 DAYS

down facing the roof deck. Prior or wall covering as specified in A PERIOD OF AT LEAST 45 DAYS covering as specified in the most

THICK, MECHANICALLY ATTACHED 150., 151., 153., 1191-110 al between the collar and the 4.5T field membrane. APS-4T ELAPSE BEFORE ROOF COATING IS

to application, the membrane the most current edition of the ELAPSE BEFORE ROOF COATING IS current edition of the BITEC

RECOVER BOARD. BITEC DOES which apply to torch applica- APM-4.5T field membrane. Roofing Material Specification collar should extend 4 inches APPLIED. (ROOF COATING MAY BE

should be unrolled completely, BITEC Roofing Material Spec APPLIED. (ROOF COATING MAY BE

NOT ALLOW THE USE OF PLASTIC tion. The contractor should be APS-4T collar should extend and Details publication. beyond the lead or copper flash- NECESSARY TO COMPLY WITH U.L.

aligned and set before the actual ification and Details publication. NECESSARY TO COMPLY WITH U.L.

ROOFER'S CEMENT WITH ANY OF familiar with NFPA 58 Standard 4" beyond the lead or copper ing. OR F.M. SYSTEM REQUIREMENTS.)

heat welding of the membrane OR F.M. SYSTEM REQUIREMENTS.) SEC. 1.00 INSULATION

ITS MEMBRANES. for the Storage and Handling SEC. 1.00 INSULATION flashing.

occurs. The membrane should SEC. 6.00 PIPE FLASHING BITEC WILL NOT COVER

of Liquefied Petroleum Gas The following insulations are SEC. 6.00 PIPE FLASHING BITEC WILL NOT COVER The following insulations are

then be rolled up half way, leav- AS WITH ANY ROOFING MEMBRANE DAMAGE OR

P R O J E C T, G O O D R O O F I N G and any other appropriate pub- acceptable for use with APM- MEMBRANE DAMAGE OR acceptable for use with APM- Where penetrations occur in FAILURE OF ANY ROOF SYSTEM,

ing the other half fully extended. Where penetrations occur in

PRACTICES SHOULD ALWAYS BE lications of the National LP Gas 4.5T: FAILURE OF ANY ROOF SYSTEM, 4.5T: the roof surface a collar of APS- RESULTINGFROMCOATINGS FROM

(This will insure that the mem- the roof surface a collar of APS- R E S U LT I N G F R O M C O AT I N G S 4T should be installed over the

FOLLOWED. CONSULT THE BITEC Association. ANOTHER MANUFACTURER.

brane will remain aligned during PERLITE 4T should be installed over the FROM ANOTHER MANUFACTURER. PERLITE base ply extending a minimum

the heat welding process.) SPECIFICATION AND DETAILS BOOK

FIRE DEPARTMENT GLASS FIBER base ply extending a minimum of GLASS FIBER 4" beyond the flanges. A metal

FOR INFORMATION GOVERNING

4" beyond the flanges. A metal ***** WARRANTIES *****

Begin torching the burn-off flashing shall be installed having

CERTAIN SYSTEMS. REGULATIONS POLYISOCYANURATE flashing shall be installed having BITEC, INC. POLYISOCYANURATE ***** WARRANTIES *****

film surface of the membrane, a continuous flange 4" minimum

The contractor should be WOOD FIBER a continuous flange 4" minimum, offers two warranties: WOOD FIBER on top of the APS-4T collar. (On BITEC, INC.

using a sweeping motion, main- offers two warranties:

familiar with all local fire codes CELLULAR GLASS on top of the APS-4T collar. (On (1) 10-YR. MATERIAL ONLY CELLULAR GLASS nailable decks, the metal flange

taining even heating. The actual TOOLS nailable decks, the metal flange

in his area. The contractor is must be nailed 3" o.c., 34" from (1) 10-YR. MATERIAL ONLY

torching motion should be done SEC. 2.00 CANTS must be nailed 3" o.c., 34" from (2) 10-YR. LIMITED INSURED SEC. 2.00 CANTS

in an L configuration, preheat- REQUIRED responsible for obtaining all nec-

the perimeter.) ROOFING WARRANTY*

the perimeter.)

(2) 10-YR. LIMITED INSURED

essary permits or certificates Flashing details, where the Flashing details, where the ALL METAL FLASHINGS MUST

ing the previously installed mem- ROOFING WARRANTY*

before any work is started. transition is from the horizon- ALL METAL FLASHINGS MUST In order to obtain warran- transition is from the horizontal BE PRIMED WITH AN ASPHALT

brane lap, then sweeping across To apply BITEC APM-4.5T tal to a vertical surface, a non- BE PRIMED WITH AN ASPHALT ty (2), which covers labor and to the vertical surface, a non- PRIMER AND ALLOWED TO In order to obtain warran-

the roll face while advancing the waterproofing membrane, the combustible cant strip must be

PERSONNEL combustible cant strip must be PRIMER AND ALLOWED TO materials, an AUTHORIZED DRY BEFORE MEMBRANE AND ty (2), which covers labor and

roll over the roof surface. As the only tools needed are: a pro- used. used.

