Professional Documents

Culture Documents

Redsail Cutting Plotter User Manual I

Uploaded by

Shahbaz GulCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Redsail Cutting Plotter User Manual I

Uploaded by

Shahbaz GulCopyright:

Available Formats

version number: 1.1.1.

140508_PRO

Redsail Tech Co., Ltd

www.hflaser.com 1

version number: 1.1.1.140508_PRO

Contents

Welcome .................................................................................................. 3

Cutter Parts ............................................................................................ 4

Front View .............................................................................................. 4

Detail of Carriage Arm .............................................................................. 5

Right Side View ....................................................................................... 6

Left Side View ......................................................................................... 7

Back View .............................................................................................. 8

Detail of Pinch Roller (Back View) ............................................................. 9

Control Panel ........................................................................................ 10

Setting up .............................................................................................. 16

Selecting a Location for Your Cutter .......................................................... 16

Connecting the Cutter to a Computer .......................................................... 16

Installing the Pen Carriage ........................................................................ 19

Installing a New Blade ............................................................................. 21

Replacing a Worn Blade ........................................................................... 22

Preparing for Cutting ............................................................................... 23

Specifications ........................................................................................ 29

Troubleshooting .................................................................................... 31

Stand Installation .................................................................... ............. 33

Redsail Tech Co., Ltd

www.hflaser.com 2

version number: 1.1.1.140508_PRO

WELCOME

Thank you for choosing a RS series cutter from RESASIL. The RESASIL

cutters give users the ability to afford a quality entry level cutter while

still receiving the durability and dependability needed to move you

through all stages of your cutting experience, from beginner to expert

alike. This manual is here to help provide a starting point in the learning

process of the RESASIL cutters or to vinyl cutting in general. Please read

it thoroughly and follow the steps carefully to help insure a trouble free

experience with your new machine. If you have any questions along the

way, we have provided a few locations to go to get those questions

answered. You can post on the RESASIL Cutter forums at

www.hflaser.com, submit a request for support on the support website at

www.hflaser.com, or call customer service at 86-531-86516855. We hope

you enjoy your experience with the RS series cutters and the REDSAIL

Cutter family.

Redsail Tech Co., Ltd

www.hflaser.com 3

version number: 1.1.1.140508_PRO

Cutter Parts

Before you start cutting, you should familiarize yourself with the cutter and its basic

parts and functions:

Front View

Used to provide input directly to the cutter. Covered in

Control Panel

detail in the Control Panel (page 10) section of this

manual.

Holds the Blade (or Pen) Carriage. Shown in detail on page

Carriage Arm

5.

Holds the media tightly to the feed roller below. Back view

Pinch Rollers

shown in detail on page 9.

Positions the cutting material during operation.

Feed Rollers

Contains the Power Cable Port, Power Switch and Fuse

Left Side Cover

Cartridge for the cutter. Shown in detail on page 7.

Contains the USB and Serial cable ports for the cutter.

Right Side Cover

Shown in detail on page 6.

Redsail Tech Co., Ltd

www.hflaser.com 4

version number: 1.1.1.140508_PRO

Detail of Carriage Arm

Blade/Pen Carriage Slot Holds the Blade/Pen Carriage in place.

Allows access to the Blade/Pen Carriage

Locking Knob

Slots for exchanging/replacing Carriages.

Redsail Tech Co., Ltd

www.hflaser.com 5

version number: 1.1.1.140508_PRO

Right Side View

Used to connect a USB cable from the cutter to a

USB Cable Port

computer.

Used to connect a serial cable from the cutter to a

Serial (COM) Cable Port

computer.

Only one of the connection cables should be used to connect the cutter to

a computer. Not both.

Redsail Tech Co., Ltd

www.hflaser.com 6

version number: 1.1.1.140508_PRO

Left Side View

Used to connect a power cable from the cutter to a wall

Power Cable Port

outlet or surge protector.

Main power switch for turning the power of the cutter

Power Switch

on(1) or off(0).

Redsail Tech Co., Ltd

www.hflaser.com 7

version number: 1.1.1.140508_PRO

Back View

Holds the media tightly to the feed roller below. Back view shown

Pinch Rollers

in detail on next page.

Redsail Tech Co., Ltd

www.hflaser.com 8

version number: 1.1.1.140508_PRO

Detail of Pinch Roller (Back View)

Adjusts the tension of how tightly the pinch roller

Pinch Roller Tension Knobs

is held to the feed roller below.

Allows you to release Pinch Rollers (either so they

Pinch Roller Release Lever

can be moved from side to side or to allow media

to be easily fed below them) by pulling up on the

Release Levers.

Redsail Tech Co., Ltd

www.hflaser.com 9

version number: 1.1.1.140508_PRO

Control Panel

The main screen of the cutter allows you to set the main settings of the cutter

including the cutting speed and cutting force options. It also allows you to cut a test

pattern or check the amount of force that is currently set.

Redsail Tech Co., Ltd

www.hflaser.com 10

version number: 1.1.1.140508_PRO

RESET Button

Press RESET button when online or offline,

clearing the memory of the machine, and setting the

origin of carriage arm to its rightmost position.

RESET

ONLINE Button

Press Online button when online, then it will be

Offline.

