Professional Documents

Culture Documents

Tabla Uw-12

Uploaded by

Christian Lopez MendezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tabla Uw-12

Uploaded by

Christian Lopez MendezCopyright:

Available Formats

Copyrighted material licensed to University of Toronto by Thomson Scientific, Inc. (www.techstreet.com).

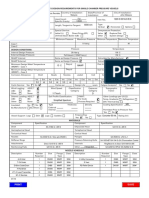

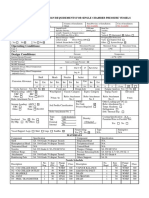

15 Table UW-12

Maximum Allowable Joint Efficiencies for Arc and Gas Welded Joints

Degree of Radiographic

Examination

(a) Full (b) Spot (c)

Type No. Joint Description Limitations Joint Category [Note (1)] [Note (2)] None

(1) Butt joints as attained by doublewelding or by None A, B, C, and D 1.00 0.85 0.70

other means that will obtain the same

quality of deposited weld metal on the inside

and outside weld surfaces to agree with the

requirements of UW-35. Welds using metal

backing strips that remain in place are

excluded.

(2) Singlewelded butt joint with backing strip (a) None except as in (b) below A, B, C, and D 0.90 0.80 0.65

other than those included under (1) (b) Circumferential butt joints with one plate offset; see A, B, and C 0.90 0.80 0.65

UW-13(b)(4) and Figure UW-13.1, sketch (i)

(3) Singlewelded butt joint without use of backing Circumferential butt joints only, not over 5/8 in. (16 mm) A, B, and C NA NA 0.60

strip thick and not over 24 in. (600 mm) outside diameter

ASME BPVC.VIII.1-2015

(4) Double full fillet lap joint (a) Longitudinal joints not over 3/8 in. (10 mm) thick A NA NA 0.55

(b) Circumferential joints not over 5/8 in. (16 mm) thick B and C [Note (3)] NA NA 0.55

(5) Single full fillet lap joints with plug welds (a) Circumferential joints [Note (4)] for attachment of B NA NA 0.50

115

conforming to UW-17 heads not over 24 in. (600 mm) outside diameter to

shells not over 1/2 in. (13 mm) thick

(b) Circumferential joints for the attachment to shells of C NA NA 0.50

jackets not over 5/8 in. (16 mm) in nominal thickness

where the distance from the center of the plug weld to

the edge of the plate is not less than 11/2 times the

diameter of the hole for the plug.

(6) Single full fillet lap joints without plug welds (a) For the attachment of heads convex to pressure to shells A and B NA NA 0.45

not over 5/8 in. (16 mm) required thickness, only with use

of fillet weld on inside of shell; or

(b) for attachment of heads having pressure on either side, A and B NA NA 0.45

to shells not over 24 in. (600 mm) inside diameter and

This copy downloaded on 2015-07-13 07:03:53 -0

not over 1/4 in. (6 mm) required thickness with fillet weld

on outside of head flange only

(7) Corner joints, full penetration, partial As limited by Figure UW-13.2 and Figure UW-16.1 C and D NA NA NA

penetration, and/or fillet welded [Note (5)]

(8) Angle joints Design per U-2(g) for Category B and C joints B, C, and D NA NA NA

GENERAL NOTE: E = 1.00 for butt joints in compression.

NOTES:

(1) See UW-12(a) and UW-51.

UW-12

(2) See UW-12(b) and UW-52.

(3) For Type No. 4 Category C joint, limitation not applicable for bolted flange connections.

You might also like

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- Dimensional Tolerances Based On API 650Document2 pagesDimensional Tolerances Based On API 650Farhan Putra100% (1)

- Anodes in Cooling Water Exchangers PDFDocument12 pagesAnodes in Cooling Water Exchangers PDFcbrittaivNo ratings yet

- Test Ring Calculation (Based On L&T Std. (6249-Lt-Eq-00-Od-0004 - Rev-1) )Document7 pagesTest Ring Calculation (Based On L&T Std. (6249-Lt-Eq-00-Od-0004 - Rev-1) )alokbdasNo ratings yet

- PPE-STD-CAL-ME-006 Rectangular Tank Thickness CalculationDocument4 pagesPPE-STD-CAL-ME-006 Rectangular Tank Thickness CalculationNadya Askar100% (1)

