Professional Documents

Culture Documents

A Review On Bi-CMOS Technology: Abdurrahman, Amit Jain

Uploaded by

maha nandhini pOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Review On Bi-CMOS Technology: Abdurrahman, Amit Jain

Uploaded by

maha nandhini pCopyright:

Available Formats

SSRG International Journal of Electronics and Communication Engineering (SSRG-IJECE) Volume 3 Issue 8 August 2016

A Review on Bi-CMOS Technology

Abdurrahman#1, Amit Jain#2

#1-B.tech final year student, #2-Assistant Professor

Department of Electronics and Communication Engineering

Poornima Institute of Engineering & Technology, Jaipur, Rajasthan, India

Abstract-At present time speed is a big issue for the [1]. In this technology we generally increase the

electronics technology. If speed is increasing then speed, current gain and performance of the devices

performance of the electronics devices are for this the BI polar devices such as transistor is

increasing. In the electronics field we use the used. When an input voltage (V1n) is apply on the

semiconductor for making an IC substrate. For BI polar transistor in the output section of BI-

making an IC we use the metal oxide as a layer by CMOS gate circuit makes the transition from high

this process we make a MOS (metal oxide to low, then the output (Vout) goes from high to

semiconductor). With the help of MOS we are low after some delay. During this delay time

making the CMOS (complementary metal oxide emitter-base junction is on reverse biased situation.

semiconductor). In the process of making CMOS This emitter-base reverse biased condition allows a

we use PMOS and NMOS. In the PMOS we use the large reverse current. In the reverse biased

P (positive) type substrate and in the NMOS we use condition base current increases and due to this hot-

the N (negative) type substrate. By the combination carrier injected into the SIO2 layer. Due to this

of PMOS and NMOS we make the CMOS. Speed of current gain decreases and current gain directly

CMOS is greater than the PMOS and NMOS. By depends upon the temperature means current gain

the increasing of speed of CMOS we use the varies according to applying input temperature

generally CMOS rather than PMOS and NMOS. [2].So finally we say that BI-CMOS is a versatile

After that we are making the BI-CMOS whose technology by which we increase the speed of

speed, current gain and performance is superior electronic devices and we decrease the power

than the CMOS technology. BI-CMOS is a consumption due to electronic devices. Due to BI

technology in which we use the BI polar process polar technology switching speed of electronic

with CMOS process. With the working BI polar devices are increased and current gain is also

process we increase the speed of CMOS increased. Due to combination of BI polar

technology. technology and CMOS technology sound of

devices are reduces. If noises are reduces then the

Keywords: CMOS; BI-CMOS; BI POLAR; PMOS; speed of the devices are by design increased. In the

NMO; LSI; MOS distinction of CMOS and BI-CMOS noise in the

CMOS technology is better than the BI-CMOS

I. INTRODUCTION technology so speed of BI-CMOS is greater than

the CMOS technology.

BI-CMOS is an electronic technology in

which we use the BI polar technology and CMOS

technology. Firstly BI-CMOS technology was used II. FUNDAMENTALOF BI-

in 1983 in this both the BI polar devices and MOS CMOSTECHNOLOGY [3]

devices are fabricated on the same chip. Due to this

speed and performance of electronic devices are In this section, we know that process in which BI

increased and power is less consumed. CMOS polar equipment and CMOS equipment are

technology basically used for the fabrication of combined and making a new technology called BI-

memories and microcomputer because CMOS has CMOS technology.

low power consumption and density is high. But

speed performance is not better. To increase the A. BI-POLAR TECHNOLOGY

speed performance we use the BI polar device with

the CMOS device. BI-CMOS devices are BI polar process is used for the fabrication of BI-

fabricated on the LSIs (large scale integration) chip

ISSN: 2348 8549 www.internationaljournalssrg.org Page 42

SSRG International Journal of Electronics and Communication Engineering (SSRG-IJECE) Volume 3 Issue 8 August 2016

CMOS. Generally BI polar is used because of its

matching capacity is good involving devices. With

the using of BI polar technology noise will be

reduces and by this current gain will be enlarged.

