Professional Documents

Culture Documents

Merc Service Manual 6 5c

Uploaded by

Hayduke themCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Merc Service Manual 6 5c

Uploaded by

Hayduke themCopyright:

Available Formats

POWER TRIM

5

C

26345

PRESTOLITE POWER TRIM PUMP

Table of Contents

Page Page

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-1 Trim Pump Removal . . . . . . . . . . . . . . . . . . . . . 5C-13

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-1 Hydraulic Repair . . . . . . . . . . . . . . . . . . . . . . . . 5C-13

Valve Pressure Specifications . . . . . . . . . . . 5C-1 Manual Release Valve Replacement . . . . 5C-13

Electrical Specifications . . . . . . . . . . . . . . . . 5C-1 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . 5C-13

Lubricants/Sealers/Adhesives . . . . . . . . . . . . . . 5C-1 Valve Body and Gear Assembly . . . . . . . . 5C-14

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-1 Motor Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-15

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-2 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . 5C-15

Thermal Circuit Breaker Operation . . . . . . . . . 5C-2 Armature Tests . . . . . . . . . . . . . . . . . . . . . . . 5C-17

Manual Release Valve Operation . . . . . . . . . . . 5C-2 Continuity Test . . . . . . . . . . . . . . . . . . . . . 5C-17

Maintaining Power Trim Pump Oil Level . . . . . 5C-2 Test For Shorts . . . . . . . . . . . . . . . . . . . . 5C-17

Air Bleeding Power Trim System . . . . . . . . . . . 5C-3 Cleaning Commutator . . . . . . . . . . . . . . 5C-17

Bleeding OUT/UP Trim Circuit . . . . . . . . . . . 5C-3 Field Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-17

Bleeding IN/DOWN Trim Circuit . . . . . . . . . 5C-3 Test For Open Circuit . . . . . . . . . . . . . . . 5C-17

Testing Power Trim Pump . . . . . . . . . . . . . . . . . 5C-4 Test For Short In Field . . . . . . . . . . . . . . 5C-18

Connecting Test Gauge . . . . . . . . . . . . . . . . 5C-4 Thermal Switch Test . . . . . . . . . . . . . . . . . . 5C-18

Internal Restriction Test . . . . . . . . . . . . . . . . 5C-5 Continuity Test . . . . . . . . . . . . . . . . . . . . . 5C-18

OUT/UP Pressure Test . . . . . . . . . . . . . . . . . 5C-5 Brush Lead Tests . . . . . . . . . . . . . . . . . . . . . 5C-18

IN/DOWN Pressure Test . . . . . . . . . . . . . . . . 5C-5 Brush Replacement . . . . . . . . . . . . . . . . . . . 5C-19

Trim Cylinder Internal Leak Test . . . . . . . . . . . . 5C-5 Brush Replacement . . . . . . . . . . . . . . . . 5C-19

Trim Cylinder Shock Piston Test . . . . . . . . . . . . 5C-7 End Cap And Brush Assembly

Motor and Electrical Bench Tests . . . . . . . . . . . 5C-7 Replacement . . . . . . . . . . . . . . . . . . . . . 5C-19

Trim Pump Motor Test (In Boat) . . . . . . . . . 5C-7 Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . 5C-20

Trim Pump Motor Test (Out of Boat) . . . . . . 5C-8 Trim Pump Installation . . . . . . . . . . . . . . . . . . . 5C-22

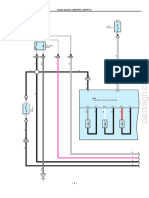

Solenoid Test (Pump in Boat) . . . . . . . . . . . 5C-9 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 5C-23

Solenoid Test (Pump Out of Boat) . . . . . . . 5C-10

110 Amp Fuse Test (Pump in Boat) . . . . . 5C-11

110 Amp Fuse Test

(Pump Out of Boat) . . . . . . . . . . . . . . . . . . 5C-12

20 Amp Fuse Test . . . . . . . . . . . . . . . . . . . . 5C-12

5C-0 – PRESTOLITE POWER TRIM PUMP 90-12934--2 1097

Identification Specifications

Some MerCruiser Sterndrives will be equipped with

a Prestolite Power Trim pump. This pump was used Valve Pressure Specifications

interchangeably with the Oildyne pump for a period

of time. Valve Pressure

2200 - 2600 PSl

Up Circuit

(15173 - 17932 kPa)

400 - 600 PSl

Down Circuit

(2759 - 4138 kPa)

Electrical Specifications

115 Amps at

Pump Amperage Draw 2200 - 2600 PSl

(15173 - 17932 kPa)

Lubricants/Sealers/

Adhesives

Description Part No.

Power Trim and Steering

92-90100A12

Fluid

2-4-C Marine Lubricant 92-825407A2

Liquid Neoprene 92-25711-2

50524

Prestolite Power Trim Pump Special Tools

Description Part No.

Test Gauge Kit 91-52915A6

Multi-Meter 91-99750

Torque Wrench (lb. ft.) 91-36210

Torque Wrench (lb. in.) 91-66274

Jumper Wire Obtain Locally

90-12934--2 1097 PRESTOLITE POWER TRIM PUMP - 5C-1

Description Maintaining Power Trim

The Prestolite Power Trim Pump has internal valving Pump Oil Level

that eliminates the need for an external reverse lock,

as was required in the past. The pump generates a ! CAUTION

higher volume of fluid, but at a lower pressure than

previous Prestolite pumps. This, in conjunction with Vent screw MUST BE backed out two (2) full turns

large I.D. hydraulic hoses (gimbal housing to pump) (after bottoming out) to vent pump reservoir.

and larger I.D. trim cylinders, should allow the drive FAILURE TO BACK SCREW OUT COULD RE-

unit to “kick-up” easier if an underwater object is SULT IN DAMAGE TO PUMP.

struck.

IMPORTANT: Check oil level with sterndrive unit

! CAUTION in the full down position.

