Professional Documents

Culture Documents

Defining Multilateral Wells

Uploaded by

Nhat CaoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Defining Multilateral Wells

Uploaded by

Nhat CaoCopyright:

Available Formats

THE DEFINING SERIES

Multilateral Wells Level 1 Level 2 Level 3

Rick von Flatern

Senior Editor

In the mid-1990s, multilateral wells proliferated worldwide as innovative

drilling and completion technologies made construction of laterals less

costly and less technically challenging. Multilateral (ML) wells comprise

more than one wellbore drilled from and connected to a single main bore. In

certain reservoirs, operators can leverage this approach to improve reser-

voir production by accessing numerous production zones or by increasing

the contact area between a wellbore and a formation with minimal increase Level 4 Level 5 Level 6

in drilling and completion costs. These techniques also reduce the environ-

mental footprint of drilling rigs and subsequent production trees, particu-

larly for land operations.

Multilateral ConfigurationsTAML Levels

Operators have used rudimentary ML wells since the 1950s. However, by

1997, they were applying the strategy in an expanding variety of configura-

tions, inspiring an industry group of operators and service companies to

form a consortiumTechnology Advancement of Multilaterals (TAML)to

develop a classification system for ML wells. The consortium chose to cate-

gorize the wells according to the type of junction used to join the main bore

to the lateral, and produced standards that were designated TAML Levels1

Figure 1. Multilateral wells are characterized according to definitions

through 6. The ascending order of these levels reflects increasing mechani-

established in 1997 during the Technology Advancement of Multilaterals

cal and pressure capability of the junction (Figure 1). As a consequence, (TAML) Forum held in Aberdeen. These standards classify junctions as

cost, complexity and risk also increase at the higher TAML levels. TAML Level 1, 2, 3, 4, 5 or 6 based on mechanical complexity, connectivity

The main bore, lateral and junction of a TAML Level 1 well are uncased. and hydraulic isolation.

This basic lateral is designed to enhance reservoir drainage from

consolidated formations. It has the advantage of low drilling and completion However, because the cement can only withstand limited differential pres-

costs, but the openhole junction makes reentry into the lateral wellbore and sure, the junction does not provide hydraulic isolation.

control of flow from the lateral impossible. TAML Level 5 wells do provide hydraulic isolation at the junction

Wells that have cased and cemented main bores and openhole laterals because pressure integrity is provided by the completion, which includes

are designated TAML Level 2. A cemented main bore significantly reduces production tubing connecting a packer in the main wellbore above the junc-

the risk of wellbore collapse and provides isolation between laterals. By tion and a packer in the lateral wellbore. Because hydraulic isolation and

placing sliding sleeves and packers in the main bore, operators can produce support are provided by the completion hardware, the junction may be a

the bores singly or commingle production. TAML Level 3 or 4 before the Level 5 completion is installed.

Placing a liner in the lateral and mechanically connecting it to the cased TAML Level 6 wells also provide hydraulic isolation at the junction. A well

and cemented main bore results in a TAML Level 3 well. A liner is a string at this level differs from a TAML Level 5 well in that pressure integrity is pro-

of casing that does not extend to the surface but is anchored or suspended vided by the main wellbore casing and a cemented or uncemented liner in the

inside a previously run casing string. This TAML Level 3 well includes a lat- lateral. The cost and complexity of creating a single-metal-element dual-bore

eral that is cased but not cemented at the junction. It is a relatively low-cost casing junction downhole has prevented TAML Level 6 wells from being devel-

option that includes reentry capabilities and a lateral that is better sup- oped. As of today, the category exists as a result of early experiments.

ported than that of Levels 1 and 2. Using sliding sleeves and packer plugs,

operators can produce the bores singly or commingle production. A TAML Choosing a Lateral Design

Level 3 junction does not provide hydraulic isolation and its use is restricted The geometry of an ML well is determined by the production targets, their

to consolidated formations. relative depths and lateral extents. The laterals may be on the same hori-

TAML Level 4 junctions are applicable in both consolidated and uncon- zontal plane at the same true vertical depth or they may be on the same

Multilateral_Fig_01_2.eps

solidated formations because both the lateral and the main bore are cased vertical plane and follow the same direction but at different depths. Within

and cemented at the junction. The junction provides fullbore access to the these two main categories, a nearly infinite number of combinations can be

lateral, and mechanical support is supplied by the tubulars and cement. created that may cover multiple zones or span out in various directions

within a single reservoir (Figure 2).