DRY BEFORE MEMBRANE AND BITEC APPLICATOR must install FLASHINGS ARE INSTALLED. materials, an AUTHORIZED

roll is advanced, a bead of modi- pane torch having a UL certi- Proper clothing should be FLASHINGS ARE INSTALLED. the roofing system. A small war- BITEC APPLICATOR must install

fied bitumen should be seen flow- fied regulator, propane bottle, worn at all times while installing SEC. 3.00 BASE SHEET SEC. 3.00 BASE SHEET The APM-4.5T field mem-

ing from between the lap seam spatula or round nose roofer's any modified membrane. Long The APM-4.5T field mem- ranty fee is assessed if the sys- brane must be fully adhered to the roofing system. A small war-

A minimum of one ply of fiber- tem is not coated or does not A minimum of one ply of fiber-

a distance of 14 to 38" from trowel, a roofer's knife, pair of sleeve shirt, long pants, leather brane must be fully adhered to the APS-4T collar and metal ranty fee is assessed if the sys-

glass TYPE G2 base sheet must glass TYPE G2 base sheet must

the membrane edge, which is work gloves, flat soled shoes the APS-4T collar and metal have a factory installed mineral flange. All seams must be trow- tem is not coated or does not

or durable flat soled shoes and be installed over the insulation be installed over the insulation

being advanced. This flow out and an ABC dry chemical fire flange. All seams must be trow- surface. Final inspection by a eled and filled with molten modi- have a factory installed mineral

work gloves. Workmen, other or deck before the membrane is or deck before the membrane is

should be consistent and unin- extinguisher. eled and filled with molten modi- BITEC FIELD REPRESENTATIVE fied bitumen. surface. Final inspection by a

than the torch operator, should heat welded. heat welded.

terrupted. Seams which are not fied bitumen. is necessary before issuance of BITEC FIELD REPRESENTATIVE

BEFORE USING THIS be no closer than 3' from open SEC. 7.00 ROOF DECK

SEC. 4.00 FASTENERS warranty. Information regard- SEC. 4.00 FASTENERS is necessary before issuance of

fully bonded can be repaired by PRODUCT, BE CERTAIN THAT ALL flame. SEC. 7.00 ROOF DECK

Consult Factory Mutual ing BITEC warranties may Consult Factory Mutual The roof deck must be warranty. Information regard-

inserting a hot trowel between INFORMATION CONCERNING THE

Research Publications governing The roof deck must be be obtained from: MANAGER Research Publications govern- smooth, dry, clean and free of ing BITEC warranties may be

the affected seam and lightly INSTALLATION OF THIS PRODUCT

THE ROOFING CONTRACTOR AND your geographical region, or FM smooth, dry, clean and free of OFTECHNICAL SERVICES by call- ing your geographical region, or sharp projections and depres- obtained from: MANAGER

torching. Upon removal of the AND SAFETY GUIDELINES

sharp projections and depres-

HIS EMPLOYEES ARE THE KEY TO J.l.OQ3A3.AM governing BITEC ing 800-535-8597. F.M. J.l.OQ3A3.AM governing sions, and properly graded to OFTECHNICAL SERVICES by call-

hot trowel, pressure should be PERTAINING THERETO HAVE BEEN

SUCCESS REGARDING SAFETY... products and systems. sions, and properly graded to BITEC products and systems. outlets. ing 800-535-8597.

applied to the top ply, forcing the READ AND FULLY UNDERSTOOD *Extended warranty periods are avail-

SAFETY SHOULD outlets. able, 12, 15 and 20 years.

modified bitumen to flow out the THE APPLICATION OF MODIFIED THE ROOFING CONTRACTOR, *Extended warranty periods are avail-

ALWAYS BE FIRST! SEC. 5.00 OUTLETS SEC. 5.00 OUTLETS able, 12, 15 and 20 years.

desired distance. MEMBRANES REQUIRES THE USE THE ROOFING CONTRACTOR, ARCHITECT, AND ENGINEER MUST

Drainage outlets shall be SOME SYSTEM DETAILS Drainage outlets shall be

OF EXPLOSIVE GAS AND MOLTEN ARCHITECT, ANDENGINEER MUST ALLOW FOR POSITIVE DRAINAGE

All side and end laps should ASPHALTS, WHICH IF MISHANDLED installed below the roof deck ALLOW FOR POSITIVE DRAINAGE ARE PROVIDED ON installed below the roof deck WHEN DESIGNING THE ROOF DECK SOME SYSTEM DETAILS

be a minimum of 4 inches and 6 CAN AND WILL CAUSE PERSONAL surface to permit POSITIVE WHEN DESIGNING THE ROOF DECK THE BACK PAGE. sur face to permit POSITIVE OR ROOF SYSTEM. BITEC DEFINES ARE PROVIDED ON

inches respectively. INJURY AND/OR PROPERTY DRAINAGE of the roof deck and OR ROOF SYSTEM. BITEC DEFINES DRAINAGE of the roof deck and POSITIVE DRAINAGE AS: ROOF THE BACK PAGE.

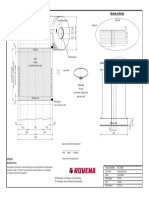

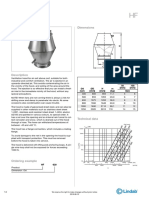

PARAPET WALL DETAIL EDGE DETAIL

TECHNICAL SCHEDULE Coping

Joint cover, 4" to

6" wide, set in

elastomeric sealant

Metal fascia, gravel stop with

low raised edge or plain drip

Modified bitumen

or asphalt

edge without raised lip. bleed out

10' max. length at edge

each piece 1/2" wide gap (4" min. flange width) 93-106

between pieces Prime flange top & bottom Revised March 2007

Bitumen

APM-4.5T ROLLSARE 1 METER WIDE AND 25.58 FEET IN LENGTH. Exterior plywood on

cleat or tapered

Modified bitumen bleed out

sealant under

FLASHING ROLLS ARE AVAILABLE IN HALF AND QUARTER WIDTHS. blocking to

provide slope

Fasteners, approx.

