Professional Documents

Culture Documents

Maintenance Practices Bloch 3

Uploaded by

rodolfostiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintenance Practices Bloch 3

Uploaded by

rodolfostiCopyright:

Available Formats

MAINTENANCE MANAGEMENT

The Wrong Maintenance

Priorities Threaten

Corporations

According to this

well-known veteran of

M any process plants as-sume that better maintenance strate-

gies will lead to higher equipment reliability. Very often,

the primary focus of these strategies is to avoid unnecessary oil changes

or to optimize compressor overhauls and the pursuit of other preventive

the reliability trenches, measures. Similarly, many of these strategies hope to help companies avoid

equipment damage and costly production interruptions by doing appro-

one of the best ways to priate maintenance just-in-time.

While these are commendable goals, they do not address the constraints

hone the survival skills that are built into vast quantities of equipment that incorporate less-than-

optimized components. Nor do such strategies remedy the numerous ran-

industry needs today dom failures that strain the maintenance budgets throughout industry today.

and into the future Staffed by harried employees, shops frequently become adept only at

replacing parts in kind. Likewise, relatively few companies position them-

is to pay attention to selves to systematically implement maintenance avoidance measures. We

know that, in existing plants and with few exceptions, failure avoidance

the basics. Taking time would be far more profitable than implementing optimized maintenance

timing on non-optimized equipment. In new equipment procurement sit-

making timeto read is uations, utilizing specifications that eliminate the very components that

risk causing frequent maintenance and downtime would provide far greater

a great way to start. returns on the incremental investment than fine-tuning an asset manage-

ment or related program.

Take, for example, the many operating plants today with literally hun-

Heinz P. Bloch, P.E., dreds of thousands of pumps that were purchased from the lowest bid-

Process Machinery Consulting ders. It is wistful thinking to expect that all components in these lowest-cost

machines represent best-available technology. In the age of downsizing,

rightsizing and outsourcing, how realistic is it to assume that all of the

various equipment manufacturers and vendors employ seasoned, well-

versed, well-read subject matter experts?

Suppose a manufacturer recently sold less-than-optimum equipment.

Knowing that we live in a litigious environment, would we really expect

this manufacturer to concede that he/she continues to make, sell or mar-

ket non-optimized equipment or components? If the answer is no, then

it is clear that the user/purchaser has to be the driver for identifying and

implementing equipment upgrades.

10 MAINTENANCE TECHNOLOGY/DECEMBER 2005

MAKE NO MISTAKE

In our mutual quest to stay informed on reliability-improve-

Trends that lead nowhere vs. ment opportunities, many readers among us recently have 1. Can a component be upgraded

trends for best-of-class noted shifts in reliability-related terminology. Today, we are find- to resist failure?

performers ing more and more old maintenance philosophies being mar- 2. If upgrading is feasible, is it

At the risk of inviting irate keted in newly packaged expressions and acronyms. also economically justified?

responses from benchmarking Whether they refer to adaptations or re-named versions of

companies, we contend that old strategies, the label on each of these repackaged philoso-

These are primary. . . these are

the trend towards increased phies is the proponents choice, However, its not much differ-

the basics. Everything else is of

benchmarking will, ultimately, ent than automobile dealers calling used cars pre-owned, or

lesser importance. Best-of-class

add little value to many enter- TV networks promoting re-runs as encore presentations.

performers know this to be a

prises. A recently published The accompanying article is not meant to be contentious,

fact and are organized accord-

article mentioned four so- nor to imply that the re-examination and streamlining of tradi-

ingly. Moreover, they are staffed

called perspectives, labeling tional asset-management or maintenance approaches has no

so as to have a persona des-

them Operations, Reliability, merit. Instead, it is meant to convey a serious concern that the

ignated and responsible individ-

Work Management and Safety mere repackaging of certain approaches is not helpful to indus-

ualwho can answer these two

& Environmental. Goals were try. Many of these maintenance initiatives are not new. In fact,

questions quickly and with

specified for each and 60 dif- theyve been practiced by best-of-class companies for decades.

great accuracy.

ferent key performance indi- Repackaging them, though, offers little in the way of real addi-

cators (KPIs) were listed as tional value for most struggling refineries and process plants-

Why upgrading is often best

useful for managing risk and those many facilities that continue to seek magic procedural

Unfortunately, even now, buy-

improving profitability. solutions while overlooking and neglecting the basics.

ing from the lowest bidder

At best, each one of those 60 Make no mistake about it: There is ample evidence that inat-

remains the predominant pro-

benchmarks may give plants tention to the basics is severely limiting the profitability of thou-

curement mode. Equally dis-

an indication of where they are sands of companies. In some instances, the continued exis-

appointing is the fact that

in the game. Yet, not any of tence of industrial enterprises is threatened if all they do is

those responsible for short-

these listings specified even search for new strategies instead of implementing the funda-

sighted decisions are often the

one of the many precise steps mental hardware, basic training and procedural changes needed

ones that block access to

that really represent lasting for survival.

systematic failure-avoidance

improvement. What good is it This urgent issue must be brought to the attention of corpo-

measures. Consequently, even

to tell a facility it is re-working rate managers truthfully and without the usual sugar-coating.

