Professional Documents

Culture Documents

Ehv Disconnectors For Smart Grid

Uploaded by

Travis Wood0 ratings0% found this document useful (0 votes)

82 views2 pagesThis document discusses the importance of integrating high voltage disconnect switches into smart grid monitoring strategies. It argues that disconnect switches are critical infrastructure that are often overlooked despite accounting for a large portion of annual maintenance costs due to failures. Monitoring disconnect switches using electronic controls rather than electromechanical systems can reduce maintenance costs, energy losses, and mechanical failure rates by detecting problems early and adjusting operation accordingly. This improved monitoring is crucial for smart grids to achieve better visibility of equipment and reduce the economic impacts of outages.

Original Description:

smart grid

Original Title

Ehv Disconnectors for Smart Grid

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses the importance of integrating high voltage disconnect switches into smart grid monitoring strategies. It argues that disconnect switches are critical infrastructure that are often overlooked despite accounting for a large portion of annual maintenance costs due to failures. Monitoring disconnect switches using electronic controls rather than electromechanical systems can reduce maintenance costs, energy losses, and mechanical failure rates by detecting problems early and adjusting operation accordingly. This improved monitoring is crucial for smart grids to achieve better visibility of equipment and reduce the economic impacts of outages.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

82 views2 pagesEhv Disconnectors For Smart Grid

Uploaded by

Travis WoodThis document discusses the importance of integrating high voltage disconnect switches into smart grid monitoring strategies. It argues that disconnect switches are critical infrastructure that are often overlooked despite accounting for a large portion of annual maintenance costs due to failures. Monitoring disconnect switches using electronic controls rather than electromechanical systems can reduce maintenance costs, energy losses, and mechanical failure rates by detecting problems early and adjusting operation accordingly. This improved monitoring is crucial for smart grids to achieve better visibility of equipment and reduce the economic impacts of outages.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

TRANSMISSION AND DISTRIBUTION

High voltage disconnect switches:

critical to smart grid deployment

by Patrick Lalong and William Morse, EHT International

With the massive investments globally in smart grid architecture projects as part of the economic stimulus packages injected in the world

economies, we are witnessing new strategies in the high voltage industry internationally.

The challenge is serious; to build

architectures capable of integrating

multiple innovations developed to

improve overall practices in the electrical

production, transport and distribution

cycle. Technologies such as wind or solar

devices, specialised monitoring devices

for high voltage equipment and household

energy management devices will all speak

the same language and rely on smart grid

architecture to communicate.

Utilities are in the process of determining

the strategies to optimise their operation Fig. 1: Pantograph disconnect switches.

and maintenance practices. In short,

they are determining the equipment they

will monitor, the parameters that will be

recorded. It has become apparent that

utilities all agree to monitor high value

equipment such as power transformers,

circuit breakers, alternators and turbines.

But we notice the strategies for monitoring

high voltage (HV) disconnect switches

is far from being unanimous. This article

discusses the reasons why many utilities

are not integrating or simply ignoring HV

disconnect switches in their smart grid

monitoring strategies. It also demonstrates

the technical and economical value of

monitoring this equipment. Finally, it takes

a look at the progress that has been

made in the field of monitoring disconnect

switches.

The main reason utilities are reluctant to

integrate the HV disconnect switches in

their smart grid strategies is that disconnect

switches are relatively inexpensive

compared to other HV equipment and do Fig. 2: Vertical break disconnect switch.

not attract the attention of management.

