Professional Documents

Culture Documents

A Comparative Study On Analysis & Design of Pre-Engineered & Conventional Industrial Building

Uploaded by

IJIRSTOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Comparative Study On Analysis & Design of Pre-Engineered & Conventional Industrial Building

Uploaded by

IJIRSTCopyright:

Available Formats

IJIRST International Journal for Innovative Research in Science & Technology| Volume 3 | Issue 10 | March 2017

ISSN (online): 2349-6010

A Comparative Study on Analysis & Design of

Pre-Engineered & Conventional Industrial

Building

Hemant Sharma

Assistant Professor

Department of Civil Engineering

K. J. Institute of Engineering & Technology, Savli, Vadodara Gujarat India

Abstract

In this case study I have analyzed, Designed and compared the pre-engineered industrial building with the conventional building

by mainly comparing the bending moments at different sections. Also I have considered different components of the pre-engineered

steel building. To design and analysis the PEB and CSB I have used Staad pro v.8 as well as Indian standard codes. And finally I

have compared these two structures in terms of Economy and Time saving of construction. I have tried many truss systems for

cladding and roofing system purpose. In the analysis I have analyzed and designed the Purlins, Girts, Eave Struts and Bracings etc.

For the design I have considered Dead Load, Live Load and Wind Load for the location of Vadodara, Gujarat as per IS Code

consideration.

Keywords: Pre-Engineered Building, Conventional Building, Staad Pro, Analysis, Design, Comparison

_______________________________________________________________________________________________________

I. INTRODUCTION

Pre-Engineered Building (PEB) concept involves the steel building systems which are predesigned and prefabricated. The basis of

the PEB concept lies in providing the section at a location only according to the requirement at that spot. The sections can be

varying throughout the length according to the bending moment diagram. This leads to the utilization of non-prismatic rigid frames

with slender elements. Tapered I sections made with built-up thin plates are used to achieve this configuration.

Conventional steel buildings (CSB) are low rise steel structures with roofing systems of truss with roof coverings. The selection

criterion of roof truss also includes the slope of the roof, fabrication and transportation methods, aesthetics, climatic conditions,

etc. Several compound and combination type of economical roof trusses can also be selected depending upon the utility. Standard

hot-rolled sections are usually used for the truss elements along with gusset plates.

Purpose

The purpose of this study is to mainly compare the techniques of engineering now a day. Also the requirement of this study is to

study the benefits and application of the pre-engineered industrial buildings. Also the purpose of this study is to minimize the time

of construction of industrial building. So that construction rate can be increased. Also the overall cost of the building will be less.

After studying this one can be able to provide the building with large clear span and low maintenance cost as well. The erection

rate will be faster and the roofing system will be energy efficient.

Use of Pre-Engineered Building

The application of pre- engineered building is of wide range. It is mainly used in Industrial and Commercial building. It can be

also used in institutional building, aviation and military purpose.

Mechanisms of Pre-Engineered Building

The pre-engineered building and conventional building are mainly compared on the basis of Bending moment and Overall

Deflection of the structure. The analysis and design has been completed in Staad Pro and with reference to the Indian Standard

codes.

Components of Industrial Steel Buildings

Typical assembly of a simple steel building system is shown below to illustrate the Synergy between the various building

components as described below:

Primary components

Secondary components

Sheeting (or) cladding

Accessories

All rights reserved by www.ijirst.org 69

A Comparative Study on Analysis & Design of Pre-Engineered & Conventional Industrial Building

(IJIRST/ Volume 3 / Issue 10/ 013)

II. METHODOLOGY

This Pre- Engineered Building has been designed in Staad pro and Used Limit state method. The Indian Standard Codes used are

Is:800-2007, IS 875 (Part I, II & III) 1987. For the wind load design IS 875 part 3 has been used.