Due to differences in internal valving, the new IMPORTANT: SAE 10W-30 or 10W-40 engine oil

Prestolite trim pump cannot be used to replace can be used in system, if Quicksilver Power Trim

an earlier Prestolite pump, or vice-versa. Use of and Steering Fluid is not available.

incorrect pump will affect trim operation and may 1. Place drive unit in the full IN/DOWN position.

cause damage to trim system.

2. Remove “Fill” screw from pump. Oil level should

The pump motor is protected from overheating by an be up to bottom of the threads in “Fill” screw hole.

internal circuit breaker (on commutator end plate), If necessary, add Quicksilver Power Trim and

that interrupts the current flow through the field wind- Steering Fluid or SAE 10W-30 or 10W-40 motor

ings in the event of an overheating condition. Electri- oil (through “Fill” screw hole).

cal current overload protection is provided to the

pump by a 110 amp fuse. Pump also is fitted with a NOTE: In tropical areas, single viscosity SAE 30 mo-

20 amp in-line fuse, which serves to protect the trim tor oil can be used.

control and harness from an overload.

Thermal Circuit Breaker

Operation

If the IN/DOWN or “Trailer” switch is kept depressed

after drive unit reaches its end of travel, a thermal

circuit breaker will open to prevent pump motor from

overheating and pump motor will stop. Release

switch(es) as soon as drive unit reaches end of

travel, to prevent this from happening. If circuit

breaker should open, allow motor to cool down and

circuit breaker will automatically reset.

Manual Release Valve

Operation

! WARNING

Before loosening manual release valve, make

sure all persons are clear of sterndrive unit.

50524

In case of a Power Trim system malfunction, the

sterndrive unit can be raised and lowered manually a - Fill Screw

by turning the manual release valve b - Vent Screw

c - Manual Release Valve

counterclockwise approximately 3 turns and moving

drive unit to desired position by hand. After drive unit

has been placed in the desired position, close valve 3. Raise and lower drive unit 6 to 10 times to purge

COMPLETELY. Power Trim system will not function any air from system; then, recheck oil level (with

properly, unless valve is completely closed. drive unit fully IN/DOWN) and add oil if

necessary.

5C-2 – PRESTOLITE POWER TRIM PUMP 90-12934--2 1097

Air Bleeding Power Trim Bleeding IN/DOWN Trim Circuit

System 1. Ensure pump reservoir is filled to proper level.

The power Trim System will purge itself of a small 2. Disconnect IN/DOWN hose from rear connection

amount of air by raising and lowering the drive unit on gimbal housing hydraulic connector. If both

several times. However, if a rebuilt trim cylinder is cylinders were rebuilt, disconnect hoses from

being installed (which has not been filled with oil), the both sides of hydraulic connector.

following bleeding procedure should be used to 3. Plug holes in hydraulic connector, using plug

remove the air from the system. (22-38609) or suitable device.

4. Direct end of trim hose(s) into container.

Bleeding OUT/UP Trim Circuit

5. Run trim pump in the UP direction until trim cylin-

1. Fill pump reservoir to proper level as explained ders are fully extended.

preceding. (Trim cylinder must be compressed).

6. Remove plug(s) from gimbal housing hydraulic

2. Disconnect OUT/UP hose from front connection connector and momentarily run trim pump in the

on trim cylinder. If both cylinders were rebuilt, dis- IN/DOWN direction until a solid, air-free stream

connect hoses from both cylinders. of fluid is expelled from rear hole(s) in hydraulic

3. Direct end of trim hose(s) into a container. connector. Reconnect trim hose(s) and tighten

securely.

4. Run trim pump in the UP direction until a solid, air-

free stream of fluid is expelled from hose(s). Re- 7. Lower drive unit to the full IN/DOWN position and

connect hose(s) and tighten securely. refill trim pump to proper level. Run trim system

IN/DOWN and OUT/UP several times and re-

5. Refill trim pump to proper level. check fluid level.

22089

22089 a - IN/DOWN Trim Hose

a - OUT/UP Trim Hose b - Hydraulic Connector

b - Front Connection on Trim Cylinder c - Plug (22-38609)

90-12934--2 1097 PRESTOLITE POWER TRIM PUMP - 5C-3

Testing Power Trim Pump

Connecting Test Gauge

1. Check trim pump oil level. Fill if necessary.

2. Place drive unit in the full IN/DOWN position.

3. Connect test gauge at the most convenient loca-

tion (at pump or hydraulic connector).

22090

Gauge Connect to Hydraulic Connector

c - Caps

d - Plugs

26344

Gauge Connected at Pump 4. Open Valve “A” and “B” and run pump UP and

a - Hydraulic Test Gauge 91-52915A6 DOWN several times (to purge air).

b - Extension Hoses 91-52915A6

c - Fittings 22-77366

NOTE: Extension hoses MUST BE used to obtain ac-

curate readings.

22126

a - Hydraulic Test Gauge (91-52915A6)

b - Gimbal Housing Hydraulic Connector

5C-4 – PRESTOLITE POWER TRIM PUMP 90-12934--2 1097

Internal Restriction Test Trim Cylinder Internal Leak

1. Open valve “A” and “B.” Test

2. Run pump OUT/UP and IN/DOWN while observ- IMPORTANT: The following test assumes that

ing gauge. pump OUT/UP pressure is within specifications

3. Replace adapter, if pressure is in excess of 200 as determined by performing “Power Trim Pump

psi (1379 kPa). Test.”

1. Reconnect trim cylinder hoses (if removed in

OUT/UP Pressure Test previous test) as follows:

1. Leave Valve “A” open and close Valve “B.” a. Remove plugs and caps.

2. Run pump OUT/UP while observing gauge. b. Install UP hose to forward hole on hydraulic

Reading should be 2200 - 2600 psi (15173 - connector. Tighten securely.

17932 kPa). If not, replace valve body and gear c. Install DOWN hose to aft hole on hydraulic

assembly. connector. Tighten securely.

