Professional Documents

Culture Documents

345B II Prod Bulletin (TEJB6083)

Uploaded by

suwarjitechnicCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

345B II Prod Bulletin (TEJB6083)

Uploaded by

suwarjitechnicCopyright:

Available Formats

Caterpillar Product Information

Product Bulletin

December 1999

Cat 345B Series II

Excavator

For Dealer Sales Personnel

Table of Contents

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Competitors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Productivity and Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Radiator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Hydraulic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fine Swing Control (Attachment). . . . . . . . . . . . . . . . . . . . 9

Swing Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fuel Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Durability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Travel Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Travel Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cross Roller Bearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Bumpers (Attachment). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Versatility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Front Linkage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Booms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Sticks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Buckets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Bucket Linkage and Linkage Pins. . . . . . . . . . . . . . . . . . . 15

Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Undercarriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operator Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

B-Series Cab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

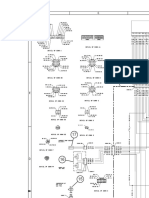

Instrument Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Consoles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Travel Pedals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Serviceability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Service Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Transportability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Summary of 345B Series II Benefits and Features . .Back cover

2 TEJB6083 Cat 345B Series II Excavator December 1999

Overview

The Cat 345B Series II is designed to give customers improved Introduction

performance and productivity in a 45 metric ton machine.

Specifically, the 345B Series II has increased horsepower,

hydraulic pump flow and swing torque when compared to the

345B. The Cat 345B Series II has the highest engine horsepower

and hydraulic power in its class, and meets Environmental

Protection Association (EPA) Tier II emission regulations.

The Cat 345B earned a favorable reputation against the competition

for productivity, economic performance and reliability. The

Cat 345B Series II differentiates itself further with higher levels

of performance and productivity.

December 1999 TEJB6083 Cat 345B Series II Excavator 3

Overview

Positioning In the Cat 300B excavator family, the 345B Series II fits between

the 330B and the 365B L machines. The 345B Series II is ideal for

sewer and water applications and heavy construction. The table

below compares brief specifications and dimensions of the

Cat 330B L, 345B L, 345B L Series II and 365B L.

330B L 345B L 345B L 365B L

Series II

Net Flywheel kW 165 216 239 287

Power hp 222 290 321 385

Operating Weight kg 34 660 44 870* 45 240* 65 900

lb 76,300 98,800* 99,650* 145,100

Engine Model 3306TA 3176C 3176C 3196

ATAAC ATAAC ATAAC

Displacement L 10.5 10.3 10.3 12

in3 638 630 630 730

Rated Engine Speed 1800 2000 2000 2000

Hydraulic Pump

Output @ L/min 2 x 240 2 x 320 2 x 360 2 x 400

Rated RPM G/min 2 x 63 2 x 85 2 x 95.1 2 x 106

Maximum Travel kmh 4.4 4.4 4.4 4.1

Speed mph 2.7 2.7 2.7 2.6

Bucket Capacity m3 0.7-2.6 1.1-3.4 1.1-3.4 1.2-4.6

yd3 1.0-3.5 1.4-4.5 1.4-4.5 1.6-6.0

Overall Track m 5.02 5.36 5.36 5.86

Length ft in 16'6" 17'7" 17'7" 19'3"

Track Gauge m 2.59 2.74** 2.74** 2.75

ft in 8'6" 9'0"** 9'0"** 9'0"

Fuel Tank L 560 600 720 800

Capacity US Gal 148 159 190 211

**Fixed gauge version add 2155 kg (4750 lb) for variable gauge.

**345B/345B II track gauge shown for fixed gauge version gauge for variable gauge

version is: 2.39 m (7'10") retracted and 2.89 m (9'6") extended.

4 TEJB6083 Cat 345B Series II Excavator December 1999

Overview

The primary 345B L Series II competitors in the 45 metric ton Competitors

size class are the Komatsu PC400-6 LC, Hitachi EX450-5 LC

(including the John Deere 450LC and Fiat Hitachi FH450-3) and

the Liebherr R954B.

Caterpillar

345B L Komatsu Hitachi Liebherr

Metric (English) Series II PC400-6 LC EX450-5 LC R954B

Operating Weight kg 45 200* 42 600 45 600 47 200

(lb) (99,650)* (95,150) (100,500) (103,950)

Flywheel Power kW (hp) 239 (321) 228 (306) 224 (301) 210 (281)

Bucket Capacity Range

(heaped) cubic meter 1.1-3.4 0.96-2.29 1.36-2.28 1.3-3.9

(cubic yard) (1.4-4.5) 1.25-3.00 (1.78-2.98) (1.7-5.1)

Engine Model Cat 3176C Komatsu Isuzu Liebherr

ATAAC SA6D125E-2 A-6RB1TQA D926 TI-E

Rated Engine Speed rpm 2000 2050 2000 2000

Displacement liter (cubic inch) 10.3 (630) 11.04 (674) 13.7 (838) 10.0 (610.3)

Hydraulic Pump Output at

Rated RPM liter per minute 2 x 360 2 x 326 2 x 360 2 x 350

(gallons per minute) (2 x 95.1) (2 x 86) (2 x 95.1) (2 x 92.5)

Relief Valve Settings kPa (psi)

Boom/Stick/Bucket 34 340 (4,980) 34 795 (5,050) 29 450 (4,270) 35 000 (5076)

Travel 34 340 (4,980) 34 795 (5,050) 34 340 (4,980) 35 000 (5076)

Swing 28 440 (4,130) 27 950 (4050) 38 400 (5568)

Pilot 3930 (570) 2940 (430)

Maximum Travel Speed km/h (mph) 4.4 (2.7) 5.5 (3.4) 5.5 (3.4) 5.0 (3.1)

Width Standard Track Shoe mm (in) 750 (30") 700 (28") 750 (30") 750 (30")

Overall Track Length meter (ft) 5.36 (17'7") 5.36 (17'7") 5.47 (17'11") 5.38 (17'8")

Track Gauge meter (ft) 2.74 (9'0")** 2.74 (9'0") 2.39 - 2.90 2.90 (9'6")

(7'10" - 9'6")

variable

Fuel Tank Refill Capacity liter 720 605 605 NA

(U.S. Gal) (190) (160) (160)

**Fixed gauge version add 2155 kg (4750 lb) for variable gauge.

**345B/345B II track gauge shown for fixed gauge version gauge for variable gauge version is: 2.39 m (7'10") retracted and

2.89 m (9'6") extended.