III. ANALYSIS & DESIGN

Industrial Building Data

Type of the Building : Clear Span -CS

Width : 20.0 m C/C

Length : 18 m C/C

Eave Height : 8m

Roof Slope : 8

Distance to Ridge : 9.56m

Main Frame Column Spacing : 4 @ 5m

Bay Spacing : 3 @ 6m

End Wall Type : Post & Beam

End Wall Column Sp acing : 4 @ 5m

Fig. 1: Geometry of in Dustrial Steel Building Con Sidered as Example

Load Cases

In this example, Static loads i.e., Dead loads and Live load are considered as per IS 875 (Part I & II) 1987.

Dynamic loads i.e. Wind load is considered as per IS 875 (Part - III) - 1987.

Static loads - (As per IS 875 (Part I & II) 1987

a) Calculation of Dead Load

Dead load = 0.15 kN/m

Bay spacing = 6 m

DL per meter = 0.9 kN/m

Calculation of Live Load:

Live Load = 0.75 kN/m

Bay spacing = 6 m

LL per meter = 4.5 kN

All rights reserved by www.ijirst.org 70

A Comparative Study on Analysis & Design of Pre-Engineered & Conventional Industrial Building

(IJIRST/ Volume 3 / Issue 10/ 013)

Dynamic loads (As per IS 875 (Part I & II) 1987)

a) Calculation of Wind Loads

For the calculation of wind loads following data have been adopted.

Max Bay Spacing: 6 m with Roof Slope 8

Location for Wind: Vadodara, GIDC (Basic wind speed= Vb= 44m/s)

In this example, building is considered to be open terrain with well scattered obstructions having height less than 10 m with

maximum dimension more than 50 m and accordingly factors K 1, K2, K3 have been calculated as per IS 875 Part III (1987).

Terrain Category- 2 Class- B

K1- Probability factor- 1.0, K2- Terrain, height and size factor- 0.98, K3- Topography factor- 1

1) Design Wind Speed

Vz = (K1 X K2 X K3) X Vb

2) Design Wind Pressure, P :

P =O.6 (Vz) kN/m

Ratio- H/W=0.4, L/W= 0.9

3) Wind Pressure Coefficients

LExternal and Internal wind coefficients are calculated for all the surfaces for both pressure and suction. Opening in the building

has been considered less than 5% and accordingly internal coefficients are taken as +0.5 and -0.5.

Fig. 2: Load Combinations

The external coefficients and internal coefficients calculated as per IS 875 Part III (1987).

Wind load on individual members are then calculated as below.

F= (Cpe - Cpi) x A x P

Where, Cpe, Cpi are external coefficients and internal coefficients respectively and A and P are Surface Area in m and Design

Wind Pressure in kN/m respectively.

All rights reserved by www.ijirst.org 71

A Comparative Study on Analysis & Design of Pre-Engineered & Conventional Industrial Building

(IJIRST/ Volume 3 / Issue 10/ 013)

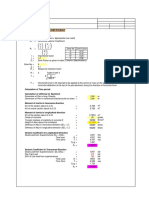

IV. DIMENSIONS OF TAPERED COLUMN

Fig. 3: Dimensions of Tapered Column

Comparison of Mom ENTS & Shear force For PEB & CSB

Fig. 4: Comparison of Mom ENTS & Shear force For PEB & CSB

All rights reserved by www.ijirst.org 72

A Comparative Study on Analysis & Design of Pre-Engineered & Conventional Industrial Building

(IJIRST/ Volume 3 / Issue 10/ 013)

Fig. 5: Comparison of PEB & CSB Bending Moment

Cost comparison & Conclusion

The Weight of PEB and conventional industrial building is calculated after the final design. Table 3 gives the weight of plane

frame Pre-Engineered building. In these tables column 1 shows the sections used. Column 2 shows the overall length of the

members and column 3 shows the calculated weight.

Similarly, Table gives the weight of conventional building in which column-1 consists of members of same cross sectional

properties. Column 2 and column 3 shows the sizes of the m embers and their length. As it seen in the Fig, PEB structure is

designed for a clear span of 20m with column in between, as in case of conventional building, where it is not possible to provide

a clear span truss and hence an interior column is provided. The conventional frame is designed using multi span truss, which is

generally used for long span trusses. Results of both PEB and Conventional buildings are tabulated in the Table respectively. It

can be noticed that, even though PEB structures provides clear span, it weighs minimum 27% - 30% lesser than that of conventional

buildings.

