Professional Documents

Culture Documents

How To Calculate Wind Loads

Uploaded by

Egyptian ResearcherOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Calculate Wind Loads

Uploaded by

Egyptian ResearcherCopyright:

Available Formats

WIND ENGINEERING & AIR QUALITY CONSULTANTS

How to Calculate Wind Loads on Roof Mounted Solar Panels in the US

By Dr. David Banks, PEng.

This paper addresses some of the frequently asked questions that we have encountered while

consulting on wind loads for dozens of solar energy designs over the past 5 years.

In the US, there are two approved methods for calculating wind loads on structures like solar

panels:

1. Use tables provided by the American Society of Civil Engineers, in ASCE 7, Minimum

Design Loads for Buildings & Structures

2. Conduct a suitable wind tunnel test, as described in ASCE Manuals and Reports on Engi-

neering Practice No. 67, Wind Tunnel Studies of Buildings and Structures.

This paper will describe the manner in which both of these methods can be performed correctly,

and will also address some other tools useful for design, such as full scale testing or computa-

tional fluid dynamics simulations.

Using the Tables in ASCE 7

As any engineer who has been charged with interpreting ASCE 7 knows, there are no tables

explicitly intended for use with roof mounted solar collectors. However, depending on the

geometry of your collectors, one of two methods is most applicable:

A. For flat or flush-mounted collectors, the external gust pressure coefficients (GCp) for the

roof itself can be used. These values can be found in Figure 6-11 and will yield conserva-

tive loads, even if the internal pressure, GCpi, is assumed to be zero.

The reason is that the air plenum underneath such panels tracks the pressure above the

panels. How well the plenum tracks the panels depends on how many panels are linked to-

gether (i.e. the size of the plenum), and more importantly, the size and spacing of the gaps

around the panels relative to the size of the plenum.

How to Calculate Wind Loads on Roof Mounted Solar Panels in the US

WIND ENGINEERING & AIR QUALITY CONSULTANTS

Note that in this situation, mechanically attached flush-mounted solar panels will not

increase the wind load on the roof structure itself. The roof load remains roughly the same,

with some fraction acting on the panels.

B. For panels tilted above 10 degrees with no wind protection on the north side, the CN

values from Table 6-18 for monosloped free roofs can be used along with equation 6-25.

(The gust effect factor, G, is considered separately for this method, and we recommend that

G be taken as 1 for solar panels). Using this table assumes that 3-second-gust wind speeds

along the roof surface are comparable to those in the approach flow.

This is generally reasonable, with the notable exception of the roof corner and edge

regions. The net effect is that:

i. Wind speeds near the surface can exceed the approach flow wind speed by

over 20% during cornering winds. As a result, for any location within 2 build-

ing heights of a roof corner, GCN should be multiplied by Kcorner = 1.5.

ii. There is additional uncertainty related to how the twisting flow patterns near

the roof edges will interact with any given panel geometry. In the absence of

testing, we advise the use of an uncertainty factor of 1.4 within 2 building

heights of a roof corner or a roof edge.

iii. Finally, tilted panels should never be placed closer than 2 panels heights from

the roof edge (or 2 panels heights + the parapet height if there is a parapet),

to avoid having the panels exposed to the very high wind acceleration right

above the roof edge.

There is an additional complication here for tilted ballasted panels, regardless of where

they are on the roof. Since these panels can slide, the GCp or GCN values (which represent

forces normal to the panel surface) should be multiplied by

Ksliding = cos() + sin()/,

where is the tilt angle, and is the friction coefficient between the panel and the roof.

This takes into account the combination of lift and drag. When the panels are slightly

lifted, they are more prone to sliding.

For both calculations A and B, the velocity pressure qz is calculated at roof height, with the

same factors for wind directionality, exposure, topography and importance as would be used

for the building itself. While we do not believe that it is necessary to design the solar panels to

a higher standard than the building upon which they sit, we also believe that it is important that

the panels not be the weakest link when the building experiences a design wind storm. For this

reason, the load combination factors of Chapter 2 of ASCE 7 (sometimes referred to as safety

factors), must be applied. This will result in a wind load safety factor or roughly 1.7.

Note that this safety factor has the effect of increasing the recurrence interval from 50 years to

roughly 700 years. In the upcoming ASCE 7-10, these safety factors will be removed, but the

recurrence interval will be increased. As a result, the design load will not change significantly

in most regions of the country.

