Professional Documents

Culture Documents

5 B503 Rev 5

Uploaded by

beyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5 B503 Rev 5

Uploaded by

beyCopyright:

Available Formats

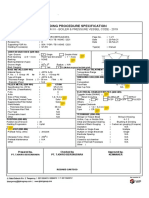

Approved: WPS No.: 5B503 Rev.

: 5

Date: March 7, 1994 Revision Date: August 17, 2000

Supporting PQR No. (s): With PWHT - L8684 (PRN054-1)

Welding Process: GTAW Type(s): Manual

JOINTS (QW-402)

Refer to WPS No. GEN for typical joint designs. This WPS may be used with or without backing.

BASE METALS (QW-403)

P-No.: 5B Group No.: 1 to P-No.: 5B Group No.: 1

Thickness Range:

Base Metal: Groove 3/16 thru 1.812 With PWHT Fillets All

Maximum Deposit Thickness Per Pass Shall Not Exceed 1/4 Inches

FILLER METALS (QW-404)

Spec. No. (SFA): 5.28

AWS No. (Class): ER80S-B6

F-No.: 6

A-No.: 4

Size of Filler Metals: 1/16, 3/32, 1/8, 5/32

Weld Metal:

Thickness Range:

Groove: 1/4 Maximum With PWHT

Fillet: All

Consumable Insert: Not Permitted

POSITIONS (QW-405) POSTWELD HEAT TREATMENT (QW-407)

Position(s) of Groove: All

Temperature Range: Condition (2): Stress Relieved

Welding Progression: Up XXX

Down ________ Time Range: N/A(WPS Not Allowed for ASME III)

Position(s) of Fillets: All

PREHEAT (QW-406) GAS (QW-408)

Preheat Temperature Minimum: 400oF Percent

Composition CFH

Interpass Temperature Maximum: ------ Gas(es) (Mixture) Flow Rate

Shielding Argon 100 15 Min

Preheat Maintenance: See WPS GEN for

Special Reqts Purge Nitrogen 100 5 Min

WPS No.: 5B503 Rev.: 5

ELECTRICAL CHARACTERISTICS (QW-409)

Current: AC or DC: DC Polarity: EN

Tungsten Electrode Size and Type 3/32 or 1/8 2% Thoriated (SFA 5.12, EWTh-2)

Pulsed Current Neither required nor prohibited

Weld Filler Metal Amp. Volt Travel

Layer(s) Process (Note 2) Range Range Speed Other

(Note 3) (IPM)

Class Dia.

GTAW ER80S-B6 1/16 60-180 10-17 --

Root Pass

GTAW ER80S-B6 3/32 60-180 10-17 --

and/or

GTAW ER80S-B6 1/8 60-180 10-17 --

Fill & Cap

GTAW ER80S-B6 5/32 60-180 10-17 --

TECHNIQUE (QW-410)

String or Weave Bead String or Weave

Orifice or Gas Cup Size Diameter Minimum

Initial and Interpass Cleaning As Per WPS No. GEN

Method of Back Gouging As Per WPS No. GEN

Multiple or Single Pass (per side) Multiple

Multiple or Single Electrodes Single

Peening Not Permitted

NOTES:

Note 1: This WPS must be used in conjunction with WPS No. GEN.

Note 2: All passes shall be made with the addition of filler metal.

Note 3: Voltage ranges are not required by ASME IX and are given for reference only.

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 403 Rev 2Document2 pages403 Rev 2beyNo ratings yet

- 104 Rev 2Document2 pages104 Rev 2beyNo ratings yet

- WPS No. 1.203 Rev. 4 GTAW Welding Process SpecificationDocument2 pagesWPS No. 1.203 Rev. 4 GTAW Welding Process SpecificationbeyNo ratings yet

- METALS INSPECTION SERVICES WELDING PROCEDUREDocument6 pagesMETALS INSPECTION SERVICES WELDING PROCEDURELuis MuñozNo ratings yet

- WPS 8 To 1-3-1 Rev2 (10-1-13)Document5 pagesWPS 8 To 1-3-1 Rev2 (10-1-13)ERA SSNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- WPSDocument2 pagesWPSJuli Agus50% (2)

- PWPS For Piping-API 1104Document6 pagesPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- Nit 2019 20 56 Wps 1569579575Document16 pagesNit 2019 20 56 Wps 1569579575vijayachiduNo ratings yet

- WPS 11-23-1Document3 pagesWPS 11-23-1Anoop Raj RaoNo ratings yet

- WPS (AsmeDocument8 pagesWPS (AsmeMohammad Elhedaby100% (6)

