Professional Documents

Culture Documents

TD Quintolubric 888 68 PDF

Uploaded by

aneesh awasthi0 ratings0% found this document useful (0 votes)

272 views2 pagesOriginal Title

td_quintolubric_888_68.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

272 views2 pagesTD Quintolubric 888 68 PDF

Uploaded by

aneesh awasthiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

QUINTOLUBRIC 888-68

FIRE RESISTANT HFD-U HYDRAULIC FLUID

APPLICATION SHEET

BENEFITS

Global formulation Best-in-class oxidation stability

Excellent shear stability Environmentally friendly

APPLICATIONS PROPERTIES

QUINTOLUBRIC 888-68 was designed to replace PROPERTIES (TEST METHOD) TYPICAL VALUES

anti-wear, mineral oil-based hydraulic fluids used in

applications where fire hazards exist. QUINTOLUBRIC Appearance Yellow to amber fluid

888-68 can also be used in environmentally sensitive Kinematic Viscosity (ASTM D445)

hydraulic applications without compromising the At 0OC 554 mm2 /s or cSt

overall hydraulic system operations. This fluid does At 20OC 135 mm2 /s or cSt

not contain water, mineral oil, or phosphate ester, At 40OC 68 mm2 /s or cSt

and is based on high-quality, synthetic, organic At 100OC 12.5 mm2 /s or cSt

esters and carefully selected additives to achieve Viscosity Index (ASTM D2270) 185

excellent hydraulic fluid performance. QUINTOLUBRIC Density at 15OC (ASTM D1298) 0.92 g/cm3

888-68 offers the lubrication level of premium, anti-

Acid Number (ASTM D974) 2.0 mg KOH/g

wear hydraulic oils, and can be used with hydraulic

components from all major manufacturers. Pour Point (ASTM D97) < -30OC (< -22OF)

Foam Test at 25oC (ASTM D892) 50-0 ml-ml

COMPATIBILITY Sequence 1

The following chart contains our recommendations Corrosion Protection

regarding the use of QUINTOLUBRIC 888-68 ISO 4404-2 Pass

with commonly used elastomers. The elastomer ASTM D665A/D130 Pass/1a

applications listed are Static, which refers to trapped Dry TOST (ASTM D943 mod.) 800 hrs

nonmoving seals such as O-rings in valve sub-plates Flash Point (ASTM D92) 304OC (572OF)

and rigid, low pressure hose connections; Mild-

Fire Point (ASTM D92) 360OC (680OF)

Dynamic, whose applications include accumulator

bladders and hose linings where the hoses are Air Release (ASTM D3427) 7 min

exposed to high pressure and light flexing; and Pump Test (ASTM D2882) <5 mg wear

Dynamic, which refers to cylinder rod seals, pump Gear Lubrication (DIN 51354-2) >12 FZG load stage

shaft seals and constantly flexing hydraulic hose.

Water Separability (ASTM D1401) 42-38-0 (30)

ml-ml-ml (min.)

quakerchem.com | quintolubric.com | info@quakerchem.com

QUINTOLUBRIC 888-68

FIRE RESISTANT HFD-U HYDRAULIC FLUID

APPLICATION SHEET

ELASTOMERS ENGINEERING DATA

METALS ISO PROPERTIES TYPICAL VALUES

QUINTOLUBRIC 888-68 is 1629 DESCRIPTION S* MD* D*

compatible with iron and steel Specific Heat at 20OC 2.06 kJ/kg OC

NBR Medium to high nitrile rubber C C C (D 2766) .49 Btu/lb OF

alloys and most nonferrous (Buna N,>30% acrylonitrile)

metals and their alloys. It is not Coefficient of Thermal 6 X 10-4 per OC

FPM Fluoroelastomer (Viton) C C C

compatible with lead, cadmium Expansion at 20OC

and has limited compatibility CR Neoprene S S S (D 1903)

with alloys containing high IIR Butyl rubber S N N Vapor Pressure (02551)