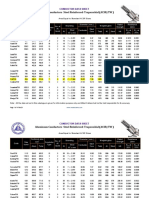

There has been no development in HV the grid operators. Every time a blackout HV disconnect switches can be

disconnect switches technology in the past occurs, utilities and their customers lose monitored primarily from the motor

30 years. Surprisingly, disconnect switch millions of dollars in transit loss penalties, operating mechanism. To do so, the old

controls are still electromechanical and and operational losses. This statement electromechanical technology is replaced

have not yet been converted to electronic shows the immediate relation between by an intelligent electronic controller

controls. Therefore, when utility decision outages and HV disconnect switches. and an optical positioning system is

makers set their priorities for monitoring However, economic costs caused by incorporated for precise position control

devices, HV disconnect switches are disconnect switch failures are not limited to and measurement of the arm of the

generally at the bottom of the list. But is these isolated events. We have determined disconnect. Ironically, this technology can

this attitude justifiable? that between 10 and 20% of the total be installed in most existing disconnect

annual maintenance costs in substations switch housings at more or less the

In a document titled the Smart Grid:

is allocated to HV disconnect switches. same cost as utilities pay for refurbishing

an introduction, prepared for the US

Considering the human resources, and the the electromechanical technology of

Department of Energy by Litos Strategic

economic costs related to the equipment their old motor operating mechanisms.

Communication, we learn: More

Electronic controls allow for variable speed

blackouts and brownouts are occurring breakages, we determined that hundreds

control and monitoring of the following

[in United States] due to the slow response of millions of dollars in maintenance is

parameters:

times of mechanical switches, a lack of allocated to HV disconnect switches every

automated analytics, and poor visibility a year. Therefore ignoring disconnect switch Disconnect mechanism position

lack of situational awareness on the part of monitoring does not make sense. Motor current, voltage and torque

energize - November 2011 - Page 26

TRANSMISSION AND DISTRIBUTION

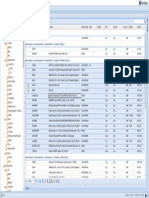

time, energy and labour. The preventive

maintenance is replaced by just-in-time

maintenance. Therefore, maintenance

is performed only when required prior to

failures saving time and money.

Energy loss reduction

Re a l t i m e m o n i t o r i n g a l l o w s f o r t h e

detection of failures before they occur such

that energy losses caused by substation

equipment failure are significantly reduced.

Energy losses can be reduced by ensuring

better contact pressure by monitoring the

Fig. 3: Disconnect contacts. position of the blade in the jaw of the switch. Fig. 6: Intelligent motorised control cabinet.

Mechanical failure rate reduction

the utility and other devices within the

Electronic monitoring has the ability to substation on the proper opening and

detect a significant change in the motor closing of the disconnect switch. Over time

torque, according to predefined values, the cams become loose and they can

and adjusts the operational speed to no longer be trusted. Also, since they can

avoid mechanical failures. Motor current lose their positioning with time, they may

is continuously monitored such that not maintain the proper closed position

overcurrent situations can be prevented of the disconnect switch itself over time.

thus increasing motor life. If the blade is not properly seated within

Detection and intervention time the jaw of the switch, there will be losses

significantly reduced and the switch will overheat. iCOD ensures

that the proper position of the blade in

Intelligent controllers generate alarms the jaw occurs at each closing. If not, an

to notify operators when a problem alarm is raised. This positioning system has

occurs or when motor torque exceeds eliminated the need for cam switches

predetermined parameters. Error codes completely. The optical positioning system

are displayed to help diagnose the (Fig. 5) provides the added smart grid

problem source. Operational data is stored abilities whereby the user can now trust

Fig. 4: Conventional cabinet with cam switches. within the controller for diagnosis when an the signals sent by the controller. Since

alarm is raised. the unit now knows where the arm of the

disconnect is, at all times throughout

Equipment and grid life time increase due manoeuvres, the devise can now be truly

to reduction of harmful harmonics operated remotely. In many cases, with the

Electronically controlled HV disconnect conventional technology, crews must be

switches with the variable speed motors sent to witness openings and closings of

can decrease the duration of the electric disconnects. This can now be eliminated.

arc reducing the harmful harmonics All monitored parameters can be

injected in the grid. Decreasing the communicated to substation control

harmonics, which damage the insulating rooms via many popular communication

paper of current and power transformers protocols. Alarms can be trigger remotely

will, therefore, increase the operational life or simply by the local display. As more than

Fig. 5: Optical positioning system. of the transformers. a year's worth of operations are stored

in the unit, stored data can be used to

Monitoring of the controller The development of a motorised control diagnose incipient faults in the disconnect.

