Professional Documents

Culture Documents

Concrete Cube Compression Test

Uploaded by

Tanu RdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Cube Compression Test

Uploaded by

Tanu RdCopyright:

Available Formats

COMPRESSION TEST ON CONCRETE CUBE

AIM:

To determine the ultimate stress to which the specimen (concrete cube) withstand.

APPARATUS:

(i) Universal Testing Machine (UTM)

(ii) Concrete cube

(iii) Scale

SPECIFICATION OF MACHINE AND SPECIMEN DETAILS:

A Compression test can be performed on UTM by keeping the test piece on base block

and moving down the central grip to apply load. The UTM is hydraulically operated and runs on

420 volts, 3 phase, 50 HZ AC supply and has four load measuring ranges. For compressive test

the machine is operated in 0-40 tonnes range.

THEORY:

Several machines and structural components such as columns and studs are subjected to

compressive loads in applications. These components are made of high compressive strength

materials. All the materials are not strong in compression. Several materials which are good in

tension are poor in compression. Contrary to this many materials are poor in tension but very

strong in compression. Cast iron is one such example. Hence determination of ultimate

compressive strength is essential before using a material. This strength is determined by

conducting a compression test. Compression test is just opposite in nature to a tensile test. Nature

of deformation an fracture is quite different from that in the tensile tests. Compressive loads tend

to squeeze the specimen. Brittle materials are generally weak in tension but strong in

compression. Hence this test is normally performed on cast iron, cement concrete etc which are

brittle materials. But ductile materials like aluminum and mild steel which are strong in tension,

are also tested in compression. From compression test we can

Draw Stress Strain curve in compression

Determine Youngs Modulus in compression.

Determine ultimate compressive strength.

Determine percentage reduction in length.

However, during this experiment only ultimate compressive strength needs to be

determined.

FORMULA USED:

Ultimate load

Ultimate stress = ------------------------------- (N/mm2)

Area of the specimen

PROCEDURE:-

1. Fix upper and lower pressure plate on the lower cross head and lower table respectively.

2. Place the specimen on the lower compression plate .the specimen should aligned exactly.

According to the marking on the compression plate in order to give the complete cross section of

the specimen a chance to participate equally in the acceptance load.

3. Then adjust the zero by lifting the lower table.

4. Operate the upper cross head to grip the upper end of the test piece.

5. The left valve in the UTM is kept in fully closed position and the right valve in the normal

open position.

6. Open the right valve and close it after lower table is slightly lifted.

7. Adjust the load to zero by using the push button.

8. Operate the lower grip operation handle lift the lower cross head up and grip fully the lower

part of the specimen then lock the specimen in this position by operation jaw locking handle.

9. Turn the right control valve slowly to open the position until (anticlockwise) we get a assumed

loading mass.

10. After that we will find that the specimen is under load and the under the locking handle.

PRECAUTION:-

The specimen should be fixed firmly in the vice on the UTM

The reading for stress and strain should be taken simultaneously, during the test

The dial indicator should be fixed firmly on the UTM and the indicator needle should be

set to zero before starting the experiment.

OBSERVATION:

Size of the Cube (a) = mm

Area of the Cube (A) = mm2

TABULATION:

S.No SPECIMEN Cross section Ultimate Load Ultimate

Area (mm) Stress

(N/mm2)

KN N

RESULT:

Thus the ultimate stress that the concrete cube can withstand = _______N/mm2.

Viva:

Differentiate between compressive strength and tensile strength.

Describe the failure mechanism of a material under compressive loading.

Theoretically compressive strength should be same as the tensile strength, but practically

it is not so. Why?

What is anisotropy? How does it affect the mechanical properties?

Compression tests are usually performed on brittle materials. Why?

Which will have a higher strength: a small specimen or a full size member made of the

same material?

How do ductile and brittle materials differ in their behavior in the compression test?

They differ in the fracture mode, in bulging action, and malleability.

What are bi-modulus materials? Give examples those materials which give value of E

different in tension and compression are called bi -modulus materials.