Its transconductance capacity is more than the

MOS technology. By the using of BI polar

technology power utilization is also less. BI polar

devices are fundamental to voltage reference

circuit, such as band gap reference.

B. CMOS TECHNOLOGY

CMOS technology is also used for fabrication of

BI-CMOS. CMOS is used very frequently because

of having excellent switching capacity and when it

is in on condition then no voltage drop will be Figure1: BlockDiagram of BI-CMOS manufacture

there. Its packaging density is high and it has low Technology [4]

transconductance because of transconductance is

directly depends on the input voltage. By the above block diagram we see that how

the BI-CMOS is fabricated. For the fabrication

g V process first we select the P/P+ substrate. P type

m in.(1)

means positive type substrate we select; in this

By the above equation we see that substrate positive ion concentration is more than

transconductance is directly depends upon input the negative ion concentration. After that we

voltage.

provide the isolation for making inductive

substrate. Then CMOS tub is implanted. After that

C. BI-CMOS TECHNOLOGY

gate terminal is fabricated. Gate terminal is

BI-CMOS process is a fusion of BI polar and fabricated using ion implantation method or using

CMOS process. Its speed and performance is more UV (ultra violet) rays for the process of deposition

than CMOS technology. It has high gain and low of polysilicon metal then gate terminal is etched for

noise level. It has low power dissipation than making pure gate terminal. After that we implant

purely BI polar technology. Current gain is the LDD (lightly doped drain). For implanting the

improved over CMOS technology. Packing density drain terminal we make the firstly NMOS and

is improved over BI polar technology.

PMOS drain then combining this drain terminal we

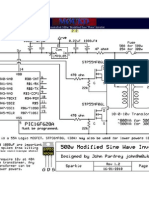

III. BLOCK DIAGRAM OF BI-CMOS make the drain terminal of CMOS. For making the

FABRICATION PROCESS NMOS and PMOS drain we use the SiGe BI polar

technology in which we firstly implanted the NPN

In this section we see that how the BI-CMOS tub such that NPN transistor then emitter window is

technology is fabricated. etched after that SiGe epitaxial layer is selected.

After that emitter and base will be defined of NPN

section. After that CMOS space is defined. After

that source and drain is defined in the specified

space. Source and drain terminal is interchangeable

means in the specified space in anywhere source

and drain will be placed. After that metal contact is

provided to the source, drain and gate terminal.

Metallization is the process in which we provide

the metal contact to the source, drain and gate

terminal by the ion implantation method. For

metallization process we use thick inductive metal.

At the end BI-CMOS is fabricated and used as a

speed gainer technology.

ISSN: 2348 8549 www.internationaljournalssrg.org Page 43

SSRG International Journal of Electronics and Communication Engineering (SSRG-IJECE) Volume 3 Issue 8 August 2016

IV. InP BI-CMOS TECHNOLOGY

InP BI-CMOS technology is used for integration of

wafer of InP and CMOS technology. With this

technology, we use fully III-IV group compound to

increase the speed.

Figure 4:Fabrication and heterogeneous integration

[5].

Above diagram is the entire process of produce

of InP BI-CMOS technology. This technology uses

Figure 2: Schematic figure of heterogeneous the heterogeneous integration process. In the above

integrationprocess consisting of diagram we see that P+ substrate is used, heat

a) Epitaxial growth, b) temporary spreader is also used [6].

Wafer bonding to a handle wafer, c) growth

V. COMPARISION BETWEEN BI-CMOS AND

substrate removal [5]

CMOS TECHNOLOGY

Comparison between BI-CMOS and CMOS is

Above figure shows that how the heterogeneous

necessary because of we should know how much

integration is processed. First of all we make the

speed is increased and how much less area is

epitaxial growth after that we handle the by the

covered.

process of wafer bonding. After that we remove the

growth substrate.