Press Online button when offline, then it will be

Online.

Press Online button when the machine working,

then the machine will stop working. Press Online

button again, recover the last work.

ONLINE

Redsail Tech Co., Ltd

www.hflaser.com 11

version number: 1.1.1.140508_PRO

SET Button

Accesses the Setup mode

Press SET button when online, the blade will be

down.

SET

TEST Button

Will cut a small test shape so that the current force

and speed settings cutter will be tested. You can use

this to determine the proper force and speed setting

needed for different materials without wasting large

amount materials from cutting full designs.

Press TEST button when offline, the machine will

make self-test.

TEST

Redsail Tech Co., Ltd

www.hflaser.com 12

version number: 1.1.1.140508_PRO

P+ Button

Adjust the cutting force

For increasing the force when online, the highest

force is 500g.

A cutting force of 100g is a good general starting

place to work from when trying to determine the

force needed for a specific material. All cuttable

materials will differ in the amount of force needed so

proper testing should be always made to determine

the amount of force to use. The amount of force used

should be enough to fully penetrate the material to be

cut while not enough to cut through the backing

material.

P+ For moving the carriage arm to the left position when

offline.

P- Button

Adjust the cutting force

For reducing the force when online, the lowest force is

50g.

A cutting force of 100g is a good general starting

place to work from when trying to determine the

force needed for a specific material. All cuttable

materials will differ in the amount of force needed so

proper testing should be always made to determine

the amount of force to use. The amount of force used

should be enough to fully penetrate the material to be

cut while not enough to cut through the backing

material.

P- For moving the carriage arm to the right position

when offline.

Redsail Tech Co., Ltd

www.hflaser.com 13

version number: 1.1.1.140508_PRO

S+ Button

Adjusts the cutting speed

For increasing the speed when online, the highest

speed is 600mm/s

A cutting speed of 16 inch/s is a reasonable default

speed that can be used for most cuts. When working

with smaller and more detailed images, a slower

speed may be required. When working with larger

and less detailed images, a higher speed can be used

to shorten the operation time.

For moving Y axis to the back position when offline.

S+

S+ Button

Adjusts the cutting speed

For reducing the speed when online, the lowest speed

is 25mm/s

A cutting speed of 16 inch/s is a reasonable default

speed that can be used for most cuts. When working

with smaller and more detailed images, a slower

speed may be required. When working with larger

and less detailed images, a higher speed can be used

to shorten the operation time.

For moving Y axis to the front position when offline.

S-

Redsail Tech Co., Ltd

www.hflaser.com 14

version number: 1.1.1.140508_PRO

OK Button

For confirming your operation.

OK

Redsail Tech Co., Ltd

www.hflaser.com 15

version number: 1.1.1.140508_PRO

Setting up

If you are setting up for the first time please take a moment to refer to the Packaging

Guide to take account off all the included components and accessories.

For help with Stand Assembly, please refer to the included instructions.

Selecting a Location for Your Cutter

The first step to setting up your cutter is finding a good location for the machine.

Consider these factors when you are selecting a suitable place:

You will need to have access to both the front and rear of the machine for operations

as well as for loading and unloading new vinyl rolls. Try to find a space with adequate

access to both the front and back of the machine.

Since your cutter is a precision cutting device, you will want to find a location that

will be stable to insure cutting accuracy. Whether placing the unit on the stand, a floor

or a table top, the accuracy of the machine will be directly related to the stability of

the platform it is placed on. Find a sturdy floor space or table top for the machine and

consider a location that will be out of the way of people and other machines with

moving parts while the cutter will be operating. Excessive moving of the machine can

not only disrupt accuracy of cutting but may also cause electrical components inside

the machine to dislodge and require otherwise unnecessary repairs and maintenance.

Fans located inside of the cutter can draw in outside dust from the area surrounding

the cutter. Excessive buildup of dust can cause either mechanical or electronic

malfunctions. Keeping the cutter as dust free as possible will help ensure trouble free

operation. Try to find an area for the cutter that will be free of any excessive dust

and use the supplied cover when not in use.

All cutters will produce a small amount of noise while operating. Please take this into

consideration when selecting a location for your cutting purposes.

Do not remove the grounding plug from the power cord or attempt to use the cutter

when it has not been properly grounded.

Connecting the Cutter to a Computer

Attach the power cord to the cutter and then plug in the unit and turn on the power.

If Using the a Serial Cable to connect your cutter to a Computer:

If you are using a Serial Cable to connect your cutter to a computer then no further

setup is necessary. Simply connect one end of the cable to the cutter and the other end

to a computer and setup is complete. If you have more than one serial connection on

your computer or you are experiencing communication issues between your cutter

and computer then you may wish to verify that the correct COM port is being used in

your software setup (see Finding Your COM Port on the page 18), but for most users

the COM port will be COM1.

Redsail Tech Co., Ltd

www.hflaser.com 16

version number: 1.1.1.140508_PRO

If Using the USB Cable to connect your cutter to a Computer:

You will need to install drivers for the USB connection to work properly. These

drivers can either be obtained from the supplied drivers disc or downloaded from the

support website (in the downloads section of www.hflaser.com).