You might also like

- Perform compression test on UTMDocument2 pagesPerform compression test on UTMakshat naiduNo ratings yet

- Strength of Materials Laboratory ExperimentsDocument20 pagesStrength of Materials Laboratory Experimentskenneth iyahenNo ratings yet

- Compression test results for 3 wood typesDocument12 pagesCompression test results for 3 wood typesMoustafa AllamNo ratings yet

- Mild Steel Tensile Test ResultsDocument30 pagesMild Steel Tensile Test ResultsDipesh GugaleNo ratings yet

- Material Testing LabDocument79 pagesMaterial Testing LabBrijesh VermaNo ratings yet

- Tension Test ReportDocument7 pagesTension Test ReportTomy GeorgeNo ratings yet

- Laboratory Manual of Tensile TestDocument11 pagesLaboratory Manual of Tensile TestVIPAN KUMARNo ratings yet

- Laboratory Manual: THIRD SEMESTER B.Tech MechanicalDocument45 pagesLaboratory Manual: THIRD SEMESTER B.Tech MechanicalhanNo ratings yet

- Exp-2 Compression TestDocument10 pagesExp-2 Compression TestHanamant HunashikattiNo ratings yet

- btech3rd-CE SOM LAB MANUALDocument21 pagesbtech3rd-CE SOM LAB MANUALvkmstp2005No ratings yet

- SM Lab ManualsDocument27 pagesSM Lab ManualspraveenampilliNo ratings yet

- Experiment 1 - TENSION TEST OF MILD STEEL SPECIMENDocument10 pagesExperiment 1 - TENSION TEST OF MILD STEEL SPECIMENSamiha Maysoon Nooria100% (1)

- Mos Lab Manual PDFDocument34 pagesMos Lab Manual PDFs.rihanaNo ratings yet

- Compression TestDocument8 pagesCompression TestKaneki SSSNo ratings yet

- Materials Testing OverviewDocument11 pagesMaterials Testing OverviewcataiceNo ratings yet

- Laboratory Manual of Tensile TestDocument12 pagesLaboratory Manual of Tensile TestVIPAN KUMARNo ratings yet

- Experiment Name: Tensile Test of Steel: ObjectivesDocument4 pagesExperiment Name: Tensile Test of Steel: ObjectivesKalikiri navyaNo ratings yet

- Som ExperimentsDocument17 pagesSom ExperimentsAnudeex ShettyNo ratings yet

- Uniaxial TestDocument6 pagesUniaxial Testanil chejaraNo ratings yet

- Compression TestDocument2 pagesCompression TestsonawanepmsNo ratings yet

- Compression TestDocument2 pagesCompression TestsonawanepmsNo ratings yet

- Experiment 1-Tensile TestDocument7 pagesExperiment 1-Tensile Testhazriel83% (6)

- Strength of MaterialsDocument24 pagesStrength of Materialsmech bhabhaNo ratings yet

- Exp-1 Tension Test PDFDocument8 pagesExp-1 Tension Test PDFHanamant HunashikattiNo ratings yet

- Material Testing Lab Compression TestDocument13 pagesMaterial Testing Lab Compression TestHimmat Singh RawatNo ratings yet

- 02 Compression TestDocument8 pages02 Compression TestWaleed ShakilNo ratings yet

- Experiment 1Document7 pagesExperiment 1waseemjuttNo ratings yet

- Compression TestDocument4 pagesCompression Testjazille2267% (3)

- Som Manual-2013 RegDocument26 pagesSom Manual-2013 RegsugunavidiyadarNo ratings yet

- Tensile Testing by Odewole TemidayoDocument10 pagesTensile Testing by Odewole Temidayostephenoladipo21No ratings yet

- Lab Report Tensile Group 5Document12 pagesLab Report Tensile Group 5Danial AqilNo ratings yet

- Strength of Materials Lab TestsDocument38 pagesStrength of Materials Lab Testsamns99No ratings yet

