Professional Documents

Culture Documents

MSC 127

Uploaded by

Eduardo Luis SouzaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSC 127

Uploaded by

Eduardo Luis SouzaCopyright:

Available Formats

MSC-127 Series

Medium Screw Compressors

Four Sizes

8-225 TR (28-791 kW)

186-335 CFM

80-200 HP

l Small Footprint

l Built-in, High Efficiency Oil Separator

l Refrigerants: R22, R134a, R404A, R407C, R507

and other HFCs

l UL Recognized

l Designed for A/C & Refrigeration

l Fully hermetic design

l Models from -50F (-46C) to 50F (10C) SST

l Models from +65F (18C) to 145F (63C) SDT

l Helium, Neon, and Other Alternate Gas Applications

l Low oil carry-over rate of less than 0.2%

l Optional vapor injection to enhance capacity

and EER/COP

l Smooth, Quiet Rotary Motion

Pioneers in Screw Compressor Technology

MSC-127 Series

Company Information

Hartford Compressors Inc. designs, manufac-

tures, and supports an extensive range of rotary

screw compressors and reciprocating compres-

sors for use in air conditioning and refrigeration

systems. With decades of experience in develop-

ing innovative products for commercial, indus-

trial, and marine applications, Hartford

Compressors sets the standard for precision

engineering, optimum performance, and cus-

tomer satisfaction.

Our latest generation of medium and large screw

compressors have been designed for long life,

low noise and vibration levels, improved reliabil-

ity, and lower operating costs. They are compati-

ble with environmentally friendly refrigerants and

gases with zero ozone depletion potential (ODP)

and zero global warming potential (GWP).

A continuing program of in-house laboratory

testing has resulted in screw compressors with the

best combination of economy and efficiency

available today.

With fewer moving parts and smooth rotary

motion, screw compressors provide reliable, non-

pulsating positive displacement compression.

Paired male and female helically profiled rotors

are machined with extreme accuracy of pitch and

thread form, to obtain tight uniform clearances.

This ensures proper sealing and dynamic bal-

ance necessary for quiet and efficient perfor-

mance. Positive displacement compression results

in stable operation at partial or full load. A built-

in separator (MSC only) creates a full self-

contained unit.

All of our products are engineering with the

highest attention to detail. Whether choosing a

standard model or one specially engineered, we

provide needed features and benefits. With this

philosophy, Hartford Compressors Inc. proudly

presents the MSC-127 which illustrates all

aspects of engineering excellence.

HARTFORD COMPRESSORS INC.

MSC-127 Series

Standard Features & Benefits

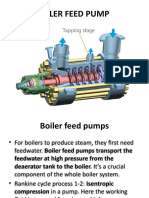

CROSS SECTIONAL VIEW

Discharge Pressure

Suction Pressure

Vapor Injection Pressure

Oil

Oil Deflector Cap

Oil Separator

Motor

Female (Drive) Rotor

Male Rotor Not Shown

Suction Check Valve

Replaceable Suction Filter Sump Heater Strip

Axial Discharge Port

Oil Strainer

Oil Temperature Sensor

FEATURE BENEFIT

Slide-Valve Capacity Control Capacity control from 100% to 20% of full load

Solid State Motor Protector Thermal motor protection

Unloading Solenoid Valves Energizes load/unload mechanism

Optical Oil Level Sensor Electronic low oil level safety, mounted externally

Oil Sump Heater Prevents refrigerant migration

XL or 2 Step Motor Start Choice of motor starting method

Built-in Suction Check Valve Prevents rotors from spinning backwards

Suction Filter Serviceable filter for compressor protection

Standard Voltages 200/3/50Hz; 230/3/60Hz; 400/3/50Hz; 460/3/60Hz

Oil Strainer Located in the oil sump to filter oil continuously

Liquid Injection Standard on air-cooled applications for oil cooling

HARTFORD COMPRESSORS INC.

MSC-127 Series

U. S. Standard Units

General Compressor Information

Motor Displacement SST Range SDT Range Estimated

Model Refrigerant Nominal HP at 60 Hz (CFM) Rotor L/D Min (F) Max (F) Min (F) Max (F) Weight (Lb.)