Calculation of Steel for PEB and CSB

Table - 1

Weight of Total Structural Steel Sections for PEB

Profile Length (Meter) Weight(KN)

Tapered member 1 137.36 202.069

Tapered member 4 20.24 24.805

FR ISMC 400 54.00 52.210

Tapered member 38 20.24 11.406

TOTAL 290.489

Table - 2

Weight of Total Structural Steel Sections for CSB

Profile Length (Meter) Weight(KN)

ST ISWB 600A 128.00 181.810

ST ISA 130X130X12 90.73 20.785

ST ISA 150X150X15 158.47 104.155

FR ISMC 400 162.00 156.629

Total 463.379

V. CONCLUSION OF THE STUDY

After doing detailed analysis of PEB and CSB, there observed 37% overall material saving & cost reduction in PEB compared to

CSB.

REFERENCES

[1] Dr. N. Subramanian, Design of Steel Structures.

[2] S. Jagadesh kannan, V. Vanitha, Comparison of Various Types of Roofs in PEB, International journal of Engineering Trends and Technology (IJETT)

Volume 22 Number 8 April 2015.

[3] S.D. Charkha, Latesh S. Sanklecha, Economizing Steel Building using Pre-engineered Steel Sections, International journal of Research in Civil

Engineering, Architecture & Design Volume 2, Issue 2, April-june, 2014, pp. 01-10.

[4] Pradeep V., Papa Rao G., Comparative Study of Pre Engineered and Conventional Industrial Building, International journal of Engineering Trends and

Technology (IJETT) Volume 9 Number 1 March 2014.

All rights reserved by www.ijirst.org 73

A Comparative Study on Analysis & Design of Pre-Engineered & Conventional Industrial Building

(IJIRST/ Volume 3 / Issue 10/ 013)

[5] Aijaz Ahmad Zende, Prof. A. V. Kulkarni, Aslam Hutagi, Comparative Study of Analysis and Design of Pre-Engineered Buildings and Conventional

Frames, IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE) ISSN : 2278-1684 Volume 5, Issue 1(Jan. Feb. 2013), pp 32-43 .

[6] Shrunkhal V. Bhagatkar, Farman Iqbal Shaikh, Bhanu Prakash Gupta, Deepak Kharta, A Study On Pre-Engineered Building A Construction Technique,

International journal of Research and Applications, ISSN :2248 - 9622, Vol. 5, Issue 3, (Part-2) March 2015, pp.

All rights reserved by www.ijirst.org 74

You might also like

- Viscous Dampers Save Structures From Earthquake Damage 7-2013Document23 pagesViscous Dampers Save Structures From Earthquake Damage 7-2013Nicolas RobertoNo ratings yet

- Seismic Response Reduction Factor Evaluation For Irregular RC Structures IJERTV8IS010114Document5 pagesSeismic Response Reduction Factor Evaluation For Irregular RC Structures IJERTV8IS010114pandurang kadamNo ratings yet

- Crane Design Guide 2Document8 pagesCrane Design Guide 2Mesfin Derbew0% (1)

- CFD Is 456 200Document80 pagesCFD Is 456 200Ali BaghbanNo ratings yet

- Segmental Post-Tensioned Concrete BridgesDocument12 pagesSegmental Post-Tensioned Concrete BridgesDimitri Mn100% (2)

- Design Basis Report - KCLDocument18 pagesDesign Basis Report - KCLmondaldgpNo ratings yet

- Saudi Masonry Code: SBC 305 - CRDocument115 pagesSaudi Masonry Code: SBC 305 - CRengahmad84No ratings yet

- Anchor Bolt Design CriteriaDocument42 pagesAnchor Bolt Design CriteriaRaditya Purnamahadi100% (2)

- Torsion Design Beam ExampleDocument9 pagesTorsion Design Beam ExampleKhajaNo ratings yet

- STAAD Analysis and Design of Residential BuildingDocument60 pagesSTAAD Analysis and Design of Residential BuildingMd Mufazzel Hossain Chowdhury100% (1)