For help in preparation of this article, thanks to Adrian Francis, Houston, Texas, USA; and

Jonathan Park, The Woodlands, Texas.

Oilfield Review 2016.

Copyright 2016 Schlumberger.

www.slb.com/defining

Stacked dual lateral Dual opposed and stacked Planar dual lateral Planar dual lateral (pitchfork) Planar opposed dual lateral

opposed triple lateral (gullwing)

Planar opposed dual lateral Lateral with herringbone pattern Lateral with opposed Planar quadrilateral Stacked planar quadrilateral

with herringbone pattern herringbone pattern

Figure 2. Stacked laterals are in the same vertical plane; opposed, or gullwing, laterals are in the same zone but run in opposite directions; and fishbone,

herringbone or whalebone patterns are created by numerous laterals that extend outward from a single horizontal main bore to cover the zone.

Because ML wells that have higher TAML designations are more com- and the main bore; TAML Levels 2 through 6 junctions may be used if the

plex, they are more costly and their configurations are more flexible. As they well includes a dual upper completion to keep the flow streams separated.

do with ML geometry, engineers choose a TAML level junction based primar-

ily on reservoir characteristics, costs and function. Handling the Pressure

Junctions can fail as a consequence of high drawdown pressures, and engi-

Common Applications neers must understand the scale of those pressures when choosing a junc-

The most frequent applications of ML wells are in reservoirs that require tion. Because drawdown pressures are exerted directly on the formation in

sand control and in heavy oil reservoirs. In the case of sand control, the TAML Levels 1, 2 and 3 junctions and on a cement sheath in TAML Level 4

reason is often slot management on offshore platforms. More reservoir can junctions, these junctions should be used only in low-drawdown environ-

be accessed from a single casing string to surface. Relatively lower-cost ments. TAML Levels 5 and 6 junctions are separated from the formation by

sand control methods for multilaterals include slotted liners or stand-alone casing and cement and able to withstand significant drawdown pressure.

screens that act as filters to prevent formation sand entering the wellbore.

These are typically Level 5 wells. Reentry

In heavy oil applications, the goal is to access more reservoir from a sin- The ability to reenter the lateral for well intervention operations is another

gle parent bore. The amount of reservoir accessed from a single surface cas- ML design consideration. Because it is a directionally drilled section that

ing can approach 100,000 ft. These are typically Level 1, 2 or 3 wells. has no junction, the lower lateral is almost always easily accessed using

standard intervention methods. Operators must make an economics-based

decision during the well planning stage to include junctions that allow

Artificial Lift through-tubing access, junctions that can be adopted to allow access after

Like many wells, multilaterals may require some form of artificial lift to installation or junctions through which no access is possible.

supplement reservoir energy to bring produced fluids to the surface. The decision to deploy lateral junctions that allow fullbore or restricted

Because most junctions do not contain pressure seals across the annulus, access is a function of the overall well design. Engineers usually opt for

laterals are rarely good candidates for injection wells that operate at ele- fullbore access if a packer is to be placed below the junction or if an artifi-

vated pressures. Pump-type systems are applicable when formation fluid is cial lift system must be located near the lower lateral. In addition, based on

produced naturally to a depth that is above the junction and shallow enough their knowledge of the reservoir, operators may require fullbore access to

for a pump to lift economic volumes of liquids to the surface. perform perforating, gravel packing, cleanout and other remedial opera-

tions. Fullbore access can be adapted to all TAML level junctions but must

Offshore Drilling be specified before installation; some commercially available junctions

Multilateral wells are suited to offshore and subsea operations. Offshore allow no access or only restricted access to the lateral and cannot be

platforms are often slot limited; they are designed to accommodate a finite adapted after installation.

number of casing strings and wellheads at the surface. Should an operator

discover the need for more wells than are allotted in the original platform Costs and Benefits

design, installing laterals that branch from the existing main bore is signifi- The decision to use an ML system and what type to use are the result of cost-

cantly less expensive than acquiring another platform. In addition, the capi- benefit analyses. In general, the less complex junctions present operators

tal and operating expenses of offshore operations are such that the cost of with lower risks and costs. But risk mitigation and cost savings must be

MLs and junctions is small by comparison. balanced against individual well and field development expectations. In

low-value reservoirs, a simple openhole lateral that has no reentry capabil-

Commingled Production ity may increase ultimate reserve recovery or accelerate production while

In many areas, commingled productionin which formation fluids from having little impact on overall drilling and completion costs. In high-value

separate zones are mixed downhole and allowed to flow as a single stream deepwater plays, installing a hydraulically sealed TAML Level 5 or Level 6

to the surfaceis not allowed or is impossible because of pressure differ- junction can drive total well costs into millions of dollars and still be a good

ences between zones. Only TAML Level 5 or Level 6 junctions provide the investment because it may save drilling another well or preserve a well slot

pressure integrity required to prevent commingling of flow from the lateral on an existing production platform.