Figure 3:Permanent bonding to CMOS after heat

spreader deposition [5]

Above diagram is that in which we see that how the

permanent bonding is provided to CMOS with the

help of heat spreader deposition. Heat is speeded

on the adhesive layer of Si CMOS. Figure 5: Comparison between CMOS & Bi-

CMOS Technology [1]

In the first graph we compared the speed of BI-

CMOS and CMOS technology. In the first graph

we see that speed of the BI-CMOS is additional

than the CMOS technology.

ISSN: 2348 8549 www.internationaljournalssrg.org Page 44

SSRG International Journal of Electronics and Communication Engineering (SSRG-IJECE) Volume 3 Issue 8 August 2016

In the second graph we compare the delay

characteristic of BI-CMOS and CMOS technology.

In this graph we see that delay in the CMOS

technology is larger than the BI-CMOS technology.

In the third graph we compare the area of BI-

CMOS and CMOS technology using. In this graph

we see that area consumed by BI-CMOS is less

than that of CMOS technology.

VI. CONCLUSION

This paper concludes that speed and performance

of BI-CMOS is more than the CMOS technology.

In the BI-CMOS technology BI polar technology is

used who increase the switching speed, increase the

current gain per unit area and increase the

transconductance. CMOS technology is also used

who decrease the power dissipation, increase the

packing density and its switching capacity is ideal.

By the combination of these two technology we

construct the BI-CMOS technology. BI-CMOS

technology is used in the SRAM (static random

access memory), DRAM (dynamic random access

memory) and REGISTERS. Finally we say that BI-

CMOS technology is very helpful technology in the

field of electronics.

REFERENCES

[1] Ikuromasuda, Katsumi ogiue, Shinji Kadono, HIGH

PERFORMANCE BI-CMOS TECHNOLOGY AND ITS

APPLICATION.

[2] Hisayo sasakimomose, Hiroshi iwai, ANALYSIS OF

THE TEMPERATURE DEPENDENCE OF HOT

CARRIER INDUCED DEGRADATION IN BI POLAR

TRANSISTOR FOR BI-CMOS, IEEE transaction on

electron devices, vol.41, No 6, JUNE 1994.

[3] T. Watanabe et al., "High speed BICMOSVLSI technology

with buried twin wellstructure," IEDM Tech. Dig., 1985,

pp.423-426.

[4] I. Masuda et al., "High speed logic circuitsCombining

bipolar and CMOS technology, Trans. Inst. Electron.

CommunicationEngineers Japan, vol. J67-C, no. 12,

pp.999-1005, Dec. 1984.

[5] Y.Royter, P.R.Patterson, J.C.Li, K.R.Elliott, T.Hussain,

M.F.Boag-OBrien, J.R.Duvall, M.C.Montes, D.A.Hitko,

J.S.Sewell, M.Sokolich, D.H.Chow, P.D.Brewer, DENSE

HETROGENEOUS INTEGRATION FOR InP BI-CMOS

TECHNOLOGY.

[6] T. Hussain et al, 2006 IPRM Proceedings, p. 85.

ISSN: 2348 8549 www.internationaljournalssrg.org Page 45

You might also like

- Seminar Report-Bicmos TechnologyDocument19 pagesSeminar Report-Bicmos Technologymbiswasray_iter0% (1)

- Seminar Report Bicmos Technology PDFDocument6 pagesSeminar Report Bicmos Technology PDFjayarajcuietNo ratings yet

- BiCMOS Circuit DesignDocument15 pagesBiCMOS Circuit Designjeevan43250% (2)

- Bicmos 2003Document31 pagesBicmos 2003Naga NikhilNo ratings yet

- Vlsi Upto 3unitDocument105 pagesVlsi Upto 3unitAsha PagidipalliNo ratings yet

- Bicmos TechnologyDocument18 pagesBicmos TechnologyRaghava RaghuNo ratings yet

- Difference Between CMOS and NMOS TechDocument5 pagesDifference Between CMOS and NMOS TechShavel Kumar100% (1)

- Realization of BicmosDocument51 pagesRealization of BicmosSravana JyothiNo ratings yet

- 297 39464 Bicmos TechnologyDocument17 pages297 39464 Bicmos TechnologyAstosh BaheraNo ratings yet