the otherwise desirable life

too many pumps, if nobody is Unfortunately, the matter cannot be explained by many consul-

cycle costing (LCC) method-

able to explain the root cause tants who know even less about equipment upgrade opportunities

ology is an academic exercise

reasons for this excessive re- than do the mechanics or maintenance technicians who have not

unless the person doing the

working at that plant? While read any relevant texts since leaving school years ago.

comparison is in a position to

its nice to point out the fact . . . Heinz Bloch

answer the two previously-

that there must be a problem asked questions.

somewhere, far more value A facility which assumes

would be derived by adequately describing the root causes that improvement initiatives spring forth from the original

and solutions. equipment manufacturer, or OEM, often will be disap-

Today, truly best-of-class performers use asset manage- pointed. When, in 1986, a representative of a prominent

ment and streamlined maintenance strategies as icing on pump manufacturer was asked why its designers didnt engi-

the cake. They realize that these approaches add value only if neer better pumps, the answer was that most customers

the basics are in place and being practiced with consistency selected pumps primarily based on cost and schedule. Accord-

and forethought. As an example, best-of-class owner/pur- ingly, sales success was linked to cost and schedule, not long-

chasers are not likely to buy from the lowest bidder. They term quality.

generally look at several competing offers and carefully exam- More recently, at a symposium in Houston, another pump

ine which of them have designed out maintenance and fail- manufacturer claimed that general-purpose pumps were

ure risk. Best-of-class companies rarely, if ever, enter into lop- designed to be overhauled or repaired every 18 months. To

sided alliances with suppliers. They will always use keep costs low, two pump manufacturers said they couldnt

well-thought-out specifications that clearly describe and afford to upgrade their pumps.

explain specific upgraded component materials, configu- And, just last spring, at the 2005 NPRA Maintenance and

rations, lubricant application methods, etc. Thus, the most Reliability Conference in New Orleans, several panel members

important attribute of true best-in-class performers is their touted key performance indicators that were largely based on

ability to provide authoritative answers to two questions: not having production interruptions. To this day, a large

MAINTENANCE TECHNOLOGY/DECEMBER 2005 11

number of managers and reliability

engineers seem to be unconcerned if

their pumps fail far more frequently

than those at a competitors facility. The 30

thought was even expressed that keep- Incl.

ing pump failures at (relatively) high Angle

levels was one of the safeguards pre- Shaft

Diameter,

venting upper-level managers from cut- D

ting the maintenance budget.

At the same NPRA conference we

met with a presenter of asset manage-

ment strategies. We attempted to

argue the monetary merit of failure Slinger Ring

reductions by selective upgrading. Diameter

When the speaker suggested that his Typically

1.7 D

organization was very effective in

identifying and recommending the 3/8 In. (10 mm)

various upgrade options, we chal- Lube

lenged his claims. We have yet to find Level

asset management consulting compa-

nies that identify the needed upgrade

measures to the degree of detail

urgently needed by industry.

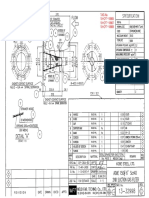

In support of our beliefs, we cited lube

application in pumps as one of the many Fig. 1. Oil ring (slinger ring) and typical dimensions

examples of industry not even being

made aware of tangible reliability risks.

This example deals with the use of oil

rings in literally millions of equipment

bearing housings, most of them in cen-

trifugal pumps. Recall that the entire

issue centers on our contention that

industry is losing knowledge and appli-

cation of the basics. Changing or fine-

tuning management approaches will not

bear the promised fruits unless the

approaches are interwoven with system-

atic upgrade efforts. The following cases

illustrate the type of dilemma with which

industry is wrestling.

Case #1:

Lifting oil with bicycle chains

While working with a client to deter-

mine the root causes of sludge in an oil

sump and bearing failure in a pump,

an experienced consultant (who was

formerly employed as director of new

pumping machinery development for

two noted manufacturers) found a

bicycle chain in the bearing housing.

Its purpose, of course, was to feed lube

oil to the bearings. Chances are that the

bearing housing was simply too narrow

to accommodate oil rings or similar

means of lube applicationa serious

reliability risk. Fig. 2. Flinger disc mounted on pump shaft (Source: www.tricomfg.com)

When the consultant questioned the

appropriateness of using a bicycle chain

12 MAINTENANCE TECHNOLOGY/DECEMBER 2005

in this manner, the pump manufac- and advocate specific component a wise choice for the reliability-

turer objected to the criticism and upgrades. These firms must know, and focused. From about 1840 until 1990,

claimed thats the way we generally do must tell, the user-client, that oil rings they were furnished in brass or

it. . .we hear no complaints. Basic sci- (Fig. 1) impose a key limitation on the bronze. More recently, and for reasons

ence, or the most elementary applica- MTBF of many pumps. we wish to subsequently spell out,

tion of engineering formulas, though, While perhaps representing one of some manufacturers have experi-

would show that the chain would have the least expensive means of applying mented with plastic and aluminum

no chance of moving at the peripheral lube oil to bearings, oil rings are rarely rings (Ref. 1). The results are mixed,

speed of the shaft at anything other

thanfor process pumpsunusually

slow speeds.