Temperature cabinet with smart grid capabilities

Therefore, it is reasonable to conclude that

Humidity Five years of research and development including HV disconnect switches in smart

Operation time have culminated in iCOD (intelligent grid deployment would benefit utilities by

control operation disconnect) and iMCC optimizing their maintenance practices

Benefits (intelligent motorised control cabinet). and increasing their grid reliability. It is

Based on the recorded data, the Designed to provide utilities and heavy not justifiable that utility decision makers

operator benefits from real time alarm industrials a level of security for their ignore this piece of equipment in their

generation and various time and substations and grids not previously smart grid strategies. The last major piece

position based analysis allowing for available. Disconnect switches by their of equipment found in substations now

just-in-time maintenance. As well ageing, ver y nature are used in part to isolate has the ability to be controlled more

maintenance, and mechanical studies areas within substations in order that efficiently, monitored in real time, predict

can be performed to increase life of the maintenance can be performed, thus failures and alarm when required. Proper

equipment. On an economic perspective, they are an integral part in the security and monitoring of the lowly disconnect switch in

electronically monitored controllers safety of substation personnel. However, the end will save millions of revenue dollars.

decrease the HV disconnect switch conventional designs have elements that The savings will come in the form of less

operational costs thanks to the following cannot be relied upon should connection maintenance required, less load losses due

aspects. to a smart grid be required. One main to overheating, predictive maintenance

component that requires much attention instead of preventive maintenance,

Preventive maintenance time reduction of substation personnel is the cam switches catastrophic failure prevention and less

found in conventional motorised control human intervention.

The monitoring of the disconnect motor

cabinets (Fig. 4).

operation allows for the substantial Contact Mario Kuisis, Martec,

reduction of the preventive maintenance The cam switches are used to signal Tel 011 485-2717, mario@martec.co.za

energize - November 2011 - Page 27

You might also like

- Condition Monitoring A Decade of Proposed TechniquesDocument15 pagesCondition Monitoring A Decade of Proposed TechniquesOsman T.No ratings yet

- Iot Based Protection of Three Phase Induction MotorDocument6 pagesIot Based Protection of Three Phase Induction Motor1345Pranmya LadEENo ratings yet

- Zhang Isei 08 01Document5 pagesZhang Isei 08 01JorgeNo ratings yet

- Dont Discriminate The Importance of Selective Coordination in Electrical Installations FINALDocument6 pagesDont Discriminate The Importance of Selective Coordination in Electrical Installations FINALsofyan_shahNo ratings yet

- Integrated High-Speed Intelligent Utility Tie Unit For Disbursed/Renewable Generation FacilitiesDocument7 pagesIntegrated High-Speed Intelligent Utility Tie Unit For Disbursed/Renewable Generation Facilitiesapi-3697505No ratings yet

- Iot Based Smart Electricity Meter and Power Theft DetectionDocument6 pagesIot Based Smart Electricity Meter and Power Theft Detectionhamed razaNo ratings yet

- 0000518A Circuit Breaker PaperDocument5 pages0000518A Circuit Breaker PaperRicardo HerreraNo ratings yet

- Case Studies MaintenanceDocument7 pagesCase Studies MaintenancemarinflorentinaoanaNo ratings yet

- Schneider Electric - Electronic Trip Circuit Breaker BasicsDocument20 pagesSchneider Electric - Electronic Trip Circuit Breaker BasicsJohn100% (3)

- A Study On AT and C Losses Control in Power System Using D-FACTS DevicesDocument8 pagesA Study On AT and C Losses Control in Power System Using D-FACTS Devicesابو كيموNo ratings yet

- Philosophy of Protective RelayingDocument20 pagesPhilosophy of Protective RelayingSasquatchCornNo ratings yet

- Introduccion A TR InteligentesDocument10 pagesIntroduccion A TR Inteligentestu_novia_nos_enganiaNo ratings yet