- Design of Industrial Warehouse IJERTV7IS020170Document5 pagesDesign of Industrial Warehouse IJERTV7IS020170Anonymous Uf0LDX6GNo ratings yet

- OSEA ASCE7-10 Most Common Errors in Seismic Design-04!14!15Document59 pagesOSEA ASCE7-10 Most Common Errors in Seismic Design-04!14!15Aie BantuganNo ratings yet

- A Comparative Study of Conventional Steel Building and Pre-Engineered Steel Building Structure Using STAAD PRODocument7 pagesA Comparative Study of Conventional Steel Building and Pre-Engineered Steel Building Structure Using STAAD PROIJRASETPublicationsNo ratings yet

- 23-Design and Construction of The Balanced Arch Bridge On The Deep Foundation PDFDocument8 pages23-Design and Construction of The Balanced Arch Bridge On The Deep Foundation PDFALFREDONo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Static Vs Dynamic PDFDocument12 pagesStatic Vs Dynamic PDFshivaniNo ratings yet

- Design of Conical Roof Structure for Liquid Sulphur Storage TankDocument7 pagesDesign of Conical Roof Structure for Liquid Sulphur Storage TankSaravanan Silamban100% (1)

- A Comparative Study On Analysis & Design of Pre-Engineered & Conventional Industrial BuildingDocument7 pagesA Comparative Study On Analysis & Design of Pre-Engineered & Conventional Industrial BuildingAyush GargNo ratings yet

- Wind and Seismic Analysis of Pre-Engineered BuildingDocument10 pagesWind and Seismic Analysis of Pre-Engineered BuildingIJRASETPublicationsNo ratings yet

- Review PaperDocument6 pagesReview PaperdhanarajNo ratings yet

- Review of Typified Designs of Trusses in The Context of Revised IS CodeDocument7 pagesReview of Typified Designs of Trusses in The Context of Revised IS CodeBasava SowmyaNo ratings yet

- Irjet V5i6276Document5 pagesIrjet V5i6276Vinit KondapureNo ratings yet

- Irjet V5i6276 PDFDocument5 pagesIrjet V5i6276 PDFAkula VeerrajuNo ratings yet

- Comparison of Conventional Steel Roof Trusses With Tubular Trusses IJERTCONV3IS19164Document4 pagesComparison of Conventional Steel Roof Trusses With Tubular Trusses IJERTCONV3IS19164irfan ullahNo ratings yet

- Comparative Study of Different Plan Configuration Buildings Using Wind AnalysisDocument9 pagesComparative Study of Different Plan Configuration Buildings Using Wind AnalysisRohit NegiNo ratings yet

- V5I1-1140Document4 pagesV5I1-1140BeauTech Engg. & Construction Pvt. Ltd.No ratings yet

- Irjet V7i9576Document4 pagesIrjet V7i9576umashankaryaligarNo ratings yet

- Cost-Effectiveness of Pre-Engineered and Conventional Steel FramesDocument7 pagesCost-Effectiveness of Pre-Engineered and Conventional Steel FramesBiswajit SahooNo ratings yet

- 2019 - Artigo - Static Structural Analysis of Pratt, Flink and Howe Steel Truss Using Ansys SoftwareDocument8 pages2019 - Artigo - Static Structural Analysis of Pratt, Flink and Howe Steel Truss Using Ansys SoftwareGiovanni Bertholdo SteckelbergNo ratings yet

- Ijstev2i10284 PDFDocument6 pagesIjstev2i10284 PDF081382991318No ratings yet

- Analysis of high-rise building using ETABSDocument6 pagesAnalysis of high-rise building using ETABSAli Asghar LangahNo ratings yet

- BunkerDocument7 pagesBunkerSrinivasan GanesanNo ratings yet

- International Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)Document8 pagesInternational Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)Parth DaxiniNo ratings yet

- Design and Analysis of Pre-Engineered Building With Subjected To Seismic Loads Using E-TabsDocument4 pagesDesign and Analysis of Pre-Engineered Building With Subjected To Seismic Loads Using E-TabsFaisal AminNo ratings yet