1210NHF6X6K R22,R407C 120 0 50 65 145 1010

1210NHF6W4K R22,R407C 80 186 20* 50 65 115 968

1210NHF6W3K R22,R407C 60 @ 1.00 20* 50 65 110 948

1210NHL6V5K R134a 60 3500 0 50 65 145 867

1210NLF6V5K R22,R507, R404A 100 RPM 0 20 65 125 990

1210NUF6V5K R22,R404A, R507 100 -50 0 65 125 990

1212NHF6X6K R22,R407C 150 0 50 65 145 1020

1212NHF6W4K R22,R407C 100 233 20* 50 65 115 983

1212NHF6W3K R22,R407C 80 @ 1.25 20* 50 65 110 963

1212NHL6V5K R134a 80 3500 0 50 65 145 884

1212NLF6V5K R22,R507, R404A 120 RPM 0 20 65 125 1002

1212NUF6V5K R22,R404A, R507 120 -50 0 65 125 1002

1215NHF6X6K R22,R407C 175 0 50 65 145 1265

1215NHF6W4K R22,R407C 120 279 20* 50 65 115 1225

1215NHF6W3K R22,R407C 100 @ 1.50 20* 50 65 110 1205

1215NHL6V5K R134a 100 3500 0 50 65 145 1109

1215NLF6V5K R22,R507, R404A 150 RPM 0 20 65 125 1250

1215NUF6V5K R22,R404A, R507 150 -50 0 65 125 1250

1218NHF6X6K R22,R407C 200 335 0 50 65 145 1260

1218NHF6W4K R22,R407C 150 @ 1.80 20* 50 65 115 1230

1218NHF6W3K R22,R407C 120 3500 20* 50 65 110 1214

1218NHL6V5K R134a 120 RPM 0 50 65 145 1120

* "NHF6W4" and "NHF6W3" models can operate down to 10F SST, however, the maximum allowable SDT is 105F.

Capacity (TR), Power (KW) and Energy Efficiency Ratio (EER), 60 Hz, R22

Saturated Saturated 1210 1212 1215 1218

Suction Discharge CAP POW CAP POW CAP POW CAP POW

Temp. F Temp. F (TR) (KW) EER (TR) (KW) EER (TR) (KW) EER (TR) (KW) EER

105 35.7 66.3 6.5 42.7 79.3 6.5 53.0 92.8 6.9 - - -

0 125 27.9 82.9 4.0 33.9 99.0 4.1 42.1 115.8 4.4 - - -

145 - - - - - - - - - - - -

105 46.9 69.1 8.2 55.4 82.5 8.1 68.8 96.6 8.5 - - -

10 125 39.0 85.5 5.5 45.7 102.2 5.4 56.7 119.6 5.7 - - -

145 - - - - - - - - - - - -

105 57.6 75.1 9.2 72.5 92.8 9.8 89.6 107.4 10.0 107.1 130.1 9.9

20 125 54.2 90.2 7.2 66.6 109.2 7.3 82.8 129.4 7.7 97.6 155.3 7.5

145 46.1 113.8 4.9 56.0 137.3 4.9 71.8 161.2 5.3 81.5 193.2 5.1

105 71.6 73.9 11.6 90.9 91.2 12.0 112.0 106.7 12.6 133.5 128.4 12.5

30 125 66.6 90.9 8.8 81.9 110.7 8.9 103.6 130.2 9.5 120.7 156.5 9.3

145 56.7 114.2 6.0 69.9 138.5 6.1 87.7 162.3 6.5 103.1 194.4 6.4

105 88.3 72.5 14.6 110.9 89.5 14.9 139.2 106.0 15.8 162.8 126.4 15.5

40 125 82.2 92.2 10.7 101.3 112.2 10.8 124.0 132.7 11.2 147.1 158.5 11.1

145 70.6 115.3 7.4 87.0 139.9 7.5 103.9 164.2 7.6 126.3 195.8 7.7

105 107.1 71.0 18.1 131.1 87.6 17.9 172.9 105.1 19.7 194.3 124.4 18.7

50 125 99.3 94.0 12.7 122.9 114.0 12.9 156.4 133.8 14.0 180.7 161.0 13.5

145 86.2 116.9 8.9 105.6 141.5 9.0 132.9 163.8 9.7 155.1 197.4 9.4

Data based on 10F subcooling/10F superheat.