levels of these metals. At 20OC 3.2 X 10-6 mmHg

EPDM Ethylene propylene rubber N N N

QUINTOLUBRIC 888-68 has At 66OC 7.5 X10-6 mm Hg

limited compatibility with hot PU Polyurethane C C C

Bulk Modulus at 20OC

dipped or electro galvanized PTFE Teflon C C C

At 210 bar 1.87 X 105 N/cm2

surfaces and good compatibility

**(S- Static, MD- Mild Dynamic, D- Dynamic) At 3,000 psi 266,900 psi

with zinc containing alloys. C = Compatible

Suitable substitutes for these S = Satisfactory for short term use, but replacement with a completely

Thermal Conductivity at 19OC (D 2717) 0.167 J/sec/m/OC

materials are available and compatible elastomer is recommended at the earliest convenience. Dielectric Breakdown Voltage 30 kV

N = Not Compatible

should be used. (D 877)

*country specific SDS are available

PAINTS AND COATINGS

QUINTOLUBRIC 888-68 IGNITION TEST DATA

is compatible with multi-

Hot Manifold Ignition Temperature >450oC

component epoxy coatings. It is

(ISO 20823)

not compatible with zinc-based

coatings. Specific coating and Auto Ignition Temperature >400oC (>750oF)

application recommendations (DIN 51794)

can be obtained from coating

manufacturers or directly from BIODEGRADABILITY TEST DATA

Quaker.

OECD-301 c 80.4% biodegradable after 28 days

FLUIDS

QUINTOLUBRIC 888-68

is compatible and miscible

with nearly all mineral oil and

polyolester-type hydraulic

fluids and with some, but not

all, phosphate esters. It is not

miscible or compatible with

water-containing fluids. For

conversion recommendations,

please contact Quaker.

quakerchem.com | quintolubric.com | info@quakerchem.com

Prior to using this product, consult the Material Safety Data Sheet for instructions regarding safe handling and environmental issues. The information contained herein is based on data

available to us and is believed to be accurate. HOWEVER, NO WARRANTY OF MERCHANTABILITY, FITNESS FOR ANY USE, OR ANY OTHER WARRANTY IS EXPRESSED OR TO BE IMPLIED,

REGARDING THE ACCURACY OF THESE DATA. THE RESULTS TO BE OBTAINED FROM THE USE THEREOF, OR THE HAZARDS CONNECTED WITH THE USE OF THE PRODUCT. Quaker Chemical

Corporation assumes no liability for any alleged ineffectiveness of the product or any injury or damage, direct or consequential, resulting from the use of this product unless such injury or

damage is solely attributable to negligence on the part of Quaker Chemical Corporation. 014113 04/2013

You might also like

- Adsorption With Activated CarbonDocument18 pagesAdsorption With Activated Carbonwibisono yaminNo ratings yet

- ENVE 420 Industrial Pollution Control: AdsorptionDocument45 pagesENVE 420 Industrial Pollution Control: AdsorptionkhushiNo ratings yet

- Quakercool 7101 ALF - TDS - 1 PDFDocument2 pagesQuakercool 7101 ALF - TDS - 1 PDFAshutosh KumarNo ratings yet

- Lecture On Solar Cooling TechnologiesSOLAR COOLINGDocument79 pagesLecture On Solar Cooling TechnologiesSOLAR COOLINGMuhammadFazrinNo ratings yet

- A Simulation Study of Performance Evaluation of Single-Stage Absorption PDFDocument10 pagesA Simulation Study of Performance Evaluation of Single-Stage Absorption PDFalmadhagiNo ratings yet

- Ferrocote PDFDocument10 pagesFerrocote PDFstijn VanhauwaertNo ratings yet

- Total Seriola 32 - Product Data SheetDocument3 pagesTotal Seriola 32 - Product Data Sheetjihad jamarei100% (1)

- The Boiler Operator Handbook PDFDocument131 pagesThe Boiler Operator Handbook PDFMaximilianoRodrigoCabestreroNo ratings yet

