Professional Documents

Culture Documents

Excavation Trenching Daily Inspection Checklist PDF

Uploaded by

Roni EnjelaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Excavation Trenching Daily Inspection Checklist PDF

Uploaded by

Roni EnjelaniCopyright:

Available Formats

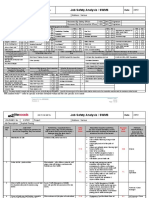

Excavation and Trenching

Daily Inspection Form

Excavation/Trench Location: Date:

Excavation Depth: Excavation Length: Excavation Width:

Description of Protective System:

Weather Conditions: Amount Precipitation Last 24 Hours:

Competent Person:

Signature of Competent Person:

Utilities: Yes No NA

1. Has JULIE been contacted at least 2 working days prior to start of digging?

2. Has Utilities identified underground installations and marked locations?

3. Have underground installations been protected, supported, or removed when the excavation is open?

4. Is the equipment operator(s) aware of overhead powerlines and required approach distances?

Excavation/Trench: Yes No NA

1. Has the soil been classified? If no, it must be assumed to be Type C.

2. Are daily inspections of the excavation, the adjacent areas, and protective systems made by a competent person prior to start of work?

3. Does the competent person have the authority to remove workers from the excavation immediately?

4. Have surface encumbrances been supported or removed?

5. Are employees protected from loose rock or soil?

6. Are all employees wearing proper PPE?

7. Are spoils, materials, and equipment set back at least 2 from the edge of excavation?

8. Has the work area been identified using barricades, fencing, or some other physical barrier?

9. Has a traffic control plan been completed and implemented?

10. Is high visible clothing worn by all employees exposed to vehicular traffic?

11. Are excavations 6 or deeper with walkways or bridges equipped with guardrails?

12. Are employees prohibited from working or walking under suspended loads?

13. Are employees prohibited from working on faces of sloped or benched excavations above other employees?

14. Has a warning system been established and used when mobile equipment is operating near the edge of the excavation?

15. Have means of egress (e.g. ladders, steps, ramps) been provided so that no employee must travel further than 25?

16. If ladders are used for egress, are they secured and do they extend at least 3 above the top of the excavation?

17. If wood ramps are used for egress, are they constructed of uniform material thickness and cleated together at the bottom?

Wet Conditions: Yes No NA

1. Have precautions been taken to protect employees from hazards posed by water accumulation?

2. If water removal equipment is in operation, is it being monitored by the Competent Person?

3. Is surface water being collected or diverted?

4. Is an inspection of the excavation, adjacent areas, and protective system performed and documented after each rainstorm?

Hazardous Atmosphere:

1. In excavations 4 or deeper, where a hazardous atmosphere exists or could reasonably exist, is the atmosphere being tested for low

oxygen, hazardous fumes, and toxic gases before employees enter the excavation?

2. Is oxygen concentration between 19.5% and 23.5%?

3. Is emergency response equipment readily available where a hazardous atmosphere could or does exist (e.g., retrieval unit)?

Additional Notes on Back

Last updated by: J. Eschbach Page 1 of 2 Last Updated: July 2014

University of Illinois at Urbana-Champaign http://safetyandcompliance.fs.illinois.edu 217-265-9828

Excavation and Trenching

Daily Inspection Form

NOTES

1. Excavations 5 deep or greater require a protective system unless the excavation is made entirely

of stable rock.

2. For excavations less that 5, a competent person can determine that a protective system is not

required.

3. Excavations 20 deep or greater require protective systems designed by a registered professional

engineer or be based on tabulated prepared and/or approved by a registered professional

engineer.

4. Excavations 4 deep or greater require a means or access/egress located within 25 of each

worker.

5. Benching is not allowed for Type C soil.

Last updated by: J. Eschbach Page 2 of 2 Last Updated: July 2014

University of Illinois at Urbana-Champaign http://safetyandcompliance.fs.illinois.edu 217-265-9828

You might also like

- Razor Wire Fence Method - Statement Rev01Document17 pagesRazor Wire Fence Method - Statement Rev01ALLANNo ratings yet

- Demolition Safety Checklist 08Document3 pagesDemolition Safety Checklist 08MDR PRAPHU75% (4)

- Excavation Trenching Daily Inspection ChecklistDocument2 pagesExcavation Trenching Daily Inspection ChecklistRajendraNo ratings yet

- Gravity Test Report Water SupplyDocument1 pageGravity Test Report Water SupplygaineyskNo ratings yet

