Professional Documents

Culture Documents

Jis g3444-1 PDF

Uploaded by

bkprodhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jis g3444-1 PDF

Uploaded by

bkprodhCopyright:

Available Formats

Pacific Pipe Public Company Limite Pacific Pipe World Class Quality Pacific Pipe World Class Quality

JIS G3444 Carbon Steel Pipe for

General Structural Purposes

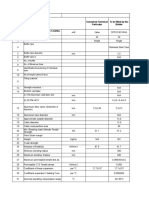

CHEMICAL COMPOSITION (%) MECHANICAL PROPERTIES

MATERIAL

OF C Si Mn P S Yield Tensile Elongation

GRADE Max Max Max Max Max Strength Strength %

N/mm2 N/mm2

STK 400 0.25 - - 0.04 0.04 235 400 23

STK 490 0.18 0.55 1.50 0.04 0.04 315 490 23

Nominal Outside Thickness Weight Cross Geometrical Modulus Radius Nominal Outside Thickness Weight Cross Geometrical Modulus Radius

Size Diameter (Plain End) Sectional Moment Of Of Size Diameter (plain end) Sectional moment of of

Area Of Inertia Section Gyration Area of inertia section gyration

mm mm mm kg/m cm2 cm4 cm3 cm mm mm mm kg/m cm2 cm4 cm3 cm

15 21.70 2.00 0.97 1.238 0.607 0.560 0.700 175 190.70 4.50 20.70 26.32 1140 120 6.59