- New Microsoft Office Power Point PresentationDocument13 pagesNew Microsoft Office Power Point Presentationbharat0791No ratings yet

- Unit # 5 Dynamic Cmos and ClockingDocument15 pagesUnit # 5 Dynamic Cmos and ClockingKiran KumariNo ratings yet

- Next:: 5.2.2 Process Discussion 5.2 Bicmos Process Technology 5.2 Bicmos Process TechnologyDocument8 pagesNext:: 5.2.2 Process Discussion 5.2 Bicmos Process Technology 5.2 Bicmos Process TechnologysirapuNo ratings yet

- History and Fundamentals of Semiconductor Devices and System on Chip (SOCDocument2 pagesHistory and Fundamentals of Semiconductor Devices and System on Chip (SOCBibin TbNo ratings yet

- VLSI Micro-Project Report Group A PDFDocument14 pagesVLSI Micro-Project Report Group A PDFganesh SawantNo ratings yet

- Advantages of CmosDocument4 pagesAdvantages of CmosvinaycmosNo ratings yet

- Bi CMOSDocument1 pageBi CMOSJunaid IkramNo ratings yet

- BiCMOS TechnologyDocument17 pagesBiCMOS TechnologyJacob ChakoNo ratings yet

- Chap02 (12 18 06) PDFDocument79 pagesChap02 (12 18 06) PDFHassan FarssiNo ratings yet

- VLSI IntroductionDocument23 pagesVLSI IntroductionSreenivasulu MamillaNo ratings yet

- Bicmos TechnologyDocument34 pagesBicmos TechnologyRahil Sharma100% (8)

- A High-Performance All-Enhancement Nmos Operational AmplifierDocument8 pagesA High-Performance All-Enhancement Nmos Operational AmplifierShivam BinjolaNo ratings yet

- CMOS Technology: An IntroductionDocument7 pagesCMOS Technology: An IntroductionMaria Ana DanganNo ratings yet

- Bicmos TechnologyDocument37 pagesBicmos TechnologyPriya SinghNo ratings yet

- IJETR011811Document6 pagesIJETR011811Anonymous gF0DJW10yNo ratings yet

- CMOS 32nm Technology BeyondDocument10 pagesCMOS 32nm Technology BeyonddevendrakphyNo ratings yet

- Bic MOSDocument1 pageBic MOSCarlos de la Calleja0% (1)

- Dec50143 Pw2 IzzDocument11 pagesDec50143 Pw2 Izziskandardaniel0063No ratings yet

- 3-VLCI - CMOS&BiCMOSDocument8 pages3-VLCI - CMOS&BiCMOSbhieestudentsNo ratings yet

- Ee503 - Ic Fabrication and Packaging TechnologyDocument34 pagesEe503 - Ic Fabrication and Packaging TechnologyPrevenaManiamNo ratings yet

- Reference Paper (30) Jehyungyoon2008Document6 pagesReference Paper (30) Jehyungyoon2008Zohaib Hasan KhanNo ratings yet

- A Review Paper On CMOS, SOI and FinFET TechnologyDocument12 pagesA Review Paper On CMOS, SOI and FinFET Technologyરાહુલ મેહ્તાNo ratings yet

- Understanding About CMOS Fabrication TechnologyDocument8 pagesUnderstanding About CMOS Fabrication TechnologyAjay Kumar MattupalliNo ratings yet

- Advanced CMOS CircuitsDocument20 pagesAdvanced CMOS CircuitsAnonymous IXvuFdeNo ratings yet

- Gifi - AbstractDocument16 pagesGifi - AbstractAakiv Bhatia80% (5)

- VLSI Backend Lab ManualDocument56 pagesVLSI Backend Lab ManualAllanki Sanyasi Rao100% (1)

- What Is A Microphone PCBDocument12 pagesWhat Is A Microphone PCBjackNo ratings yet

- Introduction To MOS TechnologiesDocument15 pagesIntroduction To MOS TechnologieslokeshwarrvrjcNo ratings yet