Calculations for tipping should also be performed for both tilted and flush panels. The latter

is perhaps less obvious. However, around the perimeter of such an array, depending on the

stiffness of the connections between panels, the panels may lift, or peel. As peeling starts,

How to Calculate Wind Loads on Roof Mounted Solar Panels in the US

WIND ENGINEERING & AIR QUALITY CONSULTANTS

the panel tilt increases, the panels can become much more susceptible to the oncoming wind.

ASCE 7 does not provide any guidance regarding how to estimate these moments for flush

mounted panels. Our experience suggests that the entire load should be applied to the outside

edge of the panel.

Many panel designs fall between the two examples cited above. For example, what about

panels at a 5 to 10 tilt with a protective wind spoiler on the north side? It is difficult to predict

how effective a wind deflector will be, or at what tilt the panels will begin interacting with the

flow. It is recommended in such cases that calculations following both methods A and B be

used, and that the method providing the highest loads be applied.

We are often asked about the potential sheltering effect of parapets. It is true that in some situ-

ations, particularly immediately behind the parapets, some wind protection is afforded to the

panels. However, 2 or 3 parapet heights from the roof corners, the magnitude and extent of the

wind acceleration a short distance above the roof is increased by the parapet, and can result in

wind loads that are 50% greater than in the absence of a parapet, particularly for unprotected

tilted panels.

We are also commonly asked about the 10 psf minimum in 6.1.4.1 of ASCE 7, which states

that the loads should not be less than 10 psf multiplied by the area of the structure projected

onto a vertical plane normal to the assumed wind direction. Using the methods above, it is

highly unlikely that loads below 10 psf will be calculated. However, we do not believe that this

limit was intended to be applied to solar panels, and with proper wind tunnel testing, we believe

that values below the 10 psf limit can be justified.

Wind tunnel testing

Three key things to remember when commissioning a test are:

1. The flow patterns on the roof are very complex, so the panels need to be testing in a flow

regime like that on the roof with big vortices, flow separation and reattachment, and local

acceleration.

2. You need to measure peak loads, not mean loads.

3. The wind is turbulent. For the peaks to be accurate, the simulation must include the right

proportion of wind gusts of all sizes.

Three things you should expect to get from the tests (and which are not addressed in ASCE 7) include:

1. How are the wind loads reduced as the array gets larger? Roof mounted solar racks are

typically rigid, so that panels cannot slide or move individually.

2. How well do the panels shelter each other? Wind loads on the edge row panels are typi-

cally much higher (2-3 times) than on the interior panels.

3. How does location on the roof affect loads? Loads will be different on the north edge,

south edge, east edge, corner, and middle of the roof.

Other tools

In some situations, modeling considerations such as Reynolds number independence can pre-

vent testing using scaled models, and outdoor full-scale or near-full-scale testing is required.

As with the scaled model in the wind tunnel, the panels must be placed in a range of positions

on the roof of a building, and the approach flow velocities and turbulence must be well under-

stood. Full scale testing provides a wide range of significant challenges, both technical and

logistical: fidelity of pressure sensors after rains, temperature drifting in the instrumentation,

and interactions with animals, to name a few.

How to Calculate Wind Loads on Roof Mounted Solar Panels in the US

WIND ENGINEERING & AIR QUALITY CONSULTANTS

Computational Fluid Dynamics (CFD) can also be used to simulate flow over the panels (and,

as always, the building). However, there are currently no accepted procedures for ensuring that

peak loads are adequately measured, so this type of analysis is not approved by ASCE 7 or

any US building codes. Nonetheless, CFD can be a valuable design tool, providing insight into

whether design changes improve performance or not.

What should a roof-rack designer do?

It is clear that using the ASCE formulas near the roof corners brings with it considerable uncer-

tainty. The methods described above may not be conservative in this region. In our experience,

the wind loads calculated with the ASCE 7 methods described above are not a significant chal-

lenge for roof-mounted building integrated PV racks which are mechanically fastened to the

building structure. However, few buildings are likely to be able handle the ballast weight that

these calculations imply. It is therefore likely that if ASCE 7 methods are used, panels near the

roof corners will need to be mechanically fastened.