- PDF Flisr PDFDocument8 pagesPDF Flisr PDFNhat Tan MaiNo ratings yet

- Ultrafast Electronic Cricuit Breaker PDFDocument2 pagesUltrafast Electronic Cricuit Breaker PDFarjun royalNo ratings yet

- Intelligent Relay For Power System ProtectionDocument35 pagesIntelligent Relay For Power System ProtectionMahesh ShendeNo ratings yet

- New Details of ProjectDocument35 pagesNew Details of ProjectMahesh ShendeNo ratings yet

- RTU Maintenence StrategyDocument15 pagesRTU Maintenence StrategyKara ButlerNo ratings yet

- ModuleDocument16 pagesModuleAbdalla ElsayedNo ratings yet

- L1 The Philosophy of Protective Relaying 04102023 044706pmDocument3 pagesL1 The Philosophy of Protective Relaying 04102023 044706pmSYED ALIYYAN IMRAN ALINo ratings yet

- Battery - Asset - MGMT - VRLA Aging CharacteristicsDocument4 pagesBattery - Asset - MGMT - VRLA Aging CharacteristicsJackie BagagnanNo ratings yet

- Paper 1608 CIRED2019Document5 pagesPaper 1608 CIRED2019romerogordonNo ratings yet

- Advanced Differential Protection Scheme Using MicrocontrollerDocument3 pagesAdvanced Differential Protection Scheme Using MicrocontrollerkavirajputNo ratings yet

- Monitoring and Diagnostics of PV Plants by A Wireless Self-Powered Sensor For Individual PanelsDocument9 pagesMonitoring and Diagnostics of PV Plants by A Wireless Self-Powered Sensor For Individual PanelsDevil faNo ratings yet

- Teorie PROTECTIIDocument177 pagesTeorie PROTECTIIbdsrlNo ratings yet

- 2208EE006.ourside DstatcomDocument7 pages2208EE006.ourside DstatcomssNo ratings yet

- ABB 63 WPO BreakerCoordination FinalDocument4 pagesABB 63 WPO BreakerCoordination FinalCA Cole100% (1)

- Parametrization of Intelligent Relays SRW01 and Identification of Occurrence of Possible Failures in Actuation and Shutdown Operations of Electric Low-Voltage Three-Phase Induction MotorsDocument6 pagesParametrization of Intelligent Relays SRW01 and Identification of Occurrence of Possible Failures in Actuation and Shutdown Operations of Electric Low-Voltage Three-Phase Induction Motorsdeywysson grigorioNo ratings yet

- Contact Hours/week:lecture:3, Tutorial:1, Practical:0::Department Core (DC)Document21 pagesContact Hours/week:lecture:3, Tutorial:1, Practical:0::Department Core (DC)AMAN GAUTAMNo ratings yet

- White Paper Digital Switch 9AKK107680A7251 ENaDocument16 pagesWhite Paper Digital Switch 9AKK107680A7251 ENaÚt ĐộNo ratings yet

- Integrated Generator Rotor and Stator Winding Condition MonitoringDocument8 pagesIntegrated Generator Rotor and Stator Winding Condition MonitoringPimolwan PikitklangNo ratings yet

- How Advanced On-Line Partial Discharge Diagnostics Can MakeDocument12 pagesHow Advanced On-Line Partial Discharge Diagnostics Can MakeBucur Ilie100% (1)

- Lect 1512Document6 pagesLect 1512filmon dissanNo ratings yet

- Why Low Quiescent Current Matters For Longer Battery LifeDocument10 pagesWhy Low Quiescent Current Matters For Longer Battery LifeNaman BairagiNo ratings yet

- Why Low Quiescent Current Matters For Longer Battery LifeDocument10 pagesWhy Low Quiescent Current Matters For Longer Battery LifeMarko MakiNo ratings yet

- Microcontroller-Based Automatic Transfer SwitchingDocument8 pagesMicrocontroller-Based Automatic Transfer SwitchingDulani FernandezNo ratings yet

