Professional Documents

Culture Documents

Mbrace Cf130 Pds

Uploaded by

aldiemozCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mbrace Cf130 Pds

Uploaded by

aldiemozCopyright:

Available Formats

PRODUCT DATA

3 03 01 00 Maintenance of

Concrete

MBRACE CF 130

Unidirectional high strength carbon fiber fabric

for the MBrace Composite Strengthening System

Description Features Benefits

MBrace CF 130 is a dry fabric High strength to weight ratio Can add significant strength to a structure without

constructed of very high strength, adding significant dead load

aerospace grade carbon fibers. These Excellent resistance to creep and fatigue Withstands sustained and cyclic load conditions

fabrics are applied onto the surface

Extremely durable Extremely resistant to a wide range of

of existing structural members in

environmental conditions

buildings, bridges, and other

structures using the MBrace family Easy installation Can be installed quickly, even in areas of

of performance polymers. The result limited access

is an externally bonded FRP (fiber Low aesthetic impact Easy to conceal, will not significantly change

reinforced polymer) reinforcement existing member dimensions, will form around

system that is engineered to increase complex surfaces

the strength and structural

performance of these members. Once

installed, the MBrace System delivers Shelf Life Substitute reinforcing steel mistakenly omitted in

externally bonded reinforcement with the construction of concrete and masonry

3 years in unopened containers

outstanding long-term physical and structures

mechanical properties. Storage

Improve the blast resistance of concrete and

Store in a cool, dry place (50 to 90 F [10 to 32 C]) masonry structures

away from direct sunlight, flame, or other hazards.

Yield Strengthening of some steel and timber

269 ft2 (25 m2) per roll structures

Packaging

Where to Use

LOCATION

APPLICATION

Available in rolls 20 in (500 mm) wide, Vertical

162 ft (50 m) long Increase load bearing capacity of concrete

beams, slabs, walls and columns Horizontal

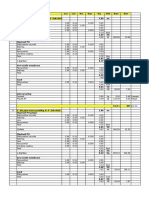

ROLL WIDTH LENGTH Improve the seismic ductility of concrete columns Exterior

269 ft 2

20 in 162 ft Improve the seismic response of concrete beam- Interior

(25 m2) (508 mm) (50 m) column connections, shear walls and collector SUBSTRATE

elements Concrete

Color Improve the seismic performance of masonry Masonry

Black shear walls and in-fill walls

Timber

Restore structural capacity to damaged or

deteriorated concrete structures Steel

Increase the strength of concrete pipes, silos,

tanks, chimneys and tunnels

Protection and Repair

MBT PROTECTION AND REPAIR PRODUCT DATA

MBRACE CF 130

Technical Data Physical Properties

Composition PROPERTY REQUIREMENT

MBrace CF 130 is composed of a dense network of Fiber Material High Strength Carbon

high strength carbon fibers held in a unidirectional

alignment with a light thermoplastic glass fiber cross Fiber Tensile Strength 720 ksi (4950 MPa)

weave yarn Areal Weight 0.062 lb/ft2

[300 g/m2]

Fabric Width 20 inch

[500 mm]

Nominal Thickness, tf (1) 0.0065 in/ply

[0.165 mm/ply]

Functional Properties

PROPERTY REQUIREMENT

CTE -0.2110-6/F

(-0.3810-6/C

NOTES:

Thermal Conductivity 65.1-Btuin/hrft2F (1) The nominal fabric thickness is based on the total area of

(9.38-W/mK) fibers (only) in a unit width. From experience, the actual

cured thickness of a single ply laminate (fibers plus

Electrical Resistivity 1.610-3cm saturating resins) is 0.020 to 0.040 in (0.6 to 1.0 mm).

(2) The tensile properties given are those to be used for

design. These values are derived by testing cured

0 Tensile Properties (2,3) laminates (per ASTM D3039) and dividing the resulting

strength and modulus per unit width by the nominal fabric

PROPERTY REQUIREMENT thickness.

