Professional Documents

Culture Documents

Abb Reb650 Busbar High Imp

Uploaded by

hizbi7Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abb Reb650 Busbar High Imp

Uploaded by

hizbi7Copyright:

Available Formats

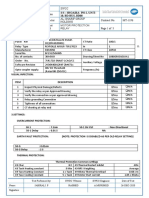

Commissioning Service

Department

Commissioning Standard Test

Formats

Description: 87B HIGH IMP. BUSBAR ABB

REB650

Equip. No. Drawing ref.: Page 1 of 6

Contractor : Contract no.: Substation No :

1. GENERAL DATA AND INFORMATION:

Panel No. Designation 87B/95B

Serial No. Rated Voltage 125 VDC

Make Aux. Voltage 110 250 VAC/DC

CT Ratio 2000/1A Frequency 50 60 Hz

2. MECHANICAL CHECKS AND VISUAL INSPECTION:

ITEM DESCRIPTION CHECKED

1 Inspect for physical damage / defects. Yes N/A

2 Verify Connections as per approved drawings. Yes N/A

3 Check tightness of all connections. Yes N/A

5 Check apparatus lists. Yes N/A

6 Check ferrules Yes N/A

7 Test Switch checked for correct function. Yes N/A

8 Check case earthing. Yes N/A

9 Watchdog contact (X319:3 , X319:2) Yes N/A

3. ELECTRICAL TESTS: With relay energized condition

ITEM DESCRIPTION CHECKED

1 Measured auxiliary supply. Yes N/A

2 Clock set at local time. Yes N/A

3 Time maintained when auxiliary supply removed. Yes N/A

5 Relay healthy (green) LED working. Yes N/A

6 Trip (red) LED working. Yes N/A

Tested by: ENG. Witnessed by:

Signature & Date: Signature & Date:

Commissioning Service

Department

Commissioning Standard Test

Formats

Description: 87B HIGH IMP. BUSBAR ABB

REB650

Equip. No. Drawing ref.: Page 2 of 6

Contractor : Contract no.: Substation No :

4. INPUTS AND OUTPUTS TESTS:

INPUT OPTO-ISOLATORS CHECKS (With Relay Energized):

Go to CONFIGURATION - MONITORING,

I/O STATUS,

then go to BINARY INPUTS VALUES ( X120 (AIM) X110 (BIO) )

to check the values after giving pulse on each BI.

OPTO TEST METHOD RESULT

INPUT (Energize only one at a time with Display FALSE to REMARKS

NO. 125V DC Station Battery voltage) TURE

X324

BI 1 ENERGIZE TB NO. X324 : 2 1 Yes N/A BB-CH PROT OUT

BI 2 ENERGIZE TB NO. X324 : 5 4 Yes N/A BB-CH PROT IN

BI 3 ENERGIZE TB NO. X324 : 6 4 Yes N/A BB-CH CT SHORTED

BB-CH IN/OUT DC

BI 4 ENERGIZE TB NO. X324 : 9 - 8 Yes N/A FAIL

BI 5 ENERGIZE TB NO. X324 : 10 8 Yes N/A RESET DC FAIL

BI 6 ENERGIZE TB NO. X324 : 13 12 Yes N/A INDICATION DC FAIL

BI 7 ENERGIZE TB NO. X324 : 14 12 Yes N/A AC SUPPLY FAIL

BI 8 ENERGIZE TB NO. X324 : 17 16 Yes N/A SPARE

BI 9 ENERGIZE TB NO. X324 : 18 16 Yes N/A SPARE

X329

BI 10 ENERGIZE TB NO. X329 : 2 1 Yes N/A SPARE

BI 11 ENERGIZE TB NO. X329 : 5 4 Yes N/A SPARE

BI 12 ENERGIZE TB NO. X329 : 6 4 Yes N/A SPARE

BI 13 ENERGIZE TB NO. X329 : 9 - 8 Yes N/A SPARE

BI 14 ENERGIZE TB NO. X329 : 10 8 Yes N/A SPARE

BI 15 ENERGIZE TB NO. X329 : 13 12 Yes N/A SPARE

BI 16 ENERGIZE TB NO. X329 : 14 12 Yes N/A SPARE

BI 17 ENERGIZE TB NO. X329 : 17 16 Yes N/A SPARE

Tested by: ENG. Witnessed by:

Signature & Date: Signature & Date:

Commissioning Service

Department

Commissioning Standard Test

Formats

Description: 87B HIGH IMP. BUSBAR ABB

REB650

Equip. No. Drawing ref.: Page 3 of 6

Contractor : Contract no.: Substation No :

BI 18 ENERGIZE TB NO. X329 : 18 16 Yes N/A SPARE

OUTPUT RELAYS CHECKS (With Relay Energized):

Test Procedure:

Go to IED CONFIGURATION,

TESTS, IED TEST, TEST MODE : ON,

then go to BINARY OUTPUTS-CHANGE THE POSITION OF EACH BO FROM FULSE TO TURE FROM

HMI,

then check contact resistance.

TEST METHOD RESULT

OUTPUT

(Energize only one relay at a time by Contact Checked REMARKS

RELAY No.

Test ON in IED TEST) 0.2

X317

BIO1 CONTACT OPERATED X317 : 1 2 (N/O) Yes N/A SPARE

BIO2 CONTACT OPERATED X317 : 3 4 (N/O) Yes N/A SPARE

BIO3 CONTACT OPERATED X317 : 5 6 (N/O) Yes N/A SPARE

BIO4 CONTACT OPERATED X317 : 7 8 (N/O) Yes N/A CT SUPVN. ALARM

BIO5 CONTACT OPERATED X317 : 9 10 (N/O) Yes N/A BB-CH OPTD

BIO6 CONTACT OPERATED X317 : 11 12 (N/O) Yes N/A SPARE

BIO7 CONTACT OPERATED X317 : 13 14 (N/O) Yes N/A SPARE

BIO8 CONTACT OPERATED X317 : 15 16 (N/O) Yes N/A SPARE

BIO9 CONTACT OPERATED X317 : 17 18 (N/O) Yes N/A SPARE

X321

BIO10 CONTACT OPERATED X321 : 1 2 (N/O) Yes N/A SPARE

BIO11 CONTACT OPERATED X321 : 3 4 (N/O) Yes N/A SPARE

BIO12 CONTACT OPERATED X321 : 5 6 (N/O) Yes N/A SPARE

BIO13 CONTACT OPERATED X321 : 7 8 (N/O) Yes N/A SPARE

BIO14 CONTACT OPERATED X321 : 9 10 (N/O) Yes N/A SPARE

BIO15 CONTACT OPERATED X321 : 11 12 (N/O) Yes N/A SPARE

BIO16 CONTACT OPERATED X321 : 13 15 (N/C) Yes N/A SPARE

BIO17 CONTACT OPERATED X321 : 14 15 (N/O) Yes N/A SPARE

BIO18 CONTACT OPERATED X321 : 16 18 (N/C) Yes N/A SPARE

BIO19 CONTACT OPERATED X321 : 17 18 (N/O) Yes N/A SPARE

Tested by: ENG. Witnessed by:

Signature & Date: Signature & Date:

Commissioning Service

Department

Commissioning Standard Test

Formats

Description: 87B HIGH IMP. BUSBAR ABB

REB650

Equip. No. Drawing ref.: Page 4 of 6

Contractor : Contract no.: Substation No :

X326

BIO20 CONTACT OPERATED X321 : 1 2 (N/O) Yes N/A SPARE

BIO21 CONTACT OPERATED X321 : 3 4 (N/O) Yes N/A SPARE

BIO22 CONTACT OPERATED X321 : 5 6 (N/O) Yes N/A SPARE

BIO23 CONTACT OPERATED X321 : 7 8 (N/O) Yes N/A SPARE

BIO24 CONTACT OPERATED X321 : 9 10 (N/O) Yes N/A SPARE

BIO25 CONTACT OPERATED X321 : 11 12 (N/O) Yes N/A SPARE

BIO26 CONTACT OPERATED X321 : 13 15 (N/C) Yes N/A SPARE

BIO27 CONTACT OPERATED X321 : 14 15 (N/O) Yes N/A SPARE

BIO28 CONTACT OPERATED X321 : 16 18 (N/C) Yes N/A SPARE

BIO29 CONTACT OPERATED X321 : 17 18 (N/O) Yes N/A SPARE

INDICATION LED TEST

LED Checks:

Go to hardware test to view the physical position of the LED.