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- Shell Corrosion Allowance For Aboveground Storage Tanks: Debra Tetteh-Wayoe, P.EngDocument8 pagesShell Corrosion Allowance For Aboveground Storage Tanks: Debra Tetteh-Wayoe, P.Engkhabiran100% (1)

- Astm C 582Document7 pagesAstm C 582Tanktech TanktechNo ratings yet

- Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsDocument2 pagesForm U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsAmit Sharma100% (1)

- U Stamp - KK Form - SampleDocument5 pagesU Stamp - KK Form - SampleshazanNo ratings yet

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDocument2 pagesElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (2)

- Asme Sec I PWHT RequirementDocument6 pagesAsme Sec I PWHT RequirementSajin ChandranNo ratings yet

- UG 45 RequirementsDocument2 pagesUG 45 Requirementsshabbir626100% (1)

- Asme Section II A-2 Sa-612 Sa-612mDocument4 pagesAsme Section II A-2 Sa-612 Sa-612mAnonymous GhPzn1xNo ratings yet

- Asme Section Ii A-2 Sa-961Document12 pagesAsme Section Ii A-2 Sa-961Anonymous GhPzn1xNo ratings yet

- Table UCS-56-1 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 1Document4 pagesTable UCS-56-1 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 1MechanicalNo ratings yet

- Check Safety Requirements For Clutch Door According To ASMEDocument3 pagesCheck Safety Requirements For Clutch Door According To ASMEtranhonghakd5533No ratings yet

- Torque Values For Isolating Gaskets On ASME B16.5 and ASME B16.47 Series....Document1 pageTorque Values For Isolating Gaskets On ASME B16.5 and ASME B16.47 Series....Shijumon Kp100% (2)

- Lesson 09 UW16 UG37 New2Document38 pagesLesson 09 UW16 UG37 New2Kandregula Mohan BabuNo ratings yet

- Pentathane 4510 - F2 EIL PDFDocument3 pagesPentathane 4510 - F2 EIL PDFsantosh0% (1)

- UG-23 UG-24 (D) : UG-32 Formed Heads, and Sections, Pressure On Concave SideDocument2 pagesUG-23 UG-24 (D) : UG-32 Formed Heads, and Sections, Pressure On Concave SideLinh0% (1)

- Radial Projection PDFDocument1 pageRadial Projection PDFapply19842371100% (1)

- Technical Delivery Conditions For Seamless Carbon Steel FittingsDocument2 pagesTechnical Delivery Conditions For Seamless Carbon Steel FittingsTanpreet Singh100% (1)

- Tube-to-Tubesheet Joints - BaherDocument51 pagesTube-to-Tubesheet Joints - BaherNAMO100% (3)

- UG-100 Pneumatic TestDocument2 pagesUG-100 Pneumatic TestInaamNo ratings yet

- Table UW-12 Maximum Allowable Joint Efficiencies For Arc and Gas Welded JointsDocument1 pageTable UW-12 Maximum Allowable Joint Efficiencies For Arc and Gas Welded Jointsluis armandoNo ratings yet

- Peaking & BandingDocument7 pagesPeaking & BandingWeld Maniac100% (1)

- API Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksDocument12 pagesAPI Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksEC BaloncestoNo ratings yet

- API 650 - SCAST Committee Response On Inquiries (APR 2019)Document28 pagesAPI 650 - SCAST Committee Response On Inquiries (APR 2019)Ignatios Staboulis0% (1)

- AutoPIPE Vessel TutorialDocument173 pagesAutoPIPE Vessel TutorialAdel Mercadejas100% (2)

- Weldolet DimensionDocument4 pagesWeldolet DimensionabhishekNo ratings yet

- If You Want The ASTM Standard For Adhesion Testing of Thermal Sprayed Coatings ASTM C633Document3 pagesIf You Want The ASTM Standard For Adhesion Testing of Thermal Sprayed Coatings ASTM C633rajauae2008100% (1)

- Asme B31.8 Nozzles CalcDocument16 pagesAsme B31.8 Nozzles CalcSAMER OSMANNo ratings yet