Oilfield Review

You might also like

- Oil Field Terms PDFDocument79 pagesOil Field Terms PDFPatrick Bolen100% (1)

- Cementing EquipmentDocument12 pagesCementing EquipmentETR0% (1)

- General Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)Document10 pagesGeneral Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)mozammilNo ratings yet

- ElastiCem Resilient Slurry SystemsDocument2 pagesElastiCem Resilient Slurry Systemsbagus918No ratings yet

- Wps PQR by UgdasDocument113 pagesWps PQR by Ugdasdash100% (1)

- rp90 1 E2 Ballot2 DraftDocument85 pagesrp90 1 E2 Ballot2 Draftzero CHIRSTNo ratings yet

- Parting The PipeDocument9 pagesParting The Pipephucbm bmNo ratings yet

- Progressive Cavity Pump Manual: Version 07/03Document23 pagesProgressive Cavity Pump Manual: Version 07/03Jose Miguel GonzalezNo ratings yet

- 15 Fishing Tools PDFDocument15 pages15 Fishing Tools PDFjoo123456789No ratings yet

- Offshore Heavy-Lift Engineering PresentationDocument31 pagesOffshore Heavy-Lift Engineering Presentationmarc121080% (5)

- Kauther Gas Depletion Compression Project Reaches Commissioning PhaseDocument32 pagesKauther Gas Depletion Compression Project Reaches Commissioning Phasebrijk1103No ratings yet

- Enviro Single Compact Pack-OffDocument1 pageEnviro Single Compact Pack-OffAderobaki GbengaNo ratings yet

- Multilateral Well Technology OverviewDocument18 pagesMultilateral Well Technology OverviewKaouachi Ahmed LouayNo ratings yet

- Buckling Analysis in Deviated Wells A Practical MethodDocument10 pagesBuckling Analysis in Deviated Wells A Practical Methodsabilco13No ratings yet

- Multilateral SolutionsDocument6 pagesMultilateral SolutionsGogoNo ratings yet

- Mark Dykstra - Stick Slip PresentationDocument16 pagesMark Dykstra - Stick Slip PresentationJasim BashirNo ratings yet

- Design of An Fpso For Offshore IndonesiaDocument88 pagesDesign of An Fpso For Offshore IndonesiaPavan Ray100% (2)

- The Story of Petroleum (For Children) PDFDocument99 pagesThe Story of Petroleum (For Children) PDFAdriano Sampaio50% (2)

- GP 10-20 26 August 2008Document41 pagesGP 10-20 26 August 2008alizareiforoushNo ratings yet

- Well Completion & StimulationDocument50 pagesWell Completion & StimulationShourovjossNo ratings yet

- Liner Procedure 5.5 ExampleDocument3 pagesLiner Procedure 5.5 ExampleLenis CeronNo ratings yet

- DNV RULES For Classification of Offshore Drilling and Support UnitsDocument93 pagesDNV RULES For Classification of Offshore Drilling and Support UnitsMeng Cher Chai100% (1)

- Presentation on challenges and technologies for HPHT wellsDocument27 pagesPresentation on challenges and technologies for HPHT wellsandrew sinagaNo ratings yet

- Design Process For Completion and WorkoversDocument72 pagesDesign Process For Completion and WorkoversDianaEstefaniaValdezNo ratings yet

- 06 Openhole IsolationDocument24 pages06 Openhole IsolationMuhammad ShahrukhNo ratings yet

- Sliding SleeveDocument13 pagesSliding SleeveSuriya BaluNo ratings yet

- Tdas West Shell 091602Document15 pagesTdas West Shell 091602amin peyvandNo ratings yet

- Saes A 103 PDFDocument15 pagesSaes A 103 PDFahmedalishNo ratings yet

- Drill Right Tools Motor ManualDocument55 pagesDrill Right Tools Motor ManualsumsolcaggNo ratings yet

- Packer Testing Program Design and Management: August 2013Document7 pagesPacker Testing Program Design and Management: August 2013wily784No ratings yet