A well designed system can achieve significantly lower wind loads than the above calculation

procedures dictate, permitting ballasted systems to be used in many situations, including near

the corners. However, the author knows of no way to acceptably demonstrate that these wind

loads reductions without physical testing.

By Dr. David Banks, PHEng

Dr. David Banks is a Principal at CPP

and is the technical lead engineer in

CPPs Solar Wind Loads group, which

has completed more than 20 stud-

ies of wind loading on solar power

systems since the start of 2008. Dr.

Banks award-winning dissertation

from Colorado State University

concerned the pressures beneath roof

top vortices on low-rise buildings.

How to Calculate Wind Loads on Roof Mounted Solar Panels in the US

You might also like

- Lingap Oct2001 Update 3398Document21 pagesLingap Oct2001 Update 3398Oreste PrincipeNo ratings yet

- "Shear-End-Pl-13" - Beam End Connection Using Shear End PlatesDocument16 pages"Shear-End-Pl-13" - Beam End Connection Using Shear End PlatesArdXkillerNo ratings yet

- Multi-Tiered Braced Frame Design Based On AISC 341-16: Project: Client: Design By: Job No.: Date: Review byDocument2 pagesMulti-Tiered Braced Frame Design Based On AISC 341-16: Project: Client: Design By: Job No.: Date: Review byRidho ZiskaNo ratings yet

- Example Workshop Dynamic FatigueDocument60 pagesExample Workshop Dynamic Fatiguesumatrablackcoffee453No ratings yet

- AISC Engg Journal 92 PDFDocument174 pagesAISC Engg Journal 92 PDFIlham setyabudiNo ratings yet

- Response Spectrum Analysis Using Femap and NX NastranDocument40 pagesResponse Spectrum Analysis Using Femap and NX NastranGana C Rover100% (1)

- Optimum Design of Stiffened Plates For Different Loads and Shapes of RibsDocument15 pagesOptimum Design of Stiffened Plates For Different Loads and Shapes of Ribsluke636250No ratings yet

- Simply Supported Member of Triple W-Shapes Design Based On AISC 14th (AISC 360-10)Document16 pagesSimply Supported Member of Triple W-Shapes Design Based On AISC 14th (AISC 360-10)Amey GudigarNo ratings yet

- Strength of LugDocument8 pagesStrength of LugnareniviNo ratings yet

- COMSOL Cohesive Zone DebondingDocument22 pagesCOMSOL Cohesive Zone DebondingAaqib AliNo ratings yet

- Strength Curves For Metal Plates in CompressionDocument36 pagesStrength Curves For Metal Plates in Compressionlcm327No ratings yet

- Tandem: I. Reaction From Midas Iii. Cross Section of Moment Plate Due To The Tension Load at Top FlangeDocument5 pagesTandem: I. Reaction From Midas Iii. Cross Section of Moment Plate Due To The Tension Load at Top FlangeBrent SeeNo ratings yet

- Z Section PropertiesDocument4 pagesZ Section PropertiesvijaystructuralNo ratings yet

- 4.6. Nonlinear Analysis of A 16-Storey RC Building Designed According To EC2 & EC8Document8 pages4.6. Nonlinear Analysis of A 16-Storey RC Building Designed According To EC2 & EC8Dipak BorsaikiaNo ratings yet

- Columna CircularDocument16 pagesColumna CircularJhoel Oscar AENo ratings yet

- Steel Designer's Manual, 6th Edition, 2003 R20070821FDocument5 pagesSteel Designer's Manual, 6th Edition, 2003 R20070821Fsaad7159No ratings yet

- Simple Connection of Angles For TENSIONDocument92 pagesSimple Connection of Angles For TENSIONfaizan ashiqueNo ratings yet

- Truss Analysis Using Finite Element Method: Input Data & Design SummaryDocument1 pageTruss Analysis Using Finite Element Method: Input Data & Design Summaryjklo12No ratings yet

- What Are The Parameters For Deflection Check in STAAD - Pro?Document2 pagesWhat Are The Parameters For Deflection Check in STAAD - Pro?Akhil VNNo ratings yet

- Research Article CFD TechniquesDocument14 pagesResearch Article CFD TechniquesMuhammad ZahidNo ratings yet

- AC 25.571-1D DTA GuidanceDocument41 pagesAC 25.571-1D DTA GuidanceRickNo ratings yet