- Tensile Test AmrDocument5 pagesTensile Test AmrAmr KhaledNo ratings yet

- Material Science and Testing LabDocument26 pagesMaterial Science and Testing LabJitendra JangidNo ratings yet

- ASTM D747 Overview PDFDocument41 pagesASTM D747 Overview PDFtangogll11No ratings yet

- Lab 1 Compresive Test PDFDocument10 pagesLab 1 Compresive Test PDFDhania BaharuddinNo ratings yet

- Sir J C Bose School of Engineering (Diploma: Adv Strength of Materials Lab ManualDocument47 pagesSir J C Bose School of Engineering (Diploma: Adv Strength of Materials Lab ManualdibyenindusNo ratings yet

- Mechanical Properties of Mild Steel Under CompressionDocument20 pagesMechanical Properties of Mild Steel Under CompressionEriane GarciaNo ratings yet

- ENCI 317 - LAB 1 - Lab MaterialDocument15 pagesENCI 317 - LAB 1 - Lab MaterialSherry YousafNo ratings yet

- Yield Strength TestDocument8 pagesYield Strength TestDr.L.V.PRASAD MeesaragandaNo ratings yet

- Material Testing Lab ManualDocument29 pagesMaterial Testing Lab ManualJithin Thomas ANo ratings yet

- Strength of Materia Lab Manual UET, LahoreDocument14 pagesStrength of Materia Lab Manual UET, LahoreRizwan Khurram100% (3)

- 09 Torsion Moment & Torsion Angle of ShaftDocument7 pages09 Torsion Moment & Torsion Angle of ShaftElaine PuiNo ratings yet

- Stress and StrainDocument42 pagesStress and StrainPaul James Thadhani100% (5)

- EME 3401 - Lab Investigation 1 ManualDocument33 pagesEME 3401 - Lab Investigation 1 ManualOmair SadiqNo ratings yet

- Mechanical Properties PDFDocument57 pagesMechanical Properties PDFvardhaNo ratings yet

- MOS Lab Manual - NewDocument41 pagesMOS Lab Manual - NewPavan Kalyan SuryavamshiNo ratings yet

- 3-Exp#03 Tensile TestDocument7 pages3-Exp#03 Tensile TestD7ooM_612No ratings yet

- 27-09 Ic 443Document61 pages27-09 Ic 443Yohn Quispe RodriguezNo ratings yet

- Tensile Test of Brass SpecimenDocument7 pagesTensile Test of Brass SpecimenmanmathkNo ratings yet

- Mechanical Behaviour of MaterialsDocument53 pagesMechanical Behaviour of MaterialsnattydreadfathelahNo ratings yet

- Exercises 8 and 9 Lab Exercise No 8Document3 pagesExercises 8 and 9 Lab Exercise No 8John NdambukiNo ratings yet

- Lecture#2Document33 pagesLecture#2CH AHMEDNo ratings yet

- Complete Tensile Test On MS BarDocument9 pagesComplete Tensile Test On MS Barafzal taiNo ratings yet

- Strength of Materials: An Introduction to the Analysis of Stress and StrainFrom EverandStrength of Materials: An Introduction to the Analysis of Stress and StrainRating: 5 out of 5 stars5/5 (1)

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Steps in Making Castings: Page 1 of 14Document14 pagesSteps in Making Castings: Page 1 of 14Tanu RdNo ratings yet

- Year: Iv - I Mech: Unconventional Machining ProcessesDocument26 pagesYear: Iv - I Mech: Unconventional Machining ProcessesTanu RdNo ratings yet

- Gautama Buddha and Development of BuddhismDocument9 pagesGautama Buddha and Development of BuddhismTanu RdNo ratings yet

- Brief History of Telangana State Movement (1948-2014Document5 pagesBrief History of Telangana State Movement (1948-2014Tanu RdNo ratings yet

- lbm0 9Document6 pageslbm0 9Tanu RdNo ratings yet

- English Tense TableDocument1 pageEnglish Tense TableTanu RdNo ratings yet

- Miscellaneous QuestionsDocument16 pagesMiscellaneous QuestionsTanu RdNo ratings yet

