Professional Documents

Culture Documents

Liquid Retaining Reinforced Concrete Section To BS 8007& BS 8110

Uploaded by

James Laurent0 ratings0% found this document useful (0 votes)

110 views1 pageCantilever water retaining wall

Original Title

RC8007010108-1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCantilever water retaining wall

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

110 views1 pageLiquid Retaining Reinforced Concrete Section To BS 8007& BS 8110

Uploaded by

James LaurentCantilever water retaining wall

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

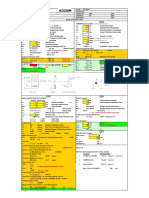

Company: NIB - PLAN Consult Ltd 2001 Techno Consultants

Address: P.O.BOX RC8007 Ver:010104

DSM User Registration No: Unregistered Copy

NIB - PLAN Consult Ltd Made by Date Page No

Project: Proposed Water Tank Tower J.L June 2017 1

Client: CHITEGO AGRO BUSINESS LTD Checked Job No Revision

Element: TANK WALL B.S 2017/1-0001

Liquid Retaining Reinforced Concrete Section to BS 8007& BS 8110

User Ref: Wall 350 Thick Datastore No 1004

Description: Wall fcu=35, W=0.2mm, h=350, c=45, dia=16, s=100, hs=175

Size & Material Properties:

2 2

Concrete strength, fcu 35 N/mm Steel strength, fy (Deformed Type 2) 460 N/mm

2

Crack width, W max 0.2 mm Steel modulus, Es 200000 N/mm

2

Restraint factor, R 0.5 Concrete modulus, Ec = 5,500 sqrt (fcu / 1.5) / 2 13284 N/mm

Section Thickness, h 350 mm Modular ratio, m = Es / Ec 15.1

2

Concrete cover, c 45 mm Average bond strength between concrete & steel, fb 2.4 N/mm

Bar size, 16 mm Direct tensile strength of immature concrete, fct 1.6 N/mm2

Bar spacing, s 100 mm Effective depth, d = h - c - / 2 297 mm

ms for steel

2

1.15 Steel area provided in b=1000 mm wide zone, As 2010 mm

Type of reinforcement Deformed

1 Type 2 Steel ratio provided over gross area, pg = As / (b h) 0.0057429 0.0013

Plain Round

Serviceability Limit State:

Moment Capacity: Steel ratio provided, p = As / (b d) 0.006768

Neutral axis depth, x = [ - m p + sqrt {(m p)2 + 2 m p} ] d 107.2 mm

Lever Arm, z = d - x / 3 261.3 mm

Distance to nearest steel bar surface, acr =sqrt[(s/2)2+(c+/2)2] - /2 64.9 mm

Strain due to the stiffening effect of concrete between cracks, as per Appendix B.4 of BS 8007:

2=kb(h-x)2/[3EsAs(d-x)] where k=1 when W max=0.2 & 1.5 when W max=0.1 0.000257

Average strain at the tension face, em=W max[1+2(acr-c)/(h-x)] / (3 acr) 0.001196

2

Stress in steel fs = Es (2+em) (d-x) / (h-x) <= fy / ms 227.2 N/mm

Service Moment Capacity, M s= fs As z 119.3 kNm/m

Applied M s 104.64 kNm/m < 119.3 kNm/m, Hence OK

Ultimate Limit State:

Moment Capacity: Neutral axis depth, x = fy As / (0.405 fcu b ms) <= 0.5 d 56.7 mm

Lever Arm z = (d - 0.45 x) <= 0.95 d 271.5 mm

Ultimate Moment Capacity, M u = 0.405 fcu b x z 218.3 kNm/m

Applied M u 160.55 kNm/m < 218.3 kNm/m, Hence OK

2

Shear Capacity: Design concrete shear stress from Table 3.8 of BS 8110: Part 1, vc 0.669 N/mm

Ultimate Shear Capacity of concrete section alone, Vc = vc b d 198.6 kN/m

Applied V c 109.87 kN/m < 198.6 kN/m, Hence OK

Minimum Reinforcement for the Control of Thermal & Shrinkage Cracking:

Concrete Surface Zone

Wall / Suspended-slab / Top of ground slab Bottom of ground slab

1.0

Wall/Suspended-slab/Top of ground slab: Surface Zone Depth, hs 175 mm

Coefficient of Thermal Expansion for mature concrete, 9.00E-06

T1, fall in temperature between the hydration peak and ambient 25 Co

T2, fall in temperature because of seasonal variations 15 Co

Effective Strain, = R (T1+T2) 0.000180

Likely maximum spacing of cracks, Smax = W max / 1111.1 mm

Steel requirements in surface zone, as per Appendix A of BS 8007:

1- Steel ratio to control crack widths, pcrw = fct / (2 fb Smax) 0.004800

2- Critical Steel ratio to distribute cracking, pcrit = fct / fy 0.003478

3- Minimum Steel ratio as per Table A.1 BS 8007, pmin 0.003500

Hence, Steel ratio required, preq 0.004800

2

Required Steel Area in 1000mm x hs deep surface zone = 1000 preq hs 840 mm

< 2010 provided, Hence OK

File: RC8007010108-1 Tab: RC8007 Date Printed: 27-06-17

You might also like

- 1 - Intro To RC Detailing - KDocument23 pages1 - Intro To RC Detailing - KAnonymous dlSmlsymHNo ratings yet

- Crack control of internal restraint in Pile Cap TopDocument5 pagesCrack control of internal restraint in Pile Cap TopSravanthi Mehar100% (1)

- Shrinkage (CEB FIP)Document4 pagesShrinkage (CEB FIP)Sabbir SiddiqueNo ratings yet

- C660 - Estimation of Autogenous Shrinkage According To EN1992-1-1Document2 pagesC660 - Estimation of Autogenous Shrinkage According To EN1992-1-1Harshana Prabhath100% (1)

- Shear Walls - An OverviewDocument6 pagesShear Walls - An OverviewTabish IslamNo ratings yet

- 23-2 Design of Floor Diaphragms MoroderDocument9 pages23-2 Design of Floor Diaphragms Morodersbarwal9No ratings yet

- Excavation CalDocument28 pagesExcavation CalngNo ratings yet

- 16 - Bruce Ireland - Joint DetailsDocument32 pages16 - Bruce Ireland - Joint DetailsTian NgNo ratings yet

- Fig. 1: Types of Shear Wall, (A) Single Storey, (B) Multi-StoreyDocument3 pagesFig. 1: Types of Shear Wall, (A) Single Storey, (B) Multi-StoreyAmer GonzalesNo ratings yet

- Slender ColumnsDocument20 pagesSlender ColumnsAnonymous N74ok75No ratings yet

- A Five Story Precast Concrete Test Building For Seismic Conditions - Design DetailsDocument8 pagesA Five Story Precast Concrete Test Building For Seismic Conditions - Design Detailswrite2eddyNo ratings yet

- Ec7 WallapDocument20 pagesEc7 WallapJJUOH85No ratings yet

- Etc - BD 28-87Document1 pageEtc - BD 28-87arun_angshuNo ratings yet

- Design For 11early Thermal CrackingDocument9 pagesDesign For 11early Thermal CrackingdhruvgokuNo ratings yet

- Guidance To The Engineering Properties of Concrete 061129Document36 pagesGuidance To The Engineering Properties of Concrete 061129Shahir ShaikhNo ratings yet

- CIRIA Restraint WallDocument5 pagesCIRIA Restraint WallMajdoline SadeddineNo ratings yet

- Repair & Retrofitting of Distressed StructuresDocument26 pagesRepair & Retrofitting of Distressed StructuressahilkaushikNo ratings yet

- Minimum Thickness For Ductile RC Structural Walls: Y.H. Chai, S.K. KunnathDocument12 pagesMinimum Thickness For Ductile RC Structural Walls: Y.H. Chai, S.K. KunnathDavid FloresNo ratings yet

- CHALMERS (Fibre-Reinforced Concrete For Industrial Construction PDFDocument162 pagesCHALMERS (Fibre-Reinforced Concrete For Industrial Construction PDFsochiva pramestiNo ratings yet

- Seismic Design To EC8 - L3Document18 pagesSeismic Design To EC8 - L3Chamil MahagamageNo ratings yet

- Seismic Design PrinciplesDocument21 pagesSeismic Design PrinciplesmaheshNo ratings yet

- Calculation of effective section properties for a cold-formed lipped channel section in bendingDocument10 pagesCalculation of effective section properties for a cold-formed lipped channel section in bendingAnca SimaNo ratings yet

- Conc. Folded SlabDocument17 pagesConc. Folded SlabBenedict CharlesNo ratings yet