- Daniel C. Harris Análisis Químico CuantitativoDocument898 pagesDaniel C. Harris Análisis Químico CuantitativoAlejandra LaraNo ratings yet

- File 1416992597Document9 pagesFile 1416992597Roberto BrionesNo ratings yet

- Nitrate Fertilisers: Rupp Industrial SolutionsDocument20 pagesNitrate Fertilisers: Rupp Industrial SolutionsCarlos Manuel Castillo SalasNo ratings yet

- Pressure. Pressure Loss in A Steam Pipe. Tabulated ExampleDocument25 pagesPressure. Pressure Loss in A Steam Pipe. Tabulated ExampleJMVNo ratings yet

- Advances in Chemical EngineeringDocument594 pagesAdvances in Chemical EngineeringSamyukta BudumuruNo ratings yet

- Libra Spectrophotometers Brochure - 2 PDFDocument10 pagesLibra Spectrophotometers Brochure - 2 PDFunconfusiusNo ratings yet

- El Recetario Industrial Hiscox Hopkins PDFDocument1,348 pagesEl Recetario Industrial Hiscox Hopkins PDFestebanNo ratings yet

- Siemens Flender 05 BipexDocument8 pagesSiemens Flender 05 BipexDhanielNo ratings yet

- IND 202 U2a Gas and Liquid Separation FCivan XXDocument61 pagesIND 202 U2a Gas and Liquid Separation FCivan XXrenatoNo ratings yet

- Piping Training Course PDFDocument411 pagesPiping Training Course PDFpjcs1974No ratings yet

- Scope: Plant Buildings For Operation and Storage IP 4-3-1Document8 pagesScope: Plant Buildings For Operation and Storage IP 4-3-1Sixto Gerardo Oña AnaguanoNo ratings yet

- ASME FiltroDocument11 pagesASME FiltroDenise AGNo ratings yet

- Netbot s15 Smart Vacuum Mmkjuicleaning Robot ManualDocument12 pagesNetbot s15 Smart Vacuum Mmkjuicleaning Robot ManualCondemor Condemor100% (1)

- Graesser ExtractorDocument1 pageGraesser Extractorsushant_jhawerNo ratings yet

- Sound Speed & Pipe Size Data: (For Ultrasonic Flowmeters)Document50 pagesSound Speed & Pipe Size Data: (For Ultrasonic Flowmeters)sherio amrousyNo ratings yet

- Kf-647 Totsucat Material Safety Data Sheet: 2. Hazards IdentificationDocument6 pagesKf-647 Totsucat Material Safety Data Sheet: 2. Hazards IdentificationEdgar Hector GarciaNo ratings yet

- Capgo - RTDsDocument4 pagesCapgo - RTDsdark*nightNo ratings yet

- Corrsheild Md4100Document11 pagesCorrsheild Md4100mevansmetreelNo ratings yet

- Enotec2 PDFDocument6 pagesEnotec2 PDFamk2009No ratings yet

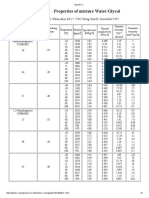

- Table 8 3 1 Properties of Mixture Water/Glycol: Extract From Vdi Warmeatlas DD 17 Vdi Verlag GMBH, Dusseldorf 1991Document2 pagesTable 8 3 1 Properties of Mixture Water/Glycol: Extract From Vdi Warmeatlas DD 17 Vdi Verlag GMBH, Dusseldorf 1991Santiago MolinaNo ratings yet

- Physics 06-Temperature, Heat, and Thermodynamics (2018)Document113 pagesPhysics 06-Temperature, Heat, and Thermodynamics (2018)Kiyu ImanNo ratings yet

- Ultipor HT For Hot Liquid ServiceDocument2 pagesUltipor HT For Hot Liquid ServiceMustafa DaoudNo ratings yet

- Control Valve Data SheetDocument1 pageControl Valve Data SheetKelly Perez LopezNo ratings yet

- Owner & Operator's Manual: ModelsDocument16 pagesOwner & Operator's Manual: ModelskmpoulosNo ratings yet