- Design Wind Force Coefficients For Hyperbolic Paraboloid Free RoofsDocument19 pagesDesign Wind Force Coefficients For Hyperbolic Paraboloid Free RoofsPhysicaldavidNo ratings yet

- Falsework Design For Steel Girder Bridge Based On NDS 2018 & AASHTO 17thDocument18 pagesFalsework Design For Steel Girder Bridge Based On NDS 2018 & AASHTO 17thjklo12No ratings yet

- Post BucklingDocument14 pagesPost BucklingthaoNo ratings yet

- Double Angle CapacityDocument2 pagesDouble Angle CapacityAlphaNo ratings yet

- CFD Analysis of Slurry Jet Behavior After Striking The Target Surface and Effect of Solid Particle Concentration On Jet FlowDocument5 pagesCFD Analysis of Slurry Jet Behavior After Striking The Target Surface and Effect of Solid Particle Concentration On Jet FlowEmperor RocaNo ratings yet

- Plain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryDocument4 pagesPlain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryShadin Asari ArabaniNo ratings yet

- Beam With TorsionDocument8 pagesBeam With TorsionRayodc100% (1)

- Sleeve Joint Connection Design, For Steel Cell Tower / Sign, Based On AISC 360-10 Input Data & Design SummaryDocument2 pagesSleeve Joint Connection Design, For Steel Cell Tower / Sign, Based On AISC 360-10 Input Data & Design SummaryAmey GudigarNo ratings yet

- MDOT GussetPlate LRFR Analysis 265108 7Document27 pagesMDOT GussetPlate LRFR Analysis 265108 7Vietanh PhungNo ratings yet

- Franc3D V6 Nastran TutorialDocument52 pagesFranc3D V6 Nastran TutorialSandeep BhatiaNo ratings yet

- Web Tapered Girder Design Based On AISC-ASD 9th Appendix F And/or AISC Design Guide 25Document4 pagesWeb Tapered Girder Design Based On AISC-ASD 9th Appendix F And/or AISC Design Guide 25Amey GudigarNo ratings yet

- Unlocked WIND-BS MethodDocument54 pagesUnlocked WIND-BS MethodAlphyl BalasabasNo ratings yet

- Scanned From A Xerox Multifunction Printer5Document1 pageScanned From A Xerox Multifunction Printer5Dennis RangwetsiNo ratings yet

- W14x43 To HSS6x6x1 - 2 Moment ConnDocument21 pagesW14x43 To HSS6x6x1 - 2 Moment ConnrajedmaglinteNo ratings yet

- Allsafe Aerospace 25-3-14Document68 pagesAllsafe Aerospace 25-3-14Sergey FedorinovNo ratings yet

- BGSCM14 C08 Ex ProbDocument85 pagesBGSCM14 C08 Ex ProbamachmouchiNo ratings yet

- Purlin Section .. Designation (DXBXCXT) Weight (N/M) 57.4866 SX (M 3) 46000 Sy (M 3) 10400Document6 pagesPurlin Section .. Designation (DXBXCXT) Weight (N/M) 57.4866 SX (M 3) 46000 Sy (M 3) 10400gelonocheNo ratings yet

- Workshop 11 PDFDocument22 pagesWorkshop 11 PDFJohan ConradieNo ratings yet

- Input Data & Design Summary: Project: Client: Design By: Job No.: Date: Review byDocument1 pageInput Data & Design Summary: Project: Client: Design By: Job No.: Date: Review byjklo12No ratings yet

- Computational Analysis of Erosion Wear Rate by Multiphase Flow in Optimum Bend Ratio of PipelineDocument8 pagesComputational Analysis of Erosion Wear Rate by Multiphase Flow in Optimum Bend Ratio of PipelineIJRASETPublicationsNo ratings yet

- Aisc - Chapter JDocument13 pagesAisc - Chapter JDinesh KumarNo ratings yet

- Steel DeckDocument13 pagesSteel Deckrini100% (1)

- Wind Loading On Solar Panels at Different Inclination AnglesDocument9 pagesWind Loading On Solar Panels at Different Inclination AnglesPauloAndresSepulvedaNo ratings yet

- ASD Safety Factor 2005AISC 4QDocument4 pagesASD Safety Factor 2005AISC 4QTuanQuachNo ratings yet