NOTE: Performance data on this page is adequate for preliminary selections. For detailed information on specific applications contact Hartford Compressors Inc.

HARTFORD COMPRESSORS INC.

MSC-127 Series

Metric Units

General Compressor Information

Motor Displacement SST Range SDT Range Estimated

Model Refrigerant Nominal KW at 50Hz (m3/hr.) Rotor L/D Min (C) Max (C) Min (C) Max (C) Weight (kG)

1210NHF6X6K R22,R407C 89 -18 10 18 63 459

1210NHF6W4K R22,R407C 60 262 -7* 10 18 46 440

1210NHF6W3K R22,R407C 45 @ 1.00 -7* 10 18 43 431

1210NHL6V5K R134a 45 2900 -18 10 18 63 394

1210NLF6V5K R22,R507, R404A 75 RPM -18 -7 18 52 450

1210NUF6V5K R22,R404A, R507 75 -46 -18 18 52 450

1212NHF6X6K R22,R407C 112 -18 10 18 63 464

1212NHF6W4K R22,R407C 75 329 -7* 10 18 46 447

1212NHF6W3K R22,R407C 60 @ 1.25 -7* 10 18 43 438

1212NHL6V5K R134a 60 2900 -18 10 18 63 402

1212NLF6V5K R22,R507, R404A 89 RPM -18 -7 18 52 455

1212NUF6V5K R22,R404A, R507 89 -46 -18 18 52 455

1215NHF6X6K R22,R407C 130 -18 10 18 63 575

1215NHF6W4K R22,R407C 89 394 -7* 10 18 46 557

1215NHF6W3K R22,R407C 75 @ 1.50 -7* 10 18 43 548

1215NHL6V5K R134a 75 2900 -18 10 18 63 504

1215NLF6V5K R22,R507, R404A 112 RPM -18 -7 18 52 568

1215NUF6V5K R22,R404A, R507 112 -46 -18 18 52 568

1218NHF6X6K R22,R407C 149 473 -18 10 18 63 573

1218NHF6W4K R22,R407C 112 @ 1.80 -7* 10 18 46 559

1218NHF6W3K R22,R407C 89 2900 -7* 10 18 43 552

1218NHL6V5K R134a 89 RPM -18 10 18 63 509

* "NHF6W4" and "NHF6W3" models can operate down to -12C SST, however, the maximum allowable SDT is 40C.

Capacity (KW), Power (KW) and Coefficient of Performance (COP), 60 Hz, R22

Saturated Saturated 1210 1212 1215 1218

Suction Discharge CAP POW CAP POW CAP POW CAP POW

Temp. C Temp. C (KW) (KW) COP (KW) (KW) COP (KW) (KW) COP (KW) (KW) COP

40 119.2 56.2 2.1 141.3 67.2 2.1 175.2 78.6 2.2 - - -

-15 50 98.8 68.4 1.4 117.5 81.7 1.4 145.6 95.6 1.5 - - -

60 - - - - - - - - - - - -

40 149.9 58.5 2.6 177.3 69.8 2.5 219.9 81.6 2.7 - - -

-10 50 129.1 70.6 1.8 150.7 84.3 1.8 186.9 98.6 1.9 - - -

60 - - - - - - - - - - - -

40 178.1 61.9 2.9 225.4 76.4 2.9 277.7 88.9 3.1 331.8 107.4 3.1

-5 50 168.5 73.3 2.3 207.3 88.9 2.3 263.7 104.7 2.5 307.0 126.0 2.4

60 146.3 90.3 1.6 179.2 109.4 1.6 230.5 128.6 1.8 264.2 154.5 1.7

40 216.4 60.9 3.6 274.7 75.2 3.7 338.7 88.4 3.8 402.6 106.0 3.8

0 50 203.9 73.9 2.8 250.8 90.1 2.8 316.3 105.8 3.0 369.4 127.1 2.9

60 177.4 90.8 2.0 218.7 110.4 2.0 272.2 129.8 2.1 321.4 155.4 2.1

40 260.4 59.9 4.4 326.8 73.9 4.4 411.8 87.8 4.7 479.6 104.5 4.6

5 50 245.8 75.0 3.3 302.9 91.3 3.3 372.0 107.8 3.5 440.6 128.7 3.4

60 215.3 91.8 2.3 265.2 111.5 2.4 318.3 131.3 2.4 384.2 156.7 2.5

40 309.5 58.7 5.3 378.9 72.5 5.2 500.3 87.1 5.2 561.5 102.8 5.5

10 50 290.9 76.4 3.8 360.2 92.6 3.9 459.5 108.7 4.2 530.5 130.8 4.1

60 256.7 93.0 2.8 315.4 112.7 2.8 397.7 131.2 3.0 462.4 158.1 2.9

Data based on 5C subcooling/5C superheat.

