Professional Documents

Culture Documents

Department of Automobile Engineering Saveetha School of Engineering

Uploaded by

Kumaran PalaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Department of Automobile Engineering Saveetha School of Engineering

Uploaded by

Kumaran PalaniCopyright:

Available Formats

DEPARTMENT OF AUTOMOBILE ENGINEERING

SAVEETHA SCHOOL OF ENGINEERING

SAVEETHA UNIVERSITY

Course Title SIMULATION OF IC ENGINE PROCESSES USING COMPUTER

Course Code AE7736

Program Level

Prerequisite NIL

Text Book Ganesan,V., Computer Simulation of spark ignition engine process, Universities

Press (I) Ltd., Hyderabad, 1996.

References 1. Gordon P. Blair, Design and simulation of Four stroke Engine, Society

ofAutomotive Engineers, Inc.

1. Ramoss,A.L., Modelling of Internal Combustion Engines Processes, McGraw Hill

Publishing Co., 1992.

2. Ashley Campbel, Thermodynamics analysis of combustion engines, John Wiley &

Sons, New York, 1986.

3. Benson,R.S., Whitehouse,N.D., Internal Combustion Engines, Pergamon Press,

Oxford, 1979.

4. Ganesan,V., Computer Simulation of spark ignition engine process, Universities

Press (I) Ltd., Hyderabad, 1996.

Course objective 1. To make the students to understand the simulation of IC engine combustion

processes using computer.

2. To educate with the fundamentals of otto cycle and diesel cycle

3. To review and implement the simulation process for petrol engine and diesel

engine

Course outcomes Upon the successful completion of the course the student will be able to:

1. Know the engine specifications and simulation of engine process.

2. To understand the combustion process in automobiles.

3. To understand the difference between the petrol and diesel engine

Course Assessment Directly Assessed in CAT exams, Model Exam, Class room activities, Lab

Course Organization 4 hours per week

2 hours per week

Course Evaluation Theory:

Internal 30%

(CIA1, CIA2 and Model Exam-20%, Attendance-5%, Assignment-5%)

External 120% (Oral-20%, End Sem. Exam-100%)

Course Content SIMULATION OF IC ENGINE PROCESSES USING COMPUTER

INTRODUCTION

Introduction Heat of reaction Measurement of URP Measurement of HRP

Adiabatic flame temperature: Complete combustion in C/H/O/N Systems, Constant

volume adiabatic combustion, constant pressure adiabatic combustion. Calculation of

adiabatic flame temperature Isentropic changes of state.

SI ENGINE SIMULATION WITH AIR AS WORKING MEDIUM

Deviation between actual and ideal cycle Problems, SI engine simulation with

adiabatic combustion, temperature drop due to fuel vaporization, full throttle

operation efficiency calculation, part-throttle operation, super charged operation.

PROGRESSIVE COMBUSTION

SI Engines simulation with progressive combustion with gas exchange process, Heat

transfer process, friction calculation, compression of simulated values, validation of

the computer code, engine performance simulation, pressure crank angle diagram and

other engine performance.

SIMULATION OF 2-STROKE SI ENGINE

Intake, Exhaust, Charging and Combustion Simulation

DIESEL ENGINE SIMULATION

Zero, one and multi zone model for combustion, different heat release and heat

transfer models, equilibrium calculations, simulation of engine performance.

