Professional Documents

Culture Documents

Nano SW Max

Uploaded by

felipe RezendeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nano SW Max

Uploaded by

felipe RezendeCopyright:

Available Formats

Membrane Element NANO-SW MAX

Performance MgSO4

Permeate Flow: 12,000 gpd (45.4 m3/d)

MgSO4 Rejection: 99.8% (99.6% minimum)

Type Configuration: Spiral Wound

Membrane Polymer: Composite Polyamide

Membrane Active Area: 440 ft2 (40.9 m2)

Feed/Brine Spacer Thickness: 26 mil (0.66 mm)

Application Data* Maximum Applied Pressure (Recommended)^: 600 psig (4.14 MPa)

Maximum Chlorine Concentration: < 0.1 PPM

Maximum Operating Temperature: 113 F (45 C)

pH Range, Operation (Cleaning): 3.0 - 9.0 (1.0 11.5)

Maximum Feedwater Turbidity: 1.0 NTU

Maximum Feedwater SDI (15 mins): 5.0

Maximum Feed Flow: 75 GPM (17.0 m3/h)

Minimum Ratio of Concentrate to

Permeate Flow for any Element: 5:1

Maximum Pressure Drop for Each Element: 15 psi

Typical Seawater Performance:

Nominal Permeate Flow: 7,150 gpd (27.0 m3/d)

Nominal Chloride Rejection: 25%

Nominal Sulfate Rejection: 99.8%

* The limitations shown here are for general use. For specific projects, operating at more conservative values may ensure the best

performance and longest life of the membrane. See Hydranautics Technical Bulletins for more detail on operation limits, cleaning

pH, and cleaning temperatures.

^ Element can withstand 1,200 psig as maximum applied pressure, however, applied feed pressure exceeding 600 psig may cause

reduction in membrane permeability.

Typical Synthetic Seawater Test Condition: 35,000 ppm NaCl + 8000 ppm MgSO4 , 200 psi (1.4 MPa), 77 F (25C), 15%

Permeate Recovery, 6.5 7.0 feed pH.

Test Conditions The stated performance is based on the following test conditions:

2000 ppm MgSO4

110 psi (0.76 MPa) Applied Pressure

77 F (25 C) Operating Temperature

15% Permeate Recovery

6.5 7.0 Feed pH

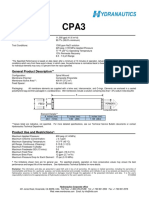

A

C

B FEED PERMEATE

CONCENTRATE

A, inches (mm) B, inches (mm) C, inches (mm) Weight, lbs. (kg)

40.0 (1016) 7.89 (200) 1.125 (28.6) 36 (16.4)

Notice: Permeate flow for individual elements may vary + or - 20 percent. Element weight may vary. All membrane elements are supplied with a brine seal,

interconnector, and o-rings. All membrane elements are supplied with a brine seal, interconnector, and o-rings. Elements are enclosed in a sealed polyethylene bag

containing deionized water, and then packaged in a cardboard box.

Hydranautics believes the information and data contained herein to be accurate and useful. The information and data are offered in good faith, but without guarantee, as

conditions and methods of use of our products are beyond our control. Hydranautics assumes no liability for results obtained or damages incurred through the application of

the presented information and data. It is the users responsibility to determine the appropriateness of Hydranautics products for the users specific end uses. 7/22/16

Hydranautics Corporate: 401 Jones Road, Oceanside, CA 92058

1-800-CPA-PURE Phone: 760-901-2500 Fax: 760-901-2578 info@Hydranautics.com

You might also like

- Hydraulic Calculation Report - PSDocument289 pagesHydraulic Calculation Report - PSAob AprilNo ratings yet

- Daniel Tian Li: Circular Column Design Based On ACI 318-05Document1 pageDaniel Tian Li: Circular Column Design Based On ACI 318-05OswardMorenoNo ratings yet

- AP CentacTraining Manual V2 PDFDocument262 pagesAP CentacTraining Manual V2 PDFubaldo caraballo89% (9)

- Walking Column Detailed DesignDocument1 pageWalking Column Detailed DesignTommaso Pascon100% (1)