NOTE: Performance data on this page is adequate for preliminary selections. For detailed information on specific applications contact Hartford Compressors Inc.

HARTFORD COMPRESSORS INC.

MSC-127 Series

Applications

l Ice Skating Rinks and Process Ice Production

l Air-Conditioning Chillers for

Commercial buildings

l Refrigeration chillers for

refrigerated warehouses

l Air-Conditioning and Process Chillers

for military and passenger ships

. . . and so much more.

Compressor Nomenclature

*

12 15 N H F 6 W 4 K 0EM BJ O C

ROTOR DIAMETER CONTROL VOLTAGE

12 = 127 mm C = 115/1/50-60

J = 230/1/50-60

ROTOR L/D RATIO

10 = 1.00 START METHOD

12 = 1.25 0 = Two step-double-delta

15 = 1.50

18 = 1.80 MOTOR VOLTAGE

AK = 200/3/60

COMPRESSOR TYPE AM = 220/3/50

B = Flanged semi-hermetic female drive BJ = 400-460/3/50-60

N = Fully hermetic female drive BK = 200-230/3/50-60

CA = 500-575/3/50-60

TEMPERATURE APPLICATION CS = 346-400/3/50-60

H = High temperature

L = Commercial temperature ASSEMBLY LEVEL

U = Low temperature 0EM = Original Equipment Mfg.

RMF = Remanufactured

REFRIGERANT

F = R22, R404A, R407C, R507 COMPRESSOR VERSION

L = R134a K = w/cast iron main housing

and inlet needle bearings

UNLOADING CONFIGURATION

6 = Automatic unloaded start (spring) MOTOR SIZING

3 = Undersize by 2 steps

4 = Undersize by 1 step

INJECTION MODE 5 = Nominal

V = Vapor & liquid injection 6 = Oversized by 1 step

W = Vapor injection only

X = Vapor & liquid injection

* For special engineered compressors,

these six characters would be replaced by SE.

Example: 1215SE1271KOEMBJO

HARTFORD COMPRESSORS INC.

MSC-127 Series

Outline Drawings

E

D

C

B

Compressor Dimensions in inches (mm)

Models A B C D E F

1210K/1212K 43.4 (1102) 19.8 (502) 12.0 (305) 13.1 (332) 14.3 (364) 14.4 (366)

1215K/1218K 47.3 (1200) 21.8 (555) 14.0 (356) 14.2 (361) 15.3 (389) 16.5 (419)

HARTFORD COMPRESSORS INC.

MSC-127 Series

Rotary Motion Operation

For clarity reasons, the compressor operation description will be limited to one lobe on

the male rotor (right) and one interlobe space of the female rotor (left). In actual

operation, as the rotors turn all of the male lobes and female interlobe spaces interact

with a uniform gas flow.

Suction Phase As a lobe of the male rotor begins to

unmesh from an interlobe space in the female rotor, a

void is created and suction gas is drawn in through the

inlet port. As the rotors continue to turn the interlobe

space increases in size, and gas flows continuously into

the compressor. Suction is sealed off when the interlobe

space reaches its maximum volume.

Compression Phase As rotation continues, the gas

in the interlobe space is carried around the

circumference of the compressor housing. Further

rotation meshes male and female lobes thus reducing

interlobe volume. Positive displacement compression

continues in the direction of the discharge port.

Discharge Phase At a point determined by the

designed built-in compressor volume ratio (V), the

discharge port is uncovered and the compressed gas is

discharged by further meshing of the male and female

interlobe space. While the meshing point of a pair of

lobes is moving axially, the next charge is being drawn

into the unmeshed portion and the working phase of

the compressor cycle are repeated.

Hartford Compressors Inc.