SESSION PLAN

UNIT SESSION TOPIC NO.OF SECTION CLASS

HOURS IN TEXT ROOM/LAB

BOOK

UNIT-1 1 Heat of reaction 1Hr 30 1.1,T1 CLASS

INTRODUCTION Measurement of Mins ROOM

URP

Measurement of

HRP

2 Adiabatic flame 1Hr 30 1.3, CLASS

temperature Mins 1.4, ROOM

derivation for T1

constant volume

3 Problem solved 1Hr 30 2.2,T1 CLASS

Adiabatic flame Mins ROOM

temperature

4 Adiabatic flame 1Hr 30 2.3.1,T1 CLASS

temperature Mins ROOM

derivation for

constant pressure

5 Problem solved 1Hr 30 2.3.1,T1 CLASS

Adiabatic flame Mins ROOM

temperature

6 Practicing the 1Hr 30 LAB

programming using Mins

calculations

UNIT-2 7 Deviation between 1Hr 30 3.1.1,T1 CLASS

SI ENGINE actual and ideal Mins ROOM

SIMULATION WITH cycle

AIR AS WORKING 8 Problem solved on 1Hr 30 3.1,T1 CLASS

MEDIUM otto cycle for Mins ROOM

different process.

9 Problem solved on 1Hr 30 3.1.3,T1 CLASS

diesel cycle for Mins ROOM

different process.

10 temperature drop 1Hr 30 3.1.3,T1 CLASS

due to fuel Mins ROOM

vaporization,

11 full throttle 1Hr 30 3.3.1, CLASS

operation Mins 3.3.2, ROOM

efficiency T1

calculation,

UNIT-3 12 SI Engines 1Hr 30 4.3,T1 CLASS

PROGRESSIVE simulation with Mins ROOM

COMBUSTION progressive

combustion with

gas exchange

process,

13 1Hr 30 4.5, CLASS

Heat transfer

Mins 46, ROOM

process,

R3

14 1Hr 30 4.3.1, CLASS

Mins 4.3.2, ROOM

friction calculation,

4.3.3,

T1

15 engine 1Hr 30 5.3.1, CLASS

performance Mins 5.3.2, ROOM

calculation and 5.3.3,

problems T1

16 Pressure crank 1Hr 30 5.1,T1 CLASS

angle diagram and Mins ROOM

other engine

performance.

17 Introduction and 1Hr 30 5.1,T1 CLASS

important to Mins ROOM

Supercharging

UNIT-4 18 Introduction for 1Hr 30 6.2,R1 CLASS

SIMULATION OF 2- two stroke Engine Mins ROOM

STROKE SI ENGINE fundamentals

19 Features of two 1Hr 30 10.2,R1 CLASS

stroke cycle Mins ROOM

engines

20 Classification of 1Hr 30 7.2,R1 CLASS

scavenging Mins ROOM

systems

21 Scavenging 1Hr 30 7.2,R1 CLASS

Terminologies Mins ROOM

22 Scavenging 1Hr 30 7.2,R1 CLASS

modeling Mins ROOM

23 Intake, Exhaust, 1Hr 30 9.2,R1 CLASS

Charging and Mins ROOM

Combustion

Simulation

UNIT-5 24 1Hr 30 2.3, CLASS

DIESEL ENGINE Zero zone model Mins 2.4, ROOM

SIMULATION for combustion 2.7,

R3

25 one zone model for 1Hr 30 2.2,R3 CLASS

combustion Mins ROOM

26 multi zone model 1Hr 30 2.3,R3 CLASS

for combustion Mins ROOM

27 different heat 1Hr 30 2.3,R3 CLASS

release and heat Mins ROOM

transfer models,

28 equilibrium 1Hr 30 2.4,R3 CLASS

calculations Mins ROOM

29 Hardware 1Hr 30 2.11,R3 CLASS

components for Mins ROOM

automation

30 Simulation of 1Hr 30 2.11,R3 CLASS

engine Mins ROOM

performance.

Points Discussed:

Review of the subject Manufacture of automotive components handled last semester:

Sl. No. Agenda Details and Decisions

The Book manufacturing process and journal of

1 Reference books / materials and manufacturing process can be included in

Journals

the departmental library.

Updating of Lecture Discussion about the and also discussed regarding the

2 Notes, Session Plan preparation and completion of lecturer notes, Session

and MILA & Plan and MILA. Flipped class

Flipped class

Discussions were made regarding the various activities

3 Activities for (Scale-Up, Pogil, Jigsaw, Critical Pedagogy and Peer-

Session Plan

Led) involved in MILA and preparation, completion.