- More 3 Second Edition WorkbookDocument98 pagesMore 3 Second Edition WorkbookKateřina CardováNo ratings yet

- 2111 PDFDocument222 pages2111 PDFmohamed elshemyNo ratings yet

- Master Thesis - Casing Wear in Multilateral Wells - Steven Ripman PDFDocument110 pagesMaster Thesis - Casing Wear in Multilateral Wells - Steven Ripman PDFBogdan StanciuNo ratings yet

- Offshore Platform FacilityDocument16 pagesOffshore Platform FacilityHari Gunawan NugrahaNo ratings yet

- Evo-Trieve® EB0 Retrievable Straddle - HalliburtonDocument2 pagesEvo-Trieve® EB0 Retrievable Straddle - HalliburtonYovaraj KarunakaranNo ratings yet

- Week 1 Introduction To Ship Construction Understanding Engineering DrawingDocument66 pagesWeek 1 Introduction To Ship Construction Understanding Engineering Drawingabood shabanehNo ratings yet

- Stuck Pipe PDFDocument16 pagesStuck Pipe PDFcarlos801No ratings yet

- GrantPrideco Drill Pipe Data TablesDocument25 pagesGrantPrideco Drill Pipe Data TableschoaybNo ratings yet

- Multilateral Well (Mohsin)Document10 pagesMultilateral Well (Mohsin)Mohsin ZiaNo ratings yet

- Simulation of Gas DehydrationDocument147 pagesSimulation of Gas DehydrationGerardo Eduardo Villalobos JuvenalNo ratings yet

- Nigeria Oil Gas Sector Report A PDFDocument50 pagesNigeria Oil Gas Sector Report A PDFyemiNo ratings yet

- Monobore Completion Design - Classification Applications BenefitDocument100 pagesMonobore Completion Design - Classification Applications BenefitAnonymous Nb2o12WyQjNo ratings yet

- LNG Offshore Receiving TerminalsDocument54 pagesLNG Offshore Receiving TerminalspoetoetNo ratings yet

- IDI06 011A Rev1.2 Well Seeker PRO ManualDocument90 pagesIDI06 011A Rev1.2 Well Seeker PRO Manualtoligado27No ratings yet

- Cementing & Casing Accessories Davis - Lynch Equipment CatalogDocument36 pagesCementing & Casing Accessories Davis - Lynch Equipment CatalogJitendra100% (1)

- Sentry Wellhead Catalog PDFDocument129 pagesSentry Wellhead Catalog PDFMuhammad TahirNo ratings yet

- Offshore201903 DL PDFDocument62 pagesOffshore201903 DL PDFEndd Gzm0% (1)

- BS EN 166 2002 PPE Personal Eye Protection SpecificationDocument39 pagesBS EN 166 2002 PPE Personal Eye Protection SpecificationNhat CaoNo ratings yet

- IMC - Lesson 1 Introduction To ShippingDocument92 pagesIMC - Lesson 1 Introduction To Shippingropes mongi100% (1)

- DM27-Casing Design - Diego Felipe Acevedo ParraDocument35 pagesDM27-Casing Design - Diego Felipe Acevedo ParraDiego FelipeNo ratings yet

- ESP Reliability Theory and Failure AnalysisDocument1 pageESP Reliability Theory and Failure Analysisazareiforoush100% (1)

- Patrick Okimi - Casing Design Horizontal WellsDocument14 pagesPatrick Okimi - Casing Design Horizontal WellsimampranadipaNo ratings yet

- Retrievable Packer Model - PCS-5Document3 pagesRetrievable Packer Model - PCS-5राजकुमार यादवNo ratings yet

- SPE 90821 Solid Expandable Tubular Technology: The Value of Planned Installation vs. ContingencyDocument8 pagesSPE 90821 Solid Expandable Tubular Technology: The Value of Planned Installation vs. ContingencymsmsoftNo ratings yet

- Api Buttress Connection Data SheetDocument7 pagesApi Buttress Connection Data SheetHanyNo ratings yet

- H03280 04 Horizontal Systems PDFDocument20 pagesH03280 04 Horizontal Systems PDFKeshav PujeriNo ratings yet

- RFT Vs MDT Vs DSTDocument6 pagesRFT Vs MDT Vs DSTAbdullah IshaqNo ratings yet

- Round I Rules - WE & CWIDocument2 pagesRound I Rules - WE & CWIKhalid ZaeemNo ratings yet