3. Stop pumping OUT/UP. Pressure should not fall

below 1900 psi (13104 kPa). If it does, check for

and/or replace following:

• External oil leaks

• Valve Body and Gear Assembly

IN/DOWN Pressure Test

1. Close Valve “A” and open Valve “B.”

2. Run pump IN/DOWN while observing gauge.

Reading should be 400 - 600 psi (2759 - 4138 kPa).

If not, replace valve body and gear assembly.

22090

3. Stop pumping IN/DOWN. Pressure should not

a - UP Hose

fall below 350 psi (2410 kPa). If it does, check for b - DOWN Hose

and/or replace the following: c - Hydraulic Connector

• External oil leaks

• Valve Body and Gear Assembly

90-12934--2 1097 PRESTOLITE POWER TRIM PUMP - 5C-5

2. Connect gauge at most convenient location. 3. Open Valve “A”and “B” and run pump OUT/UP

and IN/DOWN; several times (to purge air).

4. Run pump OUT/UP until trim cylinders are fully

extended; then, observe gauge while pumping.

Pressure should be 2200 - 2600 psi (15173 -

17932 kPa).

5. Stop pumping OUT/UP. Pressure should not fall

below 1900 psi (13104 kPa).

If readings are not within specifications, an in-

ternal trim cylinder leak is indicated. Use the fol-

lowing procedure to locate faulty cylinder.

a. If gauge is connected at pump, reconnect

gauge at gimbal housing hydraulic connec-

tor. Repeat Step 2; then, run pump in OUT/

UP direction until trim cylinder are fully ex-

tended.

b. Close Valve “B” on test gauge and repeat

Steps 3 and 4.

If Readings Are Now Within Specifications: Trim

26345 cylinder on the same side that test gauge is con-

nected, is faulty.

Gauge Connected at Pump

If Readings Are Still Not Within Specifications:

a - Hydraulic Test Gauge 91-52915A3

b - Fitting (22-77366)

Trim cylinder on the opposite side from where the test

c - Fittings (Supplied with Gauge) gauge is connected, is faulty.

d - Black Hydraulic Hose (From Gimbal Housing)

e - Gray Hydraulic Hose (From Gimbal Housing)

22126

Gauge Connected to Hydraulic Connector

a - Test Gauge

b - Coupling (Supplied with Gauge)

c - Front Hydraulic Connector Port

5C-6 – PRESTOLITE POWER TRIM PUMP 90-12934--2 1097

Trim Cylinder Shock Piston Motor and Electrical Bench

Test Tests

If trim system checks out good, but drive unit will not

trim IN/DOWN, problem may be due to a leaky trim Trim Pump Motor Test (In Boat)

cylinder shock piston. Use the following test to check

for this condition. Test gauge is not required. ! WARNING

1. Run pump in OUT/UP direction until trim cylin- DO NOT perform this test near fIammables (or ex-

ders are fully extended. plosives), as a spark may occur when making

2. Prevent trim cylinder piston rods from retracting, connections.

using a suitable device. Quicksilver Trailering Kit

works well for this purpose. ! WARNING

RemaIn clear of drive unit when performing pow-

er trim pump motor tests with pump in the boat

and hydraulic hoses connected.

1. OUT/UP Operation:

a. Connect a jumper wire between positive (+)

solenoid terminal and BLUE/WHITE motor

lead terminal.

b. Motor should run.

22562

a - Trailering Clip

3. Disconnect UP trim hose from trim cylinders.

50523

a - OUT/UP Solenoid

b - POSITIVE Terminal (+)

c - BLUE/WHITE Motor Lead Terminal

d - Jumper Wire

22089

a - UP Trim Hose

b - Front Connection

4. Run pump in IN/DOWN direction. If oil flows from

UP port on trim cylinder, shock piston is leaking

and must be replaced.

90-12934--2 1097 PRESTOLITE POWER TRIM PUMP - 5C-7

2. IN/DOWN Operation: 3. OUT/UP Operation:

a. Connect a jumper wire between positive (+) a. Connect a 12 volt positive (+) supply lead to

solenoid terminal and GREEN/WHITE motor BLUE/WHITE motor lead terminal.

lead terminal.

b. Connect the negative (-) supply lead to a

b. Motor should run. good ground on pump.

c. Motor should run.

50523

a - IN/DOWN Solenoid

b - POSITIVE Terminal (+) 50523

c - GREEN/WHITE Motor Lead Terminal a - OUT/UP Solenoid

d - Jumper Wire b - 12 Volt POSITIVE (+) Supply Lead

c - NEGATIVE (-) Supply Lead

3. If motor does not run, refer to “Motor Repair.” See

Table of Contents.

Trim Pump Motor Test (Out of Boat)

! WARNING

DO NOT perform this test near flammables (or ex-

plosives), as a spark may occur when making

connections.

1. Remove trim pump from boat. Refer to “Trim

Pump Removal.” See Table of Contents.

2. Remove fluid from trim pump reservoir.

5C-8 – PRESTOLITE POWER TRIM PUMP 90-12934--2 1097

4. IN/DOWN Operation: Solenoid Test (Pump in Boat)

a. Connect a 12 volt positive (+) supply lead to

GREEN/WHITE motor lead terminal. ! WARNING

b. Connect the negative (-) supply lead to a DO NOT perform this test near flammables (or ex-

good ground on pump. plosives), as a spark may occur when making

c. Motor should run. connections.

! CAUTION

Remain clear of drive unit when performing pow-

er trim pump motor tests with pump in boat and

hydraulic hose connected.

1. UP/OUT Solenoid:

a. Connect jumper wire between positive (+) so-

lenoid terminal and BLUE/WHITE harness

wire terminal.

b. Motor should run.

50524

a - IN/DOWN Solenoid

b - 12 Volt POSITIVE (+) Supply Lead

c - NEGATIVE (-) Supply Lead

NOTE: If motor does not run, refer to “Motor Repair.”