Result Display On or

OPTO Input Number Function

Of

LED 1 Yes N/A PROT IN/OUT

LED 2 Yes N/A CT ALARM

LED 3 Yes N/A R-PHASE ALARM

LED 4 Yes N/A Y-PHASE ALARM

LED 5 Yes N/A B-PHASE ALARM

LED 6 Yes N/A 87BB-CH TRIP

LED 7 Yes N/A R-PHASE TRIP

LED 8 Yes N/A Y-PHASE TRIP

LED 9 Yes N/A B-PHASE TRIP

LED 10 Yes N/A SPARE

LED 11 Yes N/A SPARE

LED 12 Yes N/A SPARE

LED 13 Yes N/A SPARE

Tested by: ENG. Witnessed by:

Signature & Date: Signature & Date:

Commissioning Service

Department

Commissioning Standard Test

Formats

Description: 87B HIGH IMP. BUSBAR ABB

REB650

Equip. No. Drawing ref.: Page 5 of 6

Contractor : Contract no.: Substation No :

LED 14 Yes N/A SPARE

LED 15 Yes N/A SPARE

5. SERIES & SHUNT RESISTOR MEASUREMENTS:

SERIES RESISTOR SHUNT RESISTOR

PHASE

SETTING () MEASURED () SETTING () MEASURED ()

RN

YN

BN

6. PICK UP & DROP OFF TEST FOR CT SHORTING:

R PHASE Y - PHASE B -PHASE

CURRENT

SETTING

Pickup V Drop-off V Pickup V Drop-off V Pickup V Drop-off V

7. OPERATING TIME TEST FOR CT SHORTING:

TIME APPLIED R PHASE Y - PHASE B -PHASE

SETTING VOLTAGE

Pickup (sec) Pickup (sec) Pickup (sec)

8. PICK UP & DROP OFF TEST FOR HIGH IMPEDANCE

DIFFERENTIAL:

CURREN R PHASE Y - PHASE B -PHASE

T

Tested by: ENG. Witnessed by:

Signature & Date: Signature & Date:

Commissioning Service

Department

Commissioning Standard Test

Formats

Description: 87B HIGH IMP. BUSBAR ABB

REB650

Equip. No. Drawing ref.: Page 6 of 6

Contractor : Contract no.: Substation No :

Pickup Drop- Pickup Pickup Drop- Pickup Pickup Drop- Pickup

SETTING

mA off mA V mA off mA V mA off mA V

9. OPERATING TIME TEST FOR HIGH IMPEDANCE DEFFIERENTIAL:

TIME APPLIED R PHASE Y - PHASE B -PHASE

SETTING VOLTAGE

Pickup (msec) Pickup (msec) Pickup (msec)

1 Communication with PC

2 Event Record Check

3 Disturbance Record Check

AL-BABTAIN

Tested by: ENG. Witnessed by:

Signature & Date: Signature & Date:

You might also like

- Abb Rec670 Acse Relay TestDocument10 pagesAbb Rec670 Acse Relay Testm khNo ratings yet

- Abb Rec670 Busbar High ImpDocument4 pagesAbb Rec670 Busbar High Impm khNo ratings yet

- Abb Rec670 Cap Bank ProtnDocument11 pagesAbb Rec670 Cap Bank ProtnRatheesh KumarNo ratings yet

- 1MRB520006-BEN en XS92b Computer-Based 3-Phase Test SetDocument14 pages1MRB520006-BEN en XS92b Computer-Based 3-Phase Test SetFredrikNo ratings yet

- Testing Procedure For Transformer Differential Protection Relay Using Conventional KitDocument14 pagesTesting Procedure For Transformer Differential Protection Relay Using Conventional KitRavi MehroliyaNo ratings yet

- RET 650 REPORT - 132kV CRPDocument6 pagesRET 650 REPORT - 132kV CRPAbhishek RajputNo ratings yet