24" o.c. at coping metal flange

and 8" o.c. at 1-1/2" 3"

Solid wood base flashing 3" BITEC

blocking membrane

APPROVALS UL (R13231) BITEC M.B. base

1/2"

edge strip

flashing, up and

Exterior siding, over wall BITEC

brick, etc.

SOFTENING POINT (ASTM D-36) 302F (150C) Bitumen bleed out Continuous

cleat

field membrane

turned down over

Cant strip, securely edge w/opt.

BITUMEN-POLYMER WATERPROOFING MEMBRANE,

nailed or set in BITEC M.B. surfacing or coating

REINFORCEMENT spunbond polyester fabric bitumen membrane with opt.

surfacing or coating Wood blocking,

Fasteners 3" o.c.,

Wood blocking, secured with

staggered as shown

MADE FROM SELECT APP AND DISTILLED BITUMEN,

secured with Fiberglass approp. fasteners,

PENETRATION (ASTM D5) 30 dmm @ 25C approp. fasteners, base sheet match ins.

thickness Base sheet or modified

match ins. thickness bitumen base as required,

REINFORCED WITH SPUNBOND POLYESTER FABRIC.

Base sheet stop at the outside edge

Wood framed wall or M.B. Roof insulation

SLIDE (UNI-8202) <1 mm construction shown base as required

Steel deck

of wood blocking

COLD FLEXIBILITY (UNI-8202) passed +5F (-15C) BITEC APM-4.5T is a torch properties giving the compos- APM-4.5T incorporates a

applied, mineral surfaced, modi- ite membrane similar mechani- smooth and even application

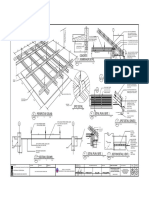

WATER TIGHTNESS (CGSB 37-GP-56M) passed ROOF DRAIN DETAIL Strainer

VENT PIPE DETAIL fied bitumen waterproofing cal characteristics in all angu- of polyethylene film to prevent

Optional M.B. seal around

lead flashing,

primed Clamping ring

Roll lead flashing

1" down

all pipe penetrations membrane composed of care- lar directions in relation to the blocking of rolls and to provide

DYNAMIC PUNCTURE (CGSB 37-GP-56M) passed M.B. target

into the pipe Set lead flange in fully selected asphalts (bitu- membrane surface. Spunbond a smooth, acceptable torching

M.B. sealant. Prime

flashing with opt. flange top & bottom men) having superior modifying polyester fabric imparts the fol- surface. Polyethylene burn-off

surfacing or before stripping.

STATIC PUNCTURE (CGSB 37-GP-56M) passed coating 4" min. flange width characteristics, blended with lowing properties to the com- film is contained on the torch-

Bit. bleed out high quality polypropylene res- posite membrane: able face of the roll. The poly-

TENSILE STRENGTH (ASTM D-412) MD = 100 lbf/in XMD = 70 lbf/in Modified bitumen target ins. APM-4.5T is reinforced with

Opt. lead flashing over the field High flexibility ethylene burn-off film acts as a

flashing, primed membrane joints spunbond polyester fabric. APM-

4.5T waterproofing membrane Puncture resistance sight indicator for the applica-

ELONGATION (ASTM D412) MD = 50% XMD = 55% Taper BITEC 4"

insulation M.B. field

memb. with

Bitumen bleed out

yields the following performance High elongation tor in determining the proper

24" to drain

LOAD STRAIN PRODUCT (CGSB 37-GP-56M) MD = 44,482 n XMD = 34,251 n

opt. surfacing Plumbing BITEC M.B. field

characteristics: flow needed to insure adequate

or coating vent stack membrane with

opt. surfacing

Mechanical strength bonding of plies and seams.

Deck clamp

40" x 40"

Treated wood

blocking

or coating Impermeable to water Fatigue resistance

THICKNESS 4.5 mm smooth surface After installation of the roof-

M.B. collar

BITEC smooth

surface M.B. Low temp flexibility Tear strength

Note: Min. 30" sq., 21/2 to 4 lb. sealed to roof collar membrane. ing membrane is complete,

ROLL WEIGHT, APPROX. 92 lbs lead flashing set on MB membrane in drain flange Thermally stable Deterioration resistance

MB sealant. Prime top surface before stripping.

Membrane plies and lead flashing extend under

M.B. sealant Base sheet or the surface may be coated

clamping ring. Stripping membrane extends 4" Base sheet or M.B. base

as required

Excellent adhesion Dimensional stability with a BITECAPPROVED ROOF

COVERAGE, INSTALLED APPROX. 75 ft2 beyond edge of flashing sheet, but not modified bitumen base Note:

beyond the edge of sump. as required Sheet lead minimum of 21/2 lbs. per foot. Resistant to acids and The mineral surface pro- COATING to increase the overall

most bases reflectivity of the system and/or

TOTAL SURFACE AREA, APPROX. 86.4 ft2 tects the membrane from age-

Puncture resistant ing caused from heat and ultra fire rating. BITEC recommends

DISTRIBUTED BY: APPROVALS: MEMBER OF: Excellent workability violet radiation. Most mineral that a period of at least 45 days

All Information is given in good vidual requirements of each con- at the date of warranty issuance, elapse before roof coatings are

Longevity surfacings yield sufficiently high

faith, but normal tolerances of tract. In consideration of the many and any addendums thereto. Under Factory amounts of solar reflectivity to applied. This will effectively allow

manufacture and testing will apply. factors involved, BITEC cannot be no circumstances will BITEC be held Mutual NATIONAL

ROOFING Spunbond polyester fabric, realized some energy savings, the membrane to cure and

BITEC reserves the right to improve held responsible for the application liable for any damage, whether per- System CONTRACTORS