If you need download the drivers from our website, then please reading the following

guidance:

There are two optional USB port for the cutting plotter. You can check it on Device

Manager of your computer .

If the USB port shows: FT232R USB UART, then you can download the USB

Driver-FTDI.

If the USB port shows: USB2.0-Serial, then you can download the USB

Driver-CH341SER.

Windows XP Users:

1. Insert the driver disc or download (and unzip if necessary) drivers to your system.

2. Connect the USB Cable to your computer and your cutter. The Found New

Hardware wizard will appear.

3. When asked, Can Windows connect to Windows Update to search for software?

select No, not this time and click next.

4. When asked, What do you want the wizard to do? select Install from a list or

specific location (Advanced) and click next.

5. Choose the Search for the best driver in these locations radio button and check

the Include this location in the search checkbox. Now type (or browse to find) the

location of the downloaded drivers/inserted drivers disc and click next.

6. When the wizard is complete, click the Finish button.

7. The Found New Hardware wizard should appear again. When it does, follow steps

3-6 again for the second driver.

Windows Vista Users:

If you want to use downloaded drivers, download them before starting the install

process.

1. Connect the USB Cable to your computer and your cutter. Then Found New

Hardware wizard will appear.

2. When told that Windows needs to install driver software select Locate and

install driver software (recommended).

3. If Windows finds and downloads your needed drivers then the process is complete.

Repeat the previous steps again for the second needed driver. If Windows does not

find and download the needed drivers proceed to the next step.

Redsail Tech Co., Ltd

www.hflaser.com 17

version number: 1.1.1.140508_PRO

4. If you are going to install the drivers from the disc insert it when advised by

Windows. If you are going to use downloaded drivers, select I dont have the disc.

Show me other options.

5. Browse to the folder where the drivers are stored and click next.

6. When the wizard is complete, click the close button.

7. The Found New Hardware wizard should appear again. When it does, follow steps

2-6 again for the second driver.

If you are using another version of Windows and require specific

instructions for installing the drivers, just also according to the appeared

wizard step by step after connecting the machine and computer with

USB cable.

Once your drivers are installed you will need to make a note of the COM

port that has been assigned to your USB Cable connection.

-Finding Your COM Port

First navigate to the Device Manager by following the below instructions

for your operating system.

Windows 95/98/Me Users:

Click Start, then select Settings -> Control Panel.

Select Device Manager.

Windows 2000/XP Users:

Click Start, tRight-click My Computer then select Properties.

Select the Hardware tab.

Click the Device Manager.

Windows Vista/7 Users:

Click Start, then in the "Start Search" box, Type "Dev" (without pressing enter); wait

for a list to show up.

Click Device Manager.

Windows 8 Users:

Click Start, Control Panel---Click Device Manager

Expand the section labeled Ports (COM & LPT).

Make a note of which number COM Port is associated with USB Serial

Port.

You will need this information to properly install your software.

Redsail Tech Co., Ltd

www.hflaser.com 18

version number: 1.1.1.140508_PRO

Installing the Pen Carriage

Most new users will benefit from practice cutting with the supplied pen

carriage until they are comfortable with normal operations of the cutter

and cutting software.

Your Pen Carriage should come assembled and appear as it does in this

image. If it does not, please refer to the pen replacement section below

for assembly instructions.

To install the pen carriage:

Loosen the locking knob Drop the pen attachment Tighten the locking knob

on the carriage arm. into place in the slot of on the carriage arm.

the carriage arm.

Redsail Tech Co., Ltd

www.hflaser.com 19

version number: 1.1.1.140508_PRO

To Replace the pen or spring inside of the Pen Carriage:

Unscrew the top cap from the Pen carriage.

Remove the top cap, the pen and the spring. Replace the pen and/or

spring as necessary. Slide the spring onto the pen from the top and

insert it back into the pen carriage.

Replace the carriage cap and screw into place.

Once you are familiar with the cutter and its basic functions, install the

blade carriage.

Redsail Tech Co., Ltd

www.hflaser.com 20

version number: 1.1.1.140508_PRO

Installing a New Blade

Set Brass Ring Remove the Insert the blade Adjust the Adjust the Brass

on Blade protective cover into the top of carriage cap Ring until it fits

Carriage to the from a new the Blade until the blade snug against the

fully down blade. carriage. is protruding Cap. This will

position approximately help keep the cap

in place during

1/64th of an

operation

inch.

Loosen the locking knob on Place Blade carriage into the Tighten the locking knob on

the carriage arm. carriage arm. the carriage arm.

Redsail Tech Co., Ltd

www.hflaser.com 21

version number: 1.1.1.140508_PRO

Replacing a Worn Blade

Press up on the release button (located on the bottom of the blade carriage) to raise the

blade and remove it.

Follow the remaining steps from Installing a New Blade on the

previous page.

Redsail Tech Co., Ltd

www.hflaser.com 22

version number: 1.1.1.140508_PRO

Preparing for Cutting

If you are going to cut from a scrap or single sheet instead of a roll, then skip

the next step on placing a vinyl roll. All other steps will be the same.