- Coupling Beam DesignDocument14 pagesCoupling Beam DesignkibzeamNo ratings yet

- DOS Web Cleat ConnectionDocument31 pagesDOS Web Cleat ConnectionArfat PatelNo ratings yet

- Seismic Design ConsiderationsDocument5 pagesSeismic Design ConsiderationserleosNo ratings yet

- CPCI Manual 5 - Chapter 7 - Product Information and CapabilityDocument61 pagesCPCI Manual 5 - Chapter 7 - Product Information and CapabilitymaharjankritamNo ratings yet

- Pinned Joint EC3Document180 pagesPinned Joint EC3Lipuvka0% (1)

- Interface shear strength at wall baseDocument1 pageInterface shear strength at wall basemathuNo ratings yet

- EC2 - Concrete Centre (Flat Slabs - 2007)Document21 pagesEC2 - Concrete Centre (Flat Slabs - 2007)florincinciNo ratings yet

- Structural Design - Post Tensioned Slab Design1Document12 pagesStructural Design - Post Tensioned Slab Design1Chamil MahagamageNo ratings yet

- Shear WallDocument238 pagesShear Wallri olNo ratings yet

- Seismic Response of Wood-Frame Construction: Part B: The Role of Wood-Framed DiaphragmsDocument4 pagesSeismic Response of Wood-Frame Construction: Part B: The Role of Wood-Framed Diaphragmsrmm99rmm99No ratings yet

- Punching ShearDocument4 pagesPunching ShearErnest NavarroNo ratings yet

- Sway Frame Steel Column DesignDocument1 pageSway Frame Steel Column DesignChirianu MarianNo ratings yet

- Crack Width Analysis Software VerificationDocument8 pagesCrack Width Analysis Software VerificationSuhail Ahamed100% (1)

- End Plates - Worked Examples With Partial Depth End Plate - Example 5Document1 pageEnd Plates - Worked Examples With Partial Depth End Plate - Example 5Kimutai Kirui AlphonceNo ratings yet

- Bolted Bracket DesignDocument2 pagesBolted Bracket Designharoub_nasNo ratings yet

- Assignment #4Document2 pagesAssignment #4Aly Arquillano JrNo ratings yet

- Shear Wall DesignDocument8 pagesShear Wall DesignkiranNo ratings yet

- TGN - 20-L2-Designing and Detailing of Lintels in Masonry WallsDocument3 pagesTGN - 20-L2-Designing and Detailing of Lintels in Masonry Wallsalberto5791No ratings yet

- Lecture 5 FoundationsDocument44 pagesLecture 5 Foundationsbeddows_sNo ratings yet

- 2.pile - Cap.design ColumnsDocument9 pages2.pile - Cap.design Columnstaha abu el hanaNo ratings yet

- Strengthening Design of Concrete Beams by Adition of Steel PlatesDocument10 pagesStrengthening Design of Concrete Beams by Adition of Steel PlatesgparratNo ratings yet

- Understanding The Complexities of Designing Diaphragms in Buildings For EarthquakesDocument21 pagesUnderstanding The Complexities of Designing Diaphragms in Buildings For Earthquakesjunhe898No ratings yet

- Watertight Roof Slabs Guidelines & General PrinciplesDocument29 pagesWatertight Roof Slabs Guidelines & General PrinciplesGoanengineerNo ratings yet

- BW - Calculation Sheet - Rev01Document15 pagesBW - Calculation Sheet - Rev01Ernest NavarroNo ratings yet

- Calculation of raft foundation design sheetDocument19 pagesCalculation of raft foundation design sheetMilan KarkiNo ratings yet

- FOOTING ANALYSISDocument5 pagesFOOTING ANALYSISBunkun15No ratings yet

- Double Tee Ridge BeamDocument3 pagesDouble Tee Ridge BeamhuyxpkissNo ratings yet

- Ba2487 PDFDocument19 pagesBa2487 PDFHazel Liow HYNo ratings yet

- TGN Level 2 Note 9 Designing A Reinforced Concrete Retaining Wall - Oct2016Document4 pagesTGN Level 2 Note 9 Designing A Reinforced Concrete Retaining Wall - Oct2016Lee WhiteheadNo ratings yet

- MasterSeries Student-Steel & Concrete FrameDocument180 pagesMasterSeries Student-Steel & Concrete FrameekaNo ratings yet