20 27.2 2.00 1.24 1.583 1.26 0.930 0.890 5.30 24.20 30.87 1330 139 6.56

2.30 1.41 1.799 1.41 1.03 0.880 6.00 27.30 34.82 1490 156 6.53

25 34.00 2.30 1.80 2.291 2.89 1.70 1.12 7.00 31.70 40.4 1710 179 6.5

32 42.70 2.30 2.29 2.919 5.97 2.80 1.43 8.20 36.90 47.01 1960 206 6.46

2.50 2.48 3.157 6.40 3.00 1.42 200 216.30 4.50 23.50 29.94 1680 155 7.49

40 48.60 2.30 2.63 3.345 8.99 3.70 1.64 5.80 30.10 38.36 2130 197 7.45

2.50 2.84 3.621 9.65 3.97 1.63 6.00 31.10 39.64 2190 203 7.44

2.80 3.16 4.029 10.6 4.36 1.62 7.00 36.10 46.03 2520 233 7.4

3.20 3.58 4.564 11.8 4.86 1.61 8.00 41.10 52.35 2840 263 7.37

50 60.50 2.30 3.30 4.205 17.8 5.90 2.06 8.20 42.10 53.61 2910 269 7.36

3.20 4.52 5.76 23.7 7.84 2.03 250 267.40 6.00 38.70 49.27 4210 315 9.24

4.00 5.57 7.1 28.5 9.41 2.00 6.60 42.40 54.08 4600 344 9.22

65 76.30 2.80 5.08 6.465 43.7 11.5 2.60 7.00 45.00 57.26 4860 363 9.21

3.20 5.77 7.349 49.2 12.9 2.59 8.00 51.20 65.19 5490 411 9.18

4.00 7.13 9.085 59.5 15.6 2.58 9.00 57.30 73.06 6110 457 9.14

80 89.10 2.80 5.96 7.591 70.7 15.9 3.05 9.30 59.20 75.41 6290 470 9.13

3.20 6.78 8.636 79.8 17.9 3.04 300 318.50 6.00 46.20 58.91 7190 452 11.1

90 101.60 3.20 7.76 9.892 120 23.6 3.48 6.90 53.00 67.55 8200 515 11

4.00 9.63 12.26 146 28.8 3.45 8.00 61.30 78.04 9410 591 11

5.00 11.90 15.17 177 34.9 3.42 9.00 68.70 87.51 10500 659 10.9

100 114.30 3.20 8.77 11.17 172 30.2 3.93 10.30 78.30 99.73 11900 744 10.9

3.50 9.58 12.18 187 32.7 3.92 350 355.60 6.40 55.10 70.21 10700 602 12.3

4.50 12.20 15.52 234 41 3.89 7.90 67.70 86.29 13000 734 12.3

125 139.80 3.60 12.10 15.4 357 51.1 4.82 9.00 76.90 98 14700 828 12.3

4.00 13.40 17.07 394 56.3 4.8 9.50 81.10 103.3 15500 871 12.2

4.50 15.00 19.13 438 62.7 4.79 12.00 102.00 129.5 19100 1080 12.2

6.00 19.80 25.22 566 80.2 4.74 12.70 107.00 136.8 20100 1130 12.2

150 165.20 4.50 17.80 22.72 734 88.9 5.68 400 406.40 7.90 77.60 98.9 19600 967 14.1

5.00 19.80 25.16 808 97.8 5.67 9.00 88.20 112.4 22200 1090 14.1

6.00 23.60 30.01 952 115 5.63 9.50 93.00 118.5 23300 1150 14

7.10 27.70 35.26 1100 134 5.6 12.00 117.00 148.7 28900 1420 14

12.70 123.00 157.1 30500 1500 13.9

Dimension Tolerances

Outside Diameter :

Class 1 : OD < 50 : 0.50mm

: OD 50 : 1%

Class 2 : OD < 50 : 0.25mm

: OD 50 : 0.5%

Thickness :

Class 1 : t < 4.00 mm : -0.50mm, +0.60mm

: t 4.00 mm : +15%, -12.5%

Class 2 : t <3.00 mm : 0.3mm

: t 3.00 mm : 10%

24

You might also like

- Swedish Requests For OHL-s - Rev04Document50 pagesSwedish Requests For OHL-s - Rev04vladaukiNo ratings yet

- AAAC - All Aluminum Alloy 6201 Conductor PDFDocument1 pageAAAC - All Aluminum Alloy 6201 Conductor PDFsualehnavedNo ratings yet

- IEEE TPC Tutorial Sag TensionCalcsDocument33 pagesIEEE TPC Tutorial Sag TensionCalcsabhijitNo ratings yet

- Carta Presentacion FerreteriaDocument10 pagesCarta Presentacion FerreteriaDrakhoNo ratings yet

- Aluminium Conductor Composite Core ACCCDocument5 pagesAluminium Conductor Composite Core ACCCAmlanshankar Deb BarmaNo ratings yet

- Dosya554386 310656Document46 pagesDosya554386 310656gvsbabu63No ratings yet

- JIS Seamless PipeDocument8 pagesJIS Seamless PipeJay PanalanginNo ratings yet

- The effect of prestressing on the inelastic creep behaviour of Australian overhead conductorsDocument43 pagesThe effect of prestressing on the inelastic creep behaviour of Australian overhead conductorsHemantha BalasuriyaNo ratings yet

- Surveying Practice IDocument2 pagesSurveying Practice IVikram RaoNo ratings yet

- NZS3404 1-2009Document165 pagesNZS3404 1-2009Tianjin Steel Guo VivianNo ratings yet

- Transmission Towers BrochureDocument24 pagesTransmission Towers BrochureGhhNo ratings yet

- Opgw System FittingsDocument35 pagesOpgw System FittingsRadu Sergiu CimpanNo ratings yet

- TransPowr ACSS Bare Overhead ConductorDocument5 pagesTransPowr ACSS Bare Overhead ConductorHyrNo ratings yet

- Development of A Low Sag Aluminium Conductor Carbon Fibre Reinforced For Transmission LinesDocument6 pagesDevelopment of A Low Sag Aluminium Conductor Carbon Fibre Reinforced For Transmission LinesVishalNo ratings yet

- 000000000001011273Document190 pages000000000001011273Dante FilhoNo ratings yet

- OPGW GTP of Various VendorsDocument19 pagesOPGW GTP of Various VendorsRamphani Nunna100% (1)