In most instances, the bicycle chain

would slip relative to the shaft surface

This is not meant

to imply that the

re-examination and

streamlining of

traditional

approaches has

no merit.

and, by virtue of the total downward-

acting weight of the heavy chain, the

side plates of the links would rub on

the shaft. Wear-related oil contamina-

tion would almost certainly result, as

was found and documented by the

consultant. All of this begs the question:

Would your asset management consul-

tants have the basic knowledge to alert

you to this? Or would your consultants

limit their contribution to the rather

obvious, i.e. telling you that youre

spending too much money on mainte-

nance, and that you have X% more

or Y% less shop backlog than the

industry-recommended average? That

would be nice to know, but wheres the

real solution?

Case #2:

The limitations of oil rings

Pump bearings in best-of-class U.S. oil

refineries failon averageevery 10

years. In certain other U.S. oil refineries,

the failure rate is three times higher, with

the average pump mean-time-between

failures (MTBF) closer to three years.

Lets re-state our earlier point: To really

add value, asset management consulting

firms will have to authoritatively advise

MAINTENANCE TECHNOLOGY/DECEMBER 2005 Circle 208 or visit www.MT-freeinfo.com 13

ISO 32 3600 RPM

105.00

100.00

95.00

Average Temperature

No Disc

90.00 .090 Viton

85.00

80.00

75.00

70.00

65.00

60.00

55.00

1 14 27 40 53 66 79 92 105 118 131 144 157 170 183 196 209

Test Duration, Minutes

Fig. 3. Flinger disc tests, ISO Grade 68, 3,600 rpm, Average Temp. vs. Time (Source www.tricomfg.com)

ISO 68 3600 RPM

105.00

100.00

95.00

Average Temperature

No Disc

90.00 .090 Viton

85.00

80.00

75.00

70.00

65.00

60.00

55.00

1 20 39 58 77 96 115 134 153 172 181 210 229

Test Duration, Minutes

Fig. 4. Flinger disc tests, ISO Grade 32, 3,600 rpm, Average Temp. vs. Time (Source www.tricomfg.com)

at best. In any event, oil rings suffer either a groove machined in the shaft,

A professional who from a number of limitations that are

rarely recognized by equipment sup-

or some stationary surfaces associated

with the bearing housing. The oil ring

has neither the time pliers and users (Ref. 2). Reliability- now tends to slow down, feeding less

focused users avoid oil rings because oil into the bearing. Many observers

nor motivation these components represent an undue have also seen oil rings that showed

reliability risk. Heres why: clear evidence of edge wear and metal

to read a page a day Even some of the most advanced loss. Needless to say, the lost metal

laser-optic shaft alignment systems will shavings end up contaminating the

will never help his not have provisions ensuring that the lubricantnot a desirable condition

shaft centerlines are absolutely hori- by any measure.

employer move zontal. Visualize, therefore, how oil oil-ring movement and circum-

ahead. rings installed on shaft systems that are

not totally parallel with the true hori-

ferential speed are affected by the

degree of immersion in the lubricant

zon will run downhill. Doing so, an oil and by lubricant viscosity. Typical

ring will make frictional contact with immersions are shown in Fig. 1, but

14 MAINTENANCE TECHNOLOGY/DECEMBER 2005

Heinz Suggests

For reliability-focused readers, Heinz Bloch has sup- of the few ways to solve your problem. The first is to

plied the following book reviews. . . work with someone in your own company who has

experience with the change process, either formally or

In 2001, Stephen Thomas 246-page book, Suc- through having already done the same work that you

cessfully Managing Change in Organizations (Indus- are trying to do. These individuals can help, but their

trial Press, New York, NY, ISBN 0-8311-3149-7), perspective is usually limited to the functional areas

became available. We paid extra attention when, in where they have experience.

2005, his highly relevant second book, Improving The next and probably most prevalent solution is to

Maintenance Reliability Through Cultural Change hire a consultant. There are both good and bad points

(Industrial Press, ISBN 0-8311-3190-X, 356 pages) about this approach. If used correctly, however, a con-

came out. sultant can be of value and can help you through the

Thomas is an experienced professional who con- process. The plus side is that what you are asking them

tinues to serve his process industry clients. He knows to do is their area of expertise. They usually have a

that, by themselves, reliability improvement philoso- great deal of experience working with firms undergo-

phies differ from actual implementation and that care- ing change. The down side is that this is their busi-

ful planning and execution of the actual work are ness. They most likely have created a process model

needed for a successful outcome. that they followa model that may or may not fit your

Nothing is more prevalent in industry today than particular needs. Another problem with the use of con-

change. Some of these change initiatives happen as sultants is that many firms tacitly transfer their respon-

organizations evolve, and often require little inter- sibility for the effort to the consultant. This withdrawal

vention. Others are more far-reaching. They involve or transfer can hurt. As good as some consultants are,

efforts specifically designed to improve organizational they eventually have to leave you on your own. When

functions. that happens, you need a good blueprint. Thomas pro-

You probably have experienced these process design vides that in his books.