50521

a - OUT/UP Solenoid

b - Positive (+) Terminal

c - BLUE/WHITE Harness Wire Terminal

d - Jumper Wire

90-12934--2 1097 PRESTOLITE POWER TRIM PUMP - 5C-9

2. IN/DOWN Solenoid: Solenoid Test (Pump Out of Boat)

a. Connect a jumper wire between positive (+)

solenoid terminal and GREEN/WHITE har- ! WARNING

ness wire terminal.

DO NOT perform this test near flammables (or ex-

b. Motor should run. plosives), as a spark may occur when making

connections.

1. Remove trim pump from boat. Refer to “Trim

Pump Removal.” See Table of Contents.

2. Remove fluid from trim pump reservoir.

3. OUT/UP Solenoid:

a. Connect 12 volt positive (+) supply lead to

BLUE/WHITE harness wire terminal.

b. Connect negative (-) supply lead to solenoid

ground terminal.

c. Connect ohmmeter leads to large terminals

on solenoid.

50521

a - IN/DOWN Solenoid

b - Positive (+) Terminal

c - GREEN/WHITE Harness Wire Terminal

d - Jumper Wire

3. If motor does not run in one direction or another,

replace appropriate solenoid. (See Wiring Dia-

gram at end of this section for wire connection

points).

50521

a - OUT/UP Solenoid

b - 12 Volt Positive (+) Supply Lead

c - Negative (-) Supply Lead

d - Ohmmeter Leads

4. Zero Ohms Reading (Full Continuity): Sole-

noid is OK.

High Ohms Reading (No Continuity): Replace

solenoid.

5C-10 – PRESTOLITE POWER TRIM PUMP 90-12934--2 1097

5. IN/DOWN Solenoid: 2. Check for voltage at terminal “2,” using volt me-

ter.

a. Connect 12 volt positive (+) supply lead to

GREEN/WHITE harness wire terminal. Voltage Indicated: Fuse OK.

Voltage Not Indicated: Replace fuse.

b. Connect negative (-) supply lead to solenoid

ground terminal.

c. Connect ohmmeter leads to large terminals

on solenoid.

50523

a - Volt Meter Negative (-) Lead

b - Volt Meter Positive (+) Lead

50521 c - Fuse

a - IN/DOWN Solenoid

b - 12 Volt Positive (+) Supply Lead

c - Negative (-) Supply Lead

d - Ohmmeter Leads

6. Zero Ohms Reading (Full Continuity): Sole-

noid is OK.

High Ohms Reading (No Continuity): Replace

solenoid.

See Wiring Diagram at the end of this section for wir-

ing connection points.

110 Amp Fuse Test (Pump in Boat)

! WARNING

DO NOT perform this test near flammables (or ex-

plosives), as a spark may occur when making

connections.

50524

1. Check for voltage at terminal “1” using a volt me-

a - Volt Meter Negative (-) Lead

ter. Voltage MUST BE indicated before proceed-

b - Volt Meter Positive (+) Lead

ing with next check. c - Fuse

90-12934--2 1097 PRESTOLITE POWER TRIM PUMP - 5C-11

110 Amp Fuse Test (Pump Out of 20 Amp Fuse Test

Boat) 1. Remove fuse from fuse holder.

1. Connect ohmmeter leads between terminals on

fuse.

ZEro Ohms Reading (Full Continuity): Fuse OK

HIGH OHMS READING (No Continuity): Replace

fuse

50521

a - Fuse Holder

2. Connect ohmmeter; one lead to each end of fuse.

50524

Zero Ohms Reading (Full Continuity): Fuse

a - 110 Amp Fuse

OK.

b - Ohmmeter Leads

HIGH OHMS READING (No Continuity):

Replace fuse.

22497

a - 20 Amp Fuse

b - Ohmmeter Leads

5C-12 – PRESTOLITE POWER TRIM PUMP 90-12934--2 1097

Trim Pump Removal Hydraulic Repair

1. Disconnect trim pump battery leads from battery

(negative lead first). Manual Release Valve Replacement

2. Disconnect trim harness connector (3 pronged) NOTE: Replacement of manual release valve can be

from trim pump. completed without removing the trim pump from

boat.

3. Remove hydraulic hoses from trim pump. Cap

end of hoses.

! WARNING

4. Remove lag bolts and washers, and lift pump and

floor bracket from boat. Before loosening the manual release valve, make

sure all people are clear of drive unit as drive unit

will drop to full IN/DOWN position when valve is

loosened.

Slowly turn manual release valve counterclockwise

to remove. To install new valve, turn valve clockwise

until it seats.

50461

a - O-ring

b - Rubber Seal

Disassembly

! CAUTION

50524 Work area must be dirt and lint free. The slightest

a - Positive Battery Lead amount of dirt in hydraulic system can cause

b - Negative Battery Lead pump malfunction.

c - Harness Connector

d - Black Hydraulic Hose (UP Hose) 1. Disconnect trim motor wires.

e - Gray Hydraulic Hose (DOWN Hose)

50520

a - BLUE/WHITE Motor Wire

b - GREEN/WHITE Motor Wire

c - BLACK Ground Wires

90-12934--2 1097 PRESTOLITE POWER TRIM PUMP - 5C-13

2. Remove mounting bolts and remove trim pump Valve Body and Gear Assembly

from floor bracket.

1. Place pump in a container to catch oil when valve

body and gear assembly is removed.

2. Remove valve body, gear assembly and seal.

50522

50460

a - Screws (8)

b - Valve Body And Gear Assembly

50522

a - Trim Pump

b - Floor Bracket

c - Mounting Bolts

3. Remove solenoids (if replacement is necessary).

50520

c - Seal

50520

a - UP Solenoid

b - DOWN Solenoid

c - Mounting Bolts (2 On Each Solenoid)

5C-14 – PRESTOLITE POWER TRIM PUMP 90-12934--2 1097

3. Install new seal in reservoir. 5. Install valve body and gear assembly.

50520

a - Seal

4. Align motor shaft with gear assembly. 50460

a - Screws (8)

b - Valve Body And Gear Assembly

c - New Seal (Not Seen)

Motor Repair

Disassembly

1. Disconnect trim pump motor leads.

50522

a - Motor Shaft

b - Gear Assembly

50459

a - Trim Pump Motor Leads

b - Solenoids

90-12934--2 1097 PRESTOLITE POWER TRIM PUMP - 5C-15

2. Remove solenoid plate and connector and 4. Remove motor assembly.

harness.