- Substation Engineer CVDocument8 pagesSubstation Engineer CVSyed Zuber AhmedNo ratings yet

- Is 802-1-2Document19 pagesIs 802-1-2mukeshNo ratings yet

- 66 KV Acsr Wolf Sag TemplateDocument2 pages66 KV Acsr Wolf Sag Templateashutosh2009No ratings yet

- E1e-016 JFE SAWL PIPEDocument20 pagesE1e-016 JFE SAWL PIPEMassimoSalaNo ratings yet

- JNC Cables PDFDocument30 pagesJNC Cables PDFVasudev AgrawalNo ratings yet

- Tower DesignDocument66 pagesTower DesignovikbasuNo ratings yet

- "Towerplus": A Software Programme Developed To Assist High Voltage Transmission Line DesignDocument4 pages"Towerplus": A Software Programme Developed To Assist High Voltage Transmission Line DesignAdiputra Satria100% (1)

- Lecture 1-Introduction To Structural Steel Sections and PropertiesDocument20 pagesLecture 1-Introduction To Structural Steel Sections and Propertiesrenjith037No ratings yet

- BJKBKDocument124 pagesBJKBKXero KrossingNo ratings yet

- TR18.03.05 Damping Study - Transmission Line On Tunrkey Basis 132kV Double Circuit LT - ACCC HAWK PDFDocument29 pagesTR18.03.05 Damping Study - Transmission Line On Tunrkey Basis 132kV Double Circuit LT - ACCC HAWK PDFAsaduzzaman KhanNo ratings yet

- Sediver Composite Suspension Insulators UsaDocument16 pagesSediver Composite Suspension Insulators UsaBruce OlsonNo ratings yet

- Is 802 1977 PDFDocument21 pagesIs 802 1977 PDFBhavin Shah0% (1)

- Japan's First Live Power Transmission Using 3-In-One Superconducting Cable (High-Temperature Supercon-Ducting Cable Demonstration Project)Document10 pagesJapan's First Live Power Transmission Using 3-In-One Superconducting Cable (High-Temperature Supercon-Ducting Cable Demonstration Project)sajuaanalsaNo ratings yet

- 155-56 Erection MarksDocument346 pages155-56 Erection MarksnarinderNo ratings yet

- Design of Tranmission Lline - 137 - Ee2Document6 pagesDesign of Tranmission Lline - 137 - Ee2RETIRED ALT100% (1)

- Loads On TowerDocument27 pagesLoads On TowerPRAKASH A 18MSE002No ratings yet

- Al-Mg-Si Alloy Wire PDFDocument12 pagesAl-Mg-Si Alloy Wire PDFgvsbabu63No ratings yet

- 5 Analysis and Design of 220kv Transmission LineTower in Different Zones I & V With Different Base PDFDocument9 pages5 Analysis and Design of 220kv Transmission LineTower in Different Zones I & V With Different Base PDFmulualemNo ratings yet

- Drum Schedule Silae - Pas - Kayu Rev.02Document18 pagesDrum Schedule Silae - Pas - Kayu Rev.02Gonzalo LopezNo ratings yet

- Umberto - Spacer Tutorial Cigre 2011Document53 pagesUmberto - Spacer Tutorial Cigre 2011Iván Camilo Díez100% (1)

- IS 802 Part-1 Sec-1 DRAFT 12oct11 PDFDocument24 pagesIS 802 Part-1 Sec-1 DRAFT 12oct11 PDFRohit DeraNo ratings yet

- Section 02 OPGWDocument17 pagesSection 02 OPGWChaitanya ShakyaNo ratings yet

- AL59 157 SQMM Transmission Line SpecificationDocument2 pagesAL59 157 SQMM Transmission Line SpecificationMohamed RafiNo ratings yet

- Overhead Line Conductor PDFDocument30 pagesOverhead Line Conductor PDFBaskar ElNo ratings yet