changes in your business, maybe more times than you His second book is especially innovative. Although

care to think about. What is important to recognize is a stand-alone volume, it ties into the theme of the first

that this condition we call change is probably the book. It neatly explains how to improve your mainte-

one constant in business today. To further complicate nance and reliability performance at the plant level by

matters, change not only affects our businesses. It has changing the organization's culture. This book is

a very real and personal effect on each of ussome of intended for middle managers in the manufacturing

them positive, some otherwise. and process industries. It demystifies the concept of

We become involved in the change process in many organizational culture and links it with the eight ele-

ways and for many reasons. Some of us have been ments of change: leadership, work process, structure,

asked to lead change efforts. Others have been group learning, technology, communication, interre-

assigned the responsibility. Many of you may have lationships and rewards. If you want to break the cycle

openly attempted to initiate change in order to make of failed improvement programs and instead use cul-

things better. Whatever your reason for being involved, tural change to help make significant and lasting

you probably have had occasions when you knew you improvements in plant performance, this book will

needed to do something, but could not figure out the show you how.

next step. From the personal examples that Thomas Overall, if you and/or your company are confronted

provides in both books, you can see that he has been by change issues, you may find what Stephen Thomas

in the same place where you are today. has to say on the subject to be of particular value.

Suppose you find yourself in this position. Take note . . . HB

MAINTENANCE TECHNOLOGY/DECEMBER 2005 15

recommendations may vary for dif- different viscosities (Ref. 2). Two results petrochemical plant suffer from oil-

ferent types of equipment. Clearly, a of this testing are shown in Fig. 3 and ring deficiencies of sufficient magni-

more deeply immersed oil ring or oil Fig. 4 for ISO Grade 32 and 68 lubri- tude to reduce bearing life from an

rings contacting an excessively viscous cants at 3,600 rpm shaft speed. assumed achievable six years to typi-

lubricant will not perform as in- In each case, with flinger discs cally only three years. Other pumps

tended. Also, for good tracking and to installed, the oil and bearing tempera- may experience oil-ring degradation

revolve with reasonable consistency, tures were compared against operation that reduces bearing life from five years

oil rings must be concentric within with the flinger disc removed and lube to four years, and so forth. The issue is

0.002 inches (0.05 mm). oil reaching the center of the lowermost so intuitively evident that, to date, no

Oil-ring operation is affected by bearing ball. From the graphs, it can be one appears to have seen fit to spend

shaft surface velocity. As an experi- seen that, at higher pump speeds, low- research funds on scientific studies.

ence-based rule, authoritative texts ering the oil level and using the trim- Accordingly, empirical observations

(Refs. 3 and 4) caution that shaft mable flinger disc will reduce oil tem- will have to suffice.

velocities as low as 2,000 fpm (~10.16 peratures. Reduced oil temperatures In any event, expanding on this

m/s) might represent the safe, or prac- will slow the rate of oil oxidation conservative estimate, we might be

tical, field-installed (non-laboratory) dealing with a plant comprising 600

limit for many oil rings. At 3,600 rpm, pumps. Suppose that of these, 18 sus-

this limit infers a maximum shaft pect pumps were being repaired every

diameter of approximately 2.125 Oil rings will not perform three years to the tune of $6,000 per

inches (~55 mm). It represents a well unless they are: incident. This would require an expen-

DN value of 7,650, where DN is the diture of $36,000 per year. If, using

product of shaft diameter (inches) Installed on shafts that are unrealis- trimmable flinger discs, the MTBR

and speed (rpm). tically close to perfect horizontality (mean-time-between-repairs) could

Reliability-focused users recom- be extended to six years, this expendi-

mend flinger discs. Since flinger discs Immersed in the lubricant just the ture would drop to $18,000 per year

are secured to the shaft, they are not right distance for the affected 5% of the plants

subject to the compounded influences pump population. Needless to say, if

of shaft horizontality, oil viscosity, Operating in a lubricant with closely one paid $50 per flinger disc, the 18

depth of immersion and ring concen- controlled viscosity discs would have cost $900 and the

tricity. They are a vast improvement investment would have had a payback

over oil rings and are, in fact, avail- Not eccentric by more than 0.002 of $18,000/$900 = 20:1. It is certainly

able in many pump models presently inches no stretch to foresee greater savings

marketed by U.S. and European sup- and even more significant payback

pliers. Ref. 1 contains an illustration Manufactured with a bore finish than demonstrated in this example

from a 1960s-vintage catalog issued reasonably close to 32 RMS after one or two years of operation.

by a then prominent, major U.S.

pump maker. The page shows the Belaboring the point

flinger discs furnished with this man- (Ref. 3) and tend to more closely main- The issue at hand is important

ufacturers pumps and states, rather tain lubricant viscosity. Incidentally, enough to be highlighted again. Man-

pointedly, anti-friction oil thrower with premium synthetic lubricants and agement often doesnt seem to get it.