- Plug Setting Tool and Junk Basket: Purpose of The ServiceDocument15 pagesPlug Setting Tool and Junk Basket: Purpose of The Servicerobin2806No ratings yet

- Spe 36761 MSDocument13 pagesSpe 36761 MSKarla CotesNo ratings yet

- Well Barrier Schematics - Practical UseDocument21 pagesWell Barrier Schematics - Practical UseDeepak RanaNo ratings yet

- HTTP Mail - AmapetcDocument37 pagesHTTP Mail - AmapetcMohamed HashemNo ratings yet

- HPHT - UdabolDocument142 pagesHPHT - UdabolSarai Illanes CarataNo ratings yet

- Well-Head SelectionDocument13 pagesWell-Head Selectionmghareeb100% (1)

- Operation Procedure For VR - HammerDocument8 pagesOperation Procedure For VR - HammerAhmed OusamaNo ratings yet

- Powerstroke Drilling Jar: Instruction Manual 4250Document24 pagesPowerstroke Drilling Jar: Instruction Manual 4250Foros IscNo ratings yet

- Seal Assemblies (Locator, Anchor, Latch)Document2 pagesSeal Assemblies (Locator, Anchor, Latch)Yougchu LuanNo ratings yet

- 3 TheoriesDocument85 pages3 TheorieslintangputriNo ratings yet

- Cement Failure Prevention and RemediationDocument4 pagesCement Failure Prevention and RemediationMohamed SouidiNo ratings yet

- Aberdeen HPHT Drilling CourseDocument2 pagesAberdeen HPHT Drilling CourseClOudyo VirgílioNo ratings yet

- Ratings Packers PDFDocument10 pagesRatings Packers PDFsabilco13No ratings yet

- Well Completion Module 1Document10 pagesWell Completion Module 1Adetula Bamidele OpeyemiNo ratings yet

- Defining HPHT PDFDocument2 pagesDefining HPHT PDFNikhil Barshettiwar100% (1)

- AC-0083 - IWCF Drilling Well Control Level 3 and 4 Cross Reference Form.Document92 pagesAC-0083 - IWCF Drilling Well Control Level 3 and 4 Cross Reference Form.HarpreetSinghNo ratings yet

- Brochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedDocument8 pagesBrochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedNightNo ratings yet

- DD Survey PDFDocument261 pagesDD Survey PDFamitsaxenazhcetNo ratings yet

- Innovative Through-Tubing Cement Packer PDFDocument2 pagesInnovative Through-Tubing Cement Packer PDFFe Maligi100% (1)

- Volumetric Well Control - When It Will Be UsedDocument17 pagesVolumetric Well Control - When It Will Be UsedR.GNo ratings yet

- 4multilateral Well DrillingDocument16 pages4multilateral Well DrillingramyNo ratings yet

- Intuitive Explanation of Pressure SurgeDocument3 pagesIntuitive Explanation of Pressure SurgeNhat CaoNo ratings yet

- User Manual Turbokador 500Document16 pagesUser Manual Turbokador 500Nhat CaoNo ratings yet

- NFPA Course Note BookDocument1 pageNFPA Course Note BookNhat CaoNo ratings yet

- Fdocuments - in - Inergen Pressure Relief Venting GuideDocument22 pagesFdocuments - in - Inergen Pressure Relief Venting GuideNhat CaoNo ratings yet

- HSAC RP2016-2 Legacy Helidecks Revision 1Document43 pagesHSAC RP2016-2 Legacy Helidecks Revision 1Nhat CaoNo ratings yet

- Accumulator Catalogue AccumulatorsDocument200 pagesAccumulator Catalogue AccumulatorsNhat CaoNo ratings yet

- Accidental Load GN eDocument62 pagesAccidental Load GN eNhat CaoNo ratings yet

- MC005021 - Cao Thanh NhatDocument1 pageMC005021 - Cao Thanh NhatNhat CaoNo ratings yet

- Bristol Uniforms Composite Gloves: Structural FirefightingDocument2 pagesBristol Uniforms Composite Gloves: Structural FirefightingNhat CaoNo ratings yet

- PIPENET® - Leading The Way in Fluid Flow Analysis Accumulators in PIPENETDocument3 pagesPIPENET® - Leading The Way in Fluid Flow Analysis Accumulators in PIPENETNhat CaoNo ratings yet

- HydrantDocument18 pagesHydrantNhat CaoNo ratings yet

- ABS Facilities On Offshore InstallationsDocument268 pagesABS Facilities On Offshore InstallationsNhat CaoNo ratings yet