- Risk Assessment Form: 1 Biophysical HazardsDocument5 pagesRisk Assessment Form: 1 Biophysical HazardsGajendran Sriram33% (3)

- Boom Truck Inspection Checklist-Daily..Document1 pageBoom Truck Inspection Checklist-Daily..Chaudhary Wasim Murtaza100% (4)

- 020 Distribution Board Inspection (Initial & Quarterly)Document1 page020 Distribution Board Inspection (Initial & Quarterly)Shashwat Pandey100% (1)

- Electrical Method StatementDocument7 pagesElectrical Method StatementDylanNo ratings yet

- Method Statment Installation LifelineDocument3 pagesMethod Statment Installation LifelineFirdaus Zainal100% (3)

- Method Statement - Relocation of Water MeterDocument5 pagesMethod Statement - Relocation of Water MeterMG50% (2)

- Method Statement For Installation of Automatic Sliding DoorDocument6 pagesMethod Statement For Installation of Automatic Sliding DoorKalid JmalNo ratings yet

- Excavation Safety ChecklistDocument1 pageExcavation Safety ChecklistJoy BD0% (1)

- Trowel Concrete Machine Pre-Use Inspection Checklist: ProjectDocument2 pagesTrowel Concrete Machine Pre-Use Inspection Checklist: ProjectImam Ali100% (1)

- JAPL-F-TE-003-Generator Daily Inspection ChecklistDocument1 pageJAPL-F-TE-003-Generator Daily Inspection ChecklistAli Hassan100% (1)

- Job Hazard Analysis DemolitionDocument2 pagesJob Hazard Analysis DemolitionvinothNo ratings yet

- ELCB ChecklistDocument4 pagesELCB ChecklistKhuda Buksh50% (4)

- CR 10 (2) D Safety Harness Inspector TEMPLATEDocument1 pageCR 10 (2) D Safety Harness Inspector TEMPLATELiam Du Piesanie0% (1)

- 1E-Motors Inspection ChecklistDocument1 page1E-Motors Inspection ChecklistAnonymous iiUUgwNo ratings yet

- Inspection and Test Plan for Earth Works Site PreparationDocument2 pagesInspection and Test Plan for Earth Works Site PreparationMustafa313100% (3)

- L'WZAAR FISH MARKET & RESTAURANT DEMOLITION CHECKLISTDocument2 pagesL'WZAAR FISH MARKET & RESTAURANT DEMOLITION CHECKLISTMohammed Javid100% (1)

- Rmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)Document2 pagesRmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)myn maliQueNo ratings yet

- Dismantling Method StatementDocument53 pagesDismantling Method Statementmilosevicsasa11100% (1)

- Final Check List Cable LayingDocument3 pagesFinal Check List Cable Layingmani_eee6180% (5)

- Ms - Concrete Chipping For Mep InstallationsDocument4 pagesMs - Concrete Chipping For Mep Installationsmoytabura9650% (2)

- Asphalt Paving JSADocument20 pagesAsphalt Paving JSAwahyu nugroho100% (3)

- H96 MaxDocument4 pagesH96 MaxRoni EnjelaniNo ratings yet

- Theoretical and Actual CombustionDocument14 pagesTheoretical and Actual CombustionErma Sulistyo R100% (1)

- Excavation Checklist PDFDocument4 pagesExcavation Checklist PDFPageduesca RouelNo ratings yet

- Daily Excavation Checklist: Project Name: LocationDocument1 pageDaily Excavation Checklist: Project Name: LocationSajid ShahNo ratings yet

- Name of Project/Site: Contractor Name: Date:: RCCB Test RegisterDocument2 pagesName of Project/Site: Contractor Name: Date:: RCCB Test RegisterRísês ÃfrözNo ratings yet

- Checklist For DB InstallationDocument1 pageChecklist For DB InstallationSatya NaiduNo ratings yet

- Checklist For Electrical Safety InspectionDocument1 pageChecklist For Electrical Safety InspectionChandresh SinghNo ratings yet

- Switchgear Inspection Checklist: Section A - Customer DataDocument1 pageSwitchgear Inspection Checklist: Section A - Customer Data20082012No ratings yet

- Jsa For Cable Tray ErectionDocument2 pagesJsa For Cable Tray Erectionanko heroNo ratings yet

- Method Statement For Cable & TerminationDocument6 pagesMethod Statement For Cable & TerminationRajuNo ratings yet