- Mechanical Engineering M.Abdul GhoziDocument4 pagesMechanical Engineering M.Abdul GhoziRizaldy PhoenksNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- (Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Document2 pages(Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Quality LaveenaNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- Clad PQRDocument5 pagesClad PQRRinshadNo ratings yet

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- 2G & 5GDocument2 pages2G & 5GRahul MoottolikandyNo ratings yet

- Automatic, Manual, Machine, or Semi-Auto.Document10 pagesAutomatic, Manual, Machine, or Semi-Auto.ChE_MattNo ratings yet

- Welding Procedure Specification for Stainless SteelDocument5 pagesWelding Procedure Specification for Stainless SteelVarun Malhotra100% (5)

- WpsDocument3 pagesWpsPankaj KumarNo ratings yet

- WPS SUMMARYDocument10 pagesWPS SUMMARYbhavin178No ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- GTAW Welding Process ParametersDocument12 pagesGTAW Welding Process Parametersmiteshpatel191No ratings yet

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- ASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelDocument3 pagesASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelBudi Setia RahmanNo ratings yet

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- STD WPSDocument1 pageSTD WPSWaqas WaqasNo ratings yet

- Welding Procedure Specification Structural-3GDocument3 pagesWelding Procedure Specification Structural-3Gdndudc78% (9)

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELDocument4 pagesWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidNo ratings yet

- Audco India Limited Welding Procedure Specification: LAB-005R1Document3 pagesAudco India Limited Welding Procedure Specification: LAB-005R1sudeep_singh1No ratings yet

- Welding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed SketchDocument4 pagesWelding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed SketchaNo ratings yet

- Welding Procedure SpecificationDocument5 pagesWelding Procedure SpecificationFranklin londono0% (1)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Weld Quality: The Role of Computers: Proceedings of the International Conference on Improved Weldment Control with Special Reference to Computer Technology Held in Vienna, Austria, 4–5 July 1988 under the Auspices of the International Institute of WeldingFrom EverandWeld Quality: The Role of Computers: Proceedings of the International Conference on Improved Weldment Control with Special Reference to Computer Technology Held in Vienna, Austria, 4–5 July 1988 under the Auspices of the International Institute of WeldingNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Offshore Electrical Engineering ManualFrom EverandOffshore Electrical Engineering ManualRating: 4 out of 5 stars4/5 (9)

- Bilad 2018 01 21Document25 pagesBilad 2018 01 21beyNo ratings yet

- Pipeline & Piping ScheduleDocument12 pagesPipeline & Piping SchedulebeyNo ratings yet

- Well Test Interpreta TionDocument6 pagesWell Test Interpreta TionbeyNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- 4 Wti Wellsite ValidationDocument6 pages4 Wti Wellsite ValidationbeyNo ratings yet

- PRN005Document2 pagesPRN005beyNo ratings yet

- 3 Wti Control of Downhole PDFDocument6 pages3 Wti Control of Downhole PDFAjendra SinghNo ratings yet

- CONOCOPHILLIPS 10-K (Annual Reports) 2009-02-25Document324 pagesCONOCOPHILLIPS 10-K (Annual Reports) 2009-02-25http://secwatch.com100% (2)

- 01 - Fluid FlowDocument76 pages01 - Fluid FlowMubarak AhmadNo ratings yet

- 2 Wti FundamentalsDocument10 pages2 Wti FundamentalsgdchanesNo ratings yet

- Lube Oil Function Test ProcedureDocument4 pagesLube Oil Function Test ProcedurebeyNo ratings yet

- Well Test Interpreta TionDocument6 pagesWell Test Interpreta TionbeyNo ratings yet

- PRN004Document2 pagesPRN004beyNo ratings yet

- PRN005Document2 pagesPRN005beyNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Document2 pagesBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- PRN List For Volume 1-113001Document1 pagePRN List For Volume 1-113001beyNo ratings yet

- Algerian Petroleum Institute Drilling IntroductionDocument210 pagesAlgerian Petroleum Institute Drilling IntroductionbeyNo ratings yet

- Section 17Document11 pagesSection 17beyNo ratings yet

- Engineering Data Book: Gas Processors Suppliers AssociationDocument30 pagesEngineering Data Book: Gas Processors Suppliers Associationbey0% (1)

- 01 - Fluid FlowDocument76 pages01 - Fluid FlowMubarak AhmadNo ratings yet

- Pipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1Document1 pagePipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1beyNo ratings yet

- API 14A UpdateDocument13 pagesAPI 14A UpdateAnonymous 70lCzDJv100% (1)

- Piping Drawings Guide: PFDs, P&IDs, Isometrics & GADsDocument89 pagesPiping Drawings Guide: PFDs, P&IDs, Isometrics & GADsbey100% (2)

- Pipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1Document1 pagePipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1beyNo ratings yet