- 0 4 Reinforced Concrete Slab Design Example 1 UnfilledDocument2 pages0 4 Reinforced Concrete Slab Design Example 1 UnfillednsureshbabuNo ratings yet

- IAG water tank wall section designDocument1 pageIAG water tank wall section designchristopherNo ratings yet

- BS5400-R-C-Design-With-Crack-Width SampleDocument1 pageBS5400-R-C-Design-With-Crack-Width SampleAlden CayagaNo ratings yet

- 5.0 Design of Top Ring BeamDocument3 pages5.0 Design of Top Ring BeamJayNo ratings yet

- Crack WidthDocument21 pagesCrack WidthBalaji HariNo ratings yet

- 6+640 Lhs Shop DrawingDocument3 pages6+640 Lhs Shop DrawingJames LaurentNo ratings yet

- NSSF Form 1Document1 pageNSSF Form 1James Laurent100% (1)

- Updated STDs2022Document4 pagesUpdated STDs2022James LaurentNo ratings yet

- New ApproachDocument4 pagesNew ApproachJames LaurentNo ratings yet

- Base Line ConditionDocument11 pagesBase Line ConditionJames LaurentNo ratings yet

- Detail For Road DesignDocument395 pagesDetail For Road DesignJames LaurentNo ratings yet

- Tanzania-Standard Specifications For Roadworks 2000Document1 pageTanzania-Standard Specifications For Roadworks 2000James LaurentNo ratings yet

- 4.3. Landscape and Physical Features 4.3.1Document7 pages4.3. Landscape and Physical Features 4.3.1James LaurentNo ratings yet

- 14 - Long Cattle Trough Cattle Trough PlanDocument1 page14 - Long Cattle Trough Cattle Trough PlanJames LaurentNo ratings yet

- General Work PlanDocument2 pagesGeneral Work PlanJames LaurentNo ratings yet

- Eia-Special Prog GRP OneDocument18 pagesEia-Special Prog GRP OneJames LaurentNo ratings yet

- REGION Budget and Action Plan For YearDocument1 pageREGION Budget and Action Plan For YearJames LaurentNo ratings yet

- Design of Low Head Weirs for Great Ruaha RiverDocument2 pagesDesign of Low Head Weirs for Great Ruaha RiverJames LaurentNo ratings yet

- Lecture 3 The Traffic StreamDocument40 pagesLecture 3 The Traffic StreamJames LaurentNo ratings yet

- Esilalei Eia Report - DraftDocument29 pagesEsilalei Eia Report - DraftJames LaurentNo ratings yet

- Survey Data Points for Land MappingDocument517 pagesSurvey Data Points for Land MappingJames LaurentNo ratings yet

- Design of Low Head Weirs for Great Ruaha RiverDocument2 pagesDesign of Low Head Weirs for Great Ruaha RiverJames LaurentNo ratings yet

- Topic 2 - Human Factors in Road TrafficDocument50 pagesTopic 2 - Human Factors in Road TrafficJames LaurentNo ratings yet

- Cross-Section Around Existing BCDocument6 pagesCross-Section Around Existing BCJames LaurentNo ratings yet

- Two-Lane Highway Capacity and Level of Service AnalysisDocument36 pagesTwo-Lane Highway Capacity and Level of Service AnalysisJames LaurentNo ratings yet

- Design of Low Head Weirs for Great Ruaha RiverDocument2 pagesDesign of Low Head Weirs for Great Ruaha RiverJames LaurentNo ratings yet

- Providing For The Safety of Pedestrians and PWD:The Most Vulnerable Road UsersDocument35 pagesProviding For The Safety of Pedestrians and PWD:The Most Vulnerable Road UsersJames LaurentNo ratings yet

- Civil Engineers: Practical Training Guidelines ForDocument7 pagesCivil Engineers: Practical Training Guidelines ForJames LaurentNo ratings yet

- Surface Old DataDocument324 pagesSurface Old DataJames LaurentNo ratings yet

- Factors that Influence Slope StabilityDocument21 pagesFactors that Influence Slope StabilityJames LaurentNo ratings yet

- FNDT DetailDocument11 pagesFNDT DetailJames LaurentNo ratings yet

- Slope Stability Vol2Document189 pagesSlope Stability Vol2James LaurentNo ratings yet