- Vacuum Cleaner Checklist Ver0Document1 pageVacuum Cleaner Checklist Ver0Nair R RakeshNo ratings yet

- Checklist For Rope Suspended Platform HSE OCP 16Document1 pageChecklist For Rope Suspended Platform HSE OCP 16Mohamed KamalNo ratings yet

- CHECKLIST - Fire Equipment Inspection - Hose ReelsDocument1 pageCHECKLIST - Fire Equipment Inspection - Hose Reelsle papi100% (1)

- HSE-F-314 Passenger-Material Hoist Monthly ChecklistDocument1 pageHSE-F-314 Passenger-Material Hoist Monthly ChecklistAhmad RazaNo ratings yet

- Check List For Installation of Earthing System: Contractor: Sub-ContractorDocument4 pagesCheck List For Installation of Earthing System: Contractor: Sub-ContractorRyn RcioNo ratings yet

- Daily Wacker Compactor ChecklistDocument1 pageDaily Wacker Compactor ChecklistStansilous Tatenda NyagomoNo ratings yet

- Shuttering WorksDocument3 pagesShuttering WorksAbdul GhaffarNo ratings yet

- Grader Daily Inspection ChecklistDocument2 pagesGrader Daily Inspection Checklistazer Azer100% (2)

- Etihad Southside Catering Facility Light Fitting Installation Method StatementDocument68 pagesEtihad Southside Catering Facility Light Fitting Installation Method StatementAnandu AshokanNo ratings yet

- Civil Work Permit: Contractor: ContractorDocument1 pageCivil Work Permit: Contractor: ContractorAshwani Dogra100% (1)

- Parking Area HIRADocument22 pagesParking Area HIRASafety DeptNo ratings yet

- Checklist For Equipment Inspection TRANSIT MIXERDocument1 pageChecklist For Equipment Inspection TRANSIT MIXERstansilous100% (1)

- Form 10 For Lifting Tools and Tackles Like Crane Chain Pully Block Hoist Sling Belt EtcDocument1 pageForm 10 For Lifting Tools and Tackles Like Crane Chain Pully Block Hoist Sling Belt EtcHEMANT RAMJI100% (1)

- SMS - SF 4.4.6.6.1 Method Statement Glass Partition InstallationDocument7 pagesSMS - SF 4.4.6.6.1 Method Statement Glass Partition InstallationAli SahibzadaNo ratings yet

- Elcb Checking Format-TDocument1 pageElcb Checking Format-TGyanendra Narayan NayakNo ratings yet

- Quality Example 1 - ITP or QCP - Footer ApprovalDocument2 pagesQuality Example 1 - ITP or QCP - Footer ApprovalBea MokNo ratings yet

- Bar Cutting Machine HSE ChecklistDocument2 pagesBar Cutting Machine HSE ChecklistMD Abdullah100% (1)

- Risk Assessment Template For Combo Roof Waterproofing Work.Document14 pagesRisk Assessment Template For Combo Roof Waterproofing Work.Majaga MabhenaNo ratings yet

- Pre Monsoon-Check ListDocument14 pagesPre Monsoon-Check ListSandeep Aher67% (6)

- Inspection Checklist For Installation of Interlocking Precast Concrete Pavers and KerbstonesDocument1 pageInspection Checklist For Installation of Interlocking Precast Concrete Pavers and KerbstonesDipin Nediya Parambath100% (3)

- No TBT / Pre Task Start!! No Work!!Document4 pagesNo TBT / Pre Task Start!! No Work!!Muhammad Iqbal Niyazi100% (3)

- Grating Handrails Ladders Stairways Quality Control and Inspection Report FormDocument1 pageGrating Handrails Ladders Stairways Quality Control and Inspection Report Formhasan_676489616No ratings yet

- Excavation Inspection ChecklistDocument3 pagesExcavation Inspection ChecklistMalefane Cortez TlatlaneNo ratings yet

- SWP CHECKLISTS - ExcavationDocument4 pagesSWP CHECKLISTS - ExcavationSrinivas Dumpala HSENo ratings yet

- Safety ChecklistDocument4 pagesSafety ChecklistRohit Shetty100% (1)

- NYC School Construction Safety Manual Excavation ChecklistDocument2 pagesNYC School Construction Safety Manual Excavation ChecklistMathan RajNo ratings yet