- 14A - E12 PADocument4 pages14A - E12 PAbeyNo ratings yet

- 2 Cyclonic LayoutDocument1 page2 Cyclonic LayoutbeyNo ratings yet

- Three-View Drawings & Technical DiagramsDocument150 pagesThree-View Drawings & Technical DiagramsMahesh KumarNo ratings yet

- CH 2 Coulombs Law APEMDocument3 pagesCH 2 Coulombs Law APEMJames FlaughNo ratings yet

- Bravo: He Small Pump Package With Big FeaturesDocument5 pagesBravo: He Small Pump Package With Big Featuresvibin globalNo ratings yet

- اعطال الموتوراتDocument65 pagesاعطال الموتوراتmoathNo ratings yet

- Power Systems Lecture Series: Part Vii. Unsymmetrical Faults (Open Case)Document26 pagesPower Systems Lecture Series: Part Vii. Unsymmetrical Faults (Open Case)Joshua Roberto GrutaNo ratings yet

- Power Dense and Robust Traction Power Inverter For The Second Generation Chevrolet Volt Extended Range EDocument8 pagesPower Dense and Robust Traction Power Inverter For The Second Generation Chevrolet Volt Extended Range Ejrz000No ratings yet

- Cisco Power Calculator ASR9010Document2 pagesCisco Power Calculator ASR9010Carlos Hoyos RosembluthNo ratings yet

- Substation 2Document26 pagesSubstation 2Jahirul QuaimNo ratings yet

- Brochure Trailer Statcom MobileDocument4 pagesBrochure Trailer Statcom MobileestebanNo ratings yet

- Xgard Type 5 CH4 Detector ManualDocument17 pagesXgard Type 5 CH4 Detector ManualwesleybaNo ratings yet

- Justification Proposed RecloserDocument3 pagesJustification Proposed Recloserjominique ferrerNo ratings yet

- of PWM DC MotorDocument21 pagesof PWM DC Motorabhay_131250% (4)

- Spec PA1049 (5720-5830+MHz+200W) Ver+1.3 180730Document2 pagesSpec PA1049 (5720-5830+MHz+200W) Ver+1.3 180730phamNo ratings yet

- Conversor DualDocument22 pagesConversor DualAndré CarlosNo ratings yet

- Kelompok 11 AC Voltage ControllerDocument55 pagesKelompok 11 AC Voltage ControllerAnonymous ugAY1fsF0aNo ratings yet

- Sic 634Document17 pagesSic 634Tri Nguyen Real EstateNo ratings yet

- Instruction Manual: Type GM-SG-AR 5 KV and 15 KV Arc-Resistant, Metal-Clad SwitchgearDocument90 pagesInstruction Manual: Type GM-SG-AR 5 KV and 15 KV Arc-Resistant, Metal-Clad SwitchgearJunior Ramirez ReyesNo ratings yet

- PGX2 IngDocument5 pagesPGX2 IngpiabNo ratings yet

- Motor Fault Simulator L Low Voltage Fault Simulation Trainer (XPO - MFS)Document1 pageMotor Fault Simulator L Low Voltage Fault Simulation Trainer (XPO - MFS)Carbon Nano TubeNo ratings yet

- 09 App J - AAMS Asset Code Specification - Consolidated (2017!02!21)Document116 pages09 App J - AAMS Asset Code Specification - Consolidated (2017!02!21)nnguyenthuanNo ratings yet

- Fronius Storage SolutionDocument4 pagesFronius Storage SolutionMihai RaduNo ratings yet

- Scan Doc0009Document9 pagesScan Doc0009Carl RichterNo ratings yet

- Cba 2000 enDocument8 pagesCba 2000 enRodrigoNo ratings yet

- RP 29fa40 Chassis FaDocument57 pagesRP 29fa40 Chassis FacarcegarNo ratings yet

- EasyRET 2L4H 12-Port Antenna SpecsDocument2 pagesEasyRET 2L4H 12-Port Antenna SpecsIgor Aguirre89% (9)

- Philips Chassis Ves1.1e LaDocument77 pagesPhilips Chassis Ves1.1e Lavcnvcn5977100% (1)

- Activity Sheet No. 3 - Current Resistance EMFDocument5 pagesActivity Sheet No. 3 - Current Resistance EMFJoena EmejasNo ratings yet

- HVX 12-17.5-24kV User GuideDocument48 pagesHVX 12-17.5-24kV User Guidestunnchuck100% (1)

- Jimma University: Jimma Institute of Technology (Jit)Document40 pagesJimma University: Jimma Institute of Technology (Jit)Haymanot LegesseNo ratings yet

- HVAC Start-Up Checklist EssentialsDocument3 pagesHVAC Start-Up Checklist EssentialsNorman CanlasNo ratings yet