179 South Street West Hartford, CT 06110 USA

Phone: 860-249-8671 Fax: 860-548-1705

Website: http://www.hartfordcompressors.com

Pioneers in Screw Compressor Technology Email: cserv@hartfordcompressors.com

2003

2003 Hartford

Hartford Compressors

Compressors Inc.

Inc. All

All rights

rights reserved.

reserved.

You might also like

- Survival GuideDocument137 pagesSurvival GuideClawsfinger100% (2)

- PDF Bobcat t190 Parts Manual SN 527711001 and Above SN 527811001 and AboveDocument377 pagesPDF Bobcat t190 Parts Manual SN 527711001 and Above SN 527811001 and AboveJager Gonzalez86% (14)

- MDBFPDocument21 pagesMDBFPRaja Vignesh100% (1)

- Complete System Administrator ChecklistDocument8 pagesComplete System Administrator Checklistيعىسسفشى نهلثىغه64% (14)

- Troubleshooting HVAC Fault Codes GuideDocument40 pagesTroubleshooting HVAC Fault Codes Guidejmdc100% (1)

- Apcd 5050 ADocument64 pagesApcd 5050 Aavinash rathodNo ratings yet

- VGD PDFDocument22 pagesVGD PDFKashif RockNo ratings yet

- Controls Operation and TroubleshootingDocument138 pagesControls Operation and TroubleshootingAnup SurendranNo ratings yet

- Field Connections Model Yk Chillers (Style F and G) With Variable Speed DriveDocument10 pagesField Connections Model Yk Chillers (Style F and G) With Variable Speed DriveJose CuevasNo ratings yet

- Chiller 201.26-rp1Document72 pagesChiller 201.26-rp1MJZENo ratings yet

- Carrier Ducted Series PDFDocument8 pagesCarrier Ducted Series PDFRajesh SoniNo ratings yet

- Comp Carly Scre Refrig 2004Document52 pagesComp Carly Scre Refrig 2004Deco DluxeNo ratings yet

- Comparison Carrier vs. McQuayDocument2 pagesComparison Carrier vs. McQuayPradeep SukumaranNo ratings yet

- 38AKS (Carrier Aircon) PDFDocument108 pages38AKS (Carrier Aircon) PDFSimeon James Defeo VillacrusisNo ratings yet

- T-Bolt Compression InspDocument15 pagesT-Bolt Compression InspANGEL MURILLONo ratings yet

- Qualitative ResearchDocument33 pagesQualitative ResearchTarekegn DengoNo ratings yet

- BSR Vs SR Coversion Guide FINAL PDFDocument39 pagesBSR Vs SR Coversion Guide FINAL PDFtvassilopoulosNo ratings yet

- CENTRIFUGAL PARTS LISTDocument126 pagesCENTRIFUGAL PARTS LISTSBD AtkinsNo ratings yet

- DVM Pro Design Software - DVM Pro SALES MODE Instructions PDFDocument83 pagesDVM Pro Design Software - DVM Pro SALES MODE Instructions PDFAnonymous yMGXv2Jhw6100% (2)

- 30XA Chiller CatalogDocument18 pages30XA Chiller CatalogKrishnan Govindaraj100% (1)

- Refrigerant Recovery and Recycling Units: Supersedes: 50.40-OM1 Form 50.40-OM1Document44 pagesRefrigerant Recovery and Recycling Units: Supersedes: 50.40-OM1 Form 50.40-OM1James MurrayNo ratings yet

- TT 400, Turbocor TIMDocument68 pagesTT 400, Turbocor TIManil kumarNo ratings yet

- Manual de Partes para Compresores Danfoss TurbocorDocument70 pagesManual de Partes para Compresores Danfoss TurbocorRobinson JimenezNo ratings yet

- Dunham-Bush AFVX-B-6SR Air-Cooled Screw Chiller SeriesDocument33 pagesDunham-Bush AFVX-B-6SR Air-Cooled Screw Chiller SeriesAhmed Sofa100% (1)

- RTAB 108 - 212: Helical Rotar y Compressor Liquid Chillers, Air CooledDocument10 pagesRTAB 108 - 212: Helical Rotar y Compressor Liquid Chillers, Air CooledloloNo ratings yet

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideFrom EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideNo ratings yet