- Ret650 Diif 1Document7 pagesRet650 Diif 1logaknathanNo ratings yet

- 220 KV Khemar CT Report - MoodabidriDocument3 pages220 KV Khemar CT Report - MoodabidriRex007 90No ratings yet

- Pre-Commissioning Test Report For Numerical Relay: ProjectDocument3 pagesPre-Commissioning Test Report For Numerical Relay: ProjectHari haranNo ratings yet

- P633 Test Tools Farhad Rev 01Document5 pagesP633 Test Tools Farhad Rev 01Neelakandan MasilamaniNo ratings yet

- 7UM6 Gen Prot-Schemes EDocument10 pages7UM6 Gen Prot-Schemes EruslaninstNo ratings yet

- T60 - SimulatorDocument5 pagesT60 - Simulatorshanthikumaravel0% (1)

- SEP671 REL670 Exercise 1 Distance Protection CharacteristicsDocument13 pagesSEP671 REL670 Exercise 1 Distance Protection Characteristicsjdzarzalejo100% (1)

- Line Differential Protection - HeddingDocument69 pagesLine Differential Protection - HeddingIgnacio Lucas Avila ManganoNo ratings yet

- Control and Protection Philosophy for Dholera SubstationDocument7 pagesControl and Protection Philosophy for Dholera SubstationManali Prajapati100% (1)

- Test Report For Feeder Protection RelayDocument3 pagesTest Report For Feeder Protection RelayHari haranNo ratings yet

- SEL-787 Pickup and Slope Test Calculations For AG2011-09Document17 pagesSEL-787 Pickup and Slope Test Calculations For AG2011-09marceloleon4100% (1)

- p443 Ksk-Mangla-2 p443 Commissioning Zones ForwaredDocument6 pagesp443 Ksk-Mangla-2 p443 Commissioning Zones ForwaredUmer EhsanNo ratings yet

- Non Dir. O/C Relay ARGUS - 7SR1102: 1. General Data & InformationDocument6 pagesNon Dir. O/C Relay ARGUS - 7SR1102: 1. General Data & InformationAnonymous dH3DIEtzNo ratings yet

- P633 - Test - Tools Farhad Rev 01Document4 pagesP633 - Test - Tools Farhad Rev 01Mosa Elnaid ElnaidNo ratings yet

- Siemens 7sd5Document20 pagesSiemens 7sd5Omer Nawaz Malik100% (1)

- Ict-1 Test ReportDocument41 pagesIct-1 Test ReportSuresh Chandra PadhyNo ratings yet

- Test Performed By: SWCC Witness: SWCC Engineer: Date of Test Name: Jabirali. P Rashed A.Murshed 26-DEC-2020 SignatureDocument5 pagesTest Performed By: SWCC Witness: SWCC Engineer: Date of Test Name: Jabirali. P Rashed A.Murshed 26-DEC-2020 SignatureAnonymous dH3DIEtzNo ratings yet

- Relay Selection Chart1Document3 pagesRelay Selection Chart1Susil Kumar Khuntia100% (1)

- Ziv Oc Ef RelayDocument10 pagesZiv Oc Ef RelayAnonymous QRER3bsNr100% (1)

- Numerical Relay Test Report SummaryDocument75 pagesNumerical Relay Test Report SummaryHari haranNo ratings yet

- Site Test Report For Differential ProtectionDocument10 pagesSite Test Report For Differential ProtectionKheireddine AounallahNo ratings yet

- P343 Report For R1Document23 pagesP343 Report For R1rohitctpp100% (1)

- 415V Side Relay Setting DataDocument8 pages415V Side Relay Setting DataRenga Ramanujan CNo ratings yet

- Site Test Report For Skid Mounted SubstationDocument12 pagesSite Test Report For Skid Mounted SubstationSoumya BhowmickNo ratings yet

- Micom P746: Numerical Busbar ProtectionDocument8 pagesMicom P746: Numerical Busbar Protectionsridhar30481647100% (1)