The assessment schemes for the course (Continuous

4 Internal Assessment Test, Assignments, and Oral

Assessment Scheme

Examination) were discussed and the same was decided

to be communicated to the students.

It was decided that students should know the various

5 Beyond syllabus signal processing tools available in Pro-E process

(Injection Moulding ) platform

The extent of course coverage and the question pattern

6 Question paper for Continuous Internal Assessment Test, Model

Pattern

Examination and the Final exam were discussed.

7 Also the materials to be uploaded in the E-learning

E-learning Moodle

Moodle were discussed.

Meeting ended at

Course Faculty Course Coordinator HOD/Automobile

Engineering

S.MADHU

You might also like

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsFrom EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsRating: 4 out of 5 stars4/5 (2)

- Worked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsFrom EverandWorked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsRating: 3 out of 5 stars3/5 (5)

- Chapter 3 Gas Power CyclesDocument42 pagesChapter 3 Gas Power CyclesAmirul HazzmiNo ratings yet

- 5350 RamjetDocument24 pages5350 RamjetkkonthenetNo ratings yet

- ME5631 Advanced Refrigeration and Air ConditioningDocument20 pagesME5631 Advanced Refrigeration and Air ConditioningKumaran Palani0% (3)

- Effective ListeningDocument17 pagesEffective ListeningShafiraNo ratings yet

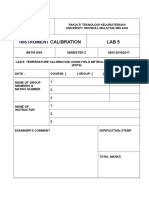

- Lab 5 - Thermocouple Temperature Calibration (PRTS)Document7 pagesLab 5 - Thermocouple Temperature Calibration (PRTS)Slim ShaddysNo ratings yet

- Teaching & Learning BiologyDocument178 pagesTeaching & Learning BiologyobsrvrNo ratings yet

- WORKBOOK in ENG 6 - 2 PDFDocument212 pagesWORKBOOK in ENG 6 - 2 PDFAnabelle Dasmarinas100% (2)

- SLAD-MXf ManualDocument10 pagesSLAD-MXf ManualReiky Aji ShaputraNo ratings yet

- Ead 536 Induction Plans For Beginning TeachersDocument7 pagesEad 536 Induction Plans For Beginning Teachersapi-337555351100% (2)

- Olympus 593 MK 610 Engine RedesignDocument13 pagesOlympus 593 MK 610 Engine RedesignIsrael Alejandro Almaguer AcevedoNo ratings yet

- Hilippine Ducational Lacement Est:: P E P TDocument30 pagesHilippine Ducational Lacement Est:: P E P TMarichanLoocNo ratings yet

- Development of The "Micro Combustor"Document6 pagesDevelopment of The "Micro Combustor"HERDI SUTANTONo ratings yet

- Simulation of The Firebox ofDocument6 pagesSimulation of The Firebox ofAli DarvishiNo ratings yet

- Heater Workbook 2006 PDFDocument16 pagesHeater Workbook 2006 PDFSandra GilbertNo ratings yet

- pp74-78 MSI10Document5 pagespp74-78 MSI10Mohamed ShabanNo ratings yet

- Thermodynamic Analysis of Spark Ignition Engines Using The Entropy Generation Minimisation MethodDocument18 pagesThermodynamic Analysis of Spark Ignition Engines Using The Entropy Generation Minimisation MethodJames Patrick TorresNo ratings yet

- Thermodynamic Modeling of Absorption Heat PumpDocument99 pagesThermodynamic Modeling of Absorption Heat PumpvidmantasNo ratings yet

- Study On The Effective Parameter of Gas Turbine Model With Intercooled Compression ProcessDocument11 pagesStudy On The Effective Parameter of Gas Turbine Model With Intercooled Compression ProcessGales SanowariNo ratings yet

- Experimental Study of Ignition of A Gasoline-Air Mixture Inside CVCCDocument12 pagesExperimental Study of Ignition of A Gasoline-Air Mixture Inside CVCCAaishi AshirbadNo ratings yet