- Cpa5 LDDocument1 pageCpa5 LDHolliver Michael Estredo Ch.No ratings yet

- CPA5-LD Membrane Element Performance SpecsDocument1 pageCPA5-LD Membrane Element Performance SpecsBassemNo ratings yet

- Cpa5 LD PDFDocument1 pageCpa5 LD PDFNarin InverterNo ratings yet

- Membrane Element Cpa5-Ld: (Low Fouling Technology) PerformanceDocument1 pageMembrane Element Cpa5-Ld: (Low Fouling Technology) PerformanceAbid HaroonNo ratings yet

- Hydranautics ESPA2-Max RO Membrane Spec SheetDocument1 pageHydranautics ESPA2-Max RO Membrane Spec SheetScribberNo ratings yet

- High-Performance Membrane Element CPA5 MAXDocument1 pageHigh-Performance Membrane Element CPA5 MAXlordsethdarknessNo ratings yet

- Hydranautics ESPA2 LD 4040Document1 pageHydranautics ESPA2 LD 4040zerocool86No ratings yet

- Esna1 LF2 LD 4040Document1 pageEsna1 LF2 LD 4040Soledad OrtegaNo ratings yet

- Membrane Element Cpa3: PerformanceDocument1 pageMembrane Element Cpa3: PerformanceMuhammad Iqbal Khan ChandioNo ratings yet

- CPA3 DatasheetDocument1 pageCPA3 DatasheetkhuramNo ratings yet

- Hydranautics CPA2 4040Document1 pageHydranautics CPA2 4040jdk18No ratings yet

- Membrane Specs: High-Flow RO ElementDocument1 pageMembrane Specs: High-Flow RO ElementsadNo ratings yet

- CPA2 4040 SpecificationDocument1 pageCPA2 4040 SpecificationasdasNo ratings yet

- ESPA2-Membrane Element 4040: Performance: TypeDocument1 pageESPA2-Membrane Element 4040: Performance: Typepo bangkokNo ratings yet

- MembranesDocument1 pageMembranesalkasbi952No ratings yet

- Membrane Element Cpa2: Application DataDocument1 pageMembrane Element Cpa2: Application DataMilton Jiménez NaveaNo ratings yet

- Cpa2 4040 PDFDocument1 pageCpa2 4040 PDFcarlos pachecoNo ratings yet

- Membrane Element CPA2-4040: PerformanceDocument1 pageMembrane Element CPA2-4040: Performancecarlos pachecoNo ratings yet

- Membrane Element SWC - 2540: PerformanceDocument1 pageMembrane Element SWC - 2540: PerformanceAshish GulrandheNo ratings yet

- OltremareDocument1 pageOltremareAfraz ShaikhNo ratings yet

- Membrane Element SWC3+: PerformanceDocument1 pageMembrane Element SWC3+: PerformanceAshraf BayomiNo ratings yet

- Hydranautics ESPA1 8040Document1 pageHydranautics ESPA1 8040hazim.houssemNo ratings yet

- Hydranautics SWC5 LD LDocument1 pageHydranautics SWC5 LD LAlexis Jara VidalNo ratings yet

- Sea2 4040 PDFDocument1 pageSea2 4040 PDFMd. Suruz ZamanNo ratings yet

- SanRO HS PDFDocument1 pageSanRO HS PDFjohn_paisNo ratings yet

- Hydranautics CPA2 L PDFDocument1 pageHydranautics CPA2 L PDFMilton Jiménez NaveaNo ratings yet

- Lenntech: Membrane Element Cpa2Document1 pageLenntech: Membrane Element Cpa2Daniel LagosNo ratings yet

- 4-1. NE8040-HRM - 200311 - LHK - Ver 1.0Document2 pages4-1. NE8040-HRM - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Hydranautics ESPA2 LD Low Fouling Membrane Element LenntechDocument1 pageHydranautics ESPA2 LD Low Fouling Membrane Element Lenntechzerocool86No ratings yet

- Hydranautics ESPA2 LD LDocument1 pageHydranautics ESPA2 LD LZi Wei LeongNo ratings yet