December 1999 TEJB6083 Cat 345B Series II Excavator 5

Productivity and Performance

Engine The Cat 345B Series II offers the highest engine horsepower of any

machine in its class, and 11 percent higher engine horsepower than

the Cat 345B. This extra horsepower contributes to the increased

productivity and performance of the 345B Series II.

Cat 3176C ATAAC engine

Manufacturer Caterpillar Caterpillar Komatsu Hitachi Liebherr

Model 345B 345B PC400-6 EX450-5 R954B

Series II

Engine output kW 216 239 228 224 210

PS 294 325 310 305 285

HP 290 321 306 301 281

Power Index 90% 100% 95% 94% 88%

The Cat 345B Series II utilizes the Cat 3176C ATAAC engine.

Cat 3100 series engines are designed for increased power output,

fuel efficiency and reliability. The 3176C uses an Advanced Diesel

Engine Module (ADEM II) fuel system for optimal fuel injection

control, high fuel efficiency and wide ambient temperature

operation. The ADEM II also minimizes emissions, helping the

345B Series II comply with EPA Tier II emissions regulations.

6 TEJB6083 Cat 345B Series II Excavator December 1999

Productivity and Performance

Engine Performance

345B 345B Series II

Machine Model Cat 3176C ATAAC Cat 3176C ATAAC

Engine Model DITA DITA

Displacement 10.3 liter (630 in3) 10.3 liter (630 in3)

Bore 125 mm (4.92 in) 125 mm (4.92 in)

Stroke 140 mm (5.51 in) 140 mm (5.51 in)

Rated Speed 2000 rpm 2000 rpm

Hi-Idle Speed 2200 rpm 2200 rpm

AEC Speed Auto 1300 rpm 1300 rpm

Rated Power (Net) 216 kW (294 PS) (290 hp) 239 kW (325 PS) (321 hp)

Max. Torque 126 kg-m (911 ft-lb) 140 kg-m (1012 ft-lb)

Max. Altitude 4600 m (15,000 ft) 4600 m (15,000 ft)

Displacement/Power 0.048 l/kW (2.17 in3/hp) 0.043 l/kW (1.96 in3/hp)

To accommodate higher engine power, the 345B Series II radiator Radiator

and oil cooler sizes have increased by approximately 10 percent.

These changes result in higher ambient temperature capability

for the standard machine (up to 45C [113F] for Akashi-sourced

machines and up to 48C [118F] for Aurora-sourced). Like the

345B, the 345B Series II radiator fan is hydraulically driven which

allows the radiator to be isolated from the engine compartment for

improved cooling efficiency and reduced sound levels. However,

new for the 345B Series II is a variable speed fan, where speed

varies in response to coolant temperature to reduce fuel

consumption during cooler ambient conditions. A coolant level

sensor is located inside the radiator reserve tank. An icon on the cab

monitor lights up if the coolant falls below a predetermined level.

Radiator

December 1999 TEJB6083 Cat 345B Series II Excavator 7

Productivity and Performance

Hydraulic System The 345B Series II hydraulic system is an open-center two-pump

system featuring new Rexroth pumps. The new Rexroth pumps

increase hydraulic performance, with 12.5 percent more pump

flow than the 345B. Redesigned control valve stems accommodate

the higher flow rates and maintain the excellent controllability of

the 345B.

Cat hydraulic components are designed to minimize energy loss.

The 345B Series II hydraulic system, with new Rexroth pumps

and redesigned control valve stems, minimizes hydraulic pressure

loss through the main control valve. Energy output is transferred

efficiently to the implements, optimizing performance and

productivity.

Rexroth pump

Hydraulic Pump Performance

Manufacturer Caterpillar Caterpillar Komatsu Hitachi Liebherr

Model 345B 345B PC400-6 EX450-5 R954

Series II

Main Relief kPa 34 340 34 340 34 795 29 450 35 000

Pressure (psi) (4980) (4980) (5050) (4270) (5076)

Pump Flow liter/min 2 x 320 2 x 360 2 x 326 2 x 360 2 x 350

(GPM) (2 x 85) (2 x 95.1) (2 x 86) (2 x 95.1) (2 x 92.5)

The 345B Series II hydraulic system is a cross-sensing system.

With this system, either of the two hydraulic pumps can absorb

100 percent of engine power, if the other pump is unloaded ensuring

maximum utilization of the available engine power for high

production. The cross-sensing system also uses a hydraulic

control to ensure faster response and smoother flow increases

for improved controllability.

8 TEJB6083 Cat 345B Series II Excavator December 1999

Productivity and Performance

Fine Swing Control (Attachment)

Fine Swing Control is available for the 345B Series II as an

attachment. Fine Swing Control is ideal for pipe laying. Stops and

starts are smoother, enhancing operator controllability of heavy

loads. The control switch for Fine Swing control is located in the

right control panel.