- ADR241CDocument11 pagesADR241CNamrata ShettiNo ratings yet

- Procedure For Testing P643 Transformer Differential Relay: Prepared by Eng: Mohamad TauseefDocument36 pagesProcedure For Testing P643 Transformer Differential Relay: Prepared by Eng: Mohamad TauseefAbdul RahmanNo ratings yet

- Magnetizing CurrentDocument4 pagesMagnetizing CurrentSureshraja9977No ratings yet

- 400 KV Bus Changeover &isolationDocument4 pages400 KV Bus Changeover &isolationSreekanthMylavarapuNo ratings yet

- N6166 E05 F871 TR Diff Relay 7UT613Document6 pagesN6166 E05 F871 TR Diff Relay 7UT613মোঃ মহসিনNo ratings yet

- SA2007-000028 - en Differential Protection For Special Power Transformers With RET 670Document11 pagesSA2007-000028 - en Differential Protection For Special Power Transformers With RET 670shyam_krishnan_16No ratings yet

- Relay Setting Calculation-NPC-Yas152Document15 pagesRelay Setting Calculation-NPC-Yas152মোঃ মহসিনNo ratings yet

- CEWE Panelinstrument - Catalogue2Document36 pagesCEWE Panelinstrument - Catalogue2catalinccNo ratings yet

- 7UT - Diff Bias SlopeDocument11 pages7UT - Diff Bias SlopeksarawanNo ratings yet

- O/C E/F Relay Test ReportDocument2 pagesO/C E/F Relay Test ReportMd. zahidul IslamNo ratings yet

- Secondary Injection Testing For Transformer Differential PDocument25 pagesSecondary Injection Testing For Transformer Differential PAdetunji TaiwoNo ratings yet

- T60TDocument39 pagesT60TMourad BenderradjiNo ratings yet

- Site Test Report For Differential Relay ProtectionDocument10 pagesSite Test Report For Differential Relay ProtectionTufail AlamNo ratings yet

- 07a Backup OCEF Relay - Tech. Data Check List CompletedDocument6 pages07a Backup OCEF Relay - Tech. Data Check List CompletedAnupam0103No ratings yet

- 7-How To Test 7sa522Document39 pages7-How To Test 7sa522ahmedNo ratings yet

- Testing of BushingDocument8 pagesTesting of BushingAmir Ali khanNo ratings yet

- Baranagar-TSS Relay Test ReportDocument75 pagesBaranagar-TSS Relay Test ReportHari haranNo ratings yet

- Site Test Report For OVER CURRENT Relay (7SJ60XX) : Customer Contract # Project Job # Location Equipment TagDocument4 pagesSite Test Report For OVER CURRENT Relay (7SJ60XX) : Customer Contract # Project Job # Location Equipment TagAdetunji TaiwoNo ratings yet

- MiCOM P54 X - Current Diff Prot Relays - CT RequirementDocument5 pagesMiCOM P54 X - Current Diff Prot Relays - CT RequirementpayNo ratings yet

- Battery Alarm User ManualDocument22 pagesBattery Alarm User ManualSandeep KumarNo ratings yet

- PSB Abb Rel670 Final Test ReportDocument7 pagesPSB Abb Rel670 Final Test ReportAbhishek RajputNo ratings yet

- ALSTOM CT Calculation GuideDocument2 pagesALSTOM CT Calculation GuideYogesh PatilNo ratings yet

- 7UM62 Installation Instr 02Document6 pages7UM62 Installation Instr 02Eduardo Garcia PNo ratings yet

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsFrom EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsNo ratings yet

- Commissioning Service Department Commissioning Standard Test FormatsDocument6 pagesCommissioning Service Department Commissioning Standard Test Formatsm khNo ratings yet

- AccsDocument8 pagesAccsm kh100% (1)

- Motor Protection Relay Test ReportDocument8 pagesMotor Protection Relay Test ReportAnonymous dH3DIEtzNo ratings yet

- Line Differential Red670Document12 pagesLine Differential Red670Ashish ChughNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Function Test - AccsDocument11 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Function Test - AccsDinesh PitchaivelNo ratings yet