ASSOCIATION

used as a reinforcement in APM- depending on building construc- accept the roof coating.

and change its products at any of its products and for conditions sonal injury or property damage, 4.5T has isotropic mechanical

A SS I F I ED tion and use. Some heat absorp-

time without prior notice or advice. beyond its control. All claims filed which occur during or after the CL Membrane for Roofing Systems

The use of BITEC products is deter- against BITEC warranties will be application of the membrane. U L Classified By

Underwriters Laboratories, Inc.

tion values are given below, cal-

culated on the basis of an ideal

mined by local conditions and indi- subject to the provisions set forth

R-13231

As to an external fire exposure only

49S8

black surface as being 100%:

PACKAGING

Ideal Black 100% Palletized units contain 20

rolls of APM-4.5T waterproofing

Bituminous Surface 94%

membrane. Each unit is shrink

Gray Mineral 85% wrapped in a special polyethyl-

For more information concerning this and other fine BITEC products, Tan Mineral 57% ene bag for stability. BITEC rec-

CALL 1-800-535-8597 Visit our web site at www.bi-tec.com

White Mineral 30%

ommends that units of material

Manufacturers of Advanced Technology Waterproofing Membranes be single stacked.

Ask for Manager, Technical Services P.O. Box 497 No. 2 Industrial Park Drive Morrilton, Arkansas 72110 Fax (501) 354-3019 Phone 1-800-535-8597

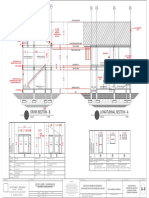

PARAPET WALL DETAIL EDGE DETAIL

TECHNICAL SCHEDULE Coping

Joint cover, 4" to

6" wide, set in

elastomeric sealant

Metal fascia, gravel stop with

low raised edge or plain drip

Modified bitumen

or asphalt

bleed out

10' max. length edge without raised lip.

(4" min. flange width) at edge

each piece 1/2" wide gap

between pieces Prime flange top & bottom

Bitumen Revised April 2007

SPM-3.5H ROLLSARE 1 METER WIDE AND 33.9 FEET IN LENGTH. Exterior plywood on

cleat or tapered Modified bitumen

sealant under

bleed out

blocking to Fasteners, approx.

FLASHING ROLLS ARE AVAILABLE IN HALF AND QUARTER WIDTHS. provide slope 24" o.c. at coping metal flange

SPM-3.5H

and 8" o.c. at 1-1/2" 3"

Solid wood base flashing BITEC

Product Technical Bulletin

3"

blocking 1/2" membrane

APPROVALS UL (R13231) BITEC M.B. base

flashing, up and

edge strip

Exterior siding, over wall BITEC

brick, etc. field membrane

SOFTENING POINT (ASTM D-36) 250F (120C) Bitumen bleed out Continuous

cleat turned down over

Cant strip, securely edge w/opt.

nailed or set in BITEC M.B.

BITUMEN-POLYMER WATERPROOFING MEMBRANE,

surfacing or coating

bitumen membrane with opt.

REINFORCEMENT spunbond polyester fabric surfacing or coating Wood blocking,

Fasteners 3" o.c.,

Wood blocking, secured with

approp. fasteners, staggered as shown

MADE FROM SELECT SBS AND DISTILLED BITUMEN,

secured with Fiberglass

match ins.

PENETRATION (ASTM D5) 40 dmm @ 25C approp. fasteners,

match ins. thickness

base sheet

thickness Base sheet or modified

bitumen base as required,

Base sheet

REINFORCED WITH SPUNBOND POLYESTER FABRIC.

Roof insulation stop at the outside edge

Wood framed wall or M.B. of wood blocking

SLIDE (UNI-8202) <1 mm construction shown base as required

Steel deck

COLD FLEXIBILITY (UNI-8202) passed -13F (-25C) BITEC SPM-3.5H is a hot High elongation low the specific adhesive manu-

asphalt applied, mineral sur- Mechanical strength facturers installation specifica-

WATER TIGHTNESS (CGSB 37-GP-56M) passed ROOF DRAIN DETAIL Strainer

VENT PIPE DETAIL faced, modified bitumen water- tions.)

Optional

Roll lead flashing

M.B. seal around

Fatigue resistance

lead flashing,

Clamping ring 1" down

all pipe penetrations proofing membrane composed

primed

Tear strength After installation of the roof-

DYNAMIC PUNCTURE (CGSB 37-GP-56M) passed M.B. target

into the pipe Set lead flange in of carefully selected asphalts

M.B. sealant. Prime

(bitumen) having superior mod- ing membrane is complete,

flashing with opt. flange top & bottom Deterioration resistance

STATIC PUNCTURE (CGSB 37-GP-56M) passed

surfacing or

coating

before stripping.

ifying characteristics, blended the surface may be coated

4" min. flange width

Dimensional stability with a BITEC APPROVED ROOF

Bit. bleed out with high quality styrene-butadi-

TENSILE STRENGTH (ASTM D-412) MD = 105 lbf/in XMD = 75 lbf/in Opt. lead

Modified bitumen target

ene-styrene rubber. SPM-3.5H The mineral surface pro- COATING to increase the overall

flashing over the field

flashing, primed membrane joints

is reinforced with spunbond poly- tects the membrane from age- reflectivity of the system and/or

ELONGATION (ASTM D412) MD = 60% XMD = 70% Taper BITEC 4"

ester fabric. SPM-3.5H water- ing caused from heat and ultra fire rating. BITEC recommends

M.B. field

insulation

24" to drain memb. with

Bitumen bleed out

proofing membrane yields the violet radiation. Most mineral that a period of at least 45 days

opt. surfacing Plumbing

LOAD STRAIN PRODUCT (CGSB 37-GP-56M) MD = 56,048 n XMD = 46,706 n or coating vent stack

BITEC M.B. field

membrane with following performance charac- surfacings yield sufficiently high elapse before roof coatings are

Deck clamp Treated wood

opt. surfacing

or coating teristics: amounts of solar reflectivity to applied. This will effectively allow

THICKNESS 3.5 mm

40" x 40"

smooth surface

blocking realized some energy savings, the membrane to cure and

Note: Min. 30" sq., 21/2 to 4 lb.