Place the roll on the top of the stand rollers

Redsail Tech Co., Ltd

www.hflaser.com 23

version number: 1.1.1.140508_PRO

Release the Pinch Rollers by pulling up on the Pinch Roller Release

Levers.

Redsail Tech Co., Ltd

www.hflaser.com 24

version number: 1.1.1.140508_PRO

Feed the vinyl underneath the pinch rollers (if working from a single

sheet instead of a roll, the vinyl can also be feed from the front).

Redsail Tech Co., Ltd

www.hflaser.com 25

version number: 1.1.1.140508_PRO

Adjust the pinch rollers so there is one roller located on each side of the

vinyl (one cutter with 3 or more rollers, one roller near the center). Avoid

lowering a pinch roller to the gap between the two feed rollers.

Leave a gap of between -1 from the edge of the roller and the edge

of the vinyl on both sides.

Engage the Pinch Rollers by pushing down on the Pinch Roller Release

Levers.

Redsail Tech Co., Ltd

www.hflaser.com 26

version number: 1.1.1.140508_PRO

If the cutter is not already on, turn it on now

Adjust the vinyl to the position where you want to make your cutting start

by using the Up and Down Arrow Keys on the Control Panel.

Redsail Tech Co., Ltd

www.hflaser.com 27

version number: 1.1.1.140508_PRO

Adjust the carriage arm to the position where you want your cutting to

start by using the Left and Right Arrow Keys.

Now press the OK button to tell the cutter that this is the location where

you would like the cut to begin.

Then operating your cutting design in the software to output, then

machine will start working.

When choosing a starting location for your design, remember that the

process will start in the bottom right area of the design. Please leave

enough room to the left of and behind the starting location to finish your

cut.

If you would like to make other adjustments to the pressure, speed, or

other settings you can do so now. If you are setting up for your first cut

with the machine then the default values should be a good starting point.

If you make any adjustments to your cutter, make sure that you return to

the main screen before you attempt to cut. If you are unsure how to do

this, refer to the Control Panel section of the manual on page 10.

Redsail Tech Co., Ltd

www.hflaser.com 28

version number: 1.1.1.140508_PRO

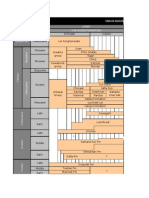

Specifications

Desktop Cutting Plotter

Model RS360C RS450C RS500C

Control system Risc micro-controller

Drive type Stepper motor

Media Size (mm) 360 450 500

Cutting size (mm) 260 350 400

Cutting speed 600mm/s

Cutting force 50-500 g

Lcd display English

Resolution 1000 DPI

Repeatability(mm) 0.01

Command HPGL

Interface 232/USB

Power 90~240V / 50~60Hz

Warranty 12 Months

Vinyl Cutter

Model RS720C RS800C RS1120C RS1360C

Control system Risc micro-controller

Drive type Stepper motor

Media Size (mm) 720 800 1120 1360

Cutting size (mm) 620 700 1000 1200

Cutting speed 600mm/s

Cutting force 50-500 g

Lcd display English

Resolution 1000 DPI

Repeatability(mm) 0.01

Command HPGL

Interface 232/USB

Power 90~240V / 50~60Hz

Warranty 12 Months

Redsail Tech Co., Ltd

www.hflaser.com 29

version number: 1.1.1.140508_PRO

Large Format Plotter

Model RS1600C RS1780C RS2000C

Control system Risc micro-controller

Drive type Stepper motor

Media Size (mm) 1600 1780 2000

Cutting size (mm) 1500 1680 1900

Cutting speed 600mm/s

Cutting force 50-500 g

Lcd display English

Resolution 1000 DPI

Repeatability(mm) 0.01

Command HPGL

Interface 232/USB

Power 90~240V / 50~60Hz

Warranty 12 Months

Redsail Tech Co., Ltd

www.hflaser.com 30

version number: 1.1.1.140508_PRO

Troubleshooting

The cutter is unresponsive to Communication issues can arise if the

communications from the cutter was powered on while the software

computer and software. is trying to send data to the cutter. Exiting

the cutter screen of software and

returning to the main software screen

may resolve this issue. If not, save all

work and try exiting the software and

restarting with the cutter powered on. It is

good practice to start software with the

cutter powered on to avoid

communication problems.

Make sure that your output device in

software is set to the correct COM port.

Your COM port can be found by

following the instructions in the Finding

Your COM Port section of this manual

on page 14. You can change your COM

Port by right-clicking on the COM Port in

the device manager and going to the

advanced section of the Port Settings tab.

Adjust your Flow Control settings to

Hardware by first locating your COM

Port in the device manager (By following

the instructions on page 14), then

right-click the COM Port and select

Properties. On the Port Settings tab,

change to Flow Control option to

Hardware.

The cutter performs erratically Some computers do not work well when

during cuts, stops cutting before connected via the USB port of the cutters.

the cut is finished, or cuts lines If you are having problems while cutting

that do not appear in the design. and are using the USB cable to connect

from your cutter to computer, you may

wish to try the serial cable connection to

avoid further problems. If a serial cable

connection is not available on your

computer, you can try a third party USB

Redsail Tech Co., Ltd

www.hflaser.com 31

version number: 1.1.1.140508_PRO

to serial connecter or a PCI card serial

adapter for your computer.

