Professional Documents

Culture Documents

Round Wood Is The Simplest Shape Used in The Construction Industry. It Is Made of Logs From

Uploaded by

Uzair Maqbool KhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Round Wood Is The Simplest Shape Used in The Construction Industry. It Is Made of Logs From

Uploaded by

Uzair Maqbool KhanCopyright:

Available Formats

1) What do you know about round wood and sawn sections (3.1 and 3.2)?

Round wood is the simplest shape used in the construction industry. It is made of logs from

trunks or straight branches from which the bark has been removed and which may have been

slightly machined to obtain a cylindrical shape. Roundwood is used in a large variety of

structures, essentially outdoor: poles for telephone or electric wires, child games, acoustic walls,

retaining walls, bridges, towers. Roundwood is the shape that requires fewer mechanical

operations. As a minimum number of longitudinal fibres are cut during the process, the

variability in mechanical properties is somehow smaller than in sawn sections. The circular shape

is well adapted for compression forces because this shape has no weak axis. Joints between two

members are more difficult because there is no plane surface to ensure contact. Round wood is

particularly prone to tangential shrinkage cracks because all annual rings remain continuous

Sawn Section is one of the most widely used form of timber in construction. Sections are

typically square, for columns, and rectangles, for beams. Because of the limited length of

commercially available logs, the length is limited to 6 m, 8 m at most. Some dimensions are

standard and easily found in the commercial circuits. It is of course possible to order sections in

specific dimensions but the cost is likely to be higher and, as the elements must have been sawn

recently, they are as dry (or as wet) as the log from which they have been sawn; the additional

drying after sawing in standard sections cannot take place here.

Q) Can you explain what the system effect is?

In engineering design of multiple member wood structural systems, simple mechanical models

are often used to determine the load effects in each member. Quite often, the actual behaviour

of the system implies mechanical interaction between elements in the system, which is

neglected in a simple engineering analysis, but may be described by more advanced models, or

verified by testing. Since the theory of plasticity cannot be applied in general for timber

structures, structural system effects for timber cannot be quantified by simple engineering

calculation methods.

Systems effect in timber systems due to

unlikely that maximum load effects occur at cross-sections with very low strength

redistribution of load effects such that cross-sections with low strength and stiffness will

generally not have large load effects

non-linear material behaviour

Its like timber is a heterogeneous material its stiffness is not constant throughout the section

and if the cross section is stiff from somewhere it will attract larger force then the section or

connection which is less stiffness. Is simple words this is the system effects.

Q) What verifications have to be made for a prismatic beam in bending?

A prismatic beam in bending following verification must be made.

1. Section Modulus must me checked in Bending

2. Sectional Area must be sectioned in Shear

3. Section verified for lateral torsional buckling

Q) What is the behaviour of purlins, depending on the position of the section, vertical or not.

Purlin is a horizontal member connected between the rafters, which transfer the load from the

roof to the rafter. The position of the purlin defines the loading condition over the purlin.

If the purlin is placed perpendicular to the roof then the roof is going to transfer the loading in

such a way that it would lead to bending and if the purlin is placed vertical then the loading

transferred from the top is going to have two components, a vertical force acting in the major

bending axis and a horizontal force acting in weak axis.

You might also like

- Building Code of Pakistan 2021Document614 pagesBuilding Code of Pakistan 2021Uzair Maqbool KhanNo ratings yet

- AIR Modeller 75 2017-12-20 - 01Document68 pagesAIR Modeller 75 2017-12-20 - 01JoãoGilbertoAraújoPontes100% (4)

- Structural Condition Assessments GuidelineDocument24 pagesStructural Condition Assessments GuidelineHardeep Sohl83% (6)

- Additional Truss NotesDocument7 pagesAdditional Truss Notesmdavies20No ratings yet

- A Truss Is Essentially A Triangulated System ofDocument10 pagesA Truss Is Essentially A Triangulated System ofMohammed HazemNo ratings yet

- 347R-14 Guide To Formwork For ConcreteDocument40 pages347R-14 Guide To Formwork For ConcreteJacky Leong100% (1)