M.B. collar

BITEC smooth

surface M.B. Impermeable to water depending on building construc- accept the roof coating.

sealed to roof collar membrane.

ROLL WEIGHT, APPROX. 100 lbs

lead flashing set on MB membrane in

MB sealant. Prime top surface before stripping.

drain flange Low temp flexibility tion and use. Some heat absorp-

M.B. sealant Base sheet or

Membrane plies and lead flashing extend under

clamping ring. Stripping membrane extends 4" Base sheet or M.B. base Thermally stable tion values are given below, cal-

COVERAGE, INSTALLED APPROX. 100 ft2 beyond edge of flashing sheet, but not

beyond the edge of sump.

modified bitumen base

as required

Note:

Sheet lead minimum of 21/2 lbs. per foot.

as required

Excellent adhesion

culated on the basis of an ideal PACKAGING

black surface as being 100%:

TOTAL SURFACE AREA, APPROX. 111.2 ft2 Resistant to acids and

most bases Palletized units contain 20

Ideal Black 100%

DISTRIBUTED BY: APPROVALS: MEMBER OF: Puncture resistant rolls of SPM-3.5H waterproofing

All Information is given in good vidual requirements of each con- at the date of warranty issuance, Bituminous Surface 94%

faith, but normal tolerances of tract. In consideration of the many and any addendums thereto. Under Excellent workability membrane. Each unit is shrink

manufacture and testing will apply. factors involved, BITEC cannot be no circumstances will BITEC be held NATIONAL Longevity Gray Mineral 85% wrapped in a special polyethyl-

BITEC reserves the right to improve held responsible for the application liable for any damage, whether per-

ROOFING

CONTRACTORS Tan Mineral 57% ene bag for stability. BITEC rec-

ASSOCIATION Spunbond polyester fabric, ommends that units of material

and change its products at any of its products and for conditions sonal injury or property damage, White Mineral 30%

A SS I F I E used as a reinforcement in SPM- be single stacked.

time without prior notice or advice. beyond its control. All claims filed which occur during or after the

D

CL Membrane for Roofing Systems

The use of BITEC products is deter- against BITEC warranties will be application of the membrane. U L Classified By

Underwriters Laboratories, Inc.

3.5H has isotropic mechanical

properties giving the compos-

mined by local conditions and indi- subject to the provisions set forth

As to an external fire exposure only

SPM-3.5H incorporates a

R-13231

49S8

ite membrane similar mechani- smooth and even application of

cal characteristics in all angu- fine sand to prevent blocking of

lar directions in relation to the rolls and to provide a smooth,

membrane surface. Spunbond acceptable application surface.

polyester fabric imparts the fol- SPM-3.5H can be applied by

lowing properties to the com- using hot asphalt or by using any

posite membrane: BITEC APPROVED ELASTOMERIC

For more information concerning this and other fine BITEC products,

High flexibility COLD PROCESS ADHESIVE.*

CALL 1-800-535-8597 Visit our web site at www.bi-tec.com

(When using cold adhesives, fol-

Manufacturers of Advanced Technology Waterproofing Membranes Puncture resistance

Ask for Manager, Technical Services P.O. Box 497 No. 2 Industrial Park Drive Morrilton, Arkansas 72110 Fax (501) 354-3019 Phone 1-800-535-8597

*Cold adhesive application is not UL Classified.

You might also like

- Truss DEtailDocument1 pageTruss DEtailjerick calingasanNo ratings yet

- Moisture resistant gypsum board curtain wall detailsDocument1 pageMoisture resistant gypsum board curtain wall detailsNadim SherifNo ratings yet

- TGS Sukhoi Su-35sDocument1 pageTGS Sukhoi Su-35sairsoft doença100% (1)

- 19PG0089 - Plans Page 9-17Document9 pages19PG0089 - Plans Page 9-17asebdcivilengNo ratings yet

- Ø48 mm Pipe Pole Foundation DrawingDocument1 pageØ48 mm Pipe Pole Foundation DrawingSinan SuleymanovNo ratings yet

- Trench Drain PDFDocument2 pagesTrench Drain PDFMax ViejaNo ratings yet

- Shop Frontage Corridor: 3-Washing SinkDocument1 pageShop Frontage Corridor: 3-Washing SinkManish SharmaNo ratings yet

- Cap 232 Plan VectorDocument2 pagesCap 232 Plan VectormichaelguzziNo ratings yet

- F-18 Park Jet (Part Templates Non-Tiled) Rev ADocument1 pageF-18 Park Jet (Part Templates Non-Tiled) Rev AvscribNo ratings yet

- 64 Scholes Shops Rev.1-DT-2Document1 page64 Scholes Shops Rev.1-DT-2art cafeNo ratings yet

- American-Marsh Pumps Series 460 OSD Flex-Coupled ANSI End Suction Pumps SpecsDocument24 pagesAmerican-Marsh Pumps Series 460 OSD Flex-Coupled ANSI End Suction Pumps Specsjuan davidNo ratings yet