- Chiller WSC ZentraliaDocument128 pagesChiller WSC ZentraliaJoseNo ratings yet

- 30HXY/HXC: Water-Cooled Screw ChillerDocument15 pages30HXY/HXC: Water-Cooled Screw ChillerJohn Soto100% (1)

- 30g, H-8t Carrier ChillerDocument122 pages30g, H-8t Carrier ChillerAwo Orumila Giraldolegra100% (1)

- CTS Central AC Plant Mech. - CTS - NSQF-5Document62 pagesCTS Central AC Plant Mech. - CTS - NSQF-5Syed tahirNo ratings yet

- Heavy Equipment Solution in One PlaceDocument32 pagesHeavy Equipment Solution in One PlaceEri MalindoNo ratings yet

- hs3200 Issue 12 H Parts List CustomerDocument13 pageshs3200 Issue 12 H Parts List Customermk saravananNo ratings yet

- Green Series WC Screw Chillers IOMDocument73 pagesGreen Series WC Screw Chillers IOMBilal Khan0% (1)

- MicroTech III Chiller UC Modbus Tech Sheet Daikin ED 15121-9LRDocument34 pagesMicroTech III Chiller UC Modbus Tech Sheet Daikin ED 15121-9LRSeñorNo ratings yet

- Product Catalog: Air Cooled ChillersDocument28 pagesProduct Catalog: Air Cooled Chillersit4728No ratings yet

- Screw Compressor Troubleshooting Guide: Caution: Never Run The Compressor in Reverse!Document2 pagesScrew Compressor Troubleshooting Guide: Caution: Never Run The Compressor in Reverse!thenshan100% (2)

- (Clivet-1803-5C1712) Water Cooled Screw Chiller (Flooded Type)Document18 pages(Clivet-1803-5C1712) Water Cooled Screw Chiller (Flooded Type)d.gitaNo ratings yet

- DCLC Centrifugal Chillers for Cooling and EfficiencyDocument6 pagesDCLC Centrifugal Chillers for Cooling and Efficiencygerald077No ratings yet

- Top HVAC Company in IndiaDocument11 pagesTop HVAC Company in Indiamails4gaurav360No ratings yet

- U.S.A Semi-CompressorDocument202 pagesU.S.A Semi-CompressorMechanical PowerNo ratings yet

- SC0501 01 - en UsDocument3 pagesSC0501 01 - en Usalimoya13No ratings yet

- YCAL0317CDocument114 pagesYCAL0317CDaniel Pinto GodoyNo ratings yet

- Service Information: GeneralDocument4 pagesService Information: GeneralDNo ratings yet

- York Air Cooled Screw Liquid Chillers Style A LatitudeDocument64 pagesYork Air Cooled Screw Liquid Chillers Style A Latitudeasmchilltech100% (3)

- Parts List PC CompressorDocument20 pagesParts List PC CompressorSyed Ali KhanNo ratings yet

- Pit Installations - Restricted Airflow SituationsDocument16 pagesPit Installations - Restricted Airflow Situationsfarshan296015No ratings yet

- Daikin MicroTech III RegisterDocument42 pagesDaikin MicroTech III RegisterYudaNo ratings yet

- SB0018: Adding Line Inductor to Variable Speed Oil Pump DriveDocument2 pagesSB0018: Adding Line Inductor to Variable Speed Oil Pump DrivemikenilsonNo ratings yet

- Yaep GZDocument36 pagesYaep GZMahmod King75% (4)

- Magnum Version 8 Manual Rev1.7Document172 pagesMagnum Version 8 Manual Rev1.7shahzad32552372100% (1)

- 38HK 03 PD 60HZ 2011Document32 pages38HK 03 PD 60HZ 2011Ahmed Jabir100% (1)

- Tarifas RefrigeracionDocument152 pagesTarifas Refrigeracionluam_0705No ratings yet

- High Ambient Air Cooled Liquid ChillerDocument60 pagesHigh Ambient Air Cooled Liquid Chillerfmtechac75% (4)

- RLC PRC005 E4 - 0110Document60 pagesRLC PRC005 E4 - 0110jefhdez0% (1)

- Brochure For York ChillerDocument8 pagesBrochure For York ChillervenkatearNo ratings yet

- VCV WesperDocument12 pagesVCV Wesperciperu55No ratings yet

- Technical Manual For Air-Cooled Rooftop Package - (FDXA04-2020,21B)Document32 pagesTechnical Manual For Air-Cooled Rooftop Package - (FDXA04-2020,21B)yusuf mohd sallehNo ratings yet