50459

a - Solenoid Plate

b - Nut

c - Screws

d - Solenoids

e - Spacer

f - Connector and Harness

26506

3. Remove valve body and gear assembly. a - Nut And Washer (2)

b - End Plate Assembly

c - Field and Frame Assembly

d - Armature

e - Small Thrust Washer(s)

f - Large Thrust Washer

g - Spacer (1)

h - Studs (2)

i - Reservoir

50460

a - Screws (8)

b - Valve Body And Gear Assembly

c - Seal (Not Seen)

5C-16 – PRESTOLITE POWER TRIM PUMP 90-12934--2 1097

Armature Tests 1. Clean commutator with “00” garnet grit sandpa-

per. DO NOT use emery paper.

CONTINUITY TEST 2. Check gaps between commutator bars for mate-

rial. Remove material if present.

1. Check armature for continuity. Set ohmmeter on

Rx1 scale. Connect leads as shown.

Continuity Indicated: Armature is grounded (re-

place armature).

Continuity Not Indicated: Armature is OK.

50520

a - Commutator

b - Gap

50461

Field Test

a - Ohmmeter

b - Meter Lead - Place On Armature Shaft TEST FOR OPEN CIRCUIT

c - Meter Lead - Place On All Commutator Bars (One At A Time)

1. Set ohmmeter to Rx1 scale and connect meter

TEST FOR SHORTS leads between field leads.

Zero Ohms Indicated (Full Continuity): Field OK.

1. Check armature on a growler (follow growler

manufacturers instructions). Indication of a short Zero Ohms Not Indicated (No Continuity):

requires replacement. Replace field assembly.

CLEANING COMMUTATOR

NOTE: If commutator is worn it can be turned down

on a lathe or an armature conditioner tool.

50461

a - Ohmmeter

b - Meter Leads - Connect Between Field Leads

c - Field Leads

90-12934--2 1097 PRESTOLITE POWER TRIM PUMP - 5C-17

TEST FOR SHORT IN FIELD Brush Lead Tests

1. Set ohmmeter on Rx1 scale. Connect ohmmeter

1. Set ohmmeter on Rx1 scale. Connect leads as

between field brush lead and field frame.

shown. Test positive brush lead for ground.

Zero Ohms Indicated (full continuity) - Short

Continuity Indicated: Grounded condition; replace

indicated (Replace field assembly).

end plate assembly.

Zero Ohms Not Indicated (no continuity) - Field OK.

No continuity: Brush lead OK.

50461

a - Ohmmeter

b - Meter Lead - Place On Positive Brush Holder Lead 50460

c - Meter Lead - Place On Frame

a - Ohmmeter

d - Field Lead

b - Meter Lead - Place On Positive Brush Lead

c - Meter Lead - Place On End Cap

Thermal Switch Test

2. Set ohmmeter on rx1 scale. Connect leads as

CONTINUITY TEST shown. Test negative brush lead for an open

condition.

1. Test thermal circuit breaker for continuity, using

ohmmeter set on Rx1 scale. Continuity Indicated: Brush lead OK.

Zero Ohms Indicated (Full Continuity): Thermal Continuity NOT Indicated: Inspect lead for a poor

switch OK. connection.

Zero Ohms Not Indicated (No Continuity):

Replace thermal switch.

26507

a - Place Meter Lead At This Point 50460

b - Place Meter Lead At Ground a - Ohmmeter

b - Meter Lead - Place On Negative Brush Lead

c - Meter Lead - Place On End Cap

d - Positive Brush Lead

5C-18 – PRESTOLITE POWER TRIM PUMP 90-12934--2 1097

Brush Replacement END CAP AND BRUSH ASSEMBLY

REPLACEMENT

Inspect brushes and replace if:

1. Cut off field to positive brush holder lead as close

• Pitted to brush holder as possible.

• Chipped 2. Using 70-30 tin-lead alloy rosin core solder,

solder field lead to brush holder on new end cap.

• Brush is less than 1/4 in. (6mm) long

• Leads are fraying

BRUSH REPLACEMENT

1. Cut brush leads off as close to brush holders as

possible.

2. Using 70-30 tin-lead alloy rosin core solder, sol-

der new brushes to brush holders.

50459

a - Field Lead

b - Positive Brush Holder

c - End Cap

26507

a - Brush Leads

b - Brush Holders

90-12934--2 1097 PRESTOLITE POWER TRIM PUMP - 5C-19

Reassembly NOTE: Brush holder tool can be made as shown.

1. Install armature and washers.

26507

3. Spread brushes with brush holder tool and install

end plate over armature. Secure end cap with

nuts and washers.

26506

a - Large Washer

b - Small Washer(s)

c - Armature

d - Reservoir

e - Long Stud

f - Sleeve (1)

g - Small Stud 26507

h - Connector And Harness Holder

2. Install field and frame assembly. Align index mark

a - End Plate

on field and frame assembly with mark on

reservoir.

4. Ensure seal is in place in reservoir.

50459

50520

a - Index Marks - Align a - Seal

b - Field And Frame Assembly

c - Reservoir

5C-20 – PRESTOLITE POWER TRIM PUMP 90-12934--2 1097

5. Align motor shaft with gear assembly. 7. Install solenoid plate and connector and harness.

50459

a - Solenoid Plate

b - Nut

c - Screws

50522 d - Solenoids

a - Motor Shaft e - Spacer

b - Gear Assembly f - Connector And Harness

6. Install valve body and gear assembly. 8. Secure trim pump motor leads to solenoids.

50460

a - Screws (8)

b - Valve Body and Gear Assembly 50459

c - New Seal (Not Seen) a - Blue Lead - Connect to OUT/UP Solenoid

b - Green Lead - Connect to IN/DOWN Solenoid

c - OUT/UP Solenoid

d - IN/DOWN Solenoid

90-12934--2 1097 PRESTOLITE POWER TRIM PUMP - 5C-21

9. Install trim pump on floor bracket. Tighten Trim Pump Installation

securely.