- Analogi MaterialovDocument8 pagesAnalogi MaterialovrouquinNo ratings yet

- Iron MaterialsDocument26 pagesIron MaterialsRossembert Laime Martinez100% (1)

- F. Huang - Engineering ThermodynamicsDocument52 pagesF. Huang - Engineering ThermodynamicsHectorCabz100% (1)

- Session 2 Wiring and Setting - LATAMDocument58 pagesSession 2 Wiring and Setting - LATAMPaulo Augusto GarayNo ratings yet

- Steam Tracing Design Considerations and InstallationDocument6 pagesSteam Tracing Design Considerations and InstallationaimangamalNo ratings yet

- Saidur2010 - Energy, Exergy and Economic Analysis of Industrial Boilers PDFDocument10 pagesSaidur2010 - Energy, Exergy and Economic Analysis of Industrial Boilers PDFRuben Alejandro Velandia UsugaNo ratings yet

- Questionaire For Drum Flaker - NEWDocument2 pagesQuestionaire For Drum Flaker - NEWBhavin TalatiNo ratings yet

- Actuador XRPDocument16 pagesActuador XRPNicolas AndradeNo ratings yet

- LRGCC 2018 Fundamentals: Fundamentals of Separation of Gases, Liquids, and SolidsDocument49 pagesLRGCC 2018 Fundamentals: Fundamentals of Separation of Gases, Liquids, and SolidsJohn Anthoni100% (1)

- Dump Valves: DVU SeriesDocument2 pagesDump Valves: DVU SeriesalopezvillavicencioNo ratings yet

- Elutriation: R K, Essen, GermanyDocument14 pagesElutriation: R K, Essen, GermanyRay CNo ratings yet

- CH22 LectDocument60 pagesCH22 LectdaNo ratings yet

- Ce Ic106d eDocument2 pagesCe Ic106d eredabeakNo ratings yet

- Heat Transfer Enhancement in Externally Finned Tubes and Internally Finned Tubes and Annuli 1st Ed 2020 978-3-030 20747 2 978 3 030 20748 9 CompressDocument181 pagesHeat Transfer Enhancement in Externally Finned Tubes and Internally Finned Tubes and Annuli 1st Ed 2020 978-3-030 20747 2 978 3 030 20748 9 CompressMateus BanuthNo ratings yet

- Cromatografo de Gas NaturalDocument8 pagesCromatografo de Gas NaturalJinhichi Molero RodriguezNo ratings yet

- Heat Exchanger (Cooler)Document14 pagesHeat Exchanger (Cooler)nuradiadnan100% (1)

- Standard Conditions Actual Conditions: Conversion of SM To AmDocument1 pageStandard Conditions Actual Conditions: Conversion of SM To AmMurali MuthuNo ratings yet

- Electrolyser-Operating Manual PDFDocument6 pagesElectrolyser-Operating Manual PDFcderin20000% (1)

- Heat Exchanger Sizing E-3010A #1Document2 pagesHeat Exchanger Sizing E-3010A #1Luis Enrique Leyva Ovalle100% (1)

- Heat Transfer and Pressure Drop Characteristics of Finned Tube Banks in Forced Convection (Comparison of The Heat Transfer Characteristics Between Spiral Fin and Serrated Fin)Document14 pagesHeat Transfer and Pressure Drop Characteristics of Finned Tube Banks in Forced Convection (Comparison of The Heat Transfer Characteristics Between Spiral Fin and Serrated Fin)nadir adel100% (1)

- Iso 731 1 1977Document4 pagesIso 731 1 1977Tahir Nizam100% (1)

- Effective October 2010 Energy EfficientDocument10 pagesEffective October 2010 Energy EfficientAlla Naveen KumarNo ratings yet

- Jet Reynolds Number Nozzle-Plate SpacingDocument2 pagesJet Reynolds Number Nozzle-Plate SpacingBurak GülenNo ratings yet

- Calcination Roasting PredominaceAreaDocument48 pagesCalcination Roasting PredominaceAreaVikramaditya MathkarNo ratings yet