(meaning flinger disc) ensures posi- operation at typical process pump Our view is simply that asset man-

tive lubrication and eliminates the speeds, the rate of oxidation is agement and maintenance strategies

problems associated with oil rings. extremely slow. In that case, concern are rather pointless if oil rings and

Indeed, oil rings were problematic in over oxidation issues on hermetically flinger discs, the pitfalls of millions of

the 1960s, and, more than 40 years later, closed pump bearing housings are of inadequate old-style constant level

they are still causing problems in many very academic interest. lubricators and a veritable host of

field installations. Retrofit flinger discs other basic issues are either not

(see Fig. 2) are available as cost-effec- Economic value explored known or not addressed.

tive upgrade and retrofit options. Made Upon close examination, and with Much money is lost when the basics

to oversized dimensions, they can be competent failure analysis, many are not understood. If each of 10

easily trimmed to the required diame- observers have reached the conclusion important or failure-prone compo-

ter. Their elastomer will fold into an that a large percentage of oil rings show nents, practices, commissions or omis-

umbrella shape during insertion signs of severe abrasion. It is undis- sions in a pump were to reduce its reli-

through a narrow bearing-housing puted and well known that the result- ability by 10%, raise 0.9 to the tenth

bore and will then snap back into its ing lube oil contamination is reflected power and convince yourself that you

regular disc shape. in premature bearing failures. Based on get less than 35% overall reliability.

In 2003 and 2004, thorough testing these observations, it has been esti- Staying with vulnerable components

was done on a Viton discsconfigura- mated that at least 5% of the centrifu- and not upgrading is a very poor choice

tion at different speeds and with oils of gal pumps installed in the average indeed. Before looking for high tech

16 MAINTENANCE TECHNOLOGY/DECEMBER 2005

and whatever else might be icing on Surely, a professional who has nei- 3.Wilcock, Donald F., and Richard E.

the cake, a reliability-focused organi- ther the time nor motivation to read a Booser, Bearing Design and Application,

zation will learn to view every repair page a day will never help his employer (1957), McGraw-Hill, New York, NY

event as an opportunity to upgrade! move ahead.

4.Bloch, Heinz P.; Centrifugal Pump

(Ref. 5) In the words of Mark Twain: A man Cooling and Lubricant ApplicationA

Furthermore, if a manager is really who chooses not to read is just as igno- Technology Update, International Pump

serious about upgrading the knowledge rant as a man who cannot read. To Users Symposium, Texas A&M University,

base of a reliability workforce, he or she which we might add that managers Houston, TX, 2005

will cheerfully spend a few hundred who choose not to make their people

dollars on solid textbooks that explain learn would serve their stakeholders 5.Bloch, Heinz P., (1998) Improving

Machinery Reliability, Third Edition, Gulf

hundreds of these upgrade opportuni- better by going on permanent vacation. Publishing Company, Houston, TX, ISBN

ties. He or she will know, or at least Before encouraging or allowing sub- 0-88415-661-3

accept as fact, that implementing one ordinates to simply decorate the cake,

or more of a number of highly cost-jus- a good manager will see to it that the

tified upgrade examples will definitely underlying foundation, that is, the cake Heinz P. Bloch is a professional engi-

avoid failures. Since the average API itself, is edible. That implies that the neer with over 43 years of experience

pump failure event costs U.S. refiner- basics are in place. in reliability engineering and mainte-

ies in excess of $10,000 (Ref. 2), a sin- nance cost reduction. He has written

gle avoided failure represents a three- References: 14 comprehensive books on these sub-

week payback for, say, a modest $600 jects and continues to advise process

1.Bloch, Heinz P.; Slinger Rings Revis-

spent on books. ited, Hydrocarbon Processing, August 2002

plants worldwide on reliability im-

A good manager will probably insist provement and maintenance cost-

that his/her reliability staffers read 200 2.Bloch, Heinz P. and Alan Budris; reduction opportunities.

textbook pages per yearthis adds up to (2004) Pump Users Handbook: Life Exten-

a single page per work day. A good man- sion, The Fairmont Press, Inc., Lilburn, GA

ager will not tolerate any excuses. 30047, ISBN 0-88173-452-7

Circle 200 or visit www.MT-freeinfo.com Circle 200 or visit www.MT-freeinfo.com 17

You might also like

- What Is Reliability and Asset ManagementDocument2 pagesWhat Is Reliability and Asset ManagementissnitamiNo ratings yet

- Reliability Centered Maintenance Rcm A Complete Guide - 2019 EditionFrom EverandReliability Centered Maintenance Rcm A Complete Guide - 2019 EditionNo ratings yet

- How To Implement Maintenance Planning & SchedulingDocument18 pagesHow To Implement Maintenance Planning & SchedulingIrete FemiNo ratings yet

- 03 CMRP RoadmapDocument7 pages03 CMRP RoadmapNagy ElrasheedyNo ratings yet

- Motor Management PDFDocument130 pagesMotor Management PDFtranhuutuongNo ratings yet

- Improvement of Transient Stability of Two Machine System Using Static VAR Compensator and Power System StabilizerDocument4 pagesImprovement of Transient Stability of Two Machine System Using Static VAR Compensator and Power System StabilizereditorijsaaNo ratings yet

- SALVO Project Innovations Descriptor v2Document15 pagesSALVO Project Innovations Descriptor v2foca88No ratings yet