- Cmos Technology GroupDocument56 pagesCmos Technology GroupAiman NabihahNo ratings yet

- MINOR2 DfinalocxDocument32 pagesMINOR2 DfinalocxVenkatesh KumarNo ratings yet

- 110429_psec_workshop_drake_size_dependenceDocument25 pages110429_psec_workshop_drake_size_dependencezlh14188No ratings yet

- L11a 4345 Sp02Document24 pagesL11a 4345 Sp02Sanjay GargNo ratings yet

- The CMOS Inverter ExplainedDocument4 pagesThe CMOS Inverter ExplainedVidhya DsNo ratings yet

- Batch B8Document25 pagesBatch B8Techincal GaniNo ratings yet

- Design of CMOS Inverter Using Different Aspect Ratios: Key Words: CMOS Parameters, Threshold Voltage, W/LDocument6 pagesDesign of CMOS Inverter Using Different Aspect Ratios: Key Words: CMOS Parameters, Threshold Voltage, W/LArshi DhimanNo ratings yet

- Applications of Bicmos Logical Circuits HANOK DAN Mtech (Vlsi) PRESENTSDocument14 pagesApplications of Bicmos Logical Circuits HANOK DAN Mtech (Vlsi) PRESENTSmsantoshkkdNo ratings yet

- Imp For IntDocument3 pagesImp For IntsaticitechNo ratings yet

- BiCMOS TechnologyDocument21 pagesBiCMOS TechnologyMohd YasirNo ratings yet

- Physical Verification1Document163 pagesPhysical Verification1Praveen Kumar100% (1)

- High Performance Hybrid System Consisting of Inp HBT, Gan, Si Cmos and Fram MemoryDocument4 pagesHigh Performance Hybrid System Consisting of Inp HBT, Gan, Si Cmos and Fram MemoryMadhuri SutharNo ratings yet

- Understanding About CMOS Fabrication TechnologyDocument4 pagesUnderstanding About CMOS Fabrication TechnologyJayesh RaghuwanshiNo ratings yet

- Nabanita Das Susmita Sarma Mrinal Kanti Debnath Manash DebnathDocument42 pagesNabanita Das Susmita Sarma Mrinal Kanti Debnath Manash DebnathManash DebnathNo ratings yet

- CmosDocument207 pagesCmossuneeldvNo ratings yet

- CMOS BasicsDocument41 pagesCMOS BasicsYeshoda MallikarjunaNo ratings yet

- Vlsi5 BicmosDocument19 pagesVlsi5 BicmosGaurav MehraNo ratings yet

- Modeling and Simulation of LDMOS DeviceDocument5 pagesModeling and Simulation of LDMOS DeviceamrNo ratings yet

- Analog Digital Bicmos RealizationDocument63 pagesAnalog Digital Bicmos RealizationSravana JyothiNo ratings yet

- Lecture 6aDocument24 pagesLecture 6aBernard Mkumbwa Jr.No ratings yet

- Video and Camcorder Servicing and TechnologyFrom EverandVideo and Camcorder Servicing and TechnologyRating: 4 out of 5 stars4/5 (1)

- Robert Bosch Limited Money Purchase PlanDocument17 pagesRobert Bosch Limited Money Purchase Planmaha nandhini pNo ratings yet

- MM ChaptersDocument10 pagesMM Chaptersmaha nandhini pNo ratings yet

- Business-Level StrategyDocument35 pagesBusiness-Level StrategytrrNo ratings yet

- How To Analyse A Case StudyDocument6 pagesHow To Analyse A Case StudyKumudu PriyankaraNo ratings yet

- MBA Program Regulations 2017- Course PlanDocument9 pagesMBA Program Regulations 2017- Course Planmaha nandhini pNo ratings yet

- Afv Models Fuel Type 10-8-19Document4 pagesAfv Models Fuel Type 10-8-19maha nandhini pNo ratings yet

- Online Class W3Document1 pageOnline Class W3maha nandhini pNo ratings yet

- ProfRavi ORSI 2020 PDFDocument1 pageProfRavi ORSI 2020 PDFmaha nandhini pNo ratings yet