- 07 Remenikov AlexDocument25 pages07 Remenikov AlexNhat CaoNo ratings yet

- Premcote 101: Pipeline Corrosion Protection TapeDocument1 pagePremcote 101: Pipeline Corrosion Protection TapeIm ChinithNo ratings yet

- Cao Thanh Nhat: Certificate of AttendanceDocument1 pageCao Thanh Nhat: Certificate of AttendanceNhat CaoNo ratings yet

- Pipeline QRA Seminar Software Consequence ModellingDocument25 pagesPipeline QRA Seminar Software Consequence ModellingVesko IlijaziNo ratings yet

- Vietnam's Regulations on Environmental Noise StandardsDocument19 pagesVietnam's Regulations on Environmental Noise StandardsNhat CaoNo ratings yet

- 9P9 DCP PowderDocument4 pages9P9 DCP PowderNhat CaoNo ratings yet

- 5 Diesel Vs Electric - SFLBDocument1 page5 Diesel Vs Electric - SFLBLuis Fernandez de CastroNo ratings yet

- 3.2 SART - DatasheetDocument2 pages3.2 SART - DatasheetNhat CaoNo ratings yet

- ProjectDocument1 pageProjectNhat CaoNo ratings yet

- Using Descending Device Procedure: 1. Safeland Donut System ComponentDocument8 pagesUsing Descending Device Procedure: 1. Safeland Donut System ComponentNhat CaoNo ratings yet

- 3.2 SART - DatasheetDocument2 pages3.2 SART - DatasheetNhat CaoNo ratings yet

- 2.211 DONUT Specification SheetDocument4 pages2.211 DONUT Specification SheetNhat CaoNo ratings yet

- PP FeraDocument11 pagesPP FeraNhat CaoNo ratings yet

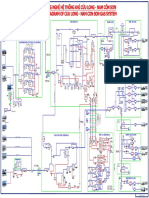

- 15.08.2016 - Sơ đồ công nghệ khí Cửu Long - NCS modifyDocument1 page15.08.2016 - Sơ đồ công nghệ khí Cửu Long - NCS modifyNhat CaoNo ratings yet

- Ds Vikingdatasheet 28-03-2019Document1 pageDs Vikingdatasheet 28-03-2019Nhat CaoNo ratings yet

- Cam, Tele QuantityDocument2 pagesCam, Tele QuantityNhat CaoNo ratings yet

- Questor NotesDocument41 pagesQuestor NotesBrion ReynosoNo ratings yet

- ONGC HR ProjectDocument126 pagesONGC HR ProjectNishant RaoNo ratings yet

- 3-2 Olav Theodorsen ISO 19008 - Application and Use of Standard Cost Coding SystemDocument26 pages3-2 Olav Theodorsen ISO 19008 - Application and Use of Standard Cost Coding SystemAjay SomasiNo ratings yet

- Produced Water - Overview of Composition, Fates and EffectsDocument51 pagesProduced Water - Overview of Composition, Fates and EffectsReeh StrappaNo ratings yet

- Vessel Class ListingDocument206 pagesVessel Class ListingLaurentiuMarianNo ratings yet

- Kamalakannan Resume (01!08!2018)Document5 pagesKamalakannan Resume (01!08!2018)Kamalakannan AyyaduraiNo ratings yet

- Global Mobile Oil and Gas AssetsDocument10 pagesGlobal Mobile Oil and Gas AssetsShashank VijayvergiaNo ratings yet

- Okpoho Platform Jackets (Splash Zone) Corrosion Mitigation Proposal - DRAFT VERSION 26-Feb-2017 - With Cover LetterDocument13 pagesOkpoho Platform Jackets (Splash Zone) Corrosion Mitigation Proposal - DRAFT VERSION 26-Feb-2017 - With Cover LetterJude EdohorNo ratings yet

- Piping Design Professional: Kamalakannan ADocument4 pagesPiping Design Professional: Kamalakannan AKamalakannan AyyaduraiNo ratings yet

- ALTAIR029 Oil&Gas Industry Brochure ParkerDocument12 pagesALTAIR029 Oil&Gas Industry Brochure Parkerkristian08No ratings yet

- Rules For Classification and Construction IV Industrial ServicesDocument62 pagesRules For Classification and Construction IV Industrial ServicesAbhijeet ChawanNo ratings yet

- Mumbai (Bombay) High North Platform FireDocument2 pagesMumbai (Bombay) High North Platform