- Study and Analysis of Pre-Engineering Building Structure: Sunil Kumar, Assit. Prof. G.B. BhaskarDocument3 pagesStudy and Analysis of Pre-Engineering Building Structure: Sunil Kumar, Assit. Prof. G.B. Bhaskarshashank adigaNo ratings yet

- Wind Analysis of Pre Engineering and ConDocument11 pagesWind Analysis of Pre Engineering and Conavic712219006No ratings yet

- Wind Analysis of Pre-Engineering and Conventional Steel Structure Using Pratt TrussDocument11 pagesWind Analysis of Pre-Engineering and Conventional Steel Structure Using Pratt TrussIJRASETPublicationsNo ratings yet

- SSRN Id3376351Document6 pagesSSRN Id3376351Hema Chandra Reddy KarimireddyNo ratings yet

- Analysis of An Industrial Structure For Wind Load: ISSN (PRINT) : 2393-8374, (ONLINE) : 2394-0697, VOLUME-5, ISSUE-2, 2018Document5 pagesAnalysis of An Industrial Structure For Wind Load: ISSN (PRINT) : 2393-8374, (ONLINE) : 2394-0697, VOLUME-5, ISSUE-2, 2018Shivakumar BtNo ratings yet

- IJCRT2306026Document8 pagesIJCRT2306026pankaj645924No ratings yet

- Ourside Calculation OnlyDocument7 pagesOurside Calculation OnlyAnishNo ratings yet

- Ijciet 08 04 210Document6 pagesIjciet 08 04 210Aashish kumarNo ratings yet

- Comparison of C - Section and H - Section Pre-Engineering Aircraft HangarDocument8 pagesComparison of C - Section and H - Section Pre-Engineering Aircraft HangarIJRASETPublicationsNo ratings yet

- CE20Document5 pagesCE20Babu SundararamanNo ratings yet

- Steel vs Bamboo Shed StructuresDocument36 pagesSteel vs Bamboo Shed StructuresAnup Satish SohoniNo ratings yet

- Design & Analysis of G + 5 Residential Building With Comparison of Conventional Slab and Flat Slab Using ETABSDocument8 pagesDesign & Analysis of G + 5 Residential Building With Comparison of Conventional Slab and Flat Slab Using ETABSIJRASETPublicationsNo ratings yet

- IJERDSEP1547Document10 pagesIJERDSEP1547wkh331985No ratings yet

- Comparing Design Procedures for Pre-Engineered BuildingsDocument6 pagesComparing Design Procedures for Pre-Engineered BuildingsAdnan AdilNo ratings yet

- Comparison of Pinned Support and Fixed Support Pre-Engineering Aircraft HangarDocument6 pagesComparison of Pinned Support and Fixed Support Pre-Engineering Aircraft HangarIJRASETPublicationsNo ratings yet

- Effectiveness and Efficiency of The Existing Building in Seismic Zone-III A Case Study of Hotel Kaashi Building in UjireDocument8 pagesEffectiveness and Efficiency of The Existing Building in Seismic Zone-III A Case Study of Hotel Kaashi Building in UjireIJRASETPublicationsNo ratings yet

- P770 778Document9 pagesP770 778Nitin shepurNo ratings yet

- Evaluation of Pre-Engineering Structure DesignDocument9 pagesEvaluation of Pre-Engineering Structure DesignAmjad PervazNo ratings yet

- Analysis and Design of PEB Using IS800 and International StandardDocument5 pagesAnalysis and Design of PEB Using IS800 and International StandardPratik R. AtwalNo ratings yet

- A Comparative Study between the Pre Engineered Building and Conventional Steel BuildingDocument9 pagesA Comparative Study between the Pre Engineered Building and Conventional Steel Buildingdawiw18153No ratings yet

- Analysis & Design of Innovative Industrial Roof: Arpita Nikam, Priyanka JoshilkarDocument9 pagesAnalysis & Design of Innovative Industrial Roof: Arpita Nikam, Priyanka Joshilkardino mohammedNo ratings yet