- Excavation Safety ChecklistDocument4 pagesExcavation Safety ChecklistloganathanNo ratings yet

- Marine EngineeringDocument4 pagesMarine EngineeringRoni EnjelaniNo ratings yet

- Xiaomi Redmi Note 8 - Full Phone SpecificationsDocument3 pagesXiaomi Redmi Note 8 - Full Phone SpecificationsRoni EnjelaniNo ratings yet

- PEP - Parts 1Document23 pagesPEP - Parts 1Roni EnjelaniNo ratings yet

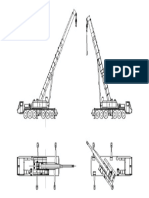

- Truck Crane 1Document1 pageTruck Crane 1Roni EnjelaniNo ratings yet

- Marine EngineeringDocument4 pagesMarine EngineeringRoni EnjelaniNo ratings yet

- Marine EngineeringDocument4 pagesMarine EngineeringRoni EnjelaniNo ratings yet

- Contoh Clamp Hose StainlessDocument1 pageContoh Clamp Hose StainlessRoni EnjelaniNo ratings yet

- Marine EngineeringDocument4 pagesMarine EngineeringRoni EnjelaniNo ratings yet

- Generator Set Operator & Maintenance Instruction ManualDocument61 pagesGenerator Set Operator & Maintenance Instruction ManualAlejandro Salas VásquezNo ratings yet

- Maritime Engineering and Ship Science - Engineering and The Environment - University of SouthamptonDocument2 pagesMaritime Engineering and Ship Science - Engineering and The Environment - University of SouthamptonRoni EnjelaniNo ratings yet

- 10 Good Reasons To Study Electrical Engineering AbroadDocument8 pages10 Good Reasons To Study Electrical Engineering AbroadRoni EnjelaniNo ratings yet

- What Is Electrical EngineeringDocument6 pagesWhat Is Electrical EngineeringRoni EnjelaniNo ratings yet

- What Is Electrical EngineeringDocument6 pagesWhat Is Electrical EngineeringRoni EnjelaniNo ratings yet

- Gen Sets 2Document7 pagesGen Sets 2Tahir MahmoodNo ratings yet

- Generator In-Situ Inspections - GER3954CDocument16 pagesGenerator In-Situ Inspections - GER3954Chozipek100% (1)

- Maintenance For Motors and Generators TFjelldalen ABBDocument20 pagesMaintenance For Motors and Generators TFjelldalen ABBRoni EnjelaniNo ratings yet

- DUP Signals Robotic Process AutomationDocument10 pagesDUP Signals Robotic Process AutomationRoni EnjelaniNo ratings yet

- An Introduction To AcousticsDocument298 pagesAn Introduction To Acousticsmarian B.No ratings yet

- Chapt 1Document21 pagesChapt 1Nguyen Huu HieuNo ratings yet

- PneumaticsDocument21 pagesPneumaticsRoni EnjelaniNo ratings yet

- Jaringan Dasar X 1Document17 pagesJaringan Dasar X 1Arifia KasastraNo ratings yet

- Design of Steel Exhibition Building: B.Q.Rahman Computer Aided Structural Engineering FINAL YEAR 2007-08, Iiit-HyderabadDocument23 pagesDesign of Steel Exhibition Building: B.Q.Rahman Computer Aided Structural Engineering FINAL YEAR 2007-08, Iiit-HyderabadRoni EnjelaniNo ratings yet

- Engineering PresentationDocument22 pagesEngineering PresentationRomani Noel S. Chavez Jr.No ratings yet

- L 14ce 55 170219174005Document44 pagesL 14ce 55 170219174005Roni EnjelaniNo ratings yet

- Loading and Unloading ClauseDocument11 pagesLoading and Unloading ClauseRoni EnjelaniNo ratings yet

- Emergency Action PlanDocument18 pagesEmergency Action PlanSanil AlateNo ratings yet

- REC107487 KPA Truck Loading and Unloading Operations V2 1 PDFDocument11 pagesREC107487 KPA Truck Loading and Unloading Operations V2 1 PDFRoni EnjelaniNo ratings yet

- 200 Questions and Answers On Practical Civil Engineering Works 2008Document84 pages200 Questions and Answers On Practical Civil Engineering Works 2008ramdj100% (4)

- 01 Introduction To Industrial Automation and ControlDocument18 pages01 Introduction To Industrial Automation and ControlPallavi SinglaNo ratings yet