- Nr-310303 Thermal Engineering IIDocument8 pagesNr-310303 Thermal Engineering IISrinivasa Rao G100% (1)

- Thermal EngineeringDocument8 pagesThermal Engineeringboppana sujwalNo ratings yet

- Optimization of A Pusher Type Reheating Furnace: An Adaptive Model Predictive Control ApproachDocument6 pagesOptimization of A Pusher Type Reheating Furnace: An Adaptive Model Predictive Control ApproachNoman AliNo ratings yet

- Turbocharger Test Stand With A Hot Gas Generator For High - Performance Supercharging SystemsDocument4 pagesTurbocharger Test Stand With A Hot Gas Generator For High - Performance Supercharging SystemsintelligentloveNo ratings yet

- Multi V Features A To Z - 20130716Document24 pagesMulti V Features A To Z - 20130716jaime giovanny buitrago arenasNo ratings yet

- Exp 12Document7 pagesExp 12Dhanush kumarNo ratings yet

- Temperature Control For Reheating Furnace WalkingDocument7 pagesTemperature Control For Reheating Furnace WalkingPrakash SarangiNo ratings yet

- User Com: Measuring Specific Heat CapacityDocument20 pagesUser Com: Measuring Specific Heat CapacityrubenssanNo ratings yet

- Installation and Servicing Manual: R 18 - C 18 - R 24 - C 24 R 28 - C 28 - R 35 - C 35Document3 pagesInstallation and Servicing Manual: R 18 - C 18 - R 24 - C 24 R 28 - C 28 - R 35 - C 35Admin TestNo ratings yet

- Thermodynamics (MME 2201) RCSDocument2 pagesThermodynamics (MME 2201) RCSsanyam KanungaNo ratings yet

- Numerical analysis of combustion and transient heat transfer processes in a two-stroke SI engineDocument7 pagesNumerical analysis of combustion and transient heat transfer processes in a two-stroke SI enginepurrab divakarNo ratings yet

- Adv Thermo - Workshop 4Document9 pagesAdv Thermo - Workshop 4Huanjing XieNo ratings yet

- CFD Modeling of Complete Walking Hearth Reheating FurnacesDocument10 pagesCFD Modeling of Complete Walking Hearth Reheating FurnacesFernando AraujoNo ratings yet

- Conf-2012-Nonlinear and Control System For A Turboshaft, FilhoDocument6 pagesConf-2012-Nonlinear and Control System For A Turboshaft, FilhoMohammadReza AminiNo ratings yet

- ENG4179 - 1 - Thermal - Engineering - 4 - 202212 2Document6 pagesENG4179 - 1 - Thermal - Engineering - 4 - 202212 2adamabbas1029No ratings yet

- Analysis of Inlet Air Temperature Effect On Gas Turbine Compressor PerfornanceDocument9 pagesAnalysis of Inlet Air Temperature Effect On Gas Turbine Compressor PerfornanceRafraf Ezdine100% (1)

- 78HE-1 Sr. No. 7 Examination of Marine Engineer OfficerDocument4 pages78HE-1 Sr. No. 7 Examination of Marine Engineer Officeryosh gurtNo ratings yet

- V002T02A015-99-GT-110Document17 pagesV002T02A015-99-GT-110Hiwa KhalediNo ratings yet

- Laminar Flame Speed ExperiementDocument9 pagesLaminar Flame Speed ExperiementVishnu SankarNo ratings yet

- Habibi 2019 IOP Conf. Ser. Mater. Sci. Eng. 645 012009Document7 pagesHabibi 2019 IOP Conf. Ser. Mater. Sci. Eng. 645 012009DƯƠNG CẨM TOÀNNo ratings yet