- API 660 Vs TEMADocument5 pagesAPI 660 Vs TEMAALONSO GOMEZNo ratings yet

- 44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTDocument8 pages44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTAvinash ShuklaNo ratings yet

- Set-On and Set-Through Nozzle InstallationDocument3 pagesSet-On and Set-Through Nozzle InstallationLiu Yangtze100% (1)

- Asme Sec Viii D1 Nma App L PDFDocument57 pagesAsme Sec Viii D1 Nma App L PDFADRIANNo ratings yet

- Job Procedure For Puncture/Floatation/Rain Water Accumulation TestDocument4 pagesJob Procedure For Puncture/Floatation/Rain Water Accumulation Testfaisal jasim100% (1)

- Atm Sto Tanks Venting Req API2000 2009 Rev1 - TESTDocument18 pagesAtm Sto Tanks Venting Req API2000 2009 Rev1 - TESTRanjit PaulNo ratings yet

- Intermediate Wind Girder CalDocument1 pageIntermediate Wind Girder CalAnonymous p0iwBoNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Emmanuel Loayza100% (1)

- 2 - 1 Ellipsoidal Head Blank WeightDocument2 pages2 - 1 Ellipsoidal Head Blank WeightSrinivasan RajenderanNo ratings yet

- Governing Thickness For Charpy Impact TestDocument1 pageGoverning Thickness For Charpy Impact TestAnonymous vnuWrIT7FWNo ratings yet

- Pressure Vessel Dimension InspectionDocument3 pagesPressure Vessel Dimension InspectionAnas Sarkiah0% (1)

- ASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )Document14 pagesASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )hardik5818100% (2)

- API 650 Datasheet 1Document16 pagesAPI 650 Datasheet 1alwacsNo ratings yet

- Yerp Design Manual Engineering Verification ChecklistDocument3 pagesYerp Design Manual Engineering Verification ChecklistZeshanNo ratings yet

- Tank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeDocument1 pageTank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeABIDEEN BAMNENo ratings yet

- DCP Nde DV 297 HLT 01Document7 pagesDCP Nde DV 297 HLT 01Chandrasekhar mishraNo ratings yet

- Sa 516 GR 70Document2 pagesSa 516 GR 70Idil FitriNo ratings yet

- UG-39 - Flat Head ReinforcementDocument3 pagesUG-39 - Flat Head ReinforcementAshish DhokNo ratings yet

- ITP SampleDocument6 pagesITP SampleMat RidhanNo ratings yet

- How To Consider Sea Transportation LoadDocument7 pagesHow To Consider Sea Transportation LoadSharun SureshNo ratings yet

- 1 TPH For 10.54P Boiler IBR Design Calculations - R2-6-2-13Document21 pages1 TPH For 10.54P Boiler IBR Design Calculations - R2-6-2-13Vishal KandNo ratings yet

- HSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterDocument2 pagesHSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterThanh Phuc Nguyen100% (1)

- NDE Requirements (ASME Sec - VIII)Document2 pagesNDE Requirements (ASME Sec - VIII)Senol LimanNo ratings yet

- Pages de ASME VIII - DIV.1 (2019) Table UW-12Document1 pagePages de ASME VIII - DIV.1 (2019) Table UW-12HamdiMallouli100% (1)

- Objective For BeamsDocument7 pagesObjective For BeamsSuvra Sankha Chattopadhyay (sscp)No ratings yet

- Macro-Examination: Test Code/Year Part/Section/Type Acceptance Criteria ReferenceDocument3 pagesMacro-Examination: Test Code/Year Part/Section/Type Acceptance Criteria ReferenceDelil Ozan100% (1)

- Ob DSSDocument14 pagesOb DSSPriyanka kumariNo ratings yet

- 01 Indice APIDocument19 pages01 Indice APIChristian Lopez MendezNo ratings yet

- Contrato Recicladora RojasDocument4 pagesContrato Recicladora RojasChristian Lopez MendezNo ratings yet

- Starlight Illumination 1080P HD 44X IP Analysis Smart Laser IR Speed Dome CameraDocument2 pagesStarlight Illumination 1080P HD 44X IP Analysis Smart Laser IR Speed Dome CameraChristian Lopez MendezNo ratings yet

- Eunb11704enc 001Document484 pagesEunb11704enc 001Christian Lopez MendezNo ratings yet