- 119504-Article Text-329721-1-10-20150716 PDFDocument8 pages119504-Article Text-329721-1-10-20150716 PDFKishore KumarNo ratings yet

- Synchronous-Frame Decoupling Currentregulators For Induction Motor Control in Highpower Drive SystemsDocument11 pagesSynchronous-Frame Decoupling Currentregulators For Induction Motor Control in Highpower Drive SystemsThiện HàNo ratings yet

- Control and Protection of Hydro Electric Power PlantDocument181 pagesControl and Protection of Hydro Electric Power PlantMd Abdul Raheman33% (3)

- Iot Circuit BreakerDocument5 pagesIot Circuit BreakerMadhuri RudravelliNo ratings yet

- Determination of Optimal Distributed Generation Size For Losses - Protection Co-Ordination and Reliability Evaluation Using ETAPDocument6 pagesDetermination of Optimal Distributed Generation Size For Losses - Protection Co-Ordination and Reliability Evaluation Using ETAPAlejandro PalaciosNo ratings yet

- Robotic Monitoring Improves Power System ReliabilityDocument14 pagesRobotic Monitoring Improves Power System ReliabilityHOD EEENo ratings yet

- 6333 FowardBasics LU-DC 20081216 Web PDFDocument12 pages6333 FowardBasics LU-DC 20081216 Web PDFbrijendra21No ratings yet

- 352164ijsetr4409 308Document5 pages352164ijsetr4409 308Paka RohitNo ratings yet

- WRK PDFDocument5 pagesWRK PDFRaghul RamasamyNo ratings yet

- Power Distribution System Improvement Using Automatic Power Theft Detection SystemDocument4 pagesPower Distribution System Improvement Using Automatic Power Theft Detection Systemshani528No ratings yet

- Multifunctional Protection RelayDocument5 pagesMultifunctional Protection RelayRawda JumaNo ratings yet

- Review of Proposed Installation of Custom Gridmetrix Load Side Voltage Detection Pilot To NPC'S Off Grid SystemDocument3 pagesReview of Proposed Installation of Custom Gridmetrix Load Side Voltage Detection Pilot To NPC'S Off Grid SystemCatrina FedericoNo ratings yet

- Load Shedding ManagementDocument4 pagesLoad Shedding ManagementEditor IJTSRD100% (1)

- Solutions: Electrical DistributionDocument15 pagesSolutions: Electrical DistributionJan GumskiNo ratings yet

- Cmozina Generator Protection PDFDocument18 pagesCmozina Generator Protection PDFEzequiel GregolinNo ratings yet

- Simulation of STATCOM for Reduction of T.H.D Using FLCDocument5 pagesSimulation of STATCOM for Reduction of T.H.D Using FLCdeepikaNo ratings yet

- Chapter One: Introduction 1.1 Background of The StudyDocument30 pagesChapter One: Introduction 1.1 Background of The StudyUzoma FrancisNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Re Voltage StabilityDocument27 pagesRe Voltage StabilityTravis WoodNo ratings yet

- Anandaram BaruaDocument1 pageAnandaram BaruaTravis WoodNo ratings yet

- Aluminum Conductors Steel Reinforced-Trapezoidal (ACSR/TW)Document4 pagesAluminum Conductors Steel Reinforced-Trapezoidal (ACSR/TW)Travis WoodNo ratings yet

- Overhead Conductor Installation Guide: Recommended PracticesDocument20 pagesOverhead Conductor Installation Guide: Recommended Practicesvjs270385No ratings yet

- Double Sampling-Wha It Means PDFDocument17 pagesDouble Sampling-Wha It Means PDFTravis WoodNo ratings yet

- April Is The Cruellest MonthDocument1 pageApril Is The Cruellest MonthTravis WoodNo ratings yet

- KSEB Technical SPec PDFDocument279 pagesKSEB Technical SPec PDFTravis WoodNo ratings yet

- 1363 Bolts and Nut Standard PDFDocument7 pages1363 Bolts and Nut Standard PDFTravis WoodNo ratings yet