Ultimate Tensile 550 ksi (3) The 0 direction denotes the direction along the length of

Strength, f*fu [3800 MPa] the fabric.

(4) The 90 direction denotes the direction along the width of

Tensile Modulus, Ef 33000 ksi the fabric.

[227 GPa]

Ultimate Tensile Strength 3.57 kips/in/ply

per Unit Width, f*fu tf [0.625 kN/mm/ply]

Tensile Modulus 215 kips/in/ply

per Unit Width, Ef tf [38 kN/mm/ply]

Ultimate Rupture Strain, fu 1.67%

90 Tensile Properties (2,4)

PROPERTY REQUIREMENT

Ultimate Tensile Strength 0

Tensile Modulus 0

Ultimate Rupture Strain n/a

MBT PROTECTION AND REPAIR PRODUCT DATA

MBRACE CF 130

How to Apply For Best Performance Health and Safety

Surface Preparation

Use caution when applying MBrace CF 130 MBRACE CF 130

1. MBrace CF 130 is applied to surfaces treated around sensitize electrical equipment. Carbon Warning

with MBrace Primer, MBrace Putty and MBrace fiber filaments can become airborne, infiltrate

MBrace Fiber Reinforcements contain carbon, glass,

Saturant. Consult the data sheets for these materials electrical equipment and cause electrical shorts.

and/or aramid fibers, MBrace CF 130 contains

for additional details. Make certain the most current versions of carbon and glass fibers. While handling MBrace

Application product data sheet and MSDS are being used; Fiber Reinforcements CF 130, wear appropriate work

call Customer Service (1-800-433-9517) to clothing to minimize contact. Product Material Safety

MBrace CF 130 is only applied as a component of

verify the most current version. Data Sheets (MSDS) are available and should be

the MBrace System.

Proper application is the responsibility of consulted and on hand whenever handling these

1. The MBrace CF 130 material should be cut to

the user. Field visits by BASF personnel products. These products are for professional and

the proper dimensions (dimensions will vary based

are for the purpose of making technical industrial use only and are only installed by trained

on project requirements) using heavy duty shears or

recommendations only and are not for and qualified applicators. Trained applicators must

a utility knife.

supervising or providing quality control on follow installation instructions.

2. Cut sections of MBrace CF 130 can be the jobsite.

temporarily stored by carefully rolling fabric into a 12

inch (600 mm) (approximate) roll. Do not fold or

crease the fabric. Fabric shoul dbe kept free of dust,

oils, moisture and other contaminants at all times.

3. Apply the MBrace CF 130 fabric directly into

uncured MBrace Saturant applied on the substrate.

There is no need to pre-wet the MBrace CF 130

fabric with MBrace Saturant prior to applying the

fabric against the substrate.

4. Using a rib roller or squeegee, press the fabric

against the substrate until visual signs of MBrace

Saturant are observed bleeding through the fabric.

The rib roller or squeegee should only be run along

the direction of the primary fibers in the fabric.

5. Apply a layer of MBrace Saturant over the top of

the MBrace CF 130 fabric to completely

encapsulate the fabric. Consult with the MBrace

Saturant data sheet on details for applying MBrace

Saturant.

Maintenance

Periodically inspect the applied material and repair

localized areas as needed. Consult an BASF

representative for additional information. Visit us on

the web for the most current product information and

news: www.BuildingSystems.BASF.com.

MBT PROTECTION AND REPAIR PRODUCT DATA

MBRACE CF 130

BASF Construction Chemicals, LLC LIMITED WARRANTY NOTICE Every reasonable effort is made to apply BASF exacting standards both in the manufacture of our products and in the information which we issue concerning these products and their use. We

warrant our products to be of good quality and will replace or, at our election, refund the purchase price of any products proved defective. Satisfactory results depend not only upon quality products, but also upon many factors

Building Systems beyond our control. Therefore, except for such replacement or refund, BASF MAKES NO WARRANTY OR GUARANTEE, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE OR

MERCHANTABILITY, RESPECTING ITS PRODUCTS, and BASF shall have no other liability with respect thereto. Any claim regarding product defect must be received in writing within one (1) year from the date of shipment. No claim

will be considered without such written notice or after the specified time interval. User shall determine the suitability of the products for the intended use and assume all risks and liability in connection therewith. Any

889 Valley Park Drive authorized change in the printed recommendations concerning the use of our products must bear the signature of the BASF Technical Manager.