- LWN Operating Manual of FanDocument20 pagesLWN Operating Manual of FanYogesh Badhe100% (1)

- 1 s2.0 S0263876299717624 MainDocument7 pages1 s2.0 S0263876299717624 Mainryan123459No ratings yet

- GAX Absorption Heat Pump Operated by Natural GasDocument15 pagesGAX Absorption Heat Pump Operated by Natural GasalmadhagiNo ratings yet

- TD Quintolubric 888 68Document2 pagesTD Quintolubric 888 68Haitham YoussefNo ratings yet

- Vasudeva-Ashtakam Sanskrit PDFDocument3 pagesVasudeva-Ashtakam Sanskrit PDFaneesh awasthiNo ratings yet

- Shiv Mahimn Stotra With ENGLISH TRANSLATIONDocument66 pagesShiv Mahimn Stotra With ENGLISH TRANSLATIONaneesh awasthi100% (2)

- Ims Manual 2019 FinalDocument58 pagesIms Manual 2019 Finalaneesh awasthi100% (7)

- Achyuta-Ashtakam Sanskrit PDF File4396Document3 pagesAchyuta-Ashtakam Sanskrit PDF File4396aneesh awasthi100% (1)

- Krishna Stotram Narada Rishi Sanskrit PDF File4520Document3 pagesKrishna Stotram Narada Rishi Sanskrit PDF File4520aneesh awasthiNo ratings yet

- Eka Sloki Bhagavatam PDFDocument3 pagesEka Sloki Bhagavatam PDFaneesh awasthiNo ratings yet

- Govinda-Stotram Sanskrit PDF File4875Document2 pagesGovinda-Stotram Sanskrit PDF File4875aneesh awasthiNo ratings yet

- Minimess Katalog PDFDocument39 pagesMinimess Katalog PDFaneesh awasthiNo ratings yet

- Pipe Supports James o PennockDocument62 pagesPipe Supports James o Pennockaneesh awasthiNo ratings yet

- Garbha-Stuti Sanskrit PDF File5816Document3 pagesGarbha-Stuti Sanskrit PDF File5816aneesh awasthiNo ratings yet

- Eka Sloki Bhagavatam PDFDocument3 pagesEka Sloki Bhagavatam PDFaneesh awasthiNo ratings yet

- Bhuvaneshwari-Ashtakam Sanskrit PDF File12659Document3 pagesBhuvaneshwari-Ashtakam Sanskrit PDF File12659aneesh awasthiNo ratings yet

- Cooling Towers: Industrial MediumDocument5 pagesCooling Towers: Industrial Mediumaneesh awasthiNo ratings yet

- Hilti Bolts ManualDocument237 pagesHilti Bolts Manualaneesh awasthiNo ratings yet

- Mps Katalog Gradior en Kap1Document9 pagesMps Katalog Gradior en Kap1TONNo ratings yet

- Kat ENDocument75 pagesKat ENaneesh awasthiNo ratings yet

- Erection Protocol - Fans PDFDocument3 pagesErection Protocol - Fans PDFaneesh awasthiNo ratings yet

- Minimess KatalogDocument39 pagesMinimess Kataloganeesh awasthiNo ratings yet

- Guarantee Parameters TrapsDocument4 pagesGuarantee Parameters Trapsaneesh awasthiNo ratings yet

- Schedule ChartDocument1 pageSchedule Chartaneesh awasthiNo ratings yet

- The Dynamic Susceptibilty VibrDocument14 pagesThe Dynamic Susceptibilty Vibraneesh awasthiNo ratings yet

- Polypropylene: Sub-Group Description Applications ProcessDocument2 pagesPolypropylene: Sub-Group Description Applications ProcessJulio GarcíaNo ratings yet

- 12 Chem CH 10 MCQSDocument12 pages12 Chem CH 10 MCQSSaran.kNo ratings yet

- Flame Test PracDocument2 pagesFlame Test PracJimBeanz75% (12)