- Design and Comparison of MultistoreyDocument3 pagesDesign and Comparison of MultistoreyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparision of Is 875part 31987 and Is 875part 32015 For Tall Junction TowerDocument3 pagesComparision of Is 875part 31987 and Is 875part 32015 For Tall Junction Towerabhay_joshi2002No ratings yet

- Comparison of Response of Building Against Wind Load As Per Wind Codes (IS 875 - (Part 3) - 1987) and (IS 875 - (Part 3) - 2015)Document1 pageComparison of Response of Building Against Wind Load As Per Wind Codes (IS 875 - (Part 3) - 1987) and (IS 875 - (Part 3) - 2015)KNo ratings yet

- .Analysis of Multistorey Building With Steel Plate Shear Wall Using CYPE and ETABS SoftwaresDocument5 pages.Analysis of Multistorey Building With Steel Plate Shear Wall Using CYPE and ETABS Softwaresप्रतीक राज पण्डितNo ratings yet

- 1628083566Document9 pages1628083566dawiw18153No ratings yet

- Comparison of Design of Steel Roof Truss Using IS 875 and SP 38Document3 pagesComparison of Design of Steel Roof Truss Using IS 875 and SP 38suraj100% (1)

- Analysis and Design of Conventional Industrial Roof Truss and Compare It With Tubular Industrial Roof TrussDocument6 pagesAnalysis and Design of Conventional Industrial Roof Truss and Compare It With Tubular Industrial Roof TrussIJSTENo ratings yet

- Warehouse DBR 29-07-2020Document6 pagesWarehouse DBR 29-07-2020KaushikNo ratings yet

- COST-EFFECTIVE PEB BUILDINGDocument4 pagesCOST-EFFECTIVE PEB BUILDINGSandeep SolankiNo ratings yet

- Comparative Analysis of PEB Structure With Varying Bay SpacingDocument12 pagesComparative Analysis of PEB Structure With Varying Bay SpacingIJRASETPublicationsNo ratings yet

- Seismic Retrofitting of RC Frame Structure Using Energy Dissipation DeviceDocument11 pagesSeismic Retrofitting of RC Frame Structure Using Energy Dissipation DeviceIJRASETPublicationsNo ratings yet

- Study For Comparison On Design of Steel Frame Using Rolled, Fabricated and PEB SectionsDocument5 pagesStudy For Comparison On Design of Steel Frame Using Rolled, Fabricated and PEB SectionsEditor IJTSRDNo ratings yet

- I JR Et 20170601003Document7 pagesI JR Et 20170601003neoNo ratings yet

- Estimation of Gust Response Factor For A Tall Building Model With 1:1.5 Plan RatiosDocument12 pagesEstimation of Gust Response Factor For A Tall Building Model With 1:1.5 Plan RatiosKhushroo LankerNo ratings yet

- Peb B D0513243Document16 pagesPeb B D0513243Daniyal AhmedNo ratings yet

- Experimental Analysis of Friction Stir Processing of Tig Welded Aluminium Alloy 6061Document7 pagesExperimental Analysis of Friction Stir Processing of Tig Welded Aluminium Alloy 6061IJIRSTNo ratings yet

- Study On Performance Evaluation of Forced Convection Solar Dryer For Turmeric (Curcuma Longa L.)Document10 pagesStudy On Performance Evaluation of Forced Convection Solar Dryer For Turmeric (Curcuma Longa L.)IJIRSTNo ratings yet

- The Effect of Diverse Recording Devices On Forensic Speaker Apperception SystemDocument9 pagesThe Effect of Diverse Recording Devices On Forensic Speaker Apperception SystemIJIRSTNo ratings yet

- Postprocessing of Compacted Images Through Consecutive DenoisingDocument4 pagesPostprocessing of Compacted Images Through Consecutive DenoisingIJIRSTNo ratings yet

- Experimental Investigation On Concrete by Replacement of Sand by Silica Sand and Artificial SandDocument6 pagesExperimental Investigation On Concrete by Replacement of Sand by Silica Sand and Artificial SandIJIRSTNo ratings yet

- Manganese: Affecting Our Environment (Water, Soil and Vegetables)Document7 pagesManganese: Affecting Our Environment (Water, Soil and Vegetables)IJIRSTNo ratings yet