Shakopee, MN, 55379 This information and all further technical advice are based on BASFs present knowledge and experience. However, BASF assumes no liability for providing such information and advice including the extent to which such information and

advice may relate to existing third party intellectual property rights, especially patent rights. In particular, BASF disclaims all CONDITIONS AND WARRANTIES, WHETHER EXPRESS OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES

OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY. BASF SHALL NOT BE RESPONSIBLE FOR CONSEQUENTIAL, INDIRECT OR INCIDENTAL DAMAGES (INCLUDING LOSS OF PROFITS) OF ANY KIND. BASF reserves

www.BuildingSystems.BASF.com the right to make any changes according to technological progress or further developments. It is the customers responsibility and obligation to carefully inspect and test any incoming goods. Performance of the product(s) described herein

should be verified by testing and carried out only by qualified experts. It is the sole responsibility of the customer to carry out and arrange for any such testing. Reference to trade names used by other companies is neither a recommendation,

Customer Service 800-433-9517 nor an endorsement of any product and does not imply that similar products could not be used.

Form No. 1031110 7/07 2007 BASF

Technical Service 800-243-6739 For professional use only. Not for sale to or use by the general public. Printed on recycled paper including 10% post-consumer fiber. Printed in U.S.A.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Understanding and Applying Ashrae Standards With LG Multi V Rev 0812091Document4 pagesUnderstanding and Applying Ashrae Standards With LG Multi V Rev 0812091Leo2pbNo ratings yet

- Civil Estimator Job DeskDocument2 pagesCivil Estimator Job DeskaldiemozNo ratings yet

- Car ShowroomDocument1 pageCar ShowroomRAHUL RATHODNo ratings yet

- Building Systems Exam Guide - Architecture Exam - NCARBDocument23 pagesBuilding Systems Exam Guide - Architecture Exam - NCARBiamarrNo ratings yet

- Ashrae - LibraryDocument16 pagesAshrae - LibraryEmeraldi Mufti RabbaniNo ratings yet

- Procedures For Designing Natural Lighting Systems in BuildingsDocument36 pagesProcedures For Designing Natural Lighting Systems in Buildingsaldiemoz100% (2)

- Articles Related To Freeport Chopper Smelter Gresik: 1. Change License Technology From Mitsubishi To OutotechDocument2 pagesArticles Related To Freeport Chopper Smelter Gresik: 1. Change License Technology From Mitsubishi To OutotechaldiemozNo ratings yet

- SaipemDocument48 pagesSaipemaldiemozNo ratings yet

- LIST GAME Playstation 4 HEN: Total Pilihan: 0Document633 pagesLIST GAME Playstation 4 HEN: Total Pilihan: 0aldiemozNo ratings yet

- South Korea: © 2013 LAND INFO Worldwide Mapping, LLCDocument3 pagesSouth Korea: © 2013 LAND INFO Worldwide Mapping, LLCaldiemozNo ratings yet

- Implications For Electronic System Operators: Definition of Personal DataDocument5 pagesImplications For Electronic System Operators: Definition of Personal DataaldiemozNo ratings yet

- Magister Teknik Sipil 2018 - 2019Document2 pagesMagister Teknik Sipil 2018 - 2019aldiemozNo ratings yet

- User's Manual: Digital CameraDocument176 pagesUser's Manual: Digital CameraaldiemozNo ratings yet

- Muhammad Feraldi Yulizar: PT. Takenaka Indonesia (Secondment To TAKENAKA-TOTAL J.O)Document3 pagesMuhammad Feraldi Yulizar: PT. Takenaka Indonesia (Secondment To TAKENAKA-TOTAL J.O)aldiemozNo ratings yet