1. Secure pump and mounting bracket to boat using

lag bolts and washers.

2. Reconnect trim hoses to pump. Black hose to left

connection; gray hose to right connection. DO

NOT cross-thread or overtighten hose fittings.

Torque to 70 - 150 lb. in. (7.9 - 16.9 NSm).

3. Reconnect trim harness connector to trim pump.

4. Reconnect battery leads to battery.

50522

5. Check fluid level and fill if necessary. (Refer to

“Maintaining Power Trim Pump Oil Level” in this

section.)

50522

a - Trim Pump

b - Floor Bracket

c - Screws and Lock Washers

50524

a - Positive Battery Lead

b - Negative Battery Lead

c - Harness Connector

d - Black Hydraulic Hose (UP Hose)

e - Gray Hydraulic Hose (DOWN Hose)

5C-22 – PRESTOLITE POWER TRIM PUMP 90-12934--2 1097

Wiring Diagram

26347

90-12934--2 1097 PRESTOLITE POWER TRIM PUMP - 5C-23

THIS PAGE IS INTENTIONALLY BLANK

5C-24 – PRESTOLITE POWER TRIM PUMP 90-12934--2 1097

You might also like

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Embassy Cruising Guides: Long Island Sound to Cape May, NJ, 19th EditionFrom EverandEmbassy Cruising Guides: Long Island Sound to Cape May, NJ, 19th EditionNo ratings yet

- Merc Service Manual 6 4bDocument40 pagesMerc Service Manual 6 4bHayduke them100% (4)

- Merc Service Manual 6 6bDocument8 pagesMerc Service Manual 6 6bHayduke themNo ratings yet

- 7 MercruiserSpecialToolsDocument64 pages7 MercruiserSpecialToolsFania Kioek100% (1)

- Alpha Transom Assembly & ServiceDocument73 pagesAlpha Transom Assembly & ServiceDave Lamers100% (1)

- Smartcraft System Tachometer and Speedometer Installation: Thank YouDocument6 pagesSmartcraft System Tachometer and Speedometer Installation: Thank YouthesaneroneNo ratings yet

- QS Prop GuideDocument112 pagesQS Prop GuideRoberto ImplatiniNo ratings yet

- Alarmes SmartcraftDocument52 pagesAlarmes SmartcraftEdgar PinheiroNo ratings yet

- Mercruiser ScantoolDocument72 pagesMercruiser Scantoolsalvatore dalessandroNo ratings yet

- Mercruiser 525 EfiDocument126 pagesMercruiser 525 EfiNicky Jans100% (1)

- Merc Service Manual 6 7aDocument18 pagesMerc Service Manual 6 7aHayduke them100% (2)

- Mercury Outboard by HP and Year Drrive Parts BreakdownDocument12 pagesMercury Outboard by HP and Year Drrive Parts Breakdownwguenon100% (2)

- Analog Gauge Connections For Digital Optimax ModelsDocument6 pagesAnalog Gauge Connections For Digital Optimax ModelsGet SmartCraft100% (1)

- Bravo3 MaintenanceDocument42 pagesBravo3 Maintenancerbarlow320No ratings yet

- Mercury Commander Side Mount ControlDocument18 pagesMercury Commander Side Mount ControlTab Sedgwick100% (1)

- Service Manual OutlineDocument20 pagesService Manual OutlineJorge LopesNo ratings yet

- Alpha One Generation II Stern DriveDocument37 pagesAlpha One Generation II Stern DriveAndrea Ignacia Ibieta100% (1)

- Quicksilver ManualDocument134 pagesQuicksilver ManualthesaneroneNo ratings yet

- Mercury Gear Case ComponentsDocument43 pagesMercury Gear Case Componentswguenon100% (1)

- Volvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi Sez.8-9Document35 pagesVolvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi Sez.8-9Luciano LiuzziNo ratings yet

- Trimm PDFDocument2 pagesTrimm PDFmarujopeNo ratings yet

- Mercury Outboard Cooling System PartsDocument11 pagesMercury Outboard Cooling System Partswguenon50% (2)

- Mercury Bulletin Fuel ModuleDocument3 pagesMercury Bulletin Fuel ModulejimniiiNo ratings yet

- Mercruiser GearcasecomponentsDocument42 pagesMercruiser GearcasecomponentswguenonNo ratings yet

- MercjetDocument30 pagesMercjetBaxter LoachNo ratings yet

- SC1000 and Smart Tow ManualDocument37 pagesSC1000 and Smart Tow ManualJerry WoodsNo ratings yet

- Mercruiser Sterndrive Drive Shaft Housing Components Exploded View Diagram and PartsDocument8 pagesMercruiser Sterndrive Drive Shaft Housing Components Exploded View Diagram and PartsGerardo Espinola Cardozo100% (1)

- Mercury MerCruiser Bravo Three 7.4L Operation and Maintenance Manual (PDF, EnG, 1 MB)Document134 pagesMercury MerCruiser Bravo Three 7.4L Operation and Maintenance Manual (PDF, EnG, 1 MB)Carl HerveyNo ratings yet

- Merc Gas EnginesDocument181 pagesMerc Gas EnginesyamyrulesNo ratings yet

- ALPHA ONE Gen.2Document43 pagesALPHA ONE Gen.2Andrea Nakicenovic100% (1)

- Outboard Model Code Reference ChartDocument2 pagesOutboard Model Code Reference Chartherbpatterson100% (1)