- Space DynamicsDocument37 pagesSpace Dynamicspurushottam KashyapNo ratings yet

- FST Handbook 2014-Final Copy 1 PDFDocument382 pagesFST Handbook 2014-Final Copy 1 PDFDelvon DownerNo ratings yet

- IS 4991 (1968) - Criteria For Blast Resistant Design of Structures For Explosions Above Ground-TableDocument1 pageIS 4991 (1968) - Criteria For Blast Resistant Design of Structures For Explosions Above Ground-TableRenieNo ratings yet

- Clean Milk ProductionDocument19 pagesClean Milk ProductionMohammad Ashraf Paul100% (3)

- SOIL ASSESSMENT AND PLANT PROPAGATION OF BELL PEPPERS (Capsicum Annuum)Document35 pagesSOIL ASSESSMENT AND PLANT PROPAGATION OF BELL PEPPERS (Capsicum Annuum)Audrey Desiderio100% (1)

- 1989 GMC Light Duty Truck Fuel and Emissions Including Driveability PDFDocument274 pages1989 GMC Light Duty Truck Fuel and Emissions Including Driveability PDFRobert Klitzing100% (1)

- Aortic Stenosis, Mitral Regurgitation, Pulmonary Stenosis, and Tricuspid Regurgitation: Causes, Symptoms, Signs, and TreatmentDocument7 pagesAortic Stenosis, Mitral Regurgitation, Pulmonary Stenosis, and Tricuspid Regurgitation: Causes, Symptoms, Signs, and TreatmentChuu Suen TayNo ratings yet

- O2 Orthodontic Lab Catalog PDFDocument20 pagesO2 Orthodontic Lab Catalog PDFplayer osamaNo ratings yet

- TutorialDocument324 pagesTutorialLuisAguilarNo ratings yet

- ML AiDocument2 pagesML AiSUYASH SHARTHINo ratings yet

- Seed SavingDocument21 pagesSeed SavingElectroPig Von FökkenGrüüven100% (2)

- Aacra Draft Preliminary Report PDFDocument385 pagesAacra Draft Preliminary Report PDFBeselam SeyedNo ratings yet

- PDFViewer - JSP 3Document46 pagesPDFViewer - JSP 3Kartik ChaudharyNo ratings yet

- JUPITER 9000K H1PreliminaryDocument1 pageJUPITER 9000K H1PreliminaryMarian FlorescuNo ratings yet

- Chap06 (6 24 06)Document74 pagesChap06 (6 24 06)pumba1234No ratings yet

- An Online ECG QRS Detection TechniqueDocument6 pagesAn Online ECG QRS Detection TechniqueIDESNo ratings yet

- Gauss Contest: Grade 8Document4 pagesGauss Contest: Grade 8peter100% (1)

- DR-M260 User Manual ENDocument87 pagesDR-M260 User Manual ENMasa NourNo ratings yet

- Introduction To Finite Element Methods (2001) (En) (489s)Document489 pagesIntroduction To Finite Element Methods (2001) (En) (489s)green77parkNo ratings yet

- Magnetic Pick UpsDocument4 pagesMagnetic Pick UpslunikmirNo ratings yet

- Handout Tematik MukhidDocument72 pagesHandout Tematik MukhidJaya ExpressNo ratings yet

- EP - EngineDocument4 pagesEP - EngineAkhmad HasimNo ratings yet

- Brochure Personal CareDocument38 pagesBrochure Personal CarechayanunNo ratings yet

- DENSO COMMON RAIL INJECTOR REPAIR GUIDEDocument22 pagesDENSO COMMON RAIL INJECTOR REPAIR GUIDEMarcoNo ratings yet

- Interactive Architecture Adaptive WorldDocument177 pagesInteractive Architecture Adaptive Worldhoma massihaNo ratings yet

- TIA Selection Tool: Release Notes V2022.05Document10 pagesTIA Selection Tool: Release Notes V2022.05Patil Amol PandurangNo ratings yet

- ROMUS 2012 Flooring CatalogueDocument20 pagesROMUS 2012 Flooring CatalogueDan George IIINo ratings yet

- Monodisperse Droplet Generators As Potential Atomizers For Spray Drying Technology PDFDocument11 pagesMonodisperse Droplet Generators As Potential Atomizers For Spray Drying Technology PDFfishvalNo ratings yet

- Problem SolutionsDocument5 pagesProblem SolutionskkappaNo ratings yet