- Services For Construction CompanyDocument19 pagesServices For Construction CompanyUzair Maqbool Khan100% (1)

- 3.design of Steel StructuresDocument13 pages3.design of Steel Structuresarju21No ratings yet

- Retaining Wall With AnchorsDocument11 pagesRetaining Wall With Anchorsmailmaverick8167100% (3)

- I Unit New'Document148 pagesI Unit New'sankarvk4uNo ratings yet

- Elevator Installation Contract - 2022 - CNMDocument5 pagesElevator Installation Contract - 2022 - CNMsolid groupNo ratings yet

- Long Span Structures ReportDocument18 pagesLong Span Structures ReportPrerana CholakheNo ratings yet

- Coupled Shear Wall: A ReviewDocument2 pagesCoupled Shear Wall: A ReviewIJSTE100% (1)

- BlowersDocument58 pagesBlowersmahmad61100% (1)

- Static and Dynamic Analysis of Grid BeamsDocument47 pagesStatic and Dynamic Analysis of Grid BeamsSurya Teja Bulusu0% (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Billboard Structures Valuation Guide: (Effective For Tax Year 2015)Document31 pagesBillboard Structures Valuation Guide: (Effective For Tax Year 2015)mobin1978No ratings yet

- Coupling Beam DesignDocument14 pagesCoupling Beam DesignkibzeamNo ratings yet

- Wind Loads On Ground Mounted Solar PanelsDocument226 pagesWind Loads On Ground Mounted Solar PanelsUzair Maqbool Khan100% (1)

- T03 08 Milosevic - GNP2020Document8 pagesT03 08 Milosevic - GNP2020Kenan KajosevicNo ratings yet

- A Study of R.C.C. Beam-Column Connection Subjected To PDFDocument7 pagesA Study of R.C.C. Beam-Column Connection Subjected To PDFInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Box Girder Analysis MethodsDocument12 pagesBox Girder Analysis Methodssujups100% (1)

- Chapter 2 - Tension MembersDocument13 pagesChapter 2 - Tension MembersSami IGNo ratings yet

- Methods of Structural Steel DesignDocument6 pagesMethods of Structural Steel Designumashankaryaligar100% (1)

- Meg Structural Conceptualization SummaryDocument10 pagesMeg Structural Conceptualization SummaryShara MarimonNo ratings yet

- Chap3 FramesDocument76 pagesChap3 FramesPalaniappan ArasappanNo ratings yet

- Chapter 2 - Frameworks: GeneralDocument2 pagesChapter 2 - Frameworks: GeneraldanieldumapitNo ratings yet

- Study On Effective Bracing Systems For High Rise Steel StructuresDocument7 pagesStudy On Effective Bracing Systems For High Rise Steel StructuresSaurabh PednekarNo ratings yet

- 3 D Finite Element Analysis of Partially Restrained Beam To Column Connections in Steel Frames PDFDocument5 pages3 D Finite Element Analysis of Partially Restrained Beam To Column Connections in Steel Frames PDFGC UniversNo ratings yet

- How to Design a Single Story Steel Building - كيف تقوم بتصميم منشأ معدني ذو طابق وحيدDocument16 pagesHow to Design a Single Story Steel Building - كيف تقوم بتصميم منشأ معدني ذو طابق وحيدAbderrahmane SaidNo ratings yet

- FEA Thin Wall Shell by Ansys and LS-dynaDocument11 pagesFEA Thin Wall Shell by Ansys and LS-dynamatteo_1234No ratings yet

- 1977 Outrigger System Design Considerations PDFDocument11 pages1977 Outrigger System Design Considerations PDFnnnNo ratings yet

- Structural MembersDocument7 pagesStructural MembersprarthumNo ratings yet

- Yaser Mozaffari Jouybari, Abbas Akbarpour NikghalbDocument8 pagesYaser Mozaffari Jouybari, Abbas Akbarpour NikghalbBasil Baby-PisharathuNo ratings yet

- Study On The Reduction of The General Overall TorsDocument12 pagesStudy On The Reduction of The General Overall Torswladimir ramrezNo ratings yet

- Shear Wall NotesDocument7 pagesShear Wall NotesArfath Khan MohammedNo ratings yet