- Indian History PicturesDocument36 pagesIndian History PicturesTanu RdNo ratings yet

- History of India: For Custom/ Business Map Quote +91 8750051915Document26 pagesHistory of India: For Custom/ Business Map Quote +91 8750051915Tanu RdNo ratings yet

- Rock paintings of prehistoric IndiaDocument43 pagesRock paintings of prehistoric IndiaTanu RdNo ratings yet

- 100 Questions On Science TechnologyDocument15 pages100 Questions On Science TechnologyvgasNo ratings yet

- Later Vedic Period and SocietyDocument13 pagesLater Vedic Period and SocietyTanu Rd0% (1)

- Seemandhra - Co.in - Strength of Materials-II (1) 0Document1 pageSeemandhra - Co.in - Strength of Materials-II (1) 0Tanu RdNo ratings yet

- Material Name Composition Properties Applications: Ferrous MetalsDocument8 pagesMaterial Name Composition Properties Applications: Ferrous MetalsTanu RdNo ratings yet

- 4A. Electron Beam Machining (EBM)Document3 pages4A. Electron Beam Machining (EBM)Tanu RdNo ratings yet

- lbm0 9Document6 pageslbm0 9Tanu RdNo ratings yet

- AEE GS EnglishDocument15 pagesAEE GS EnglishTanu RdNo ratings yet

- Seemandhra - Co.in - Machine Drawing-2 0Document1 pageSeemandhra - Co.in - Machine Drawing-2 0Tanu RdNo ratings yet

- Ecm App 78Document15 pagesEcm App 78Tanu RdNo ratings yet

- Ecg 123Document5 pagesEcg 123Tanu RdNo ratings yet

- Active and Passive Voice Tenses ChartDocument9 pagesActive and Passive Voice Tenses ChartTanu RdNo ratings yet

- Nontraditional Machining Processes LectureDocument35 pagesNontraditional Machining Processes LectureTanu RdNo ratings yet

- G1Document11 pagesG1Tanu RdNo ratings yet

- Passivevoicechart 130622150953 Phpapp01Document2 pagesPassivevoicechart 130622150953 Phpapp01Tanu RdNo ratings yet

- Current Affairs 2017 Telugu Bit Bank Download 4Document4 pagesCurrent Affairs 2017 Telugu Bit Bank Download 4Tanu RdNo ratings yet

- Active and Passive Voice Exercise: AnswersDocument11 pagesActive and Passive Voice Exercise: AnswersFxwireless100% (1)

- Verb Tenses Tutorial ExercisesDocument14 pagesVerb Tenses Tutorial ExercisesYenTranNo ratings yet

- Current Affairs 2017 Telugu Bit Bank Download 3Document5 pagesCurrent Affairs 2017 Telugu Bit Bank Download 3Tanu RdNo ratings yet

- Indian GeographyDocument190 pagesIndian GeographyV Anil Kumar100% (1)

- Modal Verbs WithkeyDocument3 pagesModal Verbs WithkeyAnonymous zqdKPKoX100% (1)

- Critical Condition for Flow Transition in a Full-Developed Annulus FlowDocument6 pagesCritical Condition for Flow Transition in a Full-Developed Annulus FlowphrqdurhNo ratings yet

- Outlines: Theory Calculation Conclusion ReferencesDocument31 pagesOutlines: Theory Calculation Conclusion ReferencesYè Paing Oo100% (3)

- Apuntes TurbomaquinasDocument5 pagesApuntes TurbomaquinasTeodoro HernandezNo ratings yet

- TorsionDocument49 pagesTorsionBandula PrasadNo ratings yet

- Tutorial Flow Measurement (GROUP D)Document8 pagesTutorial Flow Measurement (GROUP D)Nur Fatiha Aziera Ain Binti Mohd KhimeNo ratings yet