- Ideal Gas CyclesDocument8 pagesIdeal Gas CyclesMLNDG boysNo ratings yet

- 2016test 1Document1 page2016test 1Ravi Kiran HrNo ratings yet

- LAB 4 Heat Pump PDFDocument10 pagesLAB 4 Heat Pump PDFMR SASANo ratings yet

- Introduction To Universiti Teknologi Malaysia Low Speed Wind Tunnel (UTM-LST)Document14 pagesIntroduction To Universiti Teknologi Malaysia Low Speed Wind Tunnel (UTM-LST)Shuhaimi MansorNo ratings yet

- Nr210304 ThermodynamicsDocument8 pagesNr210304 ThermodynamicsSRINIVASA RAO GANTANo ratings yet

- E3.2A Performance of A Gas Turbine Engine - LabManual - v20221124Document15 pagesE3.2A Performance of A Gas Turbine Engine - LabManual - v20221124Lau YongNo ratings yet

- Ex - No: Date: Heat Balance Test On 4-Stroke Single Cylinder Diesel Engine AimDocument6 pagesEx - No: Date: Heat Balance Test On 4-Stroke Single Cylinder Diesel Engine AimPrashant Mansubrao JondhaleNo ratings yet

- Ijet 16257Document3 pagesIjet 16257Gayathri VenkatNo ratings yet

- Simulation Study of LPG Cooking BurnerDocument3 pagesSimulation Study of LPG Cooking BurnerBensinghdhas Sathiya DhasNo ratings yet

- Heat Engines: Richard Laugesen November 5, 2002Document9 pagesHeat Engines: Richard Laugesen November 5, 2002yus11No ratings yet

- Mid SemDocument2 pagesMid SemVivekananda NandamNo ratings yet

- Knock Detection in Piston Engines: Pedro Dias and Francisco BrójoDocument4 pagesKnock Detection in Piston Engines: Pedro Dias and Francisco BrójoMaxuel AntunesNo ratings yet

- 112 Design ProjectDocument15 pages112 Design Projectvtseng94No ratings yet

- Dry Contact Press Hardening Process ParametersDocument9 pagesDry Contact Press Hardening Process ParametersMickloSoberanNo ratings yet

- 2.thermal ScienceDocument9 pages2.thermal Scienceram jrpsNo ratings yet

- MET303 - Ktu QbankDocument16 pagesMET303 - Ktu QbankANAND V VNo ratings yet

- Furnace Simulation and Furnace Sizing Calculations With FurnxpertDocument3 pagesFurnace Simulation and Furnace Sizing Calculations With FurnxpertSteve WanNo ratings yet

- Manual KJ A1200Document15 pagesManual KJ A1200Manuel GeorgeNo ratings yet

- Knock Characteristics of Dual-Fuel Combustion in Diesel Engines Using Natural Gas As Primary FuelDocument8 pagesKnock Characteristics of Dual-Fuel Combustion in Diesel Engines Using Natural Gas As Primary FuelMohammad SafreedNo ratings yet

- N - AAS: 3.1 Limitations of Flame AASDocument12 pagesN - AAS: 3.1 Limitations of Flame AASGerges SamirNo ratings yet

- Object: Internal Combustion Engine LaboratoryDocument2 pagesObject: Internal Combustion Engine LaboratorySami M MaaliNo ratings yet

- 151 361 1 PBDocument7 pages151 361 1 PBElafanNo ratings yet

- Numerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityFrom EverandNumerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityNo ratings yet

- NO Reduction in Si Engine Using SCR: A Project ReportDocument3 pagesNO Reduction in Si Engine Using SCR: A Project ReportKumaran PalaniNo ratings yet

- Canteen Model 1Document1 pageCanteen Model 1Kumaran PalaniNo ratings yet

- 4.2 Hydrocarbons As The Reducing AgentDocument3 pages4.2 Hydrocarbons As The Reducing AgentKumaran PalaniNo ratings yet

- Syllab 315 DynamicsDocument3 pagesSyllab 315 DynamicsKumaran PalaniNo ratings yet