- Ficha Men ToDocument4 pagesFicha Men ToWellcome_13No ratings yet

- 2 Marks Q&ADocument1 page2 Marks Q&ASHANMUGARAJ MADASAMYNo ratings yet

- Design of Steel TrussesDocument23 pagesDesign of Steel TrussesHalina HamidNo ratings yet

- Unit 3 & 4 Composite MaterialsDocument130 pagesUnit 3 & 4 Composite MaterialsTaimoor NasserNo ratings yet

- Ce 103 LM 1Document13 pagesCe 103 LM 1shuckss taloNo ratings yet

- Outrigger System Design ConsiderationsDocument11 pagesOutrigger System Design Considerationsrabeeabuahmad100% (1)

- Nonlinear Dynamic Analysis of Base Isolated Structures: An OverviewDocument12 pagesNonlinear Dynamic Analysis of Base Isolated Structures: An OverviewlouhibiNo ratings yet

- Analytical Modelling of Infilled Frame Structures - A General ReviewDocument18 pagesAnalytical Modelling of Infilled Frame Structures - A General ReviewTariqul IslamNo ratings yet

- Icnmsme 2020 Paper v1Document10 pagesIcnmsme 2020 Paper v1Wallyson ThomasNo ratings yet

- Multi Storey Steel Building 01Document19 pagesMulti Storey Steel Building 01Dan AlexandrescuNo ratings yet

- 2 Tension MembersDocument13 pages2 Tension MembersAbel MulugetaNo ratings yet

- Slender ColumnsDocument110 pagesSlender ColumnsvishaliNo ratings yet

- Space Frame PDFDocument22 pagesSpace Frame PDFTesfahun Tekle100% (1)

- Sakarya University Journal of ScienceDocument9 pagesSakarya University Journal of Scienceomer yonevNo ratings yet

- Chapter Two, Tension Members PDFDocument10 pagesChapter Two, Tension Members PDFZeleke TaimuNo ratings yet

- Ductility and Ultimate Strength of Eccentric Braced Frame: AbstractDocument7 pagesDuctility and Ultimate Strength of Eccentric Braced Frame: AbstractAmy VinehouseNo ratings yet

- FB 40 PDFDocument4 pagesFB 40 PDFOscar ChappilliquénNo ratings yet

- 1992 Esdep Boxgirders Advancedmethods PDFDocument16 pages1992 Esdep Boxgirders Advancedmethods PDFAnne Bernadette GuironNo ratings yet

- Wither3d Lateral Forces Study Guide VimprotantDocument12 pagesWither3d Lateral Forces Study Guide VimprotantthewodrosNo ratings yet

- Deep BeamDocument9 pagesDeep BeamDeana WhiteNo ratings yet

- TB Lecture20 Example of PT Two Way SlabsDocument39 pagesTB Lecture20 Example of PT Two Way SlabsBridget Anne BenitezNo ratings yet

- Tubular, Core, and Outrigger StructuresDocument15 pagesTubular, Core, and Outrigger StructuresUmer FarooqNo ratings yet

- Seismic Design of Reinforced Concrete StructuresDocument20 pagesSeismic Design of Reinforced Concrete StructuresMladen MilicevicNo ratings yet

- Space Frames 2Document30 pagesSpace Frames 2Rutvik S R100% (2)

- Response of Structures: Elective 1 (Earthquake Engineering)Document17 pagesResponse of Structures: Elective 1 (Earthquake Engineering)DC TVNo ratings yet

- Optimized Use of Multi-Outriggers System To Stiffen Tall BuildingsDocument8 pagesOptimized Use of Multi-Outriggers System To Stiffen Tall Buildingssubhashchandra chandruNo ratings yet

- Steel Frame Beam Column Connections with Slit DampersDocument14 pagesSteel Frame Beam Column Connections with Slit DampersPriyanka VermaNo ratings yet

- Crisafulli, Carr & Park, 200011Document18 pagesCrisafulli, Carr & Park, 200011Rodrigo Medina AngelNo ratings yet