Fine swing control switch

December 1999 TEJB6083 Cat 345B Series II Excavator 9

Productivity and Performance

Swing Drives Swing acceleration and swing torque greatly affect cycle times

and productivity. The 345B Series II uses larger swing drives

and motors that increase swing torque by 16 percent compared to

345B. The higher swing torque increases swing acceleration and

results in excellent swing effectiveness. Increased swing torque

improves productivity in truck loading applications. In trenching

applications, high swing torque enables the operator to excavate

sidewalls more effectively.

Swing drives

Swing Torque and Swing Speed

345B 345B Series II

Swing Motor Capacity rev x 2/99.2 cc (rev x 2/6.1 in3) rev x 2/145.9 cc (rev x 2/8.9 in3)

Swing Speed 9.3 rpm 8.6 rpm

Swing Torque 128 000 Nm (94,700 lb-ft) 149 000 Nm (110,300 lb-ft)

Fuel Tank The 345B Series II fuel tank holds 720 L (190 US Gal) of fuel

a 20 percent increase in fuel volume when compared to the 345B

fuel tank [600 L (159 US Gal)]. The additional fuel capacity

gives operators 13 hours of continuous operation for increased

production time.

10 TEJB6083 Cat 345B Series II Excavator December 1999

Durability

The 345B Series II provides 5 percent more travel speed than the Travel Speed

345B, while maintaining the highest drawbar pull in the 45 metric

ton machine class.

The 345B Series II features new travel motors that are manufactured Travel Motors

by Caterpillar in Joliet, IL USA. The new travel motors and final

drives are more compact, minimizing the distance that they extend

beyond the width of the track shoes. This reduces the chance of

travel motor contact with rocks, debris and other obstacles in the

working environment, significantly improving reliability.

More rigid covers also protect the travel unit.

The two-speed axial piston hydraulic travel motors provide the

345B Series II with drive power that results in 5 percent more

travel speed than the 345B. Speed selection is automatic when the

operator selects the high-speed position. This enables the machine

New travel motor

to automatically change between high and low speeds depending

on drawbar pull requirements. Automatic travel speed changes

are computer controlled. This system is hydraulically actuated

and provides a momentary lag in speed change. This lag prevents

constant changes in speed due to varying drawbar pull requirements

associated with working conditions with frequent slope changes.

The new travel motors have internal disk brakes and biodegradable

oil may be used without any modifications to the motors.

Travel Motor Performance

345B 345B Series II

High Speed Low Speed High Speed Low Speed

Motor Capacity cc/rev 160 225 175 225

in3/rev 9.75 13.73 10.68 13.73

Travel Speed km/h 4.4 3.2 4.4 3.6

mph 2.7 2.0 2.7 2.2

Max. Drawbar Pull kN 322 331

lb 72,390 74,380

December 1999 TEJB6083 Cat 345B Series II Excavator 11

Durability

Cross Roller Bearing The 345B Series II uses a cross roller bearing for the swing bearing

that includes cylindrical rollers with large contact areas for increased

stability. Cross roller bearings are highly impact-resistant and have

less freeplay to reduce machine pitch during boom down operation.

Cross Roller Bearing Ball Bearing

Cross roller bearing

Bumpers (Attachment) Recognizing both customer and Cat Dealer requests, bumpers are

now available for the 345B Series II as an attachment. Bumpers

help protect the upperstructure from the work environment

minimizing contact to the service doors and other protective

panels on the upperstructure.

Optional bumpers

12 TEJB6083 Cat 345B Series II Excavator December 1999

Versatility

Caterpillar offers two boom and six stick options for the Front Linkage

345B Series II, for maximum flexibility when equipping a machine

to meet a customers specific requirements. Caterpillar offers

specialized linkages to effectively meet and provide exceptional

performance in specific applications. Offerings vary by market

area; refer to local specalogs and price lists for available boom

and sticks.

Booms

Booms for the 345B Series II are made of high tensile steel with

large cross-sections and baffles for improved strength and reduced

weight. Forged steel is used in high-stress areas (boom foot and

boom cylinder connection) for increased strength. All Cat booms

are stress-relieved to remove internal stress concentrations caused

by welding, improving life and reducing weight.

Reach Boom provides a maximum digging envelope

Mass Boom provides maximum excavating power and bucket

capacity

Sticks

Like the booms, 345B Series II sticks are made of high tensile steel

with a box-section design and baffles for strength, durability and

reduced weight. A lighter weight stick enables the machine to be

matched with a larger capacity bucket for increased lifting capacity

and payload. All Cat sticks use cast steel at the stick to boom

connection and reinforced thick bottom plates to prevent damage

from the load when the bucket is curled. All Cat sticks are stress-

relieved for improved life and reduced weight.

December 1999 TEJB6083 Cat 345B Series II Excavator 13

Versatility

Front-Linkage Combinations and Applications

Availability

Boom Stick Application Akashi Aurora

Reach R4.8 Maximizes reach and depth for trenching. NA Yes

6.9 m

R3.9 Convenient for a variety of work, such as trenching, Yes Yes

truck loading and clean-up.

R3.35 Most versatile front linkage. Good fit for 11 to 20 ton dump Yes Yes

trucks in terms of reach and bucket capacity. Also suited for

many trenching applications.

R2.9 Large bucket sizes. Also, good stability for hammer work. Yes NA

Reach Same sticks as above. For use in severe applications. Yes Yes

6.9 m

H/D

Mass M3.0 Provides a limited digging envelope with large buckets and high Yes Yes

6.55 m force levels.

M2.5 Intended for mass earthmoving applications. Buckets are very Yes NA

large with high force levels.

Buckets

Four bucket families are available for the 345B Series II (F, T, U

and G). The T and U family buckets are designed specifically for

the 345B Series II. The F and G buckets may also be used with the

Cat 350.