- MM600 V 2 BulletinDocument2 pagesMM600 V 2 Bulletinhizbi7No ratings yet

- Picplc16 v6 Schematic v101Document2 pagesPicplc16 v6 Schematic v101hizbi7No ratings yet

- Pscad trainingDocument1 pagePscad traininghizbi7No ratings yet

- PSSE 2nd Generation Wind Models Final JayDocument32 pagesPSSE 2nd Generation Wind Models Final Jayhizbi7100% (1)

- SincalUniqueFeatures EngDocument7 pagesSincalUniqueFeatures Enghizbi7No ratings yet

- Home Owner's GuideDocument20 pagesHome Owner's Guidehizbi7No ratings yet

- SVERKER900 DS en V05 PDFDocument7 pagesSVERKER900 DS en V05 PDFhizbi7No ratings yet

- Power Factor CorrectionDocument1 pagePower Factor CorrectionrdelgranadoNo ratings yet

- Protection Relay FAT Using Omicron PDFDocument96 pagesProtection Relay FAT Using Omicron PDFhizbi7No ratings yet

- OLTC Dynamic Testing P10Document16 pagesOLTC Dynamic Testing P10Marcio RangelNo ratings yet

- Underground Power Cables Catalogue 03-2010Document48 pagesUnderground Power Cables Catalogue 03-2010Edgar Sierra Rodriguez100% (1)

- The New Enhanced Dispatch Arrangement (Neda)Document28 pagesThe New Enhanced Dispatch Arrangement (Neda)hizbi7No ratings yet

- Trip Coil Signature Measurement and Analysis Techniques For Circuit BreakerDocument7 pagesTrip Coil Signature Measurement and Analysis Techniques For Circuit Breakerhizbi7No ratings yet

- Tray and Ladder Practice GuideDocument73 pagesTray and Ladder Practice GuidemariusrotaruNo ratings yet

- MMF 15Document7 pagesMMF 15Arif YusofNo ratings yet

- Diff Protection TestDocument3 pagesDiff Protection TestJohan TadlasNo ratings yet

- Slide Partial DischargeDocument119 pagesSlide Partial Dischargehizbi7100% (1)

- Code of Practice For The Electricity (Wiring) Regulations: 2015 EditionDocument356 pagesCode of Practice For The Electricity (Wiring) Regulations: 2015 EditionjackwpsoNo ratings yet

- Trafo. Diff Slope Calc Micom p643Document4 pagesTrafo. Diff Slope Calc Micom p643Anoss OlierNo ratings yet

- LockoutDocument1 pageLockouthizbi7No ratings yet

- XLPE Insulated CablesDocument32 pagesXLPE Insulated CablesMalik DausNo ratings yet

- Etap Validation Cases and Comparison Results: Load FlowDocument66 pagesEtap Validation Cases and Comparison Results: Load FlowK.RamachandranNo ratings yet

- 7SR23 (DAD) High Impedance Protection: For Internal Use Only / © Siemens AG 2012. All Rights ReservedDocument34 pages7SR23 (DAD) High Impedance Protection: For Internal Use Only / © Siemens AG 2012. All Rights Reservedhizbi7100% (1)

- Power Systems Studies and Protection of Generators (July 2017) - FAEZAHDocument5 pagesPower Systems Studies and Protection of Generators (July 2017) - FAEZAHhizbi7No ratings yet

- Installing Large Single Core CablesDocument2 pagesInstalling Large Single Core Cableshizbi7No ratings yet

- Wide Area RestorationDocument10 pagesWide Area Restorationhizbi7No ratings yet

- History Summer09 PDFDocument7 pagesHistory Summer09 PDFhizbi7No ratings yet

- 7SS52 Training 01 - 2007Document55 pages7SS52 Training 01 - 2007hizbi7100% (1)

- SF6 Sulphur Hexafluoride EN 254640 PDFDocument52 pagesSF6 Sulphur Hexafluoride EN 254640 PDFhizbi7No ratings yet

- Denison Hydraulics Goldcup Digital Hi-Iq Control: Electronic Control Card User Manual Software Version 2.2BDocument62 pagesDenison Hydraulics Goldcup Digital Hi-Iq Control: Electronic Control Card User Manual Software Version 2.2BHassan Haghighi TajvarNo ratings yet