- 02 NewDocument1 page02 NewManjaree WeerasinghaNo ratings yet

- Fpa101249 BR (A) 001-003Document3 pagesFpa101249 BR (A) 001-003chriscundyNo ratings yet

- Typical Drawing of Perimeter FenceDocument1 pageTypical Drawing of Perimeter Fencemarkmarkchanchan0902No ratings yet

- Canopy assembly installation diagramDocument1 pageCanopy assembly installation diagramErnesto LopezNo ratings yet

- Construction Details For Nordic Lam™: Product WarrantyDocument2 pagesConstruction Details For Nordic Lam™: Product WarrantyhahaerNo ratings yet

- FLOOR 2AACAsdcfdfefwaswe2dcdcedDocument1 pageFLOOR 2AACAsdcfdfefwaswe2dcdcedKanak YadavNo ratings yet

- Chi Ti T D2/ D2 Details Chi Ti T Seno D1/ Seno D1 DetailsDocument1 pageChi Ti T D2/ D2 Details Chi Ti T Seno D1/ Seno D1 DetailsPhanLạcKhanhNo ratings yet

- Blusa BlancaDocument43 pagesBlusa BlancaJONATHAN MONTES MATEUSNo ratings yet

- Concrete roof tiles notesDocument1 pageConcrete roof tiles notesanzaniNo ratings yet

- Cabana StructuralDocument1 pageCabana StructuralAlsean Soriano DetubioNo ratings yet

- Art Installation 4: Heritage Museum As ShownDocument1 pageArt Installation 4: Heritage Museum As ShownLawrence TingNo ratings yet

- SpitfireDocument1 pageSpitfireMarselloo ApuíNo ratings yet

- Ch'I Asia, Inc.: Somerset Salcedo, Makati CityDocument1 pageCh'I Asia, Inc.: Somerset Salcedo, Makati CityRolly Marc G. SoteloNo ratings yet

- Ultimate Crochet Cheat SheetDocument1 pageUltimate Crochet Cheat SheetJahNo ratings yet

- K 2882T InstallDocument1 pageK 2882T InstallGagaHarsawanNo ratings yet

- 1 Detail 2 Detail 3 Detail 4 Detail: Rev Date Drawn Description CH'K'D App'dDocument1 page1 Detail 2 Detail 3 Detail 4 Detail: Rev Date Drawn Description CH'K'D App'dsachinsaklani23No ratings yet

- Bag Layout FS 125 PDFDocument1 pageBag Layout FS 125 PDFwawa_opzNo ratings yet

- Backside of the BagDocument1 pageBackside of the Bagwawa_opzNo ratings yet

- Fpa101249 BR (D) 001-003Document3 pagesFpa101249 BR (D) 001-003chriscundyNo ratings yet

- Cross Section - B Longitudinal Section - ADocument1 pageCross Section - B Longitudinal Section - ABess Adrane JurolanNo ratings yet

- Sectiune Detaliu 2 Scara 1:20: Gspublisherversion 0.5.100.100Document1 pageSectiune Detaliu 2 Scara 1:20: Gspublisherversion 0.5.100.100Andra IoanaNo ratings yet

- High-tensile steel wire mesh and nail arrangement cross sectionDocument1 pageHigh-tensile steel wire mesh and nail arrangement cross sectionReadian FedelinNo ratings yet

- S1-521 Ticket Counter Details 02Document1 pageS1-521 Ticket Counter Details 02Milan PuzigaćaNo ratings yet

- Basic ModelDocument1 pageBasic ModelJhn Cbllr BqngNo ratings yet

- Ship specs: length, breadth, draft, speedDocument2 pagesShip specs: length, breadth, draft, speedKyaw Win TunNo ratings yet

- Robinson Pagadian - Bended Roof 9Document1 pageRobinson Pagadian - Bended Roof 9Cesar DuriasNo ratings yet

- Tenor Horn: From Boyhood Beginnings in Amateur Bands and Orchestras, DenisDocument4 pagesTenor Horn: From Boyhood Beginnings in Amateur Bands and Orchestras, DenisAntônio FelipeNo ratings yet

- Foundation of Court Asphalt+Concrete enDocument1 pageFoundation of Court Asphalt+Concrete enkamalNo ratings yet

- T-38 Park Jet Plans (Parts Templates Non-Tiled) BETA2Document1 pageT-38 Park Jet Plans (Parts Templates Non-Tiled) BETA2vscribNo ratings yet

- Build a balsa wood gliderDocument1 pageBuild a balsa wood gliderStefan IonutNo ratings yet

- Stair 3 B1-022: Stainless Steel Plinth DetailDocument1 pageStair 3 B1-022: Stainless Steel Plinth DetailArun UdayabhanuNo ratings yet

- DB-CP-RB-2018-21-006 - Final-For print-2018-08-01-R1-Layout1Document1 pageDB-CP-RB-2018-21-006 - Final-For print-2018-08-01-R1-Layout1Dilina Iroshan DissanayakeNo ratings yet

- Concrete Sunbreaker Detail: United Technologies Consolidated PartnershiDocument1 pageConcrete Sunbreaker Detail: United Technologies Consolidated PartnershiMalson GutierrezNo ratings yet

- Top fwd fuselage assemblyDocument19 pagesTop fwd fuselage assemblyDan Stefan DanNo ratings yet

- Top fwd fuselage assemblyDocument1 pageTop fwd fuselage assemblymohamed sidkyNo ratings yet

- St-Herbert Yu-S-1 PDFDocument1 pageSt-Herbert Yu-S-1 PDFSoy DesignoNo ratings yet