- Development of Satellite Data For Infrastructure Updation and Land Use/Land Cover Mapping - A Case Study From Kashipur & Chhatna Block, Bankura & Purulia District, West BengalDocument7 pagesDevelopment of Satellite Data For Infrastructure Updation and Land Use/Land Cover Mapping - A Case Study From Kashipur & Chhatna Block, Bankura & Purulia District, West BengalIJIRSTNo ratings yet

- Patterns of Crop Concentration, Crop Diversification and Crop Combination in Thiruchirappalli District, Tamil NaduDocument10 pagesPatterns of Crop Concentration, Crop Diversification and Crop Combination in Thiruchirappalli District, Tamil NaduIJIRSTNo ratings yet

- Satellite Dish Positioning SystemDocument5 pagesSatellite Dish Positioning SystemIJIRST100% (1)

- Physico-Chemical Analysis of Selected Ground Water Samples in and Around Nagapattinam District, TamilnaduDocument3 pagesPhysico-Chemical Analysis of Selected Ground Water Samples in and Around Nagapattinam District, TamilnaduIJIRSTNo ratings yet

- Induction Motor Drive Using SPWM Fed Five Level NPC Inverter For Electric Vehicle ApplicationDocument7 pagesInduction Motor Drive Using SPWM Fed Five Level NPC Inverter For Electric Vehicle ApplicationIJIRSTNo ratings yet

- Vibration Analysis of Composite Leaf Spring by Finite Element MethodDocument7 pagesVibration Analysis of Composite Leaf Spring by Finite Element MethodIJIRSTNo ratings yet

- Multi-Physics Based Simulations of A Shock Absorber Sub-SystemDocument7 pagesMulti-Physics Based Simulations of A Shock Absorber Sub-SystemIJIRSTNo ratings yet

- Arduino-UNO Based Magnetic Field Strength MeasurementDocument4 pagesArduino-UNO Based Magnetic Field Strength MeasurementIJIRSTNo ratings yet

- Custom ROMDocument3 pagesCustom ROMIJIRSTNo ratings yet

- Reconfigurable Manufacturing Systems Using The Analytical Hierarchical Process (AHP) - A ReviewDocument3 pagesReconfigurable Manufacturing Systems Using The Analytical Hierarchical Process (AHP) - A ReviewIJIRSTNo ratings yet

- Currency Recognition Blind Walking StickDocument3 pagesCurrency Recognition Blind Walking StickIJIRSTNo ratings yet

- Impact of Different Soils and Seismic Zones On Varying Height of Framed StructuresDocument8 pagesImpact of Different Soils and Seismic Zones On Varying Height of Framed StructuresIJIRSTNo ratings yet

- Efficient Revocation of Data Access in Cloud Storage Based On ABE-SchemeDocument6 pagesEfficient Revocation of Data Access in Cloud Storage Based On ABE-SchemeIJIRSTNo ratings yet

- Performance Analysis of Organic Rankine Cycle (ORC) Working On Different Refrigerant Fluids Having Low Boiling PointDocument5 pagesPerformance Analysis of Organic Rankine Cycle (ORC) Working On Different Refrigerant Fluids Having Low Boiling PointIJIRSTNo ratings yet

- Development of Tourism Near Loktak Lake (Moirang) in Manipur Using Geographical Information and Management TechniquesDocument4 pagesDevelopment of Tourism Near Loktak Lake (Moirang) in Manipur Using Geographical Information and Management TechniquesIJIRSTNo ratings yet

- Experimental Investigation On The Effect of Use of Bottom Ash As A Replacement of Fine AggregatesDocument7 pagesExperimental Investigation On The Effect of Use of Bottom Ash As A Replacement of Fine AggregatesIJIRSTNo ratings yet

- Rock Deformation by Extesometers For Underground Powerhouse of Sardar Sarovar Project (Gujarat)Document5 pagesRock Deformation by Extesometers For Underground Powerhouse of Sardar Sarovar Project (Gujarat)IJIRSTNo ratings yet