- Thermodynamics - MCQsDocument25 pagesThermodynamics - MCQsmujtabahassan100% (1)

- Test Methods, Standards and Certification Requirements: BTG Composites Inc. 2010Document68 pagesTest Methods, Standards and Certification Requirements: BTG Composites Inc. 2010ardhika setiawanNo ratings yet

- MKL 3 ReportDocument9 pagesMKL 3 ReportMatthew NelsonNo ratings yet

- Solar Water HeatingDocument2 pagesSolar Water HeatingCatherine Diccion LaciapagNo ratings yet

- 195103-MS Simulation and Performance of Immiscible WAG Pilots in Mauddud Reservoir Using Three Phase Relative Permeability With HysteresisDocument22 pages195103-MS Simulation and Performance of Immiscible WAG Pilots in Mauddud Reservoir Using Three Phase Relative Permeability With HysteresisHadi Ali ALMeftahNo ratings yet

- Cooling of Rockets 1Document15 pagesCooling of Rockets 1Bharath KumarNo ratings yet

- Phase Rule Sulphur System: Upma Shrivastava Asstt. Prof. Govt. V.Y.T.PG - Auto.College Durg ChhattisgarhDocument13 pagesPhase Rule Sulphur System: Upma Shrivastava Asstt. Prof. Govt. V.Y.T.PG - Auto.College Durg ChhattisgarhramukakaNo ratings yet

- 7A Phase TransformationsDocument15 pages7A Phase TransformationsAhmed AliNo ratings yet

- How to Separate Chemical MixturesDocument47 pagesHow to Separate Chemical MixtureschintanNo ratings yet

- Beam Design ExcelDocument3 pagesBeam Design Excelprashanth palaniNo ratings yet

- Governing Equations of FluidDocument31 pagesGoverning Equations of FluidhaftommmmNo ratings yet

- Route Selection and Deepwater Pipeline DesignDocument19 pagesRoute Selection and Deepwater Pipeline DesignSampurnanand PandeyNo ratings yet

- PDPU & AAPG Workshop ProposalDocument6 pagesPDPU & AAPG Workshop ProposalAkashShuklaNo ratings yet

- Chap3firstlawthermodynamics 130703012634 Phpapp02Document59 pagesChap3firstlawthermodynamics 130703012634 Phpapp02Anonymous q9eCZHMuSNo ratings yet

- Coh FRANC2D Tutorial PCDocument0 pagesCoh FRANC2D Tutorial PCthegreatest0888No ratings yet

- Stress Sample Calculation On Base EllDocument1 pageStress Sample Calculation On Base EllLionel TorradoNo ratings yet

- USFD in Rails & Welds DetectionDocument144 pagesUSFD in Rails & Welds DetectionLokeshwar YadagiriNo ratings yet

- Gas Dynamics Report ValidationDocument8 pagesGas Dynamics Report ValidationM.t. HabibiNo ratings yet

- Design of Packed ColumnDocument4 pagesDesign of Packed Columnمنى عبد المنعم صالح رداد منى عبد المنعم صالح ردادNo ratings yet

- TAM435 SyllabusDocument4 pagesTAM435 SyllabusSandeep Ravikumar MurthyNo ratings yet

- 1.A Type of Condenser Combines The Functions of Condenser and Cooling Tower Is CalledDocument500 pages1.A Type of Condenser Combines The Functions of Condenser and Cooling Tower Is CalledChristopher Lennon Dela CruzNo ratings yet

- Conduction HTDocument25 pagesConduction HTRamaneish SivarajNo ratings yet

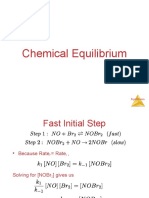

- Chemical EquilibriumDocument57 pagesChemical EquilibriumJustin AmaguinNo ratings yet

- Ahe Lab QuestionDocument3 pagesAhe Lab QuestionVijay A HwreNo ratings yet

- Pin Connected Tension MemberDocument2 pagesPin Connected Tension MemberAUNGPSNo ratings yet