- Copeland WeldedDocument198 pagesCopeland WeldedjnamatheNo ratings yet

- 5091 - Dunham 1212NHF PDFDocument8 pages5091 - Dunham 1212NHF PDFMechanical PowerNo ratings yet

- MP PC200-6 80001-UpDocument4 pagesMP PC200-6 80001-UpEdin raul Yalle rafaelNo ratings yet

- Manual Bomba EspumaDocument108 pagesManual Bomba EspumaFrancisco ManriquezNo ratings yet

- Oil Free Reciprocating Compressors - IRDocument2 pagesOil Free Reciprocating Compressors - IRvmohan01No ratings yet

- Acdx 2Document44 pagesAcdx 2GermánCastiglioniNo ratings yet

- Schematic Volume 1 and 2 Hydraulic CircuitDocument33 pagesSchematic Volume 1 and 2 Hydraulic CircuitRoke LlamocaNo ratings yet

- RMH-LC-ACV-DOC-006 RC Equipment Selection Seawater Cooled Package Air ConditionerDocument21 pagesRMH-LC-ACV-DOC-006 RC Equipment Selection Seawater Cooled Package Air Conditionercmc261185No ratings yet

- DB Corporate ProfileDocument24 pagesDB Corporate ProfileEduardo Luis SouzaNo ratings yet

- Quer Reduzir Custos Com Energia? Ter Melhor Performance e Confiabilidade? Garantir Conforto?Document1 pageQuer Reduzir Custos Com Energia? Ter Melhor Performance e Confiabilidade? Garantir Conforto?Eduardo Luis SouzaNo ratings yet

- Tempo & Zafiro: Air & Water Cooled Liquid Chillers Micro Based Control System With Ipuii C.MMC.16.03Document56 pagesTempo & Zafiro: Air & Water Cooled Liquid Chillers Micro Based Control System With Ipuii C.MMC.16.03Eduardo Luis SouzaNo ratings yet

- Calibrate Intruc PDFDocument5 pagesCalibrate Intruc PDFEduardo Luis SouzaNo ratings yet

- Acpsb-Pqp: Mobile Utility Energy Package Cooling Only UnitDocument2 pagesAcpsb-Pqp: Mobile Utility Energy Package Cooling Only UnitEduardo Luis SouzaNo ratings yet

- Hansen Technologies LLIDocument4 pagesHansen Technologies LLIghilesNo ratings yet

- ACCS 50-60Hz R407C-R410A MS0327D-0719R1 Lo 0Document20 pagesACCS 50-60Hz R407C-R410A MS0327D-0719R1 Lo 0Eduardo Luis SouzaNo ratings yet

- Products That Perform By People Who CareDocument16 pagesProducts That Perform By People Who CareFalak KhanNo ratings yet

- Hansen Technologies LLIDocument4 pagesHansen Technologies LLIghilesNo ratings yet

- Calibrate Intruc PDFDocument5 pagesCalibrate Intruc PDFEduardo Luis SouzaNo ratings yet

- Ms0488a 0810 PDFDocument40 pagesMs0488a 0810 PDFEduardo Luis SouzaNo ratings yet

- Tempo & Zafiro: Air & Water Cooled Liquid Chillers Micro Based Control System With Ipuii C.MMC.16.03Document56 pagesTempo & Zafiro: Air & Water Cooled Liquid Chillers Micro Based Control System With Ipuii C.MMC.16.03Eduardo Luis SouzaNo ratings yet

- Products That Perform By People Who CareDocument16 pagesProducts That Perform By People Who CareFalak KhanNo ratings yet

- High-Efficiency Air-Cooled Chillers for Large FacilitiesDocument24 pagesHigh-Efficiency Air-Cooled Chillers for Large FacilitiesEduardo Luis Souza100% (1)

- 10-03-28 Publ-6374Document2 pages10-03-28 Publ-6374Gaurav Panditrao UdanshivNo ratings yet

- 50.00-N1 (SB1)Document1 page50.00-N1 (SB1)Eduardo Luis SouzaNo ratings yet

- Benshaw ContatorasDocument20 pagesBenshaw ContatorasEduardo Luis SouzaNo ratings yet