- EOT SupervisionDocument2 pagesEOT SupervisionJames LaurentNo ratings yet

- Site Visit FormDocument1 pageSite Visit FormJames LaurentNo ratings yet

- Tanroads TaboraDocument3 pagesTanroads TaboraJames LaurentNo ratings yet

- Oxygen USPDocument2 pagesOxygen USPMartha Lucia Roa FonsecaNo ratings yet

- Instruction Manual Fisher 657 Diaphragm Actuator Sizes 30 30i Through 70 70i 87 en 122366Document32 pagesInstruction Manual Fisher 657 Diaphragm Actuator Sizes 30 30i Through 70 70i 87 en 122366APE MKTNo ratings yet

- Va80 PDFDocument4 pagesVa80 PDFomar leonNo ratings yet

- IJCSEIERDFEB20174Document10 pagesIJCSEIERDFEB20174TJPRC PublicationsNo ratings yet

- MAP Demo ExercisesDocument34 pagesMAP Demo ExercisesNancy HernandezNo ratings yet

- Comment To RTDocument32 pagesComment To RTLim Wee BengNo ratings yet

- Notification ACF One Range Officer RajasthanDocument2 pagesNotification ACF One Range Officer RajasthanAshok SainiNo ratings yet

- Emulsion BreakerDocument19 pagesEmulsion BreakerNovrie50% (2)

- Blueendo MorcellatorDocument7 pagesBlueendo MorcellatorLia GuslianiNo ratings yet

- Clements High School Celebrating 30 Years of Academic ExcellenceDocument22 pagesClements High School Celebrating 30 Years of Academic ExcellenceclementsrangersNo ratings yet

- 2.3 Drawing Operations: Need To See If It Really Works For All Tasks, and If Not Then Get Rid of ItDocument1 page2.3 Drawing Operations: Need To See If It Really Works For All Tasks, and If Not Then Get Rid of ItTrogo BoNo ratings yet

- Handout t1124f 1511 3869 Onb Bus Das Srs TNDocument37 pagesHandout t1124f 1511 3869 Onb Bus Das Srs TNlequangthongNo ratings yet

- Ult Studio Config 71Document18 pagesUlt Studio Config 71JoséGuedesNo ratings yet

- Dust Collection System Explosion Hazards and ProtectionDocument8 pagesDust Collection System Explosion Hazards and ProtectionsguariniNo ratings yet

- SY155WDocument4 pagesSY155WLutfi DstrNo ratings yet

- HandRail Specsgf For CfvdrfsDocument3 pagesHandRail Specsgf For CfvdrfsTarek TarekNo ratings yet

- AutoCAD CommandsDocument59 pagesAutoCAD Commandsamalendu_biswas_1No ratings yet

- History Spring08Document7 pagesHistory Spring08Anonymous 9VcxlFErfNo ratings yet

- The basics of biomass roofing materialsDocument35 pagesThe basics of biomass roofing materialsLakshmi PillaiNo ratings yet

- Zit 64 BVDocument12 pagesZit 64 BVVT86No ratings yet

- CC 848815325Document76 pagesCC 848815325patopickNo ratings yet

- The Writer Is A Young Boy Who Is Taken To The Railway Station To See Soldiers Departing For The Second World WarDocument2 pagesThe Writer Is A Young Boy Who Is Taken To The Railway Station To See Soldiers Departing For The Second World WarFariha RahmanNo ratings yet

- An Experimental Comparative Review - PK NanavatiDocument9 pagesAn Experimental Comparative Review - PK NanavatiPurvesh NanavatiNo ratings yet

- Omop Etl Template v4.0Document17 pagesOmop Etl Template v4.0kartikb60100% (1)

- Vena SIF Piping CalculationDocument5 pagesVena SIF Piping CalculationPratap KollapaneniNo ratings yet

- Advanced MICS Platform with 28 ModulationsDocument4 pagesAdvanced MICS Platform with 28 ModulationsKIRAN SONICSNo ratings yet

- A Case Study On The Unique Features of The Leading Database SystemsDocument2 pagesA Case Study On The Unique Features of The Leading Database SystemsLiezheel Mynha AlejandroNo ratings yet

- Instruction Manual - Digital Drybath - ENDocument19 pagesInstruction Manual - Digital Drybath - ENAlain ManceraNo ratings yet

- Planning of Electrical NetworksDocument32 pagesPlanning of Electrical NetworksSerge RINAUDONo ratings yet

- Catalogo General KOBA 1000 - e - 2012revDocument21 pagesCatalogo General KOBA 1000 - e - 2012revTECNIMETALNo ratings yet