- Af-41 Aluminum Drainage (Flap) Gates: Af-41 Flatback Af-41 SpigotbackDocument2 pagesAf-41 Aluminum Drainage (Flap) Gates: Af-41 Flatback Af-41 Spigotbackdont knowNo ratings yet

- Auditorium 1 2Document1 pageAuditorium 1 2AbhijeetJangidNo ratings yet

- Comfort RoomDocument1 pageComfort RoomDJNo ratings yet

- 59S-CS-518 - Steel Repair Details Sheet 2 of 5-Default - R3Document1 page59S-CS-518 - Steel Repair Details Sheet 2 of 5-Default - R3anandkc55No ratings yet

- Pivot Door New Base DetailDocument1 pagePivot Door New Base DetailradioNo ratings yet

- Cable Route PDFDocument1 pageCable Route PDFriyasNo ratings yet

- 2 3 1 4 A B E C C' D D': Front Elevation Right Side ElevationDocument1 page2 3 1 4 A B E C C' D D': Front Elevation Right Side ElevationJayson CastroNo ratings yet

- A506- TYPICLA FLOORING & WATERPROOFING DETAILSDocument1 pageA506- TYPICLA FLOORING & WATERPROOFING DETAILSØwięs MØhãmmedNo ratings yet

- DETAILS 1 - ConsultDocument1 pageDETAILS 1 - ConsultAlexander MasongsongNo ratings yet

- Estate Layout Mech-Layout2Document1 pageEstate Layout Mech-Layout2pastorgeeNo ratings yet

- Peta Situasi Dan Gambar Konstruksi Tangki 2 X 150 KL PT CK-MHU-ApproveDocument1 pagePeta Situasi Dan Gambar Konstruksi Tangki 2 X 150 KL PT CK-MHU-Approvejohan WijayaNo ratings yet

- Student Cover Letter PDFDocument1 pageStudent Cover Letter PDFdavidjovisNo ratings yet

- Marketing internship opportunity at Philips BeneluxDocument2 pagesMarketing internship opportunity at Philips BeneluxelsadwihermiatiNo ratings yet

- Carbon Nanotubes MSDSDocument9 pagesCarbon Nanotubes MSDSrgopikrishna313No ratings yet

- Iodine Revisited: Rose A CooperDocument14 pagesIodine Revisited: Rose A CooperelsadwihermiatiNo ratings yet

- Career Change Cover Letter ExampleDocument1 pageCareer Change Cover Letter ExampleelsadwihermiatiNo ratings yet

- The Biocompatibility of Carbon NanotubesDocument14 pagesThe Biocompatibility of Carbon NanotubesManuel QuistialNo ratings yet

- Nitric acid, 65% MSDSDocument6 pagesNitric acid, 65% MSDSBharat J ShettyNo ratings yet

- Intern Cover LetterDocument1 pageIntern Cover LetterelsadwihermiatiNo ratings yet

- Email Cover LetterDocument1 pageEmail Cover LetterTiara WardaniNo ratings yet

- Material Safety Data Sheet: 1 - Identification of SubstanceDocument9 pagesMaterial Safety Data Sheet: 1 - Identification of SubstanceelsadwihermiatiNo ratings yet

- Silver Iodide MSDS: Section 1: Chemical Product and Company IdentificationDocument5 pagesSilver Iodide MSDS: Section 1: Chemical Product and Company IdentificationelsadwihermiatiNo ratings yet

- Silver nitrate MSDSDocument6 pagesSilver nitrate MSDSLutfi InayahNo ratings yet

- Andreopoulos 1984Document36 pagesAndreopoulos 1984elsadwihermiatiNo ratings yet

- Crfossflow Chakrabarty2008Document12 pagesCrfossflow Chakrabarty2008elsadwihermiatiNo ratings yet

- Polymer Chemistry IntroductionDocument1 pagePolymer Chemistry IntroductionelsadwihermiatiNo ratings yet

- Acta Biomaterialia: Xinbo Sun, Zhengbing Cao, Nuala Porteous, Yuyu SunDocument9 pagesActa Biomaterialia: Xinbo Sun, Zhengbing Cao, Nuala Porteous, Yuyu SunelsadwihermiatiNo ratings yet

- Characterization of Ultrafiltration Polymeric Membranes: KeywordsDocument21 pagesCharacterization of Ultrafiltration Polymeric Membranes: KeywordselsadwihermiatiNo ratings yet

- Andrews 2004 Paper CarbonnanotubeDocument7 pagesAndrews 2004 Paper CarbonnanotubemerveNo ratings yet

- Particles: Department of Chemical Engineering University of Ereter North Park Road Exeter 4QF, U.KDocument1 pageParticles: Department of Chemical Engineering University of Ereter North Park Road Exeter 4QF, U.KelsadwihermiatiNo ratings yet

- 10.1016/0300 9467 (89) 80028 0Document1 page10.1016/0300 9467 (89) 80028 0elsadwihermiatiNo ratings yet

- Crossflow Filtration of Iron (III), Copper (II), and Cadmium (II) Aqueous Solutions With Alginic Acid/Cellulose Composite MembranesDocument8 pagesCrossflow Filtration of Iron (III), Copper (II), and Cadmium (II) Aqueous Solutions With Alginic Acid/Cellulose Composite MembraneselsadwihermiatiNo ratings yet

- Crossflow Filtration of Iron (III), Copper (II), and Cadmium (II) Aqueous Solutions With Alginic Acid/Cellulose Composite MembranesDocument8 pagesCrossflow Filtration of Iron (III), Copper (II), and Cadmium (II) Aqueous Solutions With Alginic Acid/Cellulose Composite MembraneselsadwihermiatiNo ratings yet

