Professional Documents

Culture Documents

Classifications of Stainless Steel

Uploaded by

Tarun ChandraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Classifications of Stainless Steel

Uploaded by

Tarun ChandraCopyright:

Available Formats

ClassificationsofStainlessSteel

Stainlesssteelsarecommonlydividedintofivegroups,dependingonthespecificamountsofalloyingelements,whichcontrolthemicrostructureofthe

alloy.

Austenitic

Austeniticstainlesssteelsarethemostweldableofthestainlessesandcanbedividedratherlooselyintothreegroups:commonchromiumnickel(300

series),manganesechromiumnickelnitrogen(200series)andspecialtyalloys.Austeniticisthemostpopularstainlesssteelgroupandisusedfor

numerousindustrialandconsumerapplications,suchasinchemicalplants,powerplants,foodprocessinganddairyequipment.Austeniticstainlesssteels

haveafacecenteredcubicstructure.Thoughgenerallyveryweldable,somegradescanbepronetosensitizationoftheweldheataffectedzoneandweld

metalhotcracking.

Ferritic

Ferriticstainlesssteelconsistsofironchromiumalloyswithbodycenteredcubiccrystalstructures.Theycanhavegoodductilityandformability,but

hightemperaturestrengthsarerelativelypoorwhencomparedtoausteniticgrades.Someferriticstainlesses(suchastypes409and405)used,for

example,inmufflers,exhaustsystems,kitchencountersandsinks,costlessthanotherstainlesssteels.OthermorehighlyalloyedsteelslowinCandN

(suchastypes444and261)aremorecostly,butarehighlyresistanttochlorides.

Martensitic

Martensiticstainlesssteels,suchastypes403,410,410NiMoand420,aresimilarincompositiontotheferritegroup,butcontainabalanceofCandNi

vs.CrandMohence,austeniteathightemperaturestransformstomartensiteatlowtemperatures.Likeferrite,theyalsohaveabodycenteredcubic

crystalstructureinthehardenedcondition.Thecarboncontentofthesehardenablesteelsaffectsformingandwelding.Toobtainusefulpropertiesand

preventcracking,theweldablemartensiticsusuallyrequirepreheatingandpostweldheattreatment.

Duplex

Primarilyusedinchemicalplantsandpipingapplications,theduplexstainlesssteelsaredevelopingrapidlytodayandhaveamicrostructureof

approximatelyequalamountsofferriteandaustenite.Duplexstainlesssteelstypicallycontainapproximately2225%chromiumand5%nickelwith

molybdenumandnitrogen.Althoughduplexandsomeausteniticsdohavesimilaralloyingelements,duplexeshavehigheryieldstrengthandgreater

stresscorrosioncrackingresistancetochloridethanausteniticstainlesssteels.

PrecipitationHardening

Precipitationhardeningstainlesssteelsarechromiumnickelstainlesses,whichcontainalloyingadditionssuchasaluminum,copperortitaniumthat

allowthemtobehardenedbyasolutionandagingheattreatment.Theycanbeeitherausteniticormartensiticintheagedcondition.Precipitation

hardeningstainlesssteelsaregroupedintothreetypes:martensitic,semiausteniticandaustenitic.Themartensitic(suchasType630)andsemiaustenitic

(suchasType631)canprovidehigherstrengththantheaustenitic(suchasType660,alsoknownasA286).

SelectingStainlessSteel

Theselectionofaparticulartypeofstainlesssteelwilldependonwhatrequirementsaparticularapplicationposes.Environment,expectedpartlifeand

extentofacceptablecorrosionallhelpdeterminewhattypeofstainlesstouse.Inmostcases,theprimaryfactoriscorrosionresistance,followedbytarnish

andoxidationresistance.Otherfactorsincludetheabilitytowithstandpitting,crevicecorrosionandintergranularattack.Theaustenitic/higherchromium

stainlesssteels,usuallyrequiredinveryhighorverylowtemperatures,aregenerallymorecorrosionresistantthanthelowerchromiumferriticor

martensiticstainlesses.

Moststainlesssteelsareconsideredtohavegoodweldability.Itisimportanttomakesurejointsurfacesandanyfillermetalbekeptfreefromoxide,

organicmaterialorothercontamination.

Aprincipalconcerninselectingweldingfillermetalsforstainlesssteelsistomatchtheimportantpropertiesofthebasemetal.Inaddition,fornominally

austeniticandduplexstainlesssteels,oneshouldhavesomecontrolovertheweldmetal'sferritecontent.Specificationofferriteinnominallyausteniticand

duplexstainlesssteelweldsarebaseduponFerriteNumbers(FN)definedintheAWSA4.2M/A4.2:1997standard,StandardProceduresforCalibrating

MagneticInstrumentstoMeasuretheDeltaFerriteContentofAusteniticandDuplexFerriticAusteniticStainlessSteelWeldMetal.Recommendedbythe

AmericanSocietyofMechanicalEngineersCode,themagneticallydeterminedFNismuchsimplertoobtainandismorereproduciblethan

metallographicallydeterminedpercentferrite.