- Gear Design For Quiet Reduction GearDocument8 pagesGear Design For Quiet Reduction GearTravis WoodNo ratings yet

- Analysis of Grading Ring and Heat Sink Impact on Surge Arrester PerformanceDocument7 pagesAnalysis of Grading Ring and Heat Sink Impact on Surge Arrester PerformanceTravis WoodNo ratings yet

- Ceramic Manufacturing PDFDocument41 pagesCeramic Manufacturing PDFTravis WoodNo ratings yet

- Enhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design 2169 0022.1000135Document6 pagesEnhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design 2169 0022.1000135Travis WoodNo ratings yet

- Innovative Adhesive For Sandwich SystemsDocument20 pagesInnovative Adhesive For Sandwich SystemsTravis WoodNo ratings yet

- En 10204-2004 Metallic Products - Types of Inspection DocumentsDocument10 pagesEn 10204-2004 Metallic Products - Types of Inspection DocumentsDalamagas KwnstantinosNo ratings yet

- Unidirectional Corona RingDocument2 pagesUnidirectional Corona RingTravis WoodNo ratings yet

- Mud Architecture: I J I R S E TDocument6 pagesMud Architecture: I J I R S E TJazzNo ratings yet

- Study of Single and Double Sampling PlansDocument14 pagesStudy of Single and Double Sampling PlansTravis WoodNo ratings yet

- Transformer Factory Assembly Area LayoutDocument55 pagesTransformer Factory Assembly Area LayoutTravis Wood100% (2)

- SPEED Continuous Panels Plants Design IssuesDocument18 pagesSPEED Continuous Panels Plants Design IssuesTravis WoodNo ratings yet

- 3 Sec-III-Hardware Fittings & AccessoriesDocument49 pages3 Sec-III-Hardware Fittings & AccessoriesTravis WoodNo ratings yet

- Fretting Fatigue in Overhead ConductorsDocument16 pagesFretting Fatigue in Overhead ConductorsTravis WoodNo ratings yet

- CT Grounding To Avoid Nuisance TrippingDocument2 pagesCT Grounding To Avoid Nuisance TrippingTravis WoodNo ratings yet

- SPEED Continuous Panels Plants Design IssuesDocument18 pagesSPEED Continuous Panels Plants Design IssuesTravis WoodNo ratings yet

- Anil Agarwal: Research: Mud As A Traditional Building MaterialDocument10 pagesAnil Agarwal: Research: Mud As A Traditional Building MaterialTravis WoodNo ratings yet

- ElectricalDocument34 pagesElectricalTravis WoodNo ratings yet

- An Introduction To Conway's Games and NumbersDocument30 pagesAn Introduction To Conway's Games and NumbersSilentSparrow98No ratings yet

- Spacer Damper IssuesDocument5 pagesSpacer Damper IssuesTravis WoodNo ratings yet

- Bolt InterlocksDocument5 pagesBolt InterlocksTravis WoodNo ratings yet

- CB Spec SvenskaDocument44 pagesCB Spec SvenskaTravis WoodNo ratings yet

- Introduction To Semiconductor Lasers For Optical CommunicationsDocument369 pagesIntroduction To Semiconductor Lasers For Optical CommunicationsDetian WangNo ratings yet

- 735 / 737 Feeder Protection Relay Instruction Manual: MultilinDocument146 pages735 / 737 Feeder Protection Relay Instruction Manual: MultilinJorge Gutierrez MejiaNo ratings yet

- Sensor LaserDocument3 pagesSensor LaserAbraham del Hoyo SotoNo ratings yet

- Nasa Crimp StandardsDocument114 pagesNasa Crimp StandardsscribdrichyNo ratings yet

- A Presentation ON Solar Wind Hybrid SystemDocument21 pagesA Presentation ON Solar Wind Hybrid Systemindian4uuNo ratings yet

- General Physics 2Document35 pagesGeneral Physics 2St. DymphaMaralit, Joyce Anne L.No ratings yet