- Online Class W4Document1 pageOnline Class W4maha nandhini pNo ratings yet

- Safety and Health at WorkDocument41 pagesSafety and Health at Workmaha nandhini pNo ratings yet

- Siemens 12 FullDocument4 pagesSiemens 12 Fullapi-3705095100% (1)

- Wang 2017Document13 pagesWang 2017maha nandhini pNo ratings yet

- Online Class Timetable for Batch 2019-2021Document1 pageOnline Class Timetable for Batch 2019-2021maha nandhini pNo ratings yet

- 4 1 I, Term 2, 2019-21 180: MBA Program Regulations 2017 (Amended) - Course PlanDocument10 pages4 1 I, Term 2, 2019-21 180: MBA Program Regulations 2017 (Amended) - Course Planmaha nandhini pNo ratings yet

- 13 Coimbatore PDFDocument18 pages13 Coimbatore PDFKatamoNo ratings yet

- ITC Limited Consolidated Balance Sheet 2018Document83 pagesITC Limited Consolidated Balance Sheet 2018maha nandhini pNo ratings yet

- Om - CP - 2019 (2)Document9 pagesOm - CP - 2019 (2)maha nandhini pNo ratings yet

- Week 3 - Supply Chain Operations - Six SigmaDocument4 pagesWeek 3 - Supply Chain Operations - Six SigmaBharath SaravananNo ratings yet

- Comparative Statement For Export of Agri and Processed Food ProductsDocument1 pageComparative Statement For Export of Agri and Processed Food Productsmaha nandhini pNo ratings yet

- Excel Function Session 2Document8 pagesExcel Function Session 2maha nandhini pNo ratings yet

- Afv Models Fuel Type 10-8-19Document4 pagesAfv Models Fuel Type 10-8-19maha nandhini pNo ratings yet

- Wang 2017Document13 pagesWang 2017maha nandhini pNo ratings yet

- Bus Timetable 39 20190825Document2 pagesBus Timetable 39 20190825maha nandhini pNo ratings yet

- Siemens 12 FullDocument4 pagesSiemens 12 Fullapi-3705095100% (1)

- SyllabusDocument16 pagesSyllabusmaha nandhini pNo ratings yet

- Siemens 12 FullDocument4 pagesSiemens 12 Fullapi-3705095100% (1)

- Matlab Code For Wavelet Based Image Fusion (/) : Search For Products and ProjectsDocument10 pagesMatlab Code For Wavelet Based Image Fusion (/) : Search For Products and Projectsmaha nandhini pNo ratings yet

- Embedded stethoscope visualizationDocument4 pagesEmbedded stethoscope visualizationmaha nandhini pNo ratings yet

- Mems PDFDocument40 pagesMems PDFmaha nandhini pNo ratings yet

- PDFDocument4 pagesPDFmaha nandhini pNo ratings yet

- Analog Layout Engineer with 5+ Years Experience in TSMC 28nm, TSMC 45, TSMC 65nm & GF 14nm/45nm NodesDocument5 pagesAnalog Layout Engineer with 5+ Years Experience in TSMC 28nm, TSMC 45, TSMC 65nm & GF 14nm/45nm NodeskalyanNo ratings yet

- Lesson 3 - Filters: Engr RenDocument29 pagesLesson 3 - Filters: Engr RenRennel MallariNo ratings yet

- 555 Timer IC-Block Diagram-Working-Pin Out Configuration-Data SheetDocument13 pages555 Timer IC-Block Diagram-Working-Pin Out Configuration-Data SheetΔημητριος ΣταθηςNo ratings yet

- Common Emitter Un Bypassed Emitter - Fixed Bias ConfigurationDocument14 pagesCommon Emitter Un Bypassed Emitter - Fixed Bias ConfigurationForge lastNo ratings yet

- Silicon NPN Power Transistors: Savantic Semiconductor Product SpecificationDocument3 pagesSilicon NPN Power Transistors: Savantic Semiconductor Product Specificationameer_jaburNo ratings yet