- Analysis of Agent Oriented Software EngineeringDocument5 pagesAnalysis of Agent Oriented Software EngineeringIJIRSTNo ratings yet

- Intelligent Irrigation SystemDocument5 pagesIntelligent Irrigation SystemIJIRSTNo ratings yet

- Comparative Study of Inner Core, Peripheral and RC Shear Wall SystemDocument8 pagesComparative Study of Inner Core, Peripheral and RC Shear Wall SystemIJIRSTNo ratings yet

- Women Protection Mechanism With Emergency Communication Using Hand Waving PatternDocument5 pagesWomen Protection Mechanism With Emergency Communication Using Hand Waving PatternIJIRSTNo ratings yet

- Literature Review For Designing of Portable CNC MachineDocument3 pagesLiterature Review For Designing of Portable CNC MachineIJIRSTNo ratings yet

- Infiltration, Permeability, Liquid Limit and Plastic Limit of SoilDocument12 pagesInfiltration, Permeability, Liquid Limit and Plastic Limit of SoilIJIRSTNo ratings yet

- Open Well StaircaseDocument5 pagesOpen Well StaircasesaiNo ratings yet

- Manuel S. Enverga University Foundation College of Engineering Earthquake ReportDocument5 pagesManuel S. Enverga University Foundation College of Engineering Earthquake Reporttherese abelNo ratings yet

- RYfnnd 7 LQ 1180612121529Document206 pagesRYfnnd 7 LQ 1180612121529Bickey LakhaNo ratings yet

- Cobicif-Reportdescription Eng PDFDocument700 pagesCobicif-Reportdescription Eng PDFĐạt Nguyễn TuấnNo ratings yet

- 2003 ISHPC Paper - Flexural Crack Control in Concrete Structures PDFDocument24 pages2003 ISHPC Paper - Flexural Crack Control in Concrete Structures PDFaomareltayebNo ratings yet

- Conical Shell FootingDocument6 pagesConical Shell FootingHari AppathuraiNo ratings yet

- Calculation of Seismic Coefficient: ProjectDocument1 pageCalculation of Seismic Coefficient: Projectnandu523No ratings yet

- PilesDocument17 pagesPilesntah84No ratings yet

- 420 - Review of GAD of Box CulvertsDocument34 pages420 - Review of GAD of Box Culvertsbikash kumarNo ratings yet

- Module 1 Introduction To Prestressed ConcreteDocument19 pagesModule 1 Introduction To Prestressed ConcreteDastardly HeelNo ratings yet

- Steel Build Engineering Catalogue PDFDocument6 pagesSteel Build Engineering Catalogue PDFArshalNo ratings yet

- Methodology For RCC Rectangular DrainDocument4 pagesMethodology For RCC Rectangular DrainAkash Yadav100% (2)

- Chemical Action: Types of Chemical AttackDocument14 pagesChemical Action: Types of Chemical AttackSunil KumarNo ratings yet

- Downloadmela Com ST7006 Design of BridgesDocument14 pagesDownloadmela Com ST7006 Design of BridgesSuman.SNo ratings yet

- Boundary Wall Estimate Comparision Sheet S.No Sor No. Decription Boundary Wall Total Qty Unit Rate AmountDocument6 pagesBoundary Wall Estimate Comparision Sheet S.No Sor No. Decription Boundary Wall Total Qty Unit Rate AmountInterns 2020No ratings yet

- 1505 Column Shortening of Concrete Cores and Composite Columns in A Tall Building PDFDocument7 pages1505 Column Shortening of Concrete Cores and Composite Columns in A Tall Building PDFRejoice SamboNo ratings yet

- Updated Sample Problem 2 On Mass WeightDocument1 pageUpdated Sample Problem 2 On Mass WeightmnmusorNo ratings yet

- Design codes, safety and behavior of RC structuresDocument23 pagesDesign codes, safety and behavior of RC structuresAhmad Faraz JuttNo ratings yet

- Alufix Slab Formwork Tim PDFDocument18 pagesAlufix Slab Formwork Tim PDFMae FalcunitinNo ratings yet

- Beam - GBDocument1 pageBeam - GBJake CortezNo ratings yet