- Carta Psicrometrica CARRIERDocument1 pageCarta Psicrometrica CARRIERChristian Lopez MendezNo ratings yet

- A Basic Guide of Arc Welding Electrodes: by Bruce BauerleinDocument4 pagesA Basic Guide of Arc Welding Electrodes: by Bruce BauerleinRajeev KhantwalNo ratings yet

- Jotun Facade New 21 - tcm132 91545Document5 pagesJotun Facade New 21 - tcm132 91545dnytan12345No ratings yet

- Cable MarkingDocument64 pagesCable MarkingJesús Sánchez100% (1)

- Berutox FE 18 EP: Technical Product InformationDocument1 pageBerutox FE 18 EP: Technical Product InformationMauricio SánchezNo ratings yet

- Tyre Technology ConferenceDocument20 pagesTyre Technology ConferenceChaiwat PhollookinNo ratings yet

- SyllabusDocument2 pagesSyllabusprajari ghoshNo ratings yet

- Astm d1142 PDFDocument11 pagesAstm d1142 PDFwahyu haryadiNo ratings yet

- Vibrations Eoliennes Intro PDFDocument26 pagesVibrations Eoliennes Intro PDFkolombo1776No ratings yet

- Structural Shapes: Arcelormittal International North AmericaDocument16 pagesStructural Shapes: Arcelormittal International North AmericaLeonardo SarriaNo ratings yet

- Battery ChargingDocument7 pagesBattery Charging123olympiakosNo ratings yet

- Flushing ProcedureDocument4 pagesFlushing ProcedureSarif IslamNo ratings yet

- Transmission Electrical Testing On 096Document45 pagesTransmission Electrical Testing On 096Michelle KerriganNo ratings yet

- Guide To PavementDocument74 pagesGuide To PavementCristian GiurgeaNo ratings yet

- Power Generation Using Multi Component Working FluidsDocument31 pagesPower Generation Using Multi Component Working FluidsaroontpeNo ratings yet

- Blends DyeingDocument232 pagesBlends DyeingMuhammad Qamar Tusief100% (1)

- AMBV Ball Valve 150-600#Document18 pagesAMBV Ball Valve 150-600#Heri SetyantoNo ratings yet

- 2012 Rekomendasi Pengangkutan Limbah B3Document75 pages2012 Rekomendasi Pengangkutan Limbah B3yordan abdulNo ratings yet

- FY Decor Combination GuideDocument8 pagesFY Decor Combination GuideOleg RBNo ratings yet

- 609 - Curbing Concrete Medians (2012)Document6 pages609 - Curbing Concrete Medians (2012)Inapanuri Nageshwara RaoNo ratings yet

- NSIC ListDocument769 pagesNSIC ListManav Hota0% (1)

- Skoda Kodiaq - Brief Instructions EnglishDocument36 pagesSkoda Kodiaq - Brief Instructions EnglishMario Redsocial100% (1)

- Porcelain Catalog 2024Document66 pagesPorcelain Catalog 2024roofingasrNo ratings yet

- Yanmar Engine L48N L100N User ManualDocument104 pagesYanmar Engine L48N L100N User ManualDavid Alfonso Caraballo100% (5)

- Ionpure® VNX High Flow Continuous Electrodeionization (CEDI) ModulesDocument2 pagesIonpure® VNX High Flow Continuous Electrodeionization (CEDI) ModulesEdwinNo ratings yet

- What Is Silica FumeDocument2 pagesWhat Is Silica FumeAmmarNo ratings yet

- Print Article - How To Model A Vacuum Breaker Using PIPE-FLODocument7 pagesPrint Article - How To Model A Vacuum Breaker Using PIPE-FLORafyss RodriguezNo ratings yet

- Insulation CoordinationDocument3 pagesInsulation CoordinationsujithmohandasNo ratings yet

- Crude Oil ProcessingDocument8 pagesCrude Oil Processingmarcomaciel3061No ratings yet

- PSD CEU 180Sept11-Corrosion PDFDocument17 pagesPSD CEU 180Sept11-Corrosion PDFSam ChoiNo ratings yet

- Work Permits FormatsDocument17 pagesWork Permits FormatsAjay khatriNo ratings yet