- Datasheet LG BW 400 R Dura ENGDocument1 pageDatasheet LG BW 400 R Dura ENGSaul RosalesNo ratings yet

- Lfc3-Ld: Specified PerformanceDocument1 pageLfc3-Ld: Specified PerformanceLuqmanNo ratings yet

- 1-2. NE4040-40 - 200311 - LHK - Ver 1.0Document2 pages1-2. NE4040-40 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0Document2 pages5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0Msach RoysNo ratings yet

- Hydranautics LFC3 LD LDocument1 pageHydranautics LFC3 LD LAndreNo ratings yet

- ESPA2-LD-4040 membrane specificationsDocument1 pageESPA2-LD-4040 membrane specificationsJesus SelasorNo ratings yet

- 5-2. NE4040-ARM50 - 200311 - LHK - Ver 1.0Document2 pages5-2. NE4040-ARM50 - 200311 - LHK - Ver 1.0Msach RoysNo ratings yet

- Hydranautics SWC5-LD (PW)Document1 pageHydranautics SWC5-LD (PW)mahdi rasoulianNo ratings yet

- CPA6-LD Membrane Spec SheetDocument1 pageCPA6-LD Membrane Spec Sheetmahdi rasoulianNo ratings yet

- Membrane LG CW 4040 SFDocument1 pageMembrane LG CW 4040 SFPT Deltapuro IndonesiaNo ratings yet

- CPA3 RO Element Spec SheetDocument1 pageCPA3 RO Element Spec SheetImran Ahmed KhanNo ratings yet

- 3-1. NE8040-90 - 200311 - LHK - Ver 1.0Document2 pages3-1. NE8040-90 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 4-2. NE4040-HRM - 200311 - LHK - Ver 1.0Document2 pages4-2. NE4040-HRM - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Data Sheet: LG BW 400 EsDocument1 pageData Sheet: LG BW 400 EsZi Wei LeongNo ratings yet

- Membrane LG BW 400RDocument1 pageMembrane LG BW 400RPT Deltapuro IndonesiaNo ratings yet

- 1-1. NE8040-40 - 200311 - LHK - Ver 1.0Document2 pages1-1. NE8040-40 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Datasheet LG SW 400 SR G2 ENGDocument1 pageDatasheet LG SW 400 SR G2 ENGMohamed MotaweaNo ratings yet

- Re8040-Ce - 190312 - PMKDocument2 pagesRe8040-Ce - 190312 - PMKMsach RoysNo ratings yet

- 2-1. NE8040-70 - 200311 - LHK - Ver 1.0Document2 pages2-1. NE8040-70 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 2-2. NE4040-70 - 200311 - LHK - Ver 1.0Document2 pages2-2. NE4040-70 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Ne4040 SRMDocument2 pagesNe4040 SRMMsach RoysNo ratings yet

- Data Sheet: LG BW 4040 EsDocument1 pageData Sheet: LG BW 4040 EsAcquetech AcquetechNo ratings yet

- RE16040-BE - 200907 - HSHDocument2 pagesRE16040-BE - 200907 - HSHMsach RoysNo ratings yet

- CSM Re8040 SHN LDocument2 pagesCSM Re8040 SHN LSundari RaviNo ratings yet

- Espa1: Specified PerformanceDocument1 pageEspa1: Specified PerformanceBerlin TirtaNo ratings yet

- High productivity RO element for brackish waterDocument2 pagesHigh productivity RO element for brackish waterWilly ChandraNo ratings yet

- Re8040-Br400 - 190312 - PMKDocument2 pagesRe8040-Br400 - 190312 - PMKMsach RoysNo ratings yet

- Hydranautics ESPA2 LD MAX LDocument1 pageHydranautics ESPA2 LD MAX Lzerocool86No ratings yet

- LG Chem LG BW 4040 ES L PDFDocument1 pageLG Chem LG BW 4040 ES L PDFhonoviw115No ratings yet

- Me2302 Dynamics of Machinery L T P CDocument3 pagesMe2302 Dynamics of Machinery L T P Ckumar kmNo ratings yet