- Design Analog and Mixed Circuits Lab ManualDocument61 pagesDesign Analog and Mixed Circuits Lab Manualvenkata satishNo ratings yet

- IC555 FM Modulator CircuitDocument5 pagesIC555 FM Modulator CircuitSanjeev DidelNo ratings yet

- M54HC4002 M74HC4002: Dual 4 Input Nor GateDocument9 pagesM54HC4002 M74HC4002: Dual 4 Input Nor GateStuxnetNo ratings yet

- TDA2030A: Unisonic Technologies Co., LTDDocument15 pagesTDA2030A: Unisonic Technologies Co., LTDPedro CastañedaNo ratings yet

- B2-4b Electronic Fundamentals II SRDocument102 pagesB2-4b Electronic Fundamentals II SRAlexander McfarlaneNo ratings yet

- 45 dB Variable Gain MMIC Amplifier with 0.81 dB NFDocument4 pages45 dB Variable Gain MMIC Amplifier with 0.81 dB NFutilitytrackNo ratings yet

- Type II CompensatorDocument10 pagesType II CompensatorTrương Văn TrọngNo ratings yet

- Tutorial 1 Sept 2020 PDFDocument4 pagesTutorial 1 Sept 2020 PDFusai_ahmadNo ratings yet

- DLD Assignment 1Document5 pagesDLD Assignment 1Asfand Yar0% (1)

- TN40CMSP002 2 0 2Document192 pagesTN40CMSP002 2 0 2emmasustechNo ratings yet

- Blinking Disco LEDs Using Microcontroller PIC16f877aDocument3 pagesBlinking Disco LEDs Using Microcontroller PIC16f877aTeo JavaNo ratings yet

- 12V 500w Inverter CircuitDocument4 pages12V 500w Inverter CircuitklezehNo ratings yet

- Lecture 30: Biasing MOSFET Amplifiers. MOSFET Current MirrorsDocument8 pagesLecture 30: Biasing MOSFET Amplifiers. MOSFET Current MirrorsDinesh Kumar J RNo ratings yet

- Adrv 9002Document92 pagesAdrv 9002rajNo ratings yet

- Double-Balanced Mixer and Oscillator: Philips SemiconductorsDocument12 pagesDouble-Balanced Mixer and Oscillator: Philips SemiconductorsAle MmsNo ratings yet

- P2003EVG Niko-Sem: P-Channel Logic Level EnhancementDocument5 pagesP2003EVG Niko-Sem: P-Channel Logic Level EnhancementNeto CunhaNo ratings yet

- Transistor As A SwitchDocument12 pagesTransistor As A Switcharjuna4306No ratings yet

- Voltage Detector Ic With Counter Timer: Bd45Xxxg Bd46XxxgDocument5 pagesVoltage Detector Ic With Counter Timer: Bd45Xxxg Bd46XxxgPham LongNo ratings yet

- Cmos Fully Integrated Heterodyne RF ReceiversDocument21 pagesCmos Fully Integrated Heterodyne RF ReceiversShweta GadgayNo ratings yet

- Ham - Dmz.ro - ts-2000X Service ManualDocument171 pagesHam - Dmz.ro - ts-2000X Service Manualballen4875No ratings yet

- bd9851 DatasheetDocument17 pagesbd9851 DatasheetMarcos OliveiraNo ratings yet

- Adc 0809Document12 pagesAdc 0809Carbon Nano TubeNo ratings yet

- Vlsi DocumentDocument100 pagesVlsi Documentbaburao_kodavatiNo ratings yet

- ADC0831/ADC0832/ADC0834 and ADC0838 8-Bit Serial I/O A/D Converters With Multiplexer OptionsDocument33 pagesADC0831/ADC0832/ADC0834 and ADC0838 8-Bit Serial I/O A/D Converters With Multiplexer OptionsRoy Muy GolfoNo ratings yet

- 3-O FaultDocument15 pages3-O FaultJaved Ahmed LaghariNo ratings yet