Whenselectingstainlesssteels,aweldermustalsoconsidersomethingcalled"sensitization."Ferriticstainlesssteelsandsomeausteniticstainless

steels,whichcontainappreciablefreecarbon(greaterthanabout0.04%C)canberenderedsensitivetointergranularcorrosionintheheataffectedzone

(HAZ)ofaweld.Thissensitizationoccurswhereapeaktemperatureofabout900to1600 F(482to871 C)isreachedintheHAZ.Chromiumcarbides

precipitateongrainboundaries,andintheprocessofdoingso,chromiumasanalloyelementisdepletedinthemetaladjacenttothegrainboundaries.

Then,incorrosiveservice,thisCrdepletedmetalisselectivelyattacked.Lowweldingheatinputcanlimit,butnoteliminate,sensitization.Thebest

methodsofpreventingsensitizationareselectionofverylowcarbonbasemetal(lessthan0.03%C)orselectionofagradestabilizedwithtitaniumor

niobium(alsoknownascolumbium),suchastypes321or347.Notealsothatsensitizationisalmostneveraweldmetalproblemitislargelyaheat

affectedzoneproblem.

You might also like

- Welding: Welding Is A Fabrication Process That Joins Materials, Usually Metals or Thermoplastics, byDocument6 pagesWelding: Welding Is A Fabrication Process That Joins Materials, Usually Metals or Thermoplastics, byTarun ChandraNo ratings yet

- Gaskets: Spiral-Wound Gaskets Comprise A Mix of Metallic and Filler Material. Generally, The Gasket Has ADocument2 pagesGaskets: Spiral-Wound Gaskets Comprise A Mix of Metallic and Filler Material. Generally, The Gasket Has ATarun ChandraNo ratings yet

- PUMPSDocument7 pagesPUMPSTarun ChandraNo ratings yet

- Swage Nipples MSS-SP-95 SpecificationsDocument1 pageSwage Nipples MSS-SP-95 SpecificationsTarun ChandraNo ratings yet

- Syngas CatalystDocument16 pagesSyngas CatalystTarun ChandraNo ratings yet

- What Makes Digital Marketing Differ From Social Media MarketingDocument3 pagesWhat Makes Digital Marketing Differ From Social Media MarketingTarun ChandraNo ratings yet

- HP40 NBDocument13 pagesHP40 NBTarun ChandraNo ratings yet

- Alloy-C276 (For Spring)Document6 pagesAlloy-C276 (For Spring)Tarun ChandraNo ratings yet

- Datasheet 2RE69Document9 pagesDatasheet 2RE69Tarun ChandraNo ratings yet

- Propeller Installation ProcedureDocument2 pagesPropeller Installation Proceduredanilo laraNo ratings yet

- Coupling PDFDocument68 pagesCoupling PDFmmkattaNo ratings yet

- Reformer TubesDocument3 pagesReformer TubesTarun ChandraNo ratings yet

- Storage Tank Design: Email:moemen - Hussein@alexu - Edu.egDocument58 pagesStorage Tank Design: Email:moemen - Hussein@alexu - Edu.egahmadhatakeNo ratings yet

- Tank DesignDocument164 pagesTank DesignTarun ChandraNo ratings yet

- ST ST Pipe Pressure Rating Charts Rev Sep 2010Document5 pagesST ST Pipe Pressure Rating Charts Rev Sep 2010reliability1No ratings yet

- Atmospheric Relief ValveDocument6 pagesAtmospheric Relief ValveTarun ChandraNo ratings yet

- ASTM A335 P92 SpecificationDocument4 pagesASTM A335 P92 SpecificationTarun ChandraNo ratings yet

- Mechanical Seal Plan - Pocket Guide (John Crane)Document62 pagesMechanical Seal Plan - Pocket Guide (John Crane)Tarun Chandra100% (5)

- SolenoidDocument4 pagesSolenoidTarun ChandraNo ratings yet

- Atmospheric Relief Valve ManualDocument12 pagesAtmospheric Relief Valve ManualTarun ChandraNo ratings yet

- Atmospheric Relief ValveDocument6 pagesAtmospheric Relief ValveTarun ChandraNo ratings yet

- Radial Drilling MachinesDocument4 pagesRadial Drilling MachinesTarun ChandraNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- P&ID Check ListDocument2 pagesP&ID Check ListHadi ShahsavanNo ratings yet