- The Design Is Adequate.: Column Deformation Compatibility Design Using Finite Element Method Input Data & Design SummaryDocument1 pageThe Design Is Adequate.: Column Deformation Compatibility Design Using Finite Element Method Input Data & Design SummaryCiprian Stelea100% (1)

- Flexible Diaphragm With An Opening Analysis: Input DataDocument2 pagesFlexible Diaphragm With An Opening Analysis: Input DataRidho ZiskaNo ratings yet

- Column-Base Plate Foundation Design Report, How To Design Base Plate Connections, Sample Design Report, ColumnBase Software, PCEESoft Inc.Document5 pagesColumn-Base Plate Foundation Design Report, How To Design Base Plate Connections, Sample Design Report, ColumnBase Software, PCEESoft Inc.ircivilcivilNo ratings yet

- "Prying13" - Aisc 13Th Ed. Prying Action Analysis ProgramDocument5 pages"Prying13" - Aisc 13Th Ed. Prying Action Analysis ProgramNEONo ratings yet

- Workshop 14 Radiation Enclosures: WS14-1 NAS104, Workshop 14, March 2004 2004 MSC - Software CorporationDocument24 pagesWorkshop 14 Radiation Enclosures: WS14-1 NAS104, Workshop 14, March 2004 2004 MSC - Software Corporationaiyubi2No ratings yet

- CBUSHDocument4 pagesCBUSHBita MohajerniaNo ratings yet

- Extended LECTUREDocument21 pagesExtended LECTUREbaraka100% (1)

- YS 450 UTS 530 Ys/Uts 0.849057: Api 579 - Anexo F Api 5L X65Document2 pagesYS 450 UTS 530 Ys/Uts 0.849057: Api 579 - Anexo F Api 5L X65Leonardo MathiasNo ratings yet

- Example On Is 1893Document27 pagesExample On Is 1893abhi6488No ratings yet

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- How To Calculate Wind Loads On Roof Mounted Solar Panels - Draft2Document4 pagesHow To Calculate Wind Loads On Roof Mounted Solar Panels - Draft2wellslhNo ratings yet

- Wind Load-1Document49 pagesWind Load-1like a roseNo ratings yet

- Wind Tunnel TestingDocument4 pagesWind Tunnel TestingMikeNo ratings yet

- Wind Loading ASCE 7-10Document26 pagesWind Loading ASCE 7-10Madhubalan Alagar100% (1)

- Solar2012 0483 PresentationDocument66 pagesSolar2012 0483 Presentationab_s5036No ratings yet

- CUREEpub W-29Document272 pagesCUREEpub W-29Egyptian ResearcherNo ratings yet

- Materials: Development of Vegetation-Pervious Concrete in Grid Beam System For Soil Slope ProtectionDocument16 pagesMaterials: Development of Vegetation-Pervious Concrete in Grid Beam System For Soil Slope ProtectionEgyptian ResearcherNo ratings yet

- Coastal Protection: Smart Ideas, Sustainable SolutionsDocument20 pagesCoastal Protection: Smart Ideas, Sustainable SolutionsEgyptian ResearcherNo ratings yet

- RFT Course by Hatem ElbadryDocument79 pagesRFT Course by Hatem ElbadryEgyptian ResearcherNo ratings yet

- Home Guide To Plumbing, Heating, and Air Conditioning PDFDocument194 pagesHome Guide To Plumbing, Heating, and Air Conditioning PDFEgyptian Researcher100% (1)

- A Study On Slope ProtectionDocument28 pagesA Study On Slope ProtectionEgyptian ResearcherNo ratings yet

- Piles As Retaining WallsDocument12 pagesPiles As Retaining WallsEgyptian ResearcherNo ratings yet

- CSI Course MaterialsDocument211 pagesCSI Course MaterialsEgyptian ResearcherNo ratings yet

- 2008-05 Anchoring To StoneDocument38 pages2008-05 Anchoring To StoneEgyptian ResearcherNo ratings yet

- Standard Rebar BendsDocument2 pagesStandard Rebar BendsEgyptian Researcher100% (1)

- Highway Engineering - GCPDocument5 pagesHighway Engineering - GCPEgyptian ResearcherNo ratings yet

- Consultant QC Process - Procedures Guide August 2006 PDFDocument13 pagesConsultant QC Process - Procedures Guide August 2006 PDFEgyptian ResearcherNo ratings yet