- Lecture 2 (Material and Basic Prestressing)Document22 pagesLecture 2 (Material and Basic Prestressing)Adam SalimiNo ratings yet

- Introduction - Structural Behavior - Structural SolutionsDocument7 pagesIntroduction - Structural Behavior - Structural SolutionsLorena Gonzalez VaqueroNo ratings yet

- Experimental study of the effects of continuous rod hold-down anchorages on the cyclic response of wood frame shear wallsDocument15 pagesExperimental study of the effects of continuous rod hold-down anchorages on the cyclic response of wood frame shear wallsXavierEstrellaNo ratings yet

- Steel Design Basic ConceptsDocument3 pagesSteel Design Basic ConceptsmithunNo ratings yet

- ASDIP Steel 5.1.6.2 CrackDocument1 pageASDIP Steel 5.1.6.2 CrackUzair Maqbool KhanNo ratings yet

- LU Conflict CycleDocument1 pageLU Conflict CycleUzair Maqbool KhanNo ratings yet

- Arbitration and Conciliation Conflict ResolutionDocument5 pagesArbitration and Conciliation Conflict ResolutionUzair Maqbool KhanNo ratings yet

- Conflict Resolution in Human SocietyDocument17 pagesConflict Resolution in Human SocietyUzair Maqbool KhanNo ratings yet

- Earthquake Risk Reduction and Seismic Safety EvaluDocument9 pagesEarthquake Risk Reduction and Seismic Safety EvaluUzair Maqbool KhanNo ratings yet

- LARSSON Company ProfileDocument43 pagesLARSSON Company ProfileUzair Maqbool KhanNo ratings yet

- Wind Loading On Solar Panels: Ana Camelia Sauca, Tudor Milchiș, Ferdinánd-Zsongor GobeszDocument6 pagesWind Loading On Solar Panels: Ana Camelia Sauca, Tudor Milchiș, Ferdinánd-Zsongor GobeszWepa BizNo ratings yet

- About Company:: As A DeveloperDocument12 pagesAbout Company:: As A DeveloperUzair Maqbool KhanNo ratings yet

- Weekly Progress ProformaDocument2 pagesWeekly Progress ProformaUzair Maqbool KhanNo ratings yet

- Curriculum VitaeDocument4 pagesCurriculum VitaeUzair Maqbool KhanNo ratings yet

- Rizwan SB LGS CBT-LHR-544-20-2Document5 pagesRizwan SB LGS CBT-LHR-544-20-2Uzair Maqbool KhanNo ratings yet

- Quotation: Scope of WorkDocument2 pagesQuotation: Scope of WorkUzair Maqbool KhanNo ratings yet

- Soil Stabilization Using Lime Piles Plot 45-46Document10 pagesSoil Stabilization Using Lime Piles Plot 45-46Uzair Maqbool KhanNo ratings yet

- Managing A Business EventDocument3 pagesManaging A Business EventUzair Maqbool KhanNo ratings yet

- Fatima Jinnah Women University: The Mall RawalpindiDocument1 pageFatima Jinnah Women University: The Mall RawalpindiUzair Maqbool KhanNo ratings yet

- Motivation for Advanced Masters in Structural AnalysisDocument2 pagesMotivation for Advanced Masters in Structural AnalysisUzair Maqbool KhanNo ratings yet

- 6 Examples PDFDocument34 pages6 Examples PDFAlbert DimayugaNo ratings yet

- Check Request Form 02Document1 pageCheck Request Form 02Uzair Maqbool KhanNo ratings yet

- Customer Registration FormDocument1 pageCustomer Registration FormUzair Maqbool KhanNo ratings yet

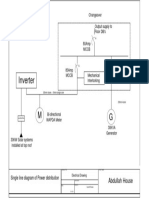

- Main Power SLDDocument1 pageMain Power SLDUzair Maqbool KhanNo ratings yet

- Measurement: Soheil GharehDocument11 pagesMeasurement: Soheil GharehHari RamNo ratings yet

- Quality Assurance Manual PDFDocument113 pagesQuality Assurance Manual PDFmuhammad iqbalNo ratings yet