The T and F family buckets are designed to be used with the

Reach boom; the U and G family buckets with the Mass boom.

Also, T family buckets are interchangeable with F family buckets;

U family buckets are interchangeable with G family buckets.

Bucket offerings vary by source plant and market area. Refer to

local specalogs and price lists for available buckets.

Each 300 B-Series bucket is equipped with a bucket flop

adjustment mechanism that enables the operator or service

technician to easily adjust the play in the joint between the stick

and bucket.

Bucket adjustment mechanism

14 TEJB6083 Cat 345B Series II Excavator December 1999

Versatility

Bucket Linkage and Linkage Pins

On the 345B Series II, the bucket linkage includes the bucket

cylinder, idler links and power link. There are two types of bucket

linkages, one each for the Reach and Mass booms. Bucket linkage

depends on stick selection. All pins used in 300 series excavator

front linkages have a think chrome plate for high wear and corrosion

resistance. The diameter of each pin is made as large as possible to

evenly distribute the shear and side loads from the stick for longer

pin and stick life.

Bucket linkage

Compatibility

The 345B Series II reach and mass excavation booms are

compatible booms can be changed without altering the base

of the machine. However, sticks must match a particular boom

reach sticks with the reach boom; mass sticks with the mass

excavation boom. There is not any compatibility between reach

sticks and mass sticks.

For bucket selection, T and F family buckets are used with the reach

boom. The U and G family buckets are used with the mass boom.

Three undercarriage types are available for the 345B Series II: Undercarriage

Standard fixed gauge (STD)

Long fixed gauge (L)

Long variable gauge (LV)

A regional, extra-wide undercarriage is available for material

handling applications.

Standard Undercarriage Types

Stability Turnability Lifting Availability

over over over over

overall front side swing overall front side Flotation Akashi Aurora

STD B C B A B C B B Yes No

L A A B B A A B A Yes Yes

LV A A A A A A A A Yes Yes

A = Excellent B = Very Good C = Good

December 1999 TEJB6083 Cat 345B Series II Excavator 15

Versatility

The 345B Series II has three track shoe configurations, each with

varying ground pressures.

Shoe Width and Ground Pressure

Shoe Width 345B Series II 345B Series II L 345B Series II LV

600 mm (24") 80 kPa (11.6 psi) 76 kPa (11.0 psi) 82 kPa (11.9 psi)

Triple Grouser

750 mm (30") 66 kPa (9.6 psi) 62 kPa (9.0 psi) 67 kPa (9.7 psi)

Triple Grouser

900 mm (35") 56 kPa (9.1 psi) 53.5 kPa (7.7 psi) 55 kPa (8.0 psi)

Triple Grouser

The availability of undercarriage versions varies by marketing area:

Standard Long Long

fixed gauge fixed gauge variable gauge

NACD Yes Yes

SCM Yes Yes

CAPL Yes Yes

CofA Yes Yes

CACo Yes Yes

16 TEJB6083 Cat 345B Series II Excavator December 1999

Operator Station

The 345B Series II cab is essentially the same as the 345B. B-Series Cab

It offers operators excellent visibility and comfort along with

superb controls. There are five different cab variations available

to meet regional requirements. (Refer to the FPIR, section 12.7

for more information.) The 345B Series II cab uses four rubber

mounts or viscous cab mounts with silicone oil to absorb vibrations

and limit sound levels inside the cab. The KAB524 high-back seat is

standard for NACD and CACo., and may be ordered as an

attachment for CAPL, CofA, SCM and CCL.

Vandalism protection is available as an attachment. Vandalism

guards may be folded and stored on the battery cover. A Falling

Objects Guarding System (FOGS) may be required in some

applications. This attachment is designed to meet legal requirements

for FOGS. It is not a Roll Over Protection Structure (ROPS).

345B Series II cab

Visibility to the work area is critical for the operator. All cabs have

laminated upper front windows and tempered lower front windows.

All other windows may be tempered glass or polycarbonate.

The right side window is not obstructed by a cab pillar, providing

adequate lighting and good visibility to the work area. The rear

window can be released with a latch and may be used as an alternate

exit. The upper window on the cab door slides open for ventilation

and communication with others on the job site. The lower door and

left rear door windows are fixed, providing good visibility to the

work area. A large polycarbonate skylight with sliding or roll-up

sunshade provides natural lighting and overhead viewing.

The wiper attaches to the right cab pillar or overhead structure

for better operator viewing to the work area. (An additional lower

windshield wiper is standard for NACD and CACo.) A sun visor

Forward viewing area

and rain protector are available as attachments for the front

windshield in some markets.

December 1999 TEJB6083 Cat 345B Series II Excavator 17

Operator Station

Instrument Panel The 345B Series II features the same instrument panel as other

Cat B-Series excavators (with the exception of the 365B). A high-

contrast color liquid crystal (LCD) screen changes color based on

the degree of urgency. An action lamp comes ON when coolant

temperature, hydraulic oil temperature or engine oil pressures reach

critical levels. The screen features gauges for fuel level, hydraulic

oil temperature and engine coolant temperature. The panel also

includes a six-digit seven-segment display that normally indicates

throttle position and clock, but can also display diagnostic codes,

calibration information and hammer mode setting.

Consoles The right and left consoles in the 345B Series II cab are similar

to those in other B-Series machines. The right console contains

the throttle dial; three-position key switch (activate the prestart

monitoring function by leaving the key in the ON position

for more than two seconds); light switch; washer switch; fine

swing control (attachment); auxiliary switches for attachments;

and back-up switches for the EPC and electronic governor.

The left console includes the control panel for the automatic

climate control air conditioning system; space for an optional

radio (for regions where this option is available) and the hydraulic

activation control lever for locking out pilot pressure to the control

levers and travel pedals.