- Surfaces in Precision Engineering, Microengineering and NanotechnologyDocument17 pagesSurfaces in Precision Engineering, Microengineering and NanotechnologyAdnan TorlakovićNo ratings yet

- Presentation No:1: Submitted To:-Maam Humaira Razzaq Submitted By: - Mateen ArifDocument15 pagesPresentation No:1: Submitted To:-Maam Humaira Razzaq Submitted By: - Mateen AriffatimaalizoyaNo ratings yet

- Motion Graphs: A Visual Guide to Velocity & AccelerationDocument5 pagesMotion Graphs: A Visual Guide to Velocity & AccelerationLumpiang TogeNo ratings yet

- Applsci 12 11268Document19 pagesApplsci 12 11268Yuvaraj muthukrishnanNo ratings yet

- Titanium Alloys in Total Joint Replacement - A Materials Science PerspectiveDocument9 pagesTitanium Alloys in Total Joint Replacement - A Materials Science PerspectiveSatria Adi NugrohoNo ratings yet

- Physics 1A Problem Set #5: Spring Forces and Ski Jump SpeedsDocument2 pagesPhysics 1A Problem Set #5: Spring Forces and Ski Jump Speedshthaier4062No ratings yet

- Order of ReactionDocument11 pagesOrder of ReactionBadar RizwanNo ratings yet

- Evaluation of Temperature Prediction Methods For Concrete MembersDocument10 pagesEvaluation of Temperature Prediction Methods For Concrete Memberssugi zhuangNo ratings yet

- Ce2202 - Mechanics of FluidsDocument3 pagesCe2202 - Mechanics of FluidsPrashant GaradNo ratings yet

- Pressure Seal Valves-GateDocument24 pagesPressure Seal Valves-GateHieu NguyenNo ratings yet

- Xapp1301 Mechanical Thermal Design GuidelinesDocument88 pagesXapp1301 Mechanical Thermal Design GuidelinesJogirek VekturNo ratings yet

- Review Article: Aerogels As Promising Thermal Insulating Materials: An OverviewDocument11 pagesReview Article: Aerogels As Promising Thermal Insulating Materials: An OverviewWullidaNo ratings yet

- 5th Grade Reading Comprehension Worksheets - Fifth Grade - Week 33Document1 page5th Grade Reading Comprehension Worksheets - Fifth Grade - Week 33Sadiqu Zzaman100% (1)

- X-Ray Filtration and Beam QualityDocument10 pagesX-Ray Filtration and Beam Qualitywajira sanjaya pereraNo ratings yet

- Chemical SensorsDocument4 pagesChemical SensorsBianca Clarice DalistanNo ratings yet

- Lab Report 3Document3 pagesLab Report 3John HowellNo ratings yet

- 2021 Farmasi Fisika Pertemuan 4 (Larutan Isotonis)Document33 pages2021 Farmasi Fisika Pertemuan 4 (Larutan Isotonis)Muhammad AminNo ratings yet

- 2005 Gelder 1 PHDDocument320 pages2005 Gelder 1 PHDMaxel Abe DamuagNo ratings yet

- Problem Set 1Document2 pagesProblem Set 1JiiiNo ratings yet

- Center of Mass, Momentum, Impulse & CollisionsDocument8 pagesCenter of Mass, Momentum, Impulse & CollisionsRolando Jerome MagoNo ratings yet

- IGEM - TD - 1 - Introduction & ScopeDocument18 pagesIGEM - TD - 1 - Introduction & ScopeEnrico ManfrinatoNo ratings yet

- 27.viscoelastic Responses of Polyhedral Oli PDFDocument5 pages27.viscoelastic Responses of Polyhedral Oli PDFVansala GanesanNo ratings yet

- Bab 9 Tingkatan 1Document16 pagesBab 9 Tingkatan 1DANAL YEAP VII ZENN MoeNo ratings yet

- Grouptheory Module6Document42 pagesGrouptheory Module6Mahalakshmi SahasranamanNo ratings yet

- TE2601E FM 03p FluidKinematicsDocument5 pagesTE2601E FM 03p FluidKinematicsthamtri03No ratings yet