- Manual Check Request Form: Payroll Fax Number: (978) 741-7110Document1 pageManual Check Request Form: Payroll Fax Number: (978) 741-7110Uzair Maqbool KhanNo ratings yet

- Sasirekha Computer ProjectDocument90 pagesSasirekha Computer ProjectAkurati RupendraNo ratings yet

- c600 17lookinsideDocument6 pagesc600 17lookinsideИван МинчевNo ratings yet

- 07 AlarmManagement enDocument39 pages07 AlarmManagement enLuis RodriguezNo ratings yet

- 350q-5 Operation ManualDocument97 pages350q-5 Operation ManualCesar Mora100% (2)

- DiGas 4000 Light E 08.02Document2 pagesDiGas 4000 Light E 08.02manit1963No ratings yet

- fEA CourseDocument3 pagesfEA CourseAnant KumbhojkarNo ratings yet

- The Weka Guard and Protector - Weka MarineDocument2 pagesThe Weka Guard and Protector - Weka MarineJoko SusiloNo ratings yet

- 5SL43407RC Datasheet enDocument5 pages5SL43407RC Datasheet enDiana Martinez SifuentesNo ratings yet

- (Mamoru Hosaka (Auth.) ) Modeling of Curves and SuDocument363 pages(Mamoru Hosaka (Auth.) ) Modeling of Curves and Suamalendu_biswas_1No ratings yet

- multirab ura signaling issuesDocument1 pagemultirab ura signaling issuessha0% (1)

- Windmill ABB MachinesDocument6 pagesWindmill ABB MachinesRadu BabauNo ratings yet

- Nurul Ain - nurulain@gmail.comDocument32 pagesNurul Ain - nurulain@gmail.comMuhamad FarhanNo ratings yet

- How To Fix Samsung CorbyDocument2 pagesHow To Fix Samsung CorbyMohd Sariffudin DaudNo ratings yet

- Explorador Ww90j6410cwec Version 02Document13 pagesExplorador Ww90j6410cwec Version 02Cristi PopescuNo ratings yet

- Mock Test Jee MainDocument142 pagesMock Test Jee MainAkash Ghosh0% (1)

- Instructions For Installation, Operating and Maintenance InstructionDocument30 pagesInstructions For Installation, Operating and Maintenance InstructionmilacronNo ratings yet

- KALEKİMDocument18 pagesKALEKİMqaisalkurdyNo ratings yet

- SN 761672 ADocument19 pagesSN 761672 ANhất TríNo ratings yet

- UDR MANUFACTURE ManufacturesDocument8 pagesUDR MANUFACTURE ManufacturesQuadri Consultancy ServicesNo ratings yet

- Data Collector 2.03.00Document20 pagesData Collector 2.03.00vyaskingNo ratings yet

- Sant Gadge Baba Amravati University: Backlog From Session Winter-2019Document2 pagesSant Gadge Baba Amravati University: Backlog From Session Winter-2019Prashant pandeNo ratings yet

- Under Water WeldingDocument23 pagesUnder Water WeldingNishanth GowdaNo ratings yet

- Electrostatic and Electromagnetic Forces: Electronic Address: Tim - Henley@mail - Utoronto.caDocument9 pagesElectrostatic and Electromagnetic Forces: Electronic Address: Tim - Henley@mail - Utoronto.caTimothy Murray HenleyNo ratings yet

- Twice As Sharp Operators ManualDocument34 pagesTwice As Sharp Operators ManualLeonardo CHTZNo ratings yet

- A Rope of Mass 0.65 KG Is Stretched Between Two Supports 30 M Apart. If The Tension in The Rope Is 120 N, How Long Will It Take A Pulse To Travel From One Support To The Other?Document6 pagesA Rope of Mass 0.65 KG Is Stretched Between Two Supports 30 M Apart. If The Tension in The Rope Is 120 N, How Long Will It Take A Pulse To Travel From One Support To The Other?peyying12No ratings yet

- GameBoy Programming ManualDocument298 pagesGameBoy Programming Manualdiceman2037100% (4)

- Sop Hydraulic Punch and ShearDocument1 pageSop Hydraulic Punch and ShearBorislav VulićNo ratings yet