Right console

Hydraulic lock lever locked

Left console

Hydraulic lock lever unlocked

18 TEJB6083 Cat 345B Series II Excavator December 1999

Operator Station

The 345B Series II features two travel pedals (with attached levers) Travel Pedals

that control the travel motors. The left pedal controls the left motor;

the right pedal controls the right motor. To increase operator foot

space, the pedals are located as far forward as possible and are

shaped to make travel easier during fine control work. A large

footrest is located to the side of each pedal. A single pedal for

straight (forward and reverse) travel is available as an attachment.

Travel pedals

December 1999 TEJB6083 Cat 345B Series II Excavator 19

Serviceability

Service Intervals The design of the 345B Series II emphasizes ground-level

maintenance. Service doors open completely on both sides of the

machine for access to maintenance areas. For easy field diagnostics,

there is a service connector that enables the service technician

to use the Electronic Technician (ET) on a portable computer.

The instrument panel offers the operator some diagnostic

capability, helping to minimize unnecessary service calls.

The service and maintenance items listed below may be

accomplished from ground level.

10 Hours/One Day Operation

Check engine oil level

Check hydraulic oil level

Check engine coolant level

Drain fuel tank water and sediment

50 Hours/Weekly Operation

Lubricate boom, stick and bucket linkage (number of locations)

Lower boom pin (2)

Boom cylinder rod (2)

Stick cylinder head (1)

Boom cylinder foot (2)

Bucket link (4)

Bucket pin (3)

Stick cylinder rod (1)

Boom and stick connection (2)

Bucket cylinder head (1)

250 Hours/Monthly Operation

Clean engine crankcase breather

Change fuel filter element

Change final filter element

Clean fuel inlet screen

Fill coolant reservoir

Check final drive oil level

Check swing drive oil level

Grease swing bearing

Change water separator element

Drain water from hydraulic tank

20 TEJB6083 Cat 345B Series II Excavator December 1999

Transportability

The 345B Series II was designed to meet transportation regulations

in North America, Europe and Japan.

Transport Height and Length

Transport Height Transport Length

Boom Stick STD-FIX LC-FIX LC-VG STD-FIX LC-FIX LC-VG

4.8 m NA 4600 mm 4600 mm NA 11 570 mm 11 670 mm

15.9" 15'1" 15'1" 38'0" 38'3"

3.9 m 3760 mm 3760 mm 3740 mm 11 790 mm 11 790 mm 11 710 mm

Reach Boom 12'10" 12'4" 12'4" 12'4" 38'8" 38'8" 38'5"

6.9 m

3.35 m 3440 mm 3620 mm 3610 mm 11 730 mm 11 760 mm 11 730 mm

22'8"

11'0" 11'3" 11'11" 11'10" 38'6" 38'7" 38'6"

2.9 m 3520 mm 3530 mm 3580 mm 11 820 mm 11 820 mm 11 820 mm

9'6" 11'7" 11'7" 11'9" 38'9" 38'9" 38'9"

3.0 m 3500 mm 3730 mm 3570 mm 11 310 mm 11 310 mm 11 310 mm

Mass Boom 9'11" 11'6" 12'3" 11'9" 37'1" 37'5" 37'1"

6.55 m

2.5 m 3660 mm 3660 mm 3660 mm 11 450 mm 11 450 mm 11 400 mm

21'6"

8'2" 12'9" 12'0" 12'0" 37'7" 37'7" 37'5"

Transport Width

600 mm shoe 750 mm shoe 900 mm shoe

Undercarriage 24 in 30 in 36 in

STD 3340 mm 3490 mm 3640 mm

10'11" 11'5" 11'11"

L 3340 mm 3490 mm 3640 mm

10'11" 11'5" 11'11"

LV (Retracted) 2990 mm 3140 mm 3290 mm

9'10" 10'4" 10'10"

December 1999 TEJB6083 Cat 345B Series II Excavator 21

Notes

22 TEJB6083 Cat 345B Series II Excavator December 1999

Notes

December 1999 TEJB6083 Cat 345B Series II Excavator 23

Summary of 345B Series II Benefits and Features

The Cat 345B Series II excavator includes several innovative features that give customers the benefits of

increased controllability, productivity and durability. Increased horsepower, pump flow and swing torque

result in faster cycle times and improved productivity. The table below lists six major benefits with the

features that contribute to them and the page number where more information can be located.

Page

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Competitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Productivity and Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Fine Swing Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Swing Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Durability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Travel Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Travel Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Bumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Versatility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Booms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Sticks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Buckets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Operator Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

B-Series Cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Serviceability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Transportability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Summary of 345B Series II Benefits and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Back cover

The information contained herein is intended for circulation only to Caterpillar and dealer employees whose duties require knowledge of such reports and is

intended exclusively for their information and training. It may contain unverified analysis and facts observed by various Caterpillar or dealer employees. However,

effort has been made to provide reliable results regarding any information comparing Caterpillar built and competitive machines. Effort has been made to use the

latest available spec sheet and other material in the full understanding that these are subject to change without notice.

Any reproduction of this release without the foregoing explanation is prohibited.

TEJB6083

December 1999

www.CAT.com

1999 Caterpillar

Printed in U.S.A.