- SRM UNIVERSITY - Ramapuram Campus Cycle Test I: Department of Mechanical Engineering PME0302Document2 pagesSRM UNIVERSITY - Ramapuram Campus Cycle Test I: Department of Mechanical Engineering PME0302Kumaran PalaniNo ratings yet

- Canteen Model 1Document1 pageCanteen Model 1Kumaran PalaniNo ratings yet

- Study Skills BookletDocument38 pagesStudy Skills BookletCybeleNo ratings yet

- The Big Five Factor Theory of PersonalityDocument5 pagesThe Big Five Factor Theory of Personalityapi-315343467No ratings yet

- Civils at A Glance: EligibilityDocument5 pagesCivils at A Glance: EligibilityHarish Kumar PNo ratings yet

- Cambridge International Examinations Cambridge Ordinary LevelDocument3 pagesCambridge International Examinations Cambridge Ordinary LevelAmanNo ratings yet

- Effects of part-time jobs on ACLC GAS 11 studentsDocument8 pagesEffects of part-time jobs on ACLC GAS 11 studentsMercy Custodio BragaNo ratings yet

- Communicative Language Teaching Approach StudyDocument78 pagesCommunicative Language Teaching Approach StudyChlea Marie Tañedo AbucejoNo ratings yet

- Chapter 1 - MastersDocument11 pagesChapter 1 - MastersQueenie Gonzales-AguloNo ratings yet

- Buster KPTPDocument39 pagesBuster KPTPapi-242143006No ratings yet

- Paper T5 Managing People and Systems: Sample Multiple Choice Questions - June 2009Document6 pagesPaper T5 Managing People and Systems: Sample Multiple Choice Questions - June 2009asad27192No ratings yet

- Revised medical certificateDocument1 pageRevised medical certificateKevin White100% (1)

- The Kinds of Training Provided at OrkinDocument3 pagesThe Kinds of Training Provided at OrkinasifibaNo ratings yet

- A Contrastive Analysis of English and Arabic Present Tense Systems With Teaching and Learning ImplicationsDocument128 pagesA Contrastive Analysis of English and Arabic Present Tense Systems With Teaching and Learning ImplicationsAbdulrauf SuleimanNo ratings yet

- Kendall Instructional PlaybookDocument11 pagesKendall Instructional Playbookapi-653182023No ratings yet

- RP Assignment BriefDocument3 pagesRP Assignment BriefishmeetvigNo ratings yet

- B7 Comp WK12Document2 pagesB7 Comp WK12Thompson TitewanNo ratings yet

- Sample MT 1 MckeyDocument6 pagesSample MT 1 MckeytortomatoNo ratings yet

- MATHS 162 Study Guide 2014Document5 pagesMATHS 162 Study Guide 2014Ming ShiNo ratings yet

- Daily English Language Lesson PlanDocument4 pagesDaily English Language Lesson PlanTHIVYAH A/P THIRUCHELVAN MoeNo ratings yet

- CBT POA and ROEDocument4 pagesCBT POA and ROEDzaky AtharizzNo ratings yet

- Scopa Cog enDocument6 pagesScopa Cog endquebradasNo ratings yet

- Learning Styles: Knowing How You Learn Can Make All The DifferenceDocument9 pagesLearning Styles: Knowing How You Learn Can Make All The DifferenceCdz Ju LaiNo ratings yet

- Educational Leadership DevelopmentDocument11 pagesEducational Leadership DevelopmentSalman Yousaf100% (1)

- City & Guilds 7822 Floristry - Level 2Document2 pagesCity & Guilds 7822 Floristry - Level 2ahi2000No ratings yet

- 2 Historical and Societal Influences On Curriculum 1 1Document42 pages2 Historical and Societal Influences On Curriculum 1 1Ogie Achilles D TestaNo ratings yet

- Danielle Marie La Penna Resume Feb 2016 WebsiteDocument2 pagesDanielle Marie La Penna Resume Feb 2016 Websiteapi-310546541No ratings yet