- 1yvs80015706 CV Ref611 VN-JP-R1Document31 pages1yvs80015706 CV Ref611 VN-JP-R1Trịnh Đức ThiệnNo ratings yet

- 3300 Power Supplies DatasheetsDocument9 pages3300 Power Supplies DatasheetsSyed Mohammad NaveedNo ratings yet

- RRZZ-65B-R4N43 Product SpecificationsDocument4 pagesRRZZ-65B-R4N43 Product SpecificationsLidia Salmeron DiazNo ratings yet

- Root Category: # Free Space (1 Part(s) )Document1 pageRoot Category: # Free Space (1 Part(s) )MiguelNo ratings yet

- 1.6mm X 1.0mm DFN Package Saves Board: Transient Voltage Suppressing Device For ESD and Surge ProtectionDocument7 pages1.6mm X 1.0mm DFN Package Saves Board: Transient Voltage Suppressing Device For ESD and Surge ProtectionxXMythicalRoseXNo ratings yet

- BTVACAHOCEG2FCN01B Datasheet GP10012FF DatasheetDocument3 pagesBTVACAHOCEG2FCN01B Datasheet GP10012FF DatasheetAnton TonchevNo ratings yet

- Leoni Whitepaper 11.2016Document4 pagesLeoni Whitepaper 11.2016Rita MizarniNo ratings yet

- Chap05 (7 5 06)Document60 pagesChap05 (7 5 06)Amar NathNo ratings yet

- 200W Single Output DC-DC Converter SpecificationsDocument3 pages200W Single Output DC-DC Converter SpecificationsAntero CasaniNo ratings yet

- MCQ LCR Circuits Master-1Document14 pagesMCQ LCR Circuits Master-1Deepak Choudhary DCNo ratings yet

- TSG Surge Reduction Filter, Three Phase - TSGSRF3630Document2 pagesTSG Surge Reduction Filter, Three Phase - TSGSRF3630Angela TienNo ratings yet

- Standard Electrode Potencial at 25°CDocument2 pagesStandard Electrode Potencial at 25°CJampier32No ratings yet

- Avr-X1600h Avr-S750h Eng SM v02Document163 pagesAvr-X1600h Avr-S750h Eng SM v02Raimundo de LimaNo ratings yet

- Panel AUO T320XVN02-A CELL 1 (DS) PDFDocument25 pagesPanel AUO T320XVN02-A CELL 1 (DS) PDFekamuktyNo ratings yet

- 3 Channel Spectrum AnalyzerDocument2 pages3 Channel Spectrum AnalyzerJack PaneNo ratings yet

- Cylindrical Proximity Magnetic Sensors for Detection of Ferrous TargetsDocument2 pagesCylindrical Proximity Magnetic Sensors for Detection of Ferrous TargetsTenuka pereraNo ratings yet

- MPM80 Series Data Sheet: 2 A Non-Isolated Buck Converter ModuleDocument20 pagesMPM80 Series Data Sheet: 2 A Non-Isolated Buck Converter ModuleytnateNo ratings yet

- Cabinets DatasheetDocument2 pagesCabinets DatasheetAhmad SaeedNo ratings yet

- EM1 CompsDocument5 pagesEM1 CompsDelta VisionNo ratings yet

- 1 PIC Evaluation Board User ManualDocument22 pages1 PIC Evaluation Board User ManualKavin Sengodan100% (1)

- Complex Numbers Multiple-ChoiceDocument4 pagesComplex Numbers Multiple-ChoiceAbhishek VirmaniNo ratings yet

- LTM 8067Document20 pagesLTM 8067Sivasankar PoovaragavanNo ratings yet

- HRH Prince of Wales Institute Engineering Tech Types DC GeneratorsDocument1 pageHRH Prince of Wales Institute Engineering Tech Types DC GeneratorsShyamal Kishore TamuliNo ratings yet

- BBJ-Series explosion-proof audible and visual alarm (IIC、tD)Document1 pageBBJ-Series explosion-proof audible and visual alarm (IIC、tD)Sigit RiyadiNo ratings yet