You might also like

- Product Comparison: Cat 385B and Hitachi EX800H-V Hydraulic ExcavatorsDocument24 pagesProduct Comparison: Cat 385B and Hitachi EX800H-V Hydraulic ExcavatorsMuhammad Purwa Prasetya100% (1)

- Sebd0809 02 01 AllDocument68 pagesSebd0809 02 01 AllMiguel Gutierrez100% (1)

- Componentes de Maquina de Oruga D10RDocument152 pagesComponentes de Maquina de Oruga D10RJesús Abreu100% (1)

- ISO Numero Control ContaminacionDocument42 pagesISO Numero Control ContaminacionOctavio Morales100% (4)

- Track Roller Frames D&ADocument62 pagesTrack Roller Frames D&Anelson troncoso galdamesNo ratings yet

- PEO003 - SGD - V4 (Personal Devt)Document60 pagesPEO003 - SGD - V4 (Personal Devt)Jela ParadiseNo ratings yet

- Global Service Learning: 320D-336D Series Hydraulic Excavators - Tier Iii EnginesDocument3 pagesGlobal Service Learning: 320D-336D Series Hydraulic Excavators - Tier Iii EnginesLea7herfaceNo ratings yet

- 86 507Document2 pages86 507AliceAlormenuNo ratings yet

- Cat 365C Vs Komatsu PC6507Document79 pagesCat 365C Vs Komatsu PC6507Kolo BenduNo ratings yet

- Machine Profiles: 16G and 16H Motor GradersDocument6 pagesMachine Profiles: 16G and 16H Motor GradersRulver Quiroz CabanillasNo ratings yet

- RM400 Wear Part TrainingDocument18 pagesRM400 Wear Part TrainingMp pmNo ratings yet

- Crawler Excavator Specifications: Service Weight 57.9 - 63.6 T Engine Output BucketsDocument14 pagesCrawler Excavator Specifications: Service Weight 57.9 - 63.6 T Engine Output Bucketsdamqn filipovNo ratings yet

- R30CDocument4 pagesR30CEnrique MurgiaNo ratings yet

- Caterpillar ADT 740 SpecDocument20 pagesCaterpillar ADT 740 SpecLorentz MelialaNo ratings yet

- Powertrain CAT 2Document29 pagesPowertrain CAT 2Marius Lakshan ThamelNo ratings yet

- Performance Report: Caterpillar 325D L vs. Caterpillar 325C LDocument10 pagesPerformance Report: Caterpillar 325D L vs. Caterpillar 325C LDANIEL VARGAS RODRIGUEZNo ratings yet

- 320C U Excavator-Before OperationDocument4 pages320C U Excavator-Before OperationPedro BarriosNo ratings yet

- 374F L TRG PDFDocument52 pages374F L TRG PDFDAnielNo ratings yet

- 5110B Prod Bulletin (TEJB7050)Document40 pages5110B Prod Bulletin (TEJB7050)suwarjitechnic100% (2)

- Hydraulic Excavator OverhaulsDocument3 pagesHydraulic Excavator OverhaulsLody100% (1)

- 86 592Document6 pages86 592zl100% (1)

- Fuel and Lubricant PDFDocument108 pagesFuel and Lubricant PDFNiño De la torreNo ratings yet

- 950H-962H Marketing BulletinDocument6 pages950H-962H Marketing BulletinWilbort Encomenderos Ruiz100% (1)

- Competitive Bulletin: Cat New H-Series EPA Tier II Engine Emissions Certified vs. Volvo B-Series Motor GradersDocument68 pagesCompetitive Bulletin: Cat New H-Series EPA Tier II Engine Emissions Certified vs. Volvo B-Series Motor GradersRulver Quiroz CabanillasNo ratings yet

- Dozers: What Are These ? & What They Does ?Document118 pagesDozers: What Are These ? & What They Does ?harirambo100% (1)

- Hydraulic Mining Shovels Cat 60xx Basic Shovel Hydraulic - System DescriptionDocument24 pagesHydraulic Mining Shovels Cat 60xx Basic Shovel Hydraulic - System DescriptionMiguel Angel RodriguezNo ratings yet

- Business Awareness: Student GuideDocument62 pagesBusiness Awareness: Student GuidePutra JawaNo ratings yet

- Safety: Operation and Maintenance Manual ExcerptDocument20 pagesSafety: Operation and Maintenance Manual ExcerptCraig GordonNo ratings yet

- Product Support OverviewDocument78 pagesProduct Support OverviewDaniel88036100% (1)

- 797B Commissioning Guidebook 07 (Procesos) PDFDocument65 pages797B Commissioning Guidebook 07 (Procesos) PDFwilmer100% (1)

- TCL005 - SGD - V4 (Jacking)Document136 pagesTCL005 - SGD - V4 (Jacking)Jela Paradise100% (4)

- BW24RSvcTraining PDFDocument134 pagesBW24RSvcTraining PDFLu Lu MaiNo ratings yet

- Sem Wheel LoeaderDocument186 pagesSem Wheel LoeaderJoel RodríguezNo ratings yet

- Caterpillar Cat 16H Motor Grader (Prefix ATS) Service Repair Manual (ATS00001 and Up)Document28 pagesCaterpillar Cat 16H Motor Grader (Prefix ATS) Service Repair Manual (ATS00001 and Up)kfm8seuudu100% (1)

- Cat 14 M Motor GraderDocument28 pagesCat 14 M Motor GraderYudhi Salman Dwi Satya0% (2)

- 02 RH40E UndercarriageDocument16 pages02 RH40E UndercarriageBladimir PadillaNo ratings yet

- sbg2470Document41 pagessbg2470mustafa özkanNo ratings yet

- JCB AttachmentDocument178 pagesJCB AttachmentEdmundas ŽemaitisNo ratings yet

- Boom Cylinder Remove and InstallDocument8 pagesBoom Cylinder Remove and InstallEDSON JONATHAN SALINAS AYALANo ratings yet

- Liebherr 942 Oil FlowDocument10 pagesLiebherr 942 Oil FlowLiebherr100% (2)

- PRDBLTN 428EvsTerex860Document31 pagesPRDBLTN 428EvsTerex860firman manalu100% (1)