- Blaster's Handbook PDFDocument180 pagesBlaster's Handbook PDFsaiful100% (1)

- MIMO Capacity Increase in UMTS/HSPA+ SystemsDocument159 pagesMIMO Capacity Increase in UMTS/HSPA+ SystemslikameleNo ratings yet

- GEOtouch®PET NEEDLE-PUNCHED NONWOVEN GEOTEXTILEDocument1 pageGEOtouch®PET NEEDLE-PUNCHED NONWOVEN GEOTEXTILEManas Kumar SamalNo ratings yet

- Best Practices in PL/SQL: Karthikeyan MDocument15 pagesBest Practices in PL/SQL: Karthikeyan MranusofiNo ratings yet

- What Is Transmission Channel ?Document12 pagesWhat Is Transmission Channel ?tusharNo ratings yet

- Fluid Mechanics Subjective QuestionsDocument3 pagesFluid Mechanics Subjective QuestionsCrewdex ProNo ratings yet

- Beginning Android DevelopmentDocument721 pagesBeginning Android DevelopmentNikola Johnny Popadic67% (3)

- Sewing 04-Needle Class 118 of Groz-Beckert For Union Special FlatseamersDocument6 pagesSewing 04-Needle Class 118 of Groz-Beckert For Union Special Flatseamersfriendztoall4351No ratings yet

- List of Organisations SAR147 Apr2012Document2 pagesList of Organisations SAR147 Apr2012Tan Lian KiatNo ratings yet

- PNG382 FT en 11Document2 pagesPNG382 FT en 11Misu1983No ratings yet

- British Standard: A Single Copy of This British Standard Is Licensed ToDocument33 pagesBritish Standard: A Single Copy of This British Standard Is Licensed ToevangalionNo ratings yet

- Foundation DesignDocument7 pagesFoundation DesignPrasad GNNo ratings yet

- Lifetime Extension Steam TurbineDocument10 pagesLifetime Extension Steam Turbineramakantinamdar100% (1)

- 2021 International Construction Benchmark Yearbook SAMPLE 1Document10 pages2021 International Construction Benchmark Yearbook SAMPLE 1Familia GonzalezNo ratings yet

- OMEGA AIR Alternative Filter Elements English PDFDocument56 pagesOMEGA AIR Alternative Filter Elements English PDFbinhleduc36No ratings yet

- Charge AmpsDocument5 pagesCharge AmpsKrishnamurthy AnantharamakrishnanNo ratings yet

- Calpeda Pump DatasheetDocument16 pagesCalpeda Pump DatasheetAhamed HussanNo ratings yet

- QSEE6800+H Signal Monitor Video and Thumbnail Streamer: Installation and Operation ManualDocument86 pagesQSEE6800+H Signal Monitor Video and Thumbnail Streamer: Installation and Operation ManualTechne PhobosNo ratings yet

- PHCbi Refrigerators MPRS163 MPRS313Document2 pagesPHCbi Refrigerators MPRS163 MPRS313Eslam HassanNo ratings yet

- Sabita Manual 2Document79 pagesSabita Manual 2Carel De Jager0% (1)

- Trouble ShootingDocument3 pagesTrouble Shootingsami4330No ratings yet

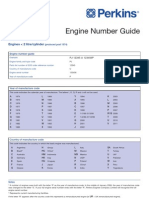

- Perkins Engine Number Guide PP827Document6 pagesPerkins Engine Number Guide PP827Muthu Manikandan100% (1)

- Smart Test Series: 1-Circle The Correct Answer. (12x1 12)Document4 pagesSmart Test Series: 1-Circle The Correct Answer. (12x1 12)Dr. AyshaNo ratings yet

- Squashing Commits with RebaseDocument4 pagesSquashing Commits with RebaseDavid BeaulieuNo ratings yet

- Environmental Engineering - Civil Engineering - McGill UniversityDocument4 pagesEnvironmental Engineering - Civil Engineering - McGill Universityamrin jannatNo ratings yet

- Base Station Antennas1Document66 pagesBase Station Antennas1redha_rebaiNo ratings yet

- Data Scrambling: A Net 2000 Ltd. White PaperDocument12 pagesData Scrambling: A Net 2000 Ltd. White PapernassarsubNo ratings yet

- Frame RelayDocument33 pagesFrame RelayDilsha AshrafNo ratings yet

- Technical Data Demag Hoist Units Volume 2: Double-Rail Crab EZDH 600 - EZDH 1000 Double-Rail Crab EZLDH 600 - EZLDH 2000Document88 pagesTechnical Data Demag Hoist Units Volume 2: Double-Rail Crab EZDH 600 - EZDH 1000 Double-Rail Crab EZLDH 600 - EZLDH 2000mohammad khoraminiaNo ratings yet