- 500kV Aluminum-Sheathed XLPE Cable in A 96m Vertical ShaftDocument6 pages500kV Aluminum-Sheathed XLPE Cable in A 96m Vertical ShaftshahpinkalNo ratings yet

- 3 9031-11KV-Composite Polymer - Disc-Insulator Specifications GTPDocument24 pages3 9031-11KV-Composite Polymer - Disc-Insulator Specifications GTPAnonymous 4kYNmixNo ratings yet

- Pole HeightsDocument1 pagePole HeightsMuhammad BilalNo ratings yet

- 4 Volume-5Document332 pages4 Volume-5Mala Seth DuttaNo ratings yet

- Overhead Conductors Trefinasa 2016webDocument52 pagesOverhead Conductors Trefinasa 2016weboaktree2010No ratings yet

- Aluminium Uses in Electrical EngineeringDocument7 pagesAluminium Uses in Electrical EngineeringTigrilloNo ratings yet

- GHCABLE CatelogDocument161 pagesGHCABLE CatelogChristian Mauricio Aldás Solís0% (1)

- Considerations Relating To The Use of High Temperature ConductorsDocument25 pagesConsiderations Relating To The Use of High Temperature ConductorsIkhlas KittaNo ratings yet

- Middle Marsyangdi Dumre Damauli Transmission LinesDocument184 pagesMiddle Marsyangdi Dumre Damauli Transmission LinesSaurav Kafle100% (2)

- SANS-1431 Withdrawal (2010)Document1 pageSANS-1431 Withdrawal (2010)Darryl007No ratings yet

- Transpowr Acsr Bare Overhead Conductor To Can/Csa C61089: Aluminum Conductor Steel-Reinforced Concentric-Lay-StrandedDocument18 pagesTranspowr Acsr Bare Overhead Conductor To Can/Csa C61089: Aluminum Conductor Steel-Reinforced Concentric-Lay-Strandedravi474No ratings yet

- PTEC - 500 - Fundamentals of Overhead Transmission Line DesignDocument2 pagesPTEC - 500 - Fundamentals of Overhead Transmission Line DesignManoraj CvNo ratings yet

- Line Materials & Stringing in 400KV LinesDocument20 pagesLine Materials & Stringing in 400KV LinesbijoyNo ratings yet

- Foundation Chimney & Pyramid Formwork DimensionsDocument10 pagesFoundation Chimney & Pyramid Formwork DimensionsAmit AdmaneNo ratings yet

- Sag Tension CalculationsDocument9 pagesSag Tension CalculationsPrayas SubediNo ratings yet

- Advancements in Electric MachinesDocument56 pagesAdvancements in Electric Machinescharles_boyle_3No ratings yet

- Pacific Pipe JIS G3444 Carbon Steel Pipe SpecsDocument1 pagePacific Pipe JIS G3444 Carbon Steel Pipe SpecsRokhmatuSivaNo ratings yet

- JIS G3444 Tube For General structureDocument1 pageJIS G3444 Tube For General structurelukmanNo ratings yet

- Jis g3466-3Document1 pageJis g3466-3Nhuận PhạmNo ratings yet

- JIS G3466 - Thailand - CONTENT1011579693989745Document1 pageJIS G3466 - Thailand - CONTENT1011579693989745Nguyễn Tiến TùngNo ratings yet

- J 33Document2 pagesJ 33bkprodhNo ratings yet

- Steel StructuralsDocument10 pagesSteel Structuralsdchz_62No ratings yet

- FE410WWA - Equivalent Steel Grades QualitiesDocument6 pagesFE410WWA - Equivalent Steel Grades QualitiesbkprodhNo ratings yet

- Soporte UboltDocument2 pagesSoporte UboltJames HansonNo ratings yet

- PTQ q4 2016 Designing Storage TanksDocument4 pagesPTQ q4 2016 Designing Storage TanksJonathan RangelNo ratings yet