- 1.1 Roller With Brush:: Fig3.1: Design of BrushDocument7 pages1.1 Roller With Brush:: Fig3.1: Design of Brush19-317 rohit PalleNo ratings yet

- Ewhtp Direct Pipe Sup Sup c751bf9f00Document4 pagesEwhtp Direct Pipe Sup Sup c751bf9f00Ayman ElMawardyNo ratings yet

- Hoop StressDocument3 pagesHoop Stresskarthikraja21No ratings yet

- SGP SyllabusDocument2 pagesSGP SyllabusPrathap VuyyuruNo ratings yet

- BC195786485247en 000302Document25 pagesBC195786485247en 000302Gabrielle França MirandaNo ratings yet

- Slam ShutDocument5 pagesSlam ShutchemtrolsNo ratings yet

- ANG 23-0616 METALINOXGROUP Several PHE FMA v1Document7 pagesANG 23-0616 METALINOXGROUP Several PHE FMA v1Alexis PradoNo ratings yet

- Wartsila 46dfDocument2 pagesWartsila 46dfFiona EdwardesNo ratings yet

- OrcaFlex Training Syllabus v10.3 PDFDocument4 pagesOrcaFlex Training Syllabus v10.3 PDFtrueman44No ratings yet

- Sy 129 201920Document9 pagesSy 129 201920anirudh patelNo ratings yet

- 5.3 Effective Moduli of CFRP LaminaDocument20 pages5.3 Effective Moduli of CFRP LaminaGanesh.MahendraNo ratings yet

- Pump 35 VTDocument5 pagesPump 35 VTjhon peñaNo ratings yet

- LabyrinthDocument9 pagesLabyrinthmohsin931No ratings yet

- Concep PlusDocument1 pageConcep PlusgerzaelNo ratings yet

- Guideline For Energy Audit ReportDocument16 pagesGuideline For Energy Audit Reportashwini_kumar1984No ratings yet

- 2123imguf ESE 2023 Mains Offline-Test SeriesDocument9 pages2123imguf ESE 2023 Mains Offline-Test SeriesDgate IrmsNo ratings yet

- CFD Analysis of Two-Bucket Savonius Rotor Using Fluent PackageDocument7 pagesCFD Analysis of Two-Bucket Savonius Rotor Using Fluent PackageAlireza Ab100% (1)

- API - FB (Cavity Relief)Document5 pagesAPI - FB (Cavity Relief)rossifrancescoNo ratings yet

- SadfasdfasdfdasdfdasDocument15 pagesSadfasdfasdfdasdfdasRoni AmaralNo ratings yet

- Materials and Processes For NDT Technology PDFDocument2 pagesMaterials and Processes For NDT Technology PDFshakeelahmadjsrNo ratings yet

- Aircraft Hydraulic SystemsDocument17 pagesAircraft Hydraulic SystemssushantreshmaNo ratings yet

- Technical Data LovejoyDocument4 pagesTechnical Data LovejoyAmandeep SinghNo ratings yet

- Plate GirdersDocument22 pagesPlate GirdersM Kishore KumarNo ratings yet

- AISC 13th - Table J3.3 Nominal Hole Dimensions PDFDocument1 pageAISC 13th - Table J3.3 Nominal Hole Dimensions PDFmuathNo ratings yet

- Service Manual - Indian Motorcycle Full-Size (2014-2016)Document645 pagesService Manual - Indian Motorcycle Full-Size (2014-2016)t.pentzekNo ratings yet

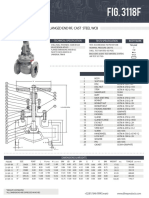

- 3118F 3318F 3618F-SeriesDocument6 pages3118F 3318F 3618F-SeriesDavid CandoNo ratings yet

- Presentation On Motors & VFD: Submitted To:-Submitted ByDocument32 pagesPresentation On Motors & VFD: Submitted To:-Submitted Byparth dosiNo ratings yet

- Wheel Loaders VocabularyDocument10 pagesWheel Loaders VocabularyLyanHyangNo ratings yet

- Ball Valve DurcoDocument48 pagesBall Valve DurcoAlex VarHerNo ratings yet

- Railing Glass Detail Calculation-1.75 KpaDocument7 pagesRailing Glass Detail Calculation-1.75 KpaSufiyan ShaikhNo ratings yet