- 345 GC Hydraulic Excavator - Technical Specifications (Electronic Only) (LAXB) AEXQ2380Document13 pages345 GC Hydraulic Excavator - Technical Specifications (Electronic Only) (LAXB) AEXQ2380souleymane aboudramane SOOBANo ratings yet

- Service Brake Wear TestDocument14 pagesService Brake Wear TestsatyaNo ratings yet

- Cat 320d LRRDocument28 pagesCat 320d LRRt1meNo ratings yet

- QESV1318 CB534 64D STMG - BookDocument200 pagesQESV1318 CB534 64D STMG - BookVictor Pinedo100% (1)

- Handbook of Ripping 12ed CATDocument32 pagesHandbook of Ripping 12ed CATbrabuantony100% (2)

- Undercarriage CATDocument24 pagesUndercarriage CATRoberto MorgadoNo ratings yet

- Plano Hidraulico RH-90Document15 pagesPlano Hidraulico RH-90Eduardo ZamoraNo ratings yet

- Serv1828 TXTDocument272 pagesServ1828 TXTCarlos ParanhosNo ratings yet

- 992G Best Maintenance Practices Text PDFDocument33 pages992G Best Maintenance Practices Text PDFSandoval Ramos Eddy100% (2)

- 924HZ Wheel Loader JZZ00001-UP (MACHINE) POWERED BY C6 PDFDocument8 pages924HZ Wheel Loader JZZ00001-UP (MACHINE) POWERED BY C6 PDFAhmed HamdyNo ratings yet

- Cat 320 B-C PDFDocument40 pagesCat 320 B-C PDFJorge Mejia95% (22)

- 740 Vs Volvo A40D (TEJB8012)Document28 pages740 Vs Volvo A40D (TEJB8012)Nova kurniawan 34100% (1)

- Technical Specifications: Track-Type TractorDocument21 pagesTechnical Specifications: Track-Type TractorRafael CasteloNo ratings yet

- Dana-Off-highway-condensed-specs Cajas Automaticas Generales PDFDocument34 pagesDana-Off-highway-condensed-specs Cajas Automaticas Generales PDFAlonso Fernando0% (1)

- Aexq3337 01Document18 pagesAexq3337 01Robel KebedeNo ratings yet

- Raiting de MotoresDocument34 pagesRaiting de Motoresvictor laraNo ratings yet

- 320D PDT ComparisonDocument22 pages320D PDT Comparisonlalo11715No ratings yet

- Caterpillar Industrial Engine Ratings GuideDocument3 pagesCaterpillar Industrial Engine Ratings Guidecharlie100% (51)

- Lecture 3 EngineDocument8 pagesLecture 3 EngineAmrit1995No ratings yet

- BMW Codes Obd IIDocument45 pagesBMW Codes Obd IIcepaezh67% (3)

- AllServiceCodes PDFDocument11 pagesAllServiceCodes PDFJose Pacheco Corrales100% (1)

- BMW Codes Obd IIDocument45 pagesBMW Codes Obd IIcepaezh67% (3)

- Electrical 1Document2 pagesElectrical 1suwarjitechnicNo ratings yet

- AC SchematicDocument6 pagesAC SchematicsuwarjitechnicNo ratings yet

- PK42502 Lifting Cylinder BoomDocument2 pagesPK42502 Lifting Cylinder BoomsuwarjitechnicNo ratings yet

- Cat 320d LRRDocument28 pagesCat 320d LRRt1meNo ratings yet

- 5130b PDFDocument20 pages5130b PDFAlexander Barrios OchoaNo ratings yet

- DM 45 LP Track Adjuster Only SN 7958Document7 pagesDM 45 LP Track Adjuster Only SN 7958suwarjitechnicNo ratings yet

- 7188Document518 pages7188suwarjitechnic100% (2)

- 8271Document698 pages8271suwarjitechnic100% (2)

- Analisis-Ekonomi-Usaha-Ayam-Petelur-Cv.-Santoso-Farm-Di-Desa-Kerjen-Kecamatan-Srengat-Kabupaten-Blitar-Economic-Analysis-Of-Layer-At-CV.-“Santoso-Farm”-In-Kerjen-Village-Srengat-Subdistrict-Blitar-Regency.pdfDocument156 pagesAnalisis-Ekonomi-Usaha-Ayam-Petelur-Cv.-Santoso-Farm-Di-Desa-Kerjen-Kecamatan-Srengat-Kabupaten-Blitar-Economic-Analysis-Of-Layer-At-CV.-“Santoso-Farm”-In-Kerjen-Village-Srengat-Subdistrict-Blitar-Regency.pdfsuwarjitechnicNo ratings yet

- Du 35 PDFDocument20 pagesDu 35 PDFVladimir Illich PinzonNo ratings yet

- 908 CatDocument12 pages908 CatLuis Fernando Vasquez Ramos100% (1)

- Shovel Loading GuidesDocument20 pagesShovel Loading Guidessuwarjitechnic100% (1)

- Jurnal RafaelDocument6 pagesJurnal RafaelAmam RafaelNo ratings yet

- 330D - Technical NPIDocument51 pages330D - Technical NPIVictor Acuña100% (7)

- G.E.T Penetration Plus TipsDocument2 pagesG.E.T Penetration Plus TipssuwarjitechnicNo ratings yet

- 5110B Prod Bulletin (TEJB7050)Document28 pages5110B Prod Bulletin (TEJB7050)suwarjitechnicNo ratings yet

- 5130B Specalog (AEHQ5234)Document8 pages5130B Specalog (AEHQ5234)suwarjitechnicNo ratings yet

- 7106V2N2 TXT (330D)Document2 pages7106V2N2 TXT (330D)suwarjitechnicNo ratings yet