Vinyl not feeding straight and the Sometimes, during shipping or movement

rightmost Pinch Roller will not of the machine, the right pinch roller will

move. become stuck on a screw located on the

back of the machine. If this occurs and is

affecting your cutting, press forcefully

against the pinch roller until it becomes

dislodged from its position. If needed,

remove the screw to reposition the pinch

roller in the desired position.

Cuts are jagged or inconsistent. The Blade may be dulled or damaged.

Replace with a new blade and try again.

Make sure that the blade can turn freely

(by attempting to turn it with your fingers

while the release button of the Blade

Carriage is pressed).

Adjust the blade depth of the Blade

Carriage and Force setting on the cutter

until you are getting solid, uniform cuts.

Start with a blade depth of around 1/64th

of an inch and a pressure setting of 100g

and try an increased pressure setting

before attempting to increase the blade

depth.

Slashes are made across the vinyl If the blade is protruding too far from the

from the blade movement during Blade Carriage then it can score and cut

cutting. material during normal operations. If this

is occurring, the blade needs to be

adjusted so that it is protruding a minimal

distance from the carriage.

Other troubleshooting solutions may be found by visiting the Customer

Forums or Technical Support Website, or by calling the Technical

Support Line (Web page addresses and Phone number on the

specifications page, 3).

Redsail Tech Co., Ltd

www.hflaser.com 32

version number: 1.1.1.140508_PRO

Stand Installation (For the cutters with stand)

Redsail Tech Co., Ltd

www.hflaser.com 33

version number: 1.1.1.140508_PRO

Assembled right side (roller

arm, column)

Needed For

1 This Step

D(x2) Long Screw

E(x2) Long Screw pad

Redsail Tech Co., Ltd

www.hflaser.com 34

version number: 1.1.1.140508_PRO

Assembled left side (roller

arm, column)

Needed For

2 This Step

D(x2) Long Screw

E(x2) Long Screw pad

Redsail Tech Co., Ltd

www.hflaser.com 35

version number: 1.1.1.140508_PRO

Assembled right side (Long

Screw, Long Screw pad) with

Needed For

3 This Step

Center Crossbeam

D(x2) Long Screw

E(x2) Long Screw pad

Redsail Tech Co., Ltd

www.hflaser.com 36

version number: 1.1.1.140508_PRO

Assembled right side (roller

arm, column, foot) with

Needed For

4 This Step

Center Crossbeam

D(x2) Long Screw

E(x2) Long Screw pad

Redsail Tech Co., Ltd

www.hflaser.com 37

version number: 1.1.1.140508_PRO

Assembled left bearing

A(x1) Rollers

Needed For

5 This Step

Redsail Tech Co., Ltd

www.hflaser.com 38

version number: 1.1.1.140508_PRO

Assembled right bearing

A(x1) Rollers

Needed For

6 This Step

Redsail Tech Co., Ltd

www.hflaser.com 39

version number: 1.1.1.140508_PRO

Completed stand

I(x1) Roller

Needed For

7 This Step

Redsail Tech Co., Ltd

www.hflaser.com 40

version number: 1.1.1.140508_PRO

Completed stand with rollers

C series Cutter

Needed For

8 This Step

Redsail Tech Co., Ltd

www.hflaser.com 41

version number: 1.1.1.140508_PRO

For your safety, proper use the productbe sure to read this

manual carefully before operation, to be fully understood and

save it for your later use. If you have any suggestions of our

products or need our help, please call:0531-86516855/56/57

Special Note: The Company reserves the rights of

changing the content and product specifications without prior

notice. All the information to check carefully make sure

accurate. Products are subject to change without notice.

Thank you for choosing Redsail Products !

REDSAIL TECHCO., LTD

Redsail Tech Co., Ltd

www.hflaser.com 42

You might also like

- Halliburton - Surface Well TestingDocument418 pagesHalliburton - Surface Well TestingChristian Motta67% (3)

- Draft IKEA Quality Management Nguyen Thu Huong 11182135Document9 pagesDraft IKEA Quality Management Nguyen Thu Huong 11182135Xuân HươngNo ratings yet

- Fonte Argus - 018534b2 (SM02 Pre Ver4)Document76 pagesFonte Argus - 018534b2 (SM02 Pre Ver4)Diogenes moises luz100% (1)

- 4 Service Manual - Packard Bell - Easynote Tj75 Tj76 Tj77 Tj78Document165 pages4 Service Manual - Packard Bell - Easynote Tj75 Tj76 Tj77 Tj78Soporte Tecnico Buenos Aires100% (1)

- Emerson Av Catalog 4825Document124 pagesEmerson Av Catalog 4825junaid khalidNo ratings yet

- Creality CR-6 SE User Manual English - Chinese PDFDocument24 pagesCreality CR-6 SE User Manual English - Chinese PDFstryzackNo ratings yet

- Rig Component PDFDocument23 pagesRig Component PDFjim carry93% (30)

- Measuring Relays and Protection Equipment: BSI Standards PublicationDocument36 pagesMeasuring Relays and Protection Equipment: BSI Standards Publicationyand_carlos86% (7)