- Key Performance Indicators For Maintenance PDFDocument6 pagesKey Performance Indicators For Maintenance PDFnhatnam06dt1No ratings yet

- CMMS Best Practices Study - ReliabilitywebDocument49 pagesCMMS Best Practices Study - Reliabilitywebfrank naranjo100% (1)

- Evolution of Maintenance StrategiesDocument10 pagesEvolution of Maintenance StrategiesmusaveerNo ratings yet

- Electrical Rotating Machine Asset Performance Management: GE PowerDocument13 pagesElectrical Rotating Machine Asset Performance Management: GE PowerMuhammad Tilal AshrafNo ratings yet

- Reliabilityweb Uptime 20131201Document69 pagesReliabilityweb Uptime 20131201catraioNo ratings yet

- Maintenance Presentation SlideDocument56 pagesMaintenance Presentation Slidekapun kumar nayakNo ratings yet

- Reliability Centered Maintenance Final ReportDocument25 pagesReliability Centered Maintenance Final Reportadityanarang147100% (2)

- 2007 Sept-Oct OptYourPlantsNumber1Asset HydroAsia KSmithDocument3 pages2007 Sept-Oct OptYourPlantsNumber1Asset HydroAsia KSmithchiclemotita2No ratings yet

- Reliability Improvement Fake News: Terrence ODocument46 pagesReliability Improvement Fake News: Terrence OWilson GarciaNo ratings yet

- IT 3976 Reliability Centered Maintenance (Wikipedia)Document6 pagesIT 3976 Reliability Centered Maintenance (Wikipedia)Gera MtzNo ratings yet

- 10 Steps To Becoming A RELIABILITY LEADER - 8-29Document60 pages10 Steps To Becoming A RELIABILITY LEADER - 8-29Jay100% (1)

- Conveyor Installation and Maintenance ManualDocument20 pagesConveyor Installation and Maintenance ManualTamal Tanu RoyNo ratings yet

- Mobius Institute ARP Brochure Aug 2021Document29 pagesMobius Institute ARP Brochure Aug 2021kalatzoiNo ratings yet

- The Seven Questions of Reliability Centered Maintenance by Bill Keeter and Doug Plucknette, Allied ReliabilityDocument3 pagesThe Seven Questions of Reliability Centered Maintenance by Bill Keeter and Doug Plucknette, Allied ReliabilityambuenaflorNo ratings yet

- Cmms CSDP TrainingDocument44 pagesCmms CSDP TrainingRudyard ZednanrefNo ratings yet

- CMMS StrategyDocument12 pagesCMMS StrategyDia Putranto HarmayNo ratings yet

- Lesson 01 PDFDocument12 pagesLesson 01 PDFAbuubakr Abdelwhab HassanNo ratings yet

- TRANSCO Profile - English 2012Document24 pagesTRANSCO Profile - English 2012Zaher Mhd SharafNo ratings yet

- Grease Refill QtyDocument3 pagesGrease Refill QtyParmasamy SubramaniNo ratings yet

- Vibration Analysis For Hydraulic PumpDocument18 pagesVibration Analysis For Hydraulic PumpManikandanNo ratings yet

- Magnetic Bearing: by NAME: N.Harshavardhan Reddy ID. NO: 18D41A0369 CLASS: Mechanical:BDocument15 pagesMagnetic Bearing: by NAME: N.Harshavardhan Reddy ID. NO: 18D41A0369 CLASS: Mechanical:BChinnu Nani AHNo ratings yet

- 5 Reasons Why PM Plans Can Contribute To Poor Asset ReliabilityDocument9 pages5 Reasons Why PM Plans Can Contribute To Poor Asset ReliabilityYury FedichkinNo ratings yet

- An Introduction To MEMS Vibration Monitoring - Analog DevicesDocument16 pagesAn Introduction To MEMS Vibration Monitoring - Analog DevicesVinicios FerrazNo ratings yet

- A Lehnberger, D Laue, SS Mallikarjun and HR MaheshDocument3 pagesA Lehnberger, D Laue, SS Mallikarjun and HR MaheshJoao Bortolussi - JBR ENGENHARIA100% (1)

- Belt Failure AnalysisDocument8 pagesBelt Failure AnalysisDavid ChandlerNo ratings yet

- Maintenance StrategiesDocument4 pagesMaintenance StrategiesSameeullahNo ratings yet

- Recommendations To Check AC Electric MotorsDocument6 pagesRecommendations To Check AC Electric MotorsHemendra JaniNo ratings yet

- Maintenance Strategy MBA Assignment - Dave PhelanDocument15 pagesMaintenance Strategy MBA Assignment - Dave PhelanDave Phelan100% (1)

- Special Report PDM Guidebook2016Document44 pagesSpecial Report PDM Guidebook2016Vinoth KumarNo ratings yet

- Condition MonitoringDocument3 pagesCondition MonitoringKashif MuhammadNo ratings yet

- ARP E Reliability Engineer CourseDocument4 pagesARP E Reliability Engineer CourseLyonelNo ratings yet

- Condition Based Maintenance EbookDocument48 pagesCondition Based Maintenance EbookDayan AGUILAR RINCONNo ratings yet