- Electrical and Ignition: Battery, Charging and Starting SystemDocument15 pagesElectrical and Ignition: Battery, Charging and Starting SystemBaxter LoachNo ratings yet

- 290 Sundancer Smart Craft ManualDocument33 pages290 Sundancer Smart Craft ManualMitch Williams100% (1)

- 74436GDocument454 pages74436Gnosuvito100% (1)

- InboardDriveSystem PDFDocument35 pagesInboardDriveSystem PDFmarujope100% (1)

- Typical Mercury Ignition SystemsDocument11 pagesTypical Mercury Ignition SystemswguenonNo ratings yet

- 31 GM SBC 2001Document1,096 pages31 GM SBC 2001The Boat DocturNo ratings yet

- Velvet Drive Liberty 5000 Series Owners ManualDocument12 pagesVelvet Drive Liberty 5000 Series Owners ManualPaul MartinNo ratings yet

- Mercarb RepairDocument29 pagesMercarb RepairSteven Walker100% (5)

- Merc Thunderbolt IV and V Ignition FlowchartDocument3 pagesMerc Thunderbolt IV and V Ignition Flowchartpat obrienNo ratings yet

- Number 6: Sterndrive Units R MR Alpha One Alpha One SSDocument7 pagesNumber 6: Sterndrive Units R MR Alpha One Alpha One SSmarujopeNo ratings yet

- MerCruiser CatalogDocument220 pagesMerCruiser CatalogstratoschaNo ratings yet

- Mercruiser AnodesDocument41 pagesMercruiser AnodesMarine Parts ChinaNo ratings yet

- Mercury Outboard by HP and Year Electrical BreakdownDocument7 pagesMercury Outboard by HP and Year Electrical Breakdownwguenon100% (1)

- 3-7L MerCruiser All Service BulletinsDocument83 pages3-7L MerCruiser All Service BulletinsGerrit DekkerNo ratings yet

- GM Block Codes 1Document16 pagesGM Block Codes 1Ionel RusuNo ratings yet

- MERCRUISER Povorotno Otkidnye Kolonki Trantsevaya Sborka Gidravlicheskaya Sistema Servisnaya InformatsiyaDocument26 pagesMERCRUISER Povorotno Otkidnye Kolonki Trantsevaya Sborka Gidravlicheskaya Sistema Servisnaya InformatsiyaViktor100% (2)

- Mercruiser Installation and AdjustmentDocument66 pagesMercruiser Installation and Adjustmentsalvatore dalessandro100% (1)

- MerCruiser Cooling SystemDocument24 pagesMerCruiser Cooling SystemJohn100% (1)

- 10-Pin Blue Data Cable RiggingDocument6 pages10-Pin Blue Data Cable RiggingajcapetillogNo ratings yet

- Lit 18626 06 75 - 1369Document90 pagesLit 18626 06 75 - 1369andysuomi100% (1)

- Assistant Automotive Shop Supervisor: Passbooks Study GuideFrom EverandAssistant Automotive Shop Supervisor: Passbooks Study GuideNo ratings yet

- Powerboater's Guide to Electrical Systems, Second EditionFrom EverandPowerboater's Guide to Electrical Systems, Second EditionRating: 5 out of 5 stars5/5 (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- Your First Powerboat: How to Find, Buy, and Enjoy the Best Boat for YouFrom EverandYour First Powerboat: How to Find, Buy, and Enjoy the Best Boat for YouNo ratings yet

- Merc Service Manual 33 Big Block DiagnosticsDocument89 pagesMerc Service Manual 33 Big Block DiagnosticsHayduke them80% (10)

- Merc Service Manual 30Document355 pagesMerc Service Manual 30Hayduke them100% (6)

- Merc Service Manual 36 Ecm DiagnosticsDocument137 pagesMerc Service Manual 36 Ecm DiagnosticsHayduke them91% (22)

- Merc Service Manual 28 Bravo Stern DrivesDocument596 pagesMerc Service Manual 28 Bravo Stern DrivesHayduke them88% (17)

- Mercruiser Service Manual - 31 2001 - Newer GM Small Block V8Document636 pagesMercruiser Service Manual - 31 2001 - Newer GM Small Block V8Des Stirling100% (6)

- Mercruiser Service Manual GM V6 4.3 CompleteDocument895 pagesMercruiser Service Manual GM V6 4.3 CompletePaul Chuon94% (16)

- Mercruiser Service Manual - 25 GM V6 1998 - 2001Document225 pagesMercruiser Service Manual - 25 GM V6 1998 - 2001an82mustang100% (3)

- Merc Service Manual 23 454 502 EnginesDocument1,027 pagesMerc Service Manual 23 454 502 EnginesHayduke them91% (11)

- Merc Service Manual 24 Supplement 6.2lDocument211 pagesMerc Service Manual 24 Supplement 6.2lHayduke them83% (12)

- Service Manual 6Document7 pagesService Manual 6wampie74No ratings yet

- Mercruiser 4 Cyl 3.0 Service ManualDocument422 pagesMercruiser 4 Cyl 3.0 Service Manualserviceguys82% (100)

- Merc Service Manual 17 305 350 EnginesDocument6 pagesMerc Service Manual 17 305 350 EnginesHayduke them100% (1)

- Mercruiser Manual GM 4 CylinderDocument348 pagesMercruiser Manual GM 4 Cylindertalleyp69% (35)

- Mercruiser Service Manual #14 Alpha I Gen II Outdrives 1991-NewerDocument715 pagesMercruiser Service Manual #14 Alpha I Gen II Outdrives 1991-NewerM5Melo100% (10)

- Merc Service Manual 18 4.3 EnginesDocument638 pagesMerc Service Manual 18 4.3 EnginesHayduke them88% (26)

- Mercruiser Manual GM 4 CylinderDocument348 pagesMercruiser Manual GM 4 Cylindertalleyp69% (35)