- Chapter 11 - Surfacing and Shape Welding PDFDocument15 pagesChapter 11 - Surfacing and Shape Welding PDFCarlos GarcíaNo ratings yet

- M.Sc. Previous, Analytical Chemistry: Paper-Iv MAX: MARKS: 100Document4 pagesM.Sc. Previous, Analytical Chemistry: Paper-Iv MAX: MARKS: 100Ƞƛǝǝm KĦáńNo ratings yet

- Axarel 6100 TDSDocument3 pagesAxarel 6100 TDSYo ANo ratings yet

- Carboset CA-600 - CST600 - CO - enDocument3 pagesCarboset CA-600 - CST600 - CO - enNilsNo ratings yet

- Food Chemistry Testing SUGAR, STARCH ETCDocument5 pagesFood Chemistry Testing SUGAR, STARCH ETCrangerblue75% (12)

- Service Bulletin: Hartzell Propeller Inc. Transmittal Sheet HC-SB-61-181A Blades - Blade Corrosion Inspection and RepairDocument12 pagesService Bulletin: Hartzell Propeller Inc. Transmittal Sheet HC-SB-61-181A Blades - Blade Corrosion Inspection and RepairDonald SimsNo ratings yet

- BlackodisingDocument2 pagesBlackodisingSwapnil Khade100% (2)

- Stability CocaineDocument17 pagesStability CocaineAmalikMalikNo ratings yet

- Hempel NORSOK Coating Systems: NORSOK M-501 Edition 5/6 System GuideDocument4 pagesHempel NORSOK Coating Systems: NORSOK M-501 Edition 5/6 System GuideAlex KuvoricNo ratings yet

- Materials Advances: PaperDocument10 pagesMaterials Advances: PapercathyyNo ratings yet

- Heat Treatment of SteelsDocument162 pagesHeat Treatment of SteelsINSTECH ConsultingNo ratings yet

- Alat LabDocument1 pageAlat LabAgus Joko PNo ratings yet

- l-3 c-163 1344837023407Document79 pagesl-3 c-163 1344837023407Kommraju Sravan Kumar100% (1)

- IOC D F-Block Element EDocument60 pagesIOC D F-Block Element EPriyanshu GehlotNo ratings yet

- E6 Isolation of GlycogenDocument19 pagesE6 Isolation of GlycogenGlenn Vincent Tumimbang100% (1)

- Diagenesis, Catagenesis, andDocument7 pagesDiagenesis, Catagenesis, andزهر البنفسج أحمدNo ratings yet

- 1.3. Other Means of Generating Enolates: Osime Meli O Li + SimeDocument14 pages1.3. Other Means of Generating Enolates: Osime Meli O Li + SimeVirendra Singh RajputNo ratings yet

- Dew Point Od Acid GasDocument4 pagesDew Point Od Acid GassrshahNo ratings yet

- Rsdc-Skill - Gap - Study-Rubber Technology and Manufacturing Process of Rubber Products PDFDocument119 pagesRsdc-Skill - Gap - Study-Rubber Technology and Manufacturing Process of Rubber Products PDFVijay YajivNo ratings yet

- Cell Chemistry and Biosynthesis 2011Document47 pagesCell Chemistry and Biosynthesis 2011ALFYANNo ratings yet

- Advantages and DisadvantagesDocument4 pagesAdvantages and DisadvantagesvenothNo ratings yet

- Jurnal NanoemulsiDocument12 pagesJurnal NanoemulsiulfiNo ratings yet

- Fuels and Combustion Part - II: DR Waqas Khalid SmmeDocument8 pagesFuels and Combustion Part - II: DR Waqas Khalid SmmeFaizan RazaNo ratings yet

- Portable Fire ExtinguishersDocument4 pagesPortable Fire ExtinguishersShreyas MNo ratings yet

- PulverizationDocument26 pagesPulverizationVasantha SudasinghaNo ratings yet

- CH 11-Metal CaastingDocument113 pagesCH 11-Metal CaastingNasir MaqsoodNo ratings yet