- VAS5054ADocument3 pagesVAS5054AKarim ElmahrokyNo ratings yet

- Oxygen USPDocument2 pagesOxygen USPMartha Lucia Roa FonsecaNo ratings yet

- Objective SAMPLEDocument4 pagesObjective SAMPLEAnnjen MuliNo ratings yet

- IJCSEIERDFEB20174Document10 pagesIJCSEIERDFEB20174TJPRC PublicationsNo ratings yet

- Tufail MaboodDocument3 pagesTufail MaboodMickey DalbeheraNo ratings yet

- Wireless Communication Assignment-1Document2 pagesWireless Communication Assignment-1rajeshkecNo ratings yet

- Space Programming 1Document10 pagesSpace Programming 1Mache SebialNo ratings yet

- Indoor Multi-Wall Path Loss Model at 1.93 GHZDocument6 pagesIndoor Multi-Wall Path Loss Model at 1.93 GHZadonniniNo ratings yet

- Manual Bristol 3808 Multivariable Transmitters en 133322 PDFDocument174 pagesManual Bristol 3808 Multivariable Transmitters en 133322 PDFROBERTO MARTINEZNo ratings yet

- Checklist for Training Cleaning StaffDocument1 pageChecklist for Training Cleaning StaffharrydrivesucrazyNo ratings yet

- LG Power Supply Reference GuideDocument29 pagesLG Power Supply Reference GuideOrlando Jose PascuaNo ratings yet

- Fix Canon Pixma MP287 Printer Error CodesDocument7 pagesFix Canon Pixma MP287 Printer Error CodesBen BennyNo ratings yet

- School Data Management System ReportDocument122 pagesSchool Data Management System ReportshekharyadawNo ratings yet

- Hands-On Exercise Oracle 10g PL SQL - v1 0Document24 pagesHands-On Exercise Oracle 10g PL SQL - v1 0pavanNo ratings yet

- Bob L200Document12 pagesBob L200LucyPher_Comte_7563No ratings yet

- General Principles - Mathes Vol 1Document1,155 pagesGeneral Principles - Mathes Vol 1Nanna de Vengerberg75% (4)

- S5 1-Bedroom Suite FloorplanDocument1 pageS5 1-Bedroom Suite FloorplanAdam HudzNo ratings yet

- Voltage Divider Bias Stabilizes BJT Transistor OutputDocument5 pagesVoltage Divider Bias Stabilizes BJT Transistor OutputMalikAlrahabiNo ratings yet

- S393 SPM Lopl Opr MS 2301 - 0Document134 pagesS393 SPM Lopl Opr MS 2301 - 0Barm FuttNo ratings yet

- 1756 Controllogix I/O ModulesDocument7 pages1756 Controllogix I/O ModulesminurajraNo ratings yet

- Jsa-Wif-9 Pulling CableDocument12 pagesJsa-Wif-9 Pulling CableY a n i. A h m e dNo ratings yet

- HUM 2220 Rome Engineering An Empire Notetaking GuideDocument4 pagesHUM 2220 Rome Engineering An Empire Notetaking GuideDelmarie RodríguezNo ratings yet

- Ups Installation and Maintenance ManualDocument141 pagesUps Installation and Maintenance ManualMuntasir100% (1)

- Cisco SD-WAN Intro SOLRST-2006 PDFDocument10 pagesCisco SD-WAN Intro SOLRST-2006 PDFffusaroNo ratings yet

- User Manual Kxtda 30 600Document252 pagesUser Manual Kxtda 30 600kabeh1No ratings yet

- Astm B633-23 - Redline Astm B633-23Document7 pagesAstm B633-23 - Redline Astm B633-23somashekar1510No ratings yet

- Advance Diploma For CivilDocument4 pagesAdvance Diploma For CivilAung Naing Latt AungNo ratings yet

- TS1A-13A: Operation and Maintenance ManualDocument204 pagesTS1A-13A: Operation and Maintenance ManualJavier AponteNo ratings yet

- 2D Vs 3D ReviewDocument7 pages2D Vs 3D ReviewBhasker RamagiriNo ratings yet