- X GR Grating Fastening System Product Data 330924Document14 pagesX GR Grating Fastening System Product Data 330924bkprodhNo ratings yet

- Schedule LevelsDocument7 pagesSchedule LevelsbkprodhNo ratings yet

- J 32Document2 pagesJ 32bkprodhNo ratings yet

- J 31Document2 pagesJ 31bkprodhNo ratings yet

- BNBM Rock Wool PDFDocument4 pagesBNBM Rock Wool PDFbkprodhNo ratings yet

- Rules of Thumb Chapter 8: VesselsDocument4 pagesRules of Thumb Chapter 8: VesselsAri KurniawanNo ratings yet

- TemJournalFebruary2016 76 79Document4 pagesTemJournalFebruary2016 76 79bkprodhNo ratings yet

- Piping-Progress-Measurement - (In Dia and in Meter)Document6 pagesPiping-Progress-Measurement - (In Dia and in Meter)bhardwaj_rahul7937100% (2)

- Mobile Crane 250T - Liebherr LTM - 1250Document12 pagesMobile Crane 250T - Liebherr LTM - 1250bkprodhNo ratings yet

- ASGEpg187 PDFDocument3 pagesASGEpg187 PDFbkprodhNo ratings yet

- Cong Truc Hai Dam PDFDocument3 pagesCong Truc Hai Dam PDFbkprodhNo ratings yet

- ETA-Danmark Technical Assessment SWE01 Sinto ST-EE Bonded AnchorDocument23 pagesETA-Danmark Technical Assessment SWE01 Sinto ST-EE Bonded AnchorbkprodhNo ratings yet

- STT Lincoln Electric PDFDocument30 pagesSTT Lincoln Electric PDFbkprodhNo ratings yet

- PROCEDURE FOR TANK FABRICATION & ERECTIONDocument15 pagesPROCEDURE FOR TANK FABRICATION & ERECTIONsenthilkumarsk88% (8)

- ETA-Danmark Technical Assessment SWE01 Sinto ST-EE Bonded AnchorDocument23 pagesETA-Danmark Technical Assessment SWE01 Sinto ST-EE Bonded AnchorbkprodhNo ratings yet

- Manhole D430: Fitting DetailsDocument1 pageManhole D430: Fitting DetailsbkprodhNo ratings yet

- X GR Grating Fastening System Product Data 330924Document14 pagesX GR Grating Fastening System Product Data 330924bkprodhNo ratings yet

- TongHeer Brouchure)Document10 pagesTongHeer Brouchure)bkprodhNo ratings yet

- TL-250M 2 PDFDocument12 pagesTL-250M 2 PDFbkprodhNo ratings yet

- Tadano TL 300 Truck CraneDocument1 pageTadano TL 300 Truck CranebkprodhNo ratings yet

- DP StraightDocument22 pagesDP StraightbkprodhNo ratings yet

- Ks FP M6-F9: Compact FiltersDocument1 pageKs FP M6-F9: Compact FiltersbkprodhNo ratings yet

- ANZ Anchoring CatWEBDocument92 pagesANZ Anchoring CatWEBbkprodhNo ratings yet

- Air Filters and Filtration Equipment WebDocument100 pagesAir Filters and Filtration Equipment WebbkprodhNo ratings yet

- Weight Breaking Load PDFDocument1 pageWeight Breaking Load PDFbkprodhNo ratings yet

- Rectify Binary Plate Efficiency BubblesDocument4 pagesRectify Binary Plate Efficiency BubblesCsaba AndrásNo ratings yet

- Comb Manual IM 106 6888QSDocument36 pagesComb Manual IM 106 6888QSsathish2829No ratings yet

- DESIGN II - ChemTran General Reference GuideDocument332 pagesDESIGN II - ChemTran General Reference GuideDebabrata MitraNo ratings yet

- Plasticizer From Vegetable Oil DerivativesDocument8 pagesPlasticizer From Vegetable Oil Derivativesilan chertokNo ratings yet