- No. Category1 Category2 1 Education Oil & Gas 2 Software CAD 3 Education Civil & MEP 4 Education Schedule 5 Education Project ControlDocument2 pagesNo. Category1 Category2 1 Education Oil & Gas 2 Software CAD 3 Education Civil & MEP 4 Education Schedule 5 Education Project ControlaldiemozNo ratings yet

- Bulls in The BronxDocument9 pagesBulls in The BronxaldiemozNo ratings yet

- BSUG EnergyPlus HVAC FeaturesDocument0 pagesBSUG EnergyPlus HVAC FeaturesRinaldyNo ratings yet

- MGT - Case Studies & HistoryDocument29 pagesMGT - Case Studies & HistoryCiprian MunteanuNo ratings yet

- Sashi BhooshanDocument28 pagesSashi BhooshanyashaswiniNo ratings yet

- Saudi X UAEDocument30 pagesSaudi X UAEgarhgelhNo ratings yet

- S001 (1) - Drawing List - Drawing TransmittalDocument1 pageS001 (1) - Drawing List - Drawing TransmittalScott McCallum100% (1)

- Elite18-Master Log-CON (Pro Mag)Document123 pagesElite18-Master Log-CON (Pro Mag)muhammad75makeNo ratings yet

- Preliminary Report On Tall BuildingDocument15 pagesPreliminary Report On Tall BuildingG V krishnaNo ratings yet

- Chemical Water Proofing Rate Ana As Per SunandaDocument5 pagesChemical Water Proofing Rate Ana As Per SunandaVinodPotphodeNo ratings yet

- Rate List For HVAC (Updated June 2021)Document6 pagesRate List For HVAC (Updated June 2021)muhammad bilal ahmedNo ratings yet

- Section - Danfoss - ManeuropDocument28 pagesSection - Danfoss - ManeuropRafael Leonardo GomezNo ratings yet

- Thermostone Block: Thermostone Block Has A Good Marketing Demand in KRGDocument9 pagesThermostone Block: Thermostone Block Has A Good Marketing Demand in KRGSarmad A. AzizNo ratings yet

- Leaflet HRD2Document8 pagesLeaflet HRD2Miroslav LuladžićNo ratings yet

- FS OneDocument1 pageFS OneDario SantosNo ratings yet

- PDF PLC Roofing GuideDocument27 pagesPDF PLC Roofing GuideBushral YusobNo ratings yet

- Method of Construction Without VideoDocument8 pagesMethod of Construction Without Videolalit kaduNo ratings yet

- Catalogue LRC TS NewDocument16 pagesCatalogue LRC TS Newliang_thailandNo ratings yet

- M.E Thesis PresentationDocument45 pagesM.E Thesis PresentationPrakash NanthagopalanNo ratings yet

- Asian Architecture Case StudyDocument17 pagesAsian Architecture Case StudydiyanahussainNo ratings yet

- Reported by ACI/TMS Committee 216Document26 pagesReported by ACI/TMS Committee 216DIDIER ANGEL LOPEZ RINCONNo ratings yet

- Yzh Affinity Heat Pump Install Manual PDFDocument16 pagesYzh Affinity Heat Pump Install Manual PDFSaid Marino CarrascoNo ratings yet

- OrdnancesDocument1,478 pagesOrdnancesSome GuyNo ratings yet

- Plinth Area For Rough Cost Est TN Pwd. 2021-2022Document15 pagesPlinth Area For Rough Cost Est TN Pwd. 2021-2022Golden KingNo ratings yet

- Application: I. Use of The FormDocument10 pagesApplication: I. Use of The FormCindy WijayaNo ratings yet

- Adobe Scan Aug 07, 2021Document3 pagesAdobe Scan Aug 07, 2021Sangram MundeNo ratings yet

- Types of Ties Used in Building Construction, Their Design and Uses PDFDocument6 pagesTypes of Ties Used in Building Construction, Their Design and Uses PDFnasirjamal33No ratings yet