- 5110B - L Prod Bulletin (TRJB9047)Document56 pages5110B - L Prod Bulletin (TRJB9047)suwarjitechnic100% (1)

- 5110b Me Perf Rep (Texr0388)Document6 pages5110b Me Perf Rep (Texr0388)suwarjitechnicNo ratings yet

- CAT 385C L Hydraulic ExcavatorsDocument28 pagesCAT 385C L Hydraulic ExcavatorsJosh Mullens100% (1)

- 5110B Prod Bulletin (TEJB7050)Document40 pages5110B Prod Bulletin (TEJB7050)suwarjitechnic100% (2)

- 5110B Prod Bulletin (TEJB7050)Document40 pages5110B Prod Bulletin (TEJB7050)suwarjitechnic100% (2)

- 5110B Performance Report II (PR00269)Document4 pages5110B Performance Report II (PR00269)suwarjitechnicNo ratings yet

- 5110B Performance Report I (PR00263)Document5 pages5110B Performance Report I (PR00263)suwarjitechnicNo ratings yet

- CAT 385C L Hydraulic ExcavatorsDocument28 pagesCAT 385C L Hydraulic ExcavatorsJosh Mullens100% (1)

- Getting Started With Experion Software GuideDocument28 pagesGetting Started With Experion Software Guidebeerman81No ratings yet

- ISORIA 20 BrochureDocument16 pagesISORIA 20 BrochuremariodalNo ratings yet

- B.A GeographyDocument8 pagesB.A GeographyShravani SalunkheNo ratings yet

- Cabinas de Bioseguridad HealforceDocument8 pagesCabinas de Bioseguridad HealforceJose HurtadoNo ratings yet

- Pway Design Guide 2011-!!!Document48 pagesPway Design Guide 2011-!!!REHAZNo ratings yet

- About Ramfs Rootfs InitramfsDocument7 pagesAbout Ramfs Rootfs InitramfsNavaneethNo ratings yet

- Riluzole For SCZDocument11 pagesRiluzole For SCZHana Rizka AnandaNo ratings yet

- PartIII Semiconductor at Equilibrium PrintDocument22 pagesPartIII Semiconductor at Equilibrium PrintK.bhogendranathareddy KuppireddyNo ratings yet

- ECE7360 Project3Document58 pagesECE7360 Project3Icaro.RedwarriorNo ratings yet

- Spring - Design - Important Points and CalculationDocument17 pagesSpring - Design - Important Points and CalculationvenkateswaranNo ratings yet

- Moses Mabhida Stadium PDFDocument4 pagesMoses Mabhida Stadium PDFHCStepNo ratings yet

- Calculation of The Size of The Mooring SystemDocument7 pagesCalculation of The Size of The Mooring SystemKyle RubricoNo ratings yet

- Seismic Enhancement of Circular RC Bridge Piers With Fiber CompositesDocument9 pagesSeismic Enhancement of Circular RC Bridge Piers With Fiber CompositesGerardoSosaDavilaNo ratings yet

- CPE211 Data Structures and Algorithms: Class OrientationDocument9 pagesCPE211 Data Structures and Algorithms: Class OrientationHaremaibNo ratings yet

- Conte R Fort WallDocument30 pagesConte R Fort Wallmirko huaranccaNo ratings yet

- Phenomenology and Social Reality - Essays in Memory of Alfred Schutz (PDFDrive)Document316 pagesPhenomenology and Social Reality - Essays in Memory of Alfred Schutz (PDFDrive)Muhammad SyarofuddinNo ratings yet

- Elemental Analysis of Crude OilsDocument8 pagesElemental Analysis of Crude OilsMirzan Alexandra Torres LaraNo ratings yet

- 5.4 Hypergeometric DistributionDocument5 pages5.4 Hypergeometric DistributionFahad IqbalNo ratings yet

- Ziad Masri - Reality Unveiled The Hidden KeyDocument172 pagesZiad Masri - Reality Unveiled The Hidden KeyAivlys93% (15)

- Mach4 G and M Code Reference ManualDocument81 pagesMach4 G and M Code Reference ManualMegi Setiawan SNo ratings yet

- BS en 10028-1Document24 pagesBS en 10028-1Andrei Balázs100% (1)

- Vulgare Mill.) Terhadap Bakteri Staphylococcus Aureus ATCC 25923Document8 pagesVulgare Mill.) Terhadap Bakteri Staphylococcus Aureus ATCC 25923MUHAMMAD RIZKY HUSULUDINNo ratings yet

- MATH 10 - Q4 - WEEK 1 - MODULE 1 - Illustrating-The-Measures-Of-Position-Quartiles-Deciles-And-PercentilesDocument23 pagesMATH 10 - Q4 - WEEK 1 - MODULE 1 - Illustrating-The-Measures-Of-Position-Quartiles-Deciles-And-PercentilesLyle Isaac L. Illaga67% (27)

- St. John of Buug Foundation IncDocument12 pagesSt. John of Buug Foundation Inctammy a. romuloNo ratings yet

- Av02 2516enDocument13 pagesAv02 2516enpagol_23_smhNo ratings yet

- Leadership Quality ManagementDocument8 pagesLeadership Quality Managementselinasimpson361No ratings yet

- Sci Problem SolutionsDocument10 pagesSci Problem SolutionsVS PUBLIC SCHOOL BangaloreNo ratings yet

- CSBS Syllabus Book 01 11 2021 1Document117 pagesCSBS Syllabus Book 01 11 2021 1PRITHVI P. K SEC 2020No ratings yet

- Spirometric Evaluation of Pulmonary Function Tests in Bronchial Asthma PatientsDocument6 pagesSpirometric Evaluation of Pulmonary Function Tests in Bronchial Asthma PatientsdelphineNo ratings yet