- RTN 620 Maintenance Guide (V100R005C00 - 04)Document571 pagesRTN 620 Maintenance Guide (V100R005C00 - 04)Sidy Elbechir DrameNo ratings yet

- 2000W Hybrid Off-Grid Inverter systemDocument4 pages2000W Hybrid Off-Grid Inverter systemhernelandNo ratings yet

- Engineer Info Report KTR2443 KTR0502 Link 1 130521-191125Document29 pagesEngineer Info Report KTR2443 KTR0502 Link 1 130521-191125Muhammad KashifNo ratings yet

- Bts Code FaultDocument11 pagesBts Code FaultChejoPSNo ratings yet

- FDK Multi-2700 Instruction ManualDocument23 pagesFDK Multi-2700 Instruction ManualpieguzNo ratings yet

- MCS48/600-TLUA5 Power System User's ManualDocument76 pagesMCS48/600-TLUA5 Power System User's ManualYasser AlqadhiNo ratings yet

- S33X USER MANUALrDocument112 pagesS33X USER MANUALrmarkpriceNo ratings yet

- Analizer EU1KY Var1.2Document13 pagesAnalizer EU1KY Var1.2Augustin SerbanNo ratings yet

- Users Manual COBHAM RepeaterDocument63 pagesUsers Manual COBHAM RepeaterMatej Pavlansky100% (1)

- Dummy Guide For R OMTDocument9 pagesDummy Guide For R OMTKulas KupalskyNo ratings yet

- E1 and T1 - SDH and PDH - DWDM - CDMA - ClockingDocument44 pagesE1 and T1 - SDH and PDH - DWDM - CDMA - Clockingsardar_fykNo ratings yet

- Packard Bell Easynote Tj75 - Wistron Sjv50-Cp - Rev SBDocument67 pagesPackard Bell Easynote Tj75 - Wistron Sjv50-Cp - Rev SBsanvivicente100% (1)

- RETU Installation InstructionDocument21 pagesRETU Installation InstructionVanek505No ratings yet

- Engineer Info Report KTI2184 KTI2199 Link 1 130521-231700Document34 pagesEngineer Info Report KTI2184 KTI2199 Link 1 130521-231700Muhammad KashifNo ratings yet

- Commisioning RBS6000 Ericsson 2GDocument11 pagesCommisioning RBS6000 Ericsson 2GZhie Al Muhajirin75% (4)

- YAESU VX-3R TX WIDEBAND 120-220 & 300-576MhzDocument2 pagesYAESU VX-3R TX WIDEBAND 120-220 & 300-576MhzCaptain Crunch100% (1)

- Alcatel Lucent 9400 AWyDocument6 pagesAlcatel Lucent 9400 AWyLan Twin SummerNo ratings yet

- Engineer Info Report PLD2238 PLD7800 Link 1 130715-155354Document34 pagesEngineer Info Report PLD2238 PLD7800 Link 1 130715-155354Muhammad KashifNo ratings yet

- Replacing NPU1 C With An NPU1 DDocument22 pagesReplacing NPU1 C With An NPU1 DhalimabiNo ratings yet

- Amphenol Telecommunication Aug2015Document52 pagesAmphenol Telecommunication Aug2015Ronie MarxistNo ratings yet

- Step by Step - Install - Moshell NewDocument6 pagesStep by Step - Install - Moshell NewAnnie Da-BathNo ratings yet

- BTS Commissioning and Software Loading Part2Document27 pagesBTS Commissioning and Software Loading Part2Zahid Mehboob100% (1)

- MHV2080AH Fujitsu HDD ManualDocument280 pagesMHV2080AH Fujitsu HDD ManualOscar RoblesNo ratings yet

- Wireless-Tek: Price ModelDocument7 pagesWireless-Tek: Price ModelNay LinNo ratings yet

- Datasheet 251Document191 pagesDatasheet 251Marcelo OemNo ratings yet

- R48 3500e Rectifier UM1R483500e PDFDocument28 pagesR48 3500e Rectifier UM1R483500e PDFHythamMidani100% (1)

- TrainingDocument23 pagesTrainingJohannSookdeoNo ratings yet

- RCMS2903-4E1-4GE (A) Configuration Guide (Rel - 02)Document70 pagesRCMS2903-4E1-4GE (A) Configuration Guide (Rel - 02)JoseMiguelBlancoAlvarez100% (1)

- Firmware Update ODU With IDU AGS-20 - r1 PDFDocument17 pagesFirmware Update ODU With IDU AGS-20 - r1 PDFmohammd khairyNo ratings yet

- EMUA ConnectionDocument12 pagesEMUA ConnectionIndRa IdNo ratings yet

- Ethernet On Mini LinkDocument12 pagesEthernet On Mini LinkmohamedNo ratings yet

- All Rbs CountersDocument20 pagesAll Rbs CountersRoberto MaciasNo ratings yet

- Обновление прошивки ODU NEC IPasolinkDocument35 pagesОбновление прошивки ODU NEC IPasolinkАнатолий ПетьковNo ratings yet

- MC MicroDocument23 pagesMC Microelectro232No ratings yet

- SONOFF DIY MODE ProtocolDocument8 pagesSONOFF DIY MODE ProtocolHabib AntouryNo ratings yet