- Activity Toxicity Iodine-Containing: Bactericidal and Solutions in WoundsDocument6 pagesActivity Toxicity Iodine-Containing: Bactericidal and Solutions in WoundselsadwihermiatiNo ratings yet

- Activity Toxicity Iodine-Containing: Bactericidal and Solutions in WoundsDocument6 pagesActivity Toxicity Iodine-Containing: Bactericidal and Solutions in WoundselsadwihermiatiNo ratings yet

- 10.1016/0300 9467 (89) 80028 0Document1 page10.1016/0300 9467 (89) 80028 0elsadwihermiatiNo ratings yet

- Design ExamplesDocument753 pagesDesign ExamplesCamille SanchezNo ratings yet

- Characterization of Ultrafiltration Polymeric Membranes: KeywordsDocument21 pagesCharacterization of Ultrafiltration Polymeric Membranes: KeywordselsadwihermiatiNo ratings yet

- Particles: Department of Chemical Engineering University of Ereter North Park Road Exeter 4QF, U.KDocument1 pageParticles: Department of Chemical Engineering University of Ereter North Park Road Exeter 4QF, U.KelsadwihermiatiNo ratings yet

- Elsa Dwihermiati: Listening Section Reading SectionDocument1 pageElsa Dwihermiati: Listening Section Reading Sectionelsadwihermiati100% (1)

- Cover Letter 1Document2 pagesCover Letter 1elsadwihermiatiNo ratings yet

- LG Electronics Air Conditioning Proposal Load SummaryDocument13 pagesLG Electronics Air Conditioning Proposal Load SummaryJuan Rafael Ruiz LopezNo ratings yet

- Rapid Visual Screening MethodDocument15 pagesRapid Visual Screening MethodsmpetrasNo ratings yet

- Curtain Wall and Glazing Report SummaryDocument14 pagesCurtain Wall and Glazing Report SummarysuhailNo ratings yet

- Sor JKR 2017 PDFDocument49 pagesSor JKR 2017 PDFRozita Abdullah Sani0% (1)

- Grad Manual Design TipsDocument10 pagesGrad Manual Design TipsDebendra Dev KhanalNo ratings yet

- Seismic Analysis of A Multi Storey RC FrameDocument7 pagesSeismic Analysis of A Multi Storey RC FrameÇhårū KêshNo ratings yet

- Handbook NCC Volume Two Energy Effciency Provisions 2016Document180 pagesHandbook NCC Volume Two Energy Effciency Provisions 2016voodoojujuNo ratings yet

- Industrial Training Report (Civil)Document29 pagesIndustrial Training Report (Civil)Anuj SrivastavaNo ratings yet

- Scope of Work For SPADocument10 pagesScope of Work For SPAAbhijeet MaheshwariNo ratings yet

- EMS load calculator guideDocument9 pagesEMS load calculator guideOhnad NatocNo ratings yet

- Guia de Especificaciones de Grout PDFDocument7 pagesGuia de Especificaciones de Grout PDFxtrememikeNo ratings yet

- Productivity Rate Chart UAEDocument7 pagesProductivity Rate Chart UAEChelle Sujetado De GuzmanNo ratings yet

- Building Code Requirements For Concrete Masonry: TEK 1-3DDocument4 pagesBuilding Code Requirements For Concrete Masonry: TEK 1-3DjerryNo ratings yet

- Calculation Method For The Seasonal Performance of Heat Pump Compact Units and Validation PDFDocument155 pagesCalculation Method For The Seasonal Performance of Heat Pump Compact Units and Validation PDFGabriel VasileNo ratings yet

- Brand Catalogue PDFDocument28 pagesBrand Catalogue PDFShiela CedronNo ratings yet

- Technical Data Sheet: Lasteek Rwe500Document2 pagesTechnical Data Sheet: Lasteek Rwe500Engr KamalNo ratings yet

- Civil Highway Network SystemDocument17 pagesCivil Highway Network Systempinky100% (4)

- Fire Protection of Construction Joints PowerpointDocument15 pagesFire Protection of Construction Joints PowerpointVadim LivitchiNo ratings yet

- Detailing of Concrete Masonry Cavity Walls 240 to 290Document64 pagesDetailing of Concrete Masonry Cavity Walls 240 to 290Sean KrieglerNo ratings yet

- Gravity ShuttersDocument8 pagesGravity ShuttersKUMAARRRNo ratings yet

- Urban Design - Mini Project (1) - 1Document31 pagesUrban Design - Mini Project (1) - 1garimaNo ratings yet

- Structural ElementsDocument8 pagesStructural ElementsEufemia CruzNo ratings yet

- HF PDFDocument1 pageHF PDFTroi LauraNo ratings yet

- Hydraulic sprinkler calculation using Hazen-Williams formulaDocument3 pagesHydraulic sprinkler calculation using Hazen-Williams formulaMiguel Angel Carcamo Ordaz100% (1)

- Zoning By-Law Section 6Document17 pagesZoning By-Law Section 6Ismail GuvendikNo ratings yet

- 2011 National Construction EstimatorDocument773 pages2011 National Construction EstimatorIsrael Allette70% (10)

- Unit 8 Special ConcretesDocument4 pagesUnit 8 Special ConcretesHemanth SaiNo ratings yet

- Steel DesignDocument14 pagesSteel DesignNordin AhmadNo ratings yet

- Fire Protection Through Innovation and ProfessionalismDocument19 pagesFire Protection Through Innovation and ProfessionalismCTHNo ratings yet

- BCITO Fees Schedule 2023 v6Document3 pagesBCITO Fees Schedule 2023 v6Lucas RibeiroNo ratings yet