- Recip Service ComprDocument124 pagesRecip Service ComprEduardo Luis Souza100% (1)

- Trane Custo Iplv CTV-PRB003-EnDocument8 pagesTrane Custo Iplv CTV-PRB003-EnAntonio HirschleNo ratings yet

- Design and Fabrication of Pedal Operated Washing MachineDocument7 pagesDesign and Fabrication of Pedal Operated Washing MachineAayush KhandelwalNo ratings yet

- 64148069036e353d2c4d1930 - Weekly Timesheet Template - My HoursDocument9 pages64148069036e353d2c4d1930 - Weekly Timesheet Template - My Hoursoces1551No ratings yet

- HW4 TutorialDocument17 pagesHW4 TutorialsatmaniaNo ratings yet

- Engine IdentificationDocument30 pagesEngine Identificationgerber damianNo ratings yet

- Data Sheet NPNB HN22PA3Document2 pagesData Sheet NPNB HN22PA3Liliana ZamoraNo ratings yet

- Credit Hours: 3 Lecture Hours: 2 Laboratory Hours: 2 Prerequisites: CSC 227Document2 pagesCredit Hours: 3 Lecture Hours: 2 Laboratory Hours: 2 Prerequisites: CSC 227Zerihun BekeleNo ratings yet

- DIGITAL MARKETING ASSIGNMENTDocument6 pagesDIGITAL MARKETING ASSIGNMENTharshita khadayteNo ratings yet

- Fmea Presentation-How-To-Do-It-RightDocument31 pagesFmea Presentation-How-To-Do-It-RightAmir Khakzad100% (1)

- Kvw-Uv: Je Ett H Hood W W C L GyDocument9 pagesKvw-Uv: Je Ett H Hood W W C L Gying_ballesterosNo ratings yet

- Smart Irrigation System (Maheen)Document15 pagesSmart Irrigation System (Maheen)kiswah computersNo ratings yet

- Flow Meter - ErrorDocument3 pagesFlow Meter - ErrorEvan YudianaNo ratings yet

- Evidence-Based ManagementDocument17 pagesEvidence-Based ManagementShruthiNo ratings yet

- Chat GPT FileDocument5 pagesChat GPT Filejagan venkatNo ratings yet

- DS2100 Standard EU ENDocument31 pagesDS2100 Standard EU ENsundaygboroNo ratings yet

- SEKSYEN RADIATOR 4B11 Mitsubishi Motors Service ManualDocument5 pagesSEKSYEN RADIATOR 4B11 Mitsubishi Motors Service ManualAz Zahra AzmanNo ratings yet

- Top 34 Unix commands for file operationsDocument11 pagesTop 34 Unix commands for file operationslokeshscribd186No ratings yet

- Automated Grading System For Teachers and StudentsDocument2 pagesAutomated Grading System For Teachers and StudentsAnone Anone0% (1)

- Auxiliary Hydraulic Unit 5 4: Feed Pressure Back-Up ValveDocument1 pageAuxiliary Hydraulic Unit 5 4: Feed Pressure Back-Up ValveJagmohan SinghNo ratings yet

- Dell Latitude 5490Document8 pagesDell Latitude 5490Noemi VelasquezNo ratings yet

- Electrical WiringDocument17 pagesElectrical WiringPachito S. SucalitNo ratings yet

- Answers Simplest Form: Grade 8 NOTES: Unit 3 - FractionsDocument17 pagesAnswers Simplest Form: Grade 8 NOTES: Unit 3 - FractionsKumidi SampatNo ratings yet

- Aiml Virtual InternshipDocument21 pagesAiml Virtual InternshipPainampuram JuhithaNo ratings yet

- SF6 Gas Stock Balance ReportDocument4 pagesSF6 Gas Stock Balance ReportJawad AmjadNo ratings yet

- Optyma Condensing Units: Lightweight and Compact SolutionDocument32 pagesOptyma Condensing Units: Lightweight and Compact SolutionviniciusschwabNo ratings yet

- PassMark - Intel Core I3-10110u at 2.10GHz - Price Performance ComparisonDocument6 pagesPassMark - Intel Core I3-10110u at 2.10GHz - Price Performance ComparisonRONNE PETSON ARAUJO DOS SANTOSNo ratings yet