- Anritsu Site Master VSWR MeasurementDocument6 pagesAnritsu Site Master VSWR MeasurementDabin ClovisNo ratings yet

- Delta V0.2 SoPDocument29 pagesDelta V0.2 SoPPassy Tshibangu Lukusa100% (1)

- Installing RBSDocument305 pagesInstalling RBSpoteNo ratings yet

- Redsail Cutting Plotter User Manual ADocument41 pagesRedsail Cutting Plotter User Manual AnosotikNo ratings yet

- Redsail Cutting Plotter User Manual ADocument41 pagesRedsail Cutting Plotter User Manual AMindy Marshall100% (3)

- Redsail C Series Cutting Plotter User ManualDocument28 pagesRedsail C Series Cutting Plotter User ManualjydproduccionNo ratings yet

- 5-6 Axis Spring Controller ManualDocument33 pages5-6 Axis Spring Controller ManualSander DuqueNo ratings yet

- Orbeat d100 Manual PDFDocument24 pagesOrbeat d100 Manual PDFJorge CarrieriNo ratings yet

- CR 10Document16 pagesCR 10PETER LOCKNo ratings yet

- Mitsubishi Meldas 600MDocument512 pagesMitsubishi Meldas 600Mratomil75% (4)

- CNC Control Panel: Instruction ManualDocument6 pagesCNC Control Panel: Instruction ManualAnkur PanwarNo ratings yet

- FX200 Manual enDocument65 pagesFX200 Manual enluisbruzzaNo ratings yet

- Speedway Interface: Plug-In ManualDocument10 pagesSpeedway Interface: Plug-In ManualGRABADOS EXPRESNo ratings yet

- Hy-Ba: User ManualDocument33 pagesHy-Ba: User ManualJeyson Castillo MenaNo ratings yet

- Prophet 08 Manual v1.3Document64 pagesProphet 08 Manual v1.3pherrerosmNo ratings yet

- Dominator V2 MODEL 1061 User Manual: Revision D 07/04/2014Document12 pagesDominator V2 MODEL 1061 User Manual: Revision D 07/04/2014scribdlatinoNo ratings yet

- General Settings Guide: Ricoh Company, LTDDocument0 pagesGeneral Settings Guide: Ricoh Company, LTDTrí Lê MinhNo ratings yet

- C24 User ManualDocument39 pagesC24 User ManualMiguel MedinaNo ratings yet

- CL 60 SM 005 User Manual En)Document24 pagesCL 60 SM 005 User Manual En)NoahNo ratings yet

- SRP350 User ManualDocument35 pagesSRP350 User ManualHaïthem BEN SALEMNo ratings yet

- DEH S1150UB Owners Manual PDFDocument64 pagesDEH S1150UB Owners Manual PDFservicios ab industrialNo ratings yet

- 2014 Call For Papers PDFDocument172 pages2014 Call For Papers PDFShahbaz GulNo ratings yet

- GeoModeling For The Enhancement of Hydrocarbon Potential of Joya Mair Oil Field PDFDocument21 pagesGeoModeling For The Enhancement of Hydrocarbon Potential of Joya Mair Oil Field PDFShahbaz Gul100% (1)

- Artcut2005 Software User Manual PDFDocument12 pagesArtcut2005 Software User Manual PDFShahbaz GulNo ratings yet

- Artcut2005 Software User Manual PDFDocument12 pagesArtcut2005 Software User Manual PDFShahbaz GulNo ratings yet

- PresentationDocument38 pagesPresentationShahbaz GulNo ratings yet

- Map Distribution of Pab FormationDocument1 pageMap Distribution of Pab FormationShahbaz GulNo ratings yet

- Borehole Acoustic WavesDocument10 pagesBorehole Acoustic WavesrizkiboyscribdNo ratings yet

- Class 1 Overview of Physical GeologyDocument5 pagesClass 1 Overview of Physical Geologyapi-3808551No ratings yet

- Bahria Town Application FormDocument1 pageBahria Town Application FormShahbaz GulNo ratings yet

- Introduction To HydrogeologyDocument42 pagesIntroduction To HydrogeologyShahbaz Gul100% (2)

- Definition and Terms Used in 3d Seismic Data InterpretationDocument16 pagesDefinition and Terms Used in 3d Seismic Data InterpretationShahbaz GulNo ratings yet

- PresentationDocument38 pagesPresentationShahbaz GulNo ratings yet

- Directional DrillingDocument16 pagesDirectional DrillingRajeev LochanamNo ratings yet

- Seismic Interpretation MNADocument68 pagesSeismic Interpretation MNAShahbaz Gul100% (3)

- Introduction To Hydrology: Master of Science Teaching Program ST 589D, Fall 2005Document18 pagesIntroduction To Hydrology: Master of Science Teaching Program ST 589D, Fall 2005Shahbaz GulNo ratings yet

- Igneous Rocks in PakistanDocument1 pageIgneous Rocks in PakistanShahbaz GulNo ratings yet

- Wire Line LoggingDocument81 pagesWire Line LoggingMuhammad Waqas100% (1)

- OGDCL - Introduction To Wireline Log InterpretationDocument203 pagesOGDCL - Introduction To Wireline Log InterpretationMohamed HeibaNo ratings yet