- Technical Report Concerning RCM. by Elisony Edward Mweladzi. Dar Es Salaam Tanzania +255 754321825Document14 pagesTechnical Report Concerning RCM. by Elisony Edward Mweladzi. Dar Es Salaam Tanzania +255 754321825Elisony EdwardNo ratings yet

- Balance LineDocument0 pagesBalance Linewsjouri2510No ratings yet

- Report of Large Motor ReliabilityDocument28 pagesReport of Large Motor Reliabilitythawatchai11222512100% (1)

- Condition Monitoring of Cooling Tower Fan Gearboxes PSM 2000 - LibreDocument10 pagesCondition Monitoring of Cooling Tower Fan Gearboxes PSM 2000 - LibreNilma Rosa Barsallo PachecoNo ratings yet

- Aladon Reliability-Mgmt E-Brochure 062116Document4 pagesAladon Reliability-Mgmt E-Brochure 062116HugoCabanillasNo ratings yet

- Calculating Maintenance and ReliabilityDocument7 pagesCalculating Maintenance and ReliabilityArdian P Noviatmoko100% (1)

- Life Cycle Institute-SMRP BOK-Detailed Outline (2840)Document3 pagesLife Cycle Institute-SMRP BOK-Detailed Outline (2840)jhonatan lorenzoNo ratings yet

- Ahmed El Sayed Elsayed Beaet: Mobius Institute Board of CertificationDocument1 pageAhmed El Sayed Elsayed Beaet: Mobius Institute Board of CertificationAhmed BeaetNo ratings yet

- Epri 1004829 PDFDocument48 pagesEpri 1004829 PDFenricoNo ratings yet

- Maintenance Management SystemDocument21 pagesMaintenance Management SystemPrerna Makhijani100% (1)

- Maintenance of Journal (Babbitt) BearingsDocument34 pagesMaintenance of Journal (Babbitt) BearingsNilav KumarNo ratings yet

- Generator Protection PPT TurboDocument29 pagesGenerator Protection PPT TurbocheshankarNo ratings yet

- Weibull Statistic and Growth Analysis in Failure PredictionsDocument9 pagesWeibull Statistic and Growth Analysis in Failure PredictionsgmitsutaNo ratings yet

- Checking Bearing AlignmentDocument4 pagesChecking Bearing AlignmentTheerayootNo ratings yet

- Successfully Utilizing CMMS EAM System Terry WiremanDocument246 pagesSuccessfully Utilizing CMMS EAM System Terry Wiremanlacoste11111No ratings yet

- Motor Installation and Maintenance ManualDocument23 pagesMotor Installation and Maintenance ManualVenkat CherukuriNo ratings yet

- Maintenance Analysis and Benchmark - M (1) - Yves LAVINA (ProConseil) - 19-09-2007Document12 pagesMaintenance Analysis and Benchmark - M (1) - Yves LAVINA (ProConseil) - 19-09-2007Eng.Bassam - UltraMedicaNo ratings yet

- Maintenance Planning Work Flow DescriptionDocument7 pagesMaintenance Planning Work Flow DescriptionAsep Herman100% (2)

- Soft Foot - What It Is and How To Minimize ItDocument6 pagesSoft Foot - What It Is and How To Minimize ItilyasNo ratings yet

- SamsungGalaxy S8Document31 pagesSamsungGalaxy S8rodolfostiNo ratings yet

- Shaft AlignmentDocument44 pagesShaft Alignmentrodolfosti100% (1)

- YFT - From 150 To 900Document1 pageYFT - From 150 To 900rodolfostiNo ratings yet

- 59529-Especificaciones para Preservacion EquiposDocument65 pages59529-Especificaciones para Preservacion EquiposrodolfostiNo ratings yet

- Strainers FycDocument1 pageStrainers FycrodolfostiNo ratings yet

- MR-1020-01-WFT, 3rd Suction Gas FilterDocument1 pageMR-1020-01-WFT, 3rd Suction Gas FilterrodolfostiNo ratings yet

- MR-1020-01-WFT, 2nd Suction Gas FilterDocument1 pageMR-1020-01-WFT, 2nd Suction Gas FilterrodolfostiNo ratings yet

- Project Number TPIT Material Requsition #TPIT Item Number SR Code Client Doc Number Purchase Order Flowserve Doc. No. Doc. Name RevDocument2 pagesProject Number TPIT Material Requsition #TPIT Item Number SR Code Client Doc Number Purchase Order Flowserve Doc. No. Doc. Name RevrodolfostiNo ratings yet

- EXXI-4130-00-00-VD-MAN-5251 - 00x-Sellos MecanicosDocument33 pagesEXXI-4130-00-00-VD-MAN-5251 - 00x-Sellos MecanicosrodolfostiNo ratings yet

- Project Number TPIT Material Requsition #TPIT Item Number SR Code Client Doc Number Purchase Order Flowserve Doc. No. Doc. Name RevDocument2 pagesProject Number TPIT Material Requsition #TPIT Item Number SR Code Client Doc Number Purchase Order Flowserve Doc. No. Doc. Name RevrodolfostiNo ratings yet