- Mercruiser Service Manual #14 Alpha I Gen II Outdrives 1991-NewerDocument715 pagesMercruiser Service Manual #14 Alpha I Gen II Outdrives 1991-NewerM5Melo100% (10)

- Merc Service Manual 11 Bravo Stern DrivesDocument596 pagesMerc Service Manual 11 Bravo Stern DrivesHayduke them92% (13)

- Merc Service Manual 11 Bravo Stern DrivesDocument596 pagesMerc Service Manual 11 Bravo Stern DrivesHayduke them92% (13)

- 7.4L 454 Mercruiser ManualDocument930 pages7.4L 454 Mercruiser ManualDaniel Marko81% (43)

- Service Manual 6Document7 pagesService Manual 6wampie74No ratings yet

- Merc Service Manual 6 7aDocument18 pagesMerc Service Manual 6 7aHayduke them100% (2)

- 7.4L 454 Mercruiser ManualDocument930 pages7.4L 454 Mercruiser ManualDaniel Marko81% (43)

- Sterndrive Unit: Drive Shaft HousingDocument36 pagesSterndrive Unit: Drive Shaft HousingAlister CaraNo ratings yet

- Sterndrive Unit: Gear Housings Mr/Alpha One/Alpha One SsDocument56 pagesSterndrive Unit: Gear Housings Mr/Alpha One/Alpha One SsdarrylloachNo ratings yet

- 7.4L 454 Mercruiser ManualDocument930 pages7.4L 454 Mercruiser ManualDaniel Marko81% (43)

- Mercruiser Service Manual 6-1b - MaintenanceDocument18 pagesMercruiser Service Manual 6-1b - Maintenancejimandmelissa2No ratings yet

- DPV10-10B 4kwDocument4 pagesDPV10-10B 4kwNovak OtaševićNo ratings yet

- 45e PPB 246Document16 pages45e PPB 246HOMERO NOGUEDANo ratings yet

- Alternator E1C10M L: Technical Data SheetDocument6 pagesAlternator E1C10M L: Technical Data SheetBaraNo ratings yet

- Accessory 84E: User ManualDocument158 pagesAccessory 84E: User Manualjimmy146No ratings yet

- Genset Startup and Commissioning Checklist C 175Document13 pagesGenset Startup and Commissioning Checklist C 175Dwi Mulyanti DwimulyantishopNo ratings yet

- Public Super Shot BayTek Service ManualDocument67 pagesPublic Super Shot BayTek Service ManualEdward JANo ratings yet

- 10+Cruise+Control+System Toyota Rav4Document75 pages10+Cruise+Control+System Toyota Rav4marranNo ratings yet

- VSX 417 KDocument90 pagesVSX 417 KИгорьNo ratings yet

- Ni-Cad General Options (Pocket, Fibre & VRPP) PDFDocument3 pagesNi-Cad General Options (Pocket, Fibre & VRPP) PDFogautierNo ratings yet

- Basic Electrical CourseDocument46 pagesBasic Electrical CourseJuarezGeronimoNo ratings yet

- BT100 User Manual PDFDocument56 pagesBT100 User Manual PDFfurqan zafarNo ratings yet

- Service Manual: iPF750 SeriesDocument245 pagesService Manual: iPF750 SeriesErnesto De la TorreNo ratings yet

- 2019 - BARUNS-20190927-052010-Introduction of JS205 A-C System Machine - English (United Kingdom)Document3 pages2019 - BARUNS-20190927-052010-Introduction of JS205 A-C System Machine - English (United Kingdom)therak pechNo ratings yet

- Activity4 ChanDocument25 pagesActivity4 Chanian jasper nathanNo ratings yet

- Computer Organization and Architecture 10th Edition Stallings Solutions ManualDocument32 pagesComputer Organization and Architecture 10th Edition Stallings Solutions Manualmitchellunderwooda4p4d100% (14)

- Rooftop Arh 022 BBDocument5 pagesRooftop Arh 022 BBrmimo1993No ratings yet

- Determination of XD and XQ Using Slip TestDocument4 pagesDetermination of XD and XQ Using Slip TestQwertyNo ratings yet

- 303-01 - 2.3L EcoBoost - Installation - EngineDocument33 pages303-01 - 2.3L EcoBoost - Installation - EngineCARLOS LIMADANo ratings yet

- Product - Catalogue - Mini - Polon AlfaDocument19 pagesProduct - Catalogue - Mini - Polon AlfaGina VNo ratings yet

- Philips SW3660 Service ID4069Document14 pagesPhilips SW3660 Service ID4069sony reseNo ratings yet

- DC SwitchgearDocument10 pagesDC SwitchgearpjchauhanNo ratings yet

- LG Www. Radioradar - NetDocument11 pagesLG Www. Radioradar - Netnidzat0% (1)

- M-057 M-E & A-E F.O. Booster UnitDocument254 pagesM-057 M-E & A-E F.O. Booster UnitВасиль Гудзь100% (1)

- Saudi Aramco Typical Inspection PlanDocument3 pagesSaudi Aramco Typical Inspection PlanOmer aliNo ratings yet

- TF500 GD PDFDocument2 pagesTF500 GD PDFeurospeed2No ratings yet

- Vehicle Transportation Aids and Vehicle Storage: ActivityDocument2 pagesVehicle Transportation Aids and Vehicle Storage: Activityaiman dotsawalNo ratings yet

- TR10RS1 User Manual WindowsDocument14 pagesTR10RS1 User Manual WindowsMarquez JuanNo ratings yet

- Yale g807 Erp18vt Lift Truck (Europe) Service Repair ManualDocument32 pagesYale g807 Erp18vt Lift Truck (Europe) Service Repair ManualSARAMQR50% (2)

- Elevator Control Module: User'SDocument19 pagesElevator Control Module: User'SJitheshbabu Babu100% (5)

- High Performance, General-Purpose, PID Control TK SeriesDocument24 pagesHigh Performance, General-Purpose, PID Control TK SeriesPasindu PriyankaraNo ratings yet