- Regional and General Geology and Tectonics of Upper Indus BasinDocument69 pagesRegional and General Geology and Tectonics of Upper Indus BasinShahbaz Gul94% (18)

- Rig component definitions guide under 40 charactersDocument70 pagesRig component definitions guide under 40 charactersHarpreetk87No ratings yet

- Well Seismic SurveyingDocument43 pagesWell Seismic Surveyinggeo-master100% (3)

- Applied and Environmental GeophysicsDocument35 pagesApplied and Environmental GeophysicsShahbaz GulNo ratings yet

- Geophysical ExplorationDocument9 pagesGeophysical ExplorationJavier RojasNo ratings yet

- Stratigraphy of PakistanDocument4 pagesStratigraphy of PakistanShahbaz GulNo ratings yet

- Upper Indus Basin GeologyDocument2 pagesUpper Indus Basin GeologyShahbaz Gul89% (9)

- Kazmi and JanDocument528 pagesKazmi and JanShahbaz Gul100% (33)

- Stratigraphy of Pakistan 2009Document400 pagesStratigraphy of Pakistan 2009Shahbaz Gul100% (2)

- Quick Setup Guide for Panasonic SIP Cordless PhonesDocument26 pagesQuick Setup Guide for Panasonic SIP Cordless PhonesputegrainNo ratings yet

- IP 3MP Bullet Full HD 1080pDocument3 pagesIP 3MP Bullet Full HD 1080pNamburu SomanadhNo ratings yet

- Topla Starter enDocument8 pagesTopla Starter enEd LionesNo ratings yet

- Double-Jacketed Gaskets For Heat Exchangers Sealabilty Behavior in Flanges With and Without Nubbin (PVP2005-71023) PDFDocument10 pagesDouble-Jacketed Gaskets For Heat Exchangers Sealabilty Behavior in Flanges With and Without Nubbin (PVP2005-71023) PDFAngel Sanchez GarciaNo ratings yet

- About KotsonsDocument31 pagesAbout KotsonsVinayak GargNo ratings yet

- Cocacola TQM ProjectDocument18 pagesCocacola TQM ProjectOmer Farooq92% (13)

- Schedule of LoadsDocument46 pagesSchedule of LoadsDel James LambongogNo ratings yet

- 2946 1307 00 Leroy Somer LSA46.2 Technical DataDocument12 pages2946 1307 00 Leroy Somer LSA46.2 Technical DataJORGE ARMANDO CARRASCO TICLLENo ratings yet

- NU Rajgir Campus Roads & EarthworksDocument37 pagesNU Rajgir Campus Roads & EarthworksSantosh ChowdaryNo ratings yet

- Catalyst 3650Document13 pagesCatalyst 3650Monitoreo MarinaNo ratings yet

- Vsphere Distributed Switch ArchitectureDocument9 pagesVsphere Distributed Switch ArchitecturekorhlNo ratings yet

- SQA-V and QwikCheck Gold Test Report 61010-1Document108 pagesSQA-V and QwikCheck Gold Test Report 61010-1rajeeshNo ratings yet

- Request For Quotation - Temporary Bridge On Kabul River (Final 11feb11) PDFDocument14 pagesRequest For Quotation - Temporary Bridge On Kabul River (Final 11feb11) PDFsubbaraoNo ratings yet

- Stock NotebookDocument6 pagesStock NotebookARIANA PONCENo ratings yet

- Hyperion Admin Guide PDFDocument490 pagesHyperion Admin Guide PDFChristopher CashNo ratings yet

- ISO2.HSE.01, Environmental Aspect Identification Impact AssessmentDocument4 pagesISO2.HSE.01, Environmental Aspect Identification Impact Assessmentfccts38100% (1)

- Panduit Metal Raceway CatalogDocument112 pagesPanduit Metal Raceway CatalognumnummoNo ratings yet

- High Expansion Foam SystemsDocument4 pagesHigh Expansion Foam SystemsCarlos YuabeNo ratings yet

- Introduction To Networks, Reference ModelsDocument38 pagesIntroduction To Networks, Reference ModelsMukesh100% (2)

- Trademark Usage GuidelinesDocument1 pageTrademark Usage GuidelinesLegal FormsNo ratings yet

- MoparChemCat2016 v00r01Document46 pagesMoparChemCat2016 v00r01Anton YashinNo ratings yet

- Siemens s7 TcpipDocument22 pagesSiemens s7 TcpipEdward NezatlenseNo ratings yet

- Frog Song Arcade ManualDocument47 pagesFrog Song Arcade Manualclxx1No ratings yet

- EBOM Final For Formula BharatDocument6 pagesEBOM Final For Formula Bharatfatehvir singh birdiNo ratings yet

- CSerialPort v1Document4 pagesCSerialPort v1gabionsNo ratings yet

- PC Replacement PolicyDocument3 pagesPC Replacement PolicyChristopher GuestNo ratings yet

- CoP MBIS MWISeDocument121 pagesCoP MBIS MWISeRob FongNo ratings yet

- Smart Zoning CiscoDocument3 pagesSmart Zoning Ciscousa_sNo ratings yet