- HCIE-R&S Huawei Certified Internetwork Expert-Routing and Switching Training Lab Guide PDFDocument228 pagesHCIE-R&S Huawei Certified Internetwork Expert-Routing and Switching Training Lab Guide PDFliviuemanuelNo ratings yet

- Vacuum Chill BlockDocument2 pagesVacuum Chill BlockAditheya Varthan MNo ratings yet

- Ricoh 2090Document832 pagesRicoh 2090cosmin176100% (1)

- Environmental Quality Control of Emission From Diesel Engines Regulations 1996 - P.U.a 429-96Document22 pagesEnvironmental Quality Control of Emission From Diesel Engines Regulations 1996 - P.U.a 429-96scribdledeeNo ratings yet

- Whatsapp, Viber and Telegram: Which Is The Best For Instant Messaging?Document6 pagesWhatsapp, Viber and Telegram: Which Is The Best For Instant Messaging?Kuningan NesiaNo ratings yet

- Standard For Safety UL ADocument49 pagesStandard For Safety UL ANhất NgônNo ratings yet

- BDOs SheetsDocument25 pagesBDOs Sheets3J Solutions BDNo ratings yet

- Fontaine Quinta RuedaDocument2 pagesFontaine Quinta RuedaHamilton MirandaNo ratings yet

- NM Group Plumbing WorkDocument33 pagesNM Group Plumbing WorkNM GROUPNo ratings yet

- Vernier, Dial, and Electronic Digital Calipers: Session 3Document40 pagesVernier, Dial, and Electronic Digital Calipers: Session 3Emman Bosito100% (1)

- Development and Evaluation - KocabaDocument263 pagesDevelopment and Evaluation - KocabaWRLSNo ratings yet

- QlassicDocument31 pagesQlassicQila HusinNo ratings yet

- NASA ERAST Program Develops High-Altitude UAVsDocument17 pagesNASA ERAST Program Develops High-Altitude UAVsEgz AguilarNo ratings yet

- 4.failure Theories and Stress ConcentrationsDocument21 pages4.failure Theories and Stress ConcentrationsAmr El SaeedNo ratings yet

- Engineering Structures: SciencedirectDocument8 pagesEngineering Structures: SciencedirectFeleki AttilaNo ratings yet

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocument12 pagesFM Global Property Loss Prevention Data Sheets: List of Figuresdaniela hritucNo ratings yet

- Elink For Windows: List of Pages in This Trip KitDocument130 pagesElink For Windows: List of Pages in This Trip KitAhmed GvNo ratings yet

- Tractor 2017 Catalogue WebDocument36 pagesTractor 2017 Catalogue WebAnonymous 1XBCMXNo ratings yet

- What Is A Gantt Chart - Gantt Chart Information, History and SoftwareDocument3 pagesWhat Is A Gantt Chart - Gantt Chart Information, History and SoftwareShaikh Saeed AlamNo ratings yet

- DseDocument20 pagesDsebrawijaya100% (1)

- Aerial Robotics Lecture 1B - 5 Agility and ManoeuvrabilityDocument4 pagesAerial Robotics Lecture 1B - 5 Agility and ManoeuvrabilityIain McCulloch100% (1)

- Zw3d2022 Lite Vs Cadbro 2022Document4 pagesZw3d2022 Lite Vs Cadbro 2022Carlos LimaNo ratings yet

- CNA09016 SGDocument8 pagesCNA09016 SGSatyarth SampathNo ratings yet

- G.25-GEMSS-G-02 Rev 01plant Design CriteriaDocument13 pagesG.25-GEMSS-G-02 Rev 01plant Design Criteriamohammad kassarNo ratings yet

- Appendix 400.4 - Traffic Count TemplateDocument7 pagesAppendix 400.4 - Traffic Count TemplateOgunranti RasaqNo ratings yet

- KB Rebar BrochureDocument4 pagesKB Rebar BrochureJun Xian Wai100% (1)