- Proteccion Maquinaria PDFDocument12 pagesProteccion Maquinaria PDFrodolfostiNo ratings yet

- Preliminary Conical StrainersDocument1 pagePreliminary Conical StrainersrodolfostiNo ratings yet

- ROTALIGN Ultra Brochure ENGLISH PDFDocument12 pagesROTALIGN Ultra Brochure ENGLISH PDFrodolfostiNo ratings yet

- Quality Control Plan Machinery Installation (Blowers & Fans)Document11 pagesQuality Control Plan Machinery Installation (Blowers & Fans)rodolfostiNo ratings yet

- Quality Control Plan Machinery Installation (Centrifugal Compressors)Document7 pagesQuality Control Plan Machinery Installation (Centrifugal Compressors)rodolfostiNo ratings yet

- EXXI 4001-00-00 VD MAN 0091 - AAX Instrucciones Equipos Auxiliares Sello GasDocument21 pagesEXXI 4001-00-00 VD MAN 0091 - AAX Instrucciones Equipos Auxiliares Sello GasrodolfostiNo ratings yet

- Các Câu Tra Không RaDocument3 pagesCác Câu Tra Không RaANH NGUYEN DANG QUENo ratings yet

- Mission Australia Annual Report 2011Document68 pagesMission Australia Annual Report 2011Gaurav NaharNo ratings yet

- Business Simulation ReportDocument12 pagesBusiness Simulation ReportTanika Agarwal100% (1)

- CT8 Financial Economics PDFDocument6 pagesCT8 Financial Economics PDFVignesh SrinivasanNo ratings yet

- ProgressionsDocument55 pagesProgressionsbrana456No ratings yet

- Batch-Bioprocess Modeling 20140315Document66 pagesBatch-Bioprocess Modeling 20140315Rozaimi Abu SamahNo ratings yet

- Cashflow and Fund FlowDocument17 pagesCashflow and Fund FlowHarking Castro ReyesNo ratings yet

- Pamela Hartigan - The Challenge For Social Entrepreneurship 2004Document4 pagesPamela Hartigan - The Challenge For Social Entrepreneurship 2004New Zealand Social Entrepreneur Fellowship - PDF Library100% (2)

- Mechanics of Financial Accounting RevisedDocument4 pagesMechanics of Financial Accounting RevisedalakshendraNo ratings yet

- Hindustan Biosynth Limited: A Project Report ONDocument60 pagesHindustan Biosynth Limited: A Project Report ONArchita ParikhNo ratings yet

- MasDocument13 pagesMasHiroshi Wakato50% (2)

- Accounting Scandal in The UKDocument12 pagesAccounting Scandal in The UKBeibarysNo ratings yet

- ADV I Chapter 2 2009Document5 pagesADV I Chapter 2 2009temedebereNo ratings yet

- Mini Case Study of JP Morgan and ChaseDocument2 pagesMini Case Study of JP Morgan and ChaseMarvin niloNo ratings yet

- V2 Exam 2 PM PDFDocument30 pagesV2 Exam 2 PM PDFMaharishi VaidyaNo ratings yet

- Course Name: (Perakaunan Kewangan Pertengahan II)Document11 pagesCourse Name: (Perakaunan Kewangan Pertengahan II)Jeya VilvamalarNo ratings yet

- Week 7-8 Financial PlanningDocument16 pagesWeek 7-8 Financial PlanningCeejay0908No ratings yet

- Unit 3-Time Value of MoneyDocument12 pagesUnit 3-Time Value of MoneyGizaw BelayNo ratings yet

- How To Calculate Present ValuesDocument16 pagesHow To Calculate Present ValuesAishwarya PotdarNo ratings yet

- Rajesh Chavan (30) Abhimanyu Nikam (1) Piyush ChaudhariDocument28 pagesRajesh Chavan (30) Abhimanyu Nikam (1) Piyush ChaudhariAbhimanyu NikamNo ratings yet

- Before Starting A Business Start Up ChecklistDocument65 pagesBefore Starting A Business Start Up ChecklistJude21No ratings yet

- Assistant Accountant CV TemplateDocument3 pagesAssistant Accountant CV TemplateAhmed TallanNo ratings yet

- Case StudyDocument12 pagesCase StudyRohit GadgeNo ratings yet

- Hart Venture CapitalDocument32 pagesHart Venture CapitalJoyce Kwok100% (1)

- Proforma of Trading PL and Balance SheetDocument2 pagesProforma of Trading PL and Balance SheetPranay Sai Garepally100% (3)

- Project Proposal by Nigah-E-Nazar FatimiDocument8 pagesProject Proposal by Nigah-E-Nazar Fatiminazarfcma5523100% (3)

- Pennar Engineered Building Systems LimitedDocument466 pagesPennar Engineered Building Systems Limitedtuv srinuvasaNo ratings yet

- Insurance Brokers in RomaniaDocument10 pagesInsurance Brokers in RomaniaIrina StefanaNo ratings yet

- SuperannuationDocument12 pagesSuperannuationNetaji DasariNo ratings yet

- Problem Statement 5Document4 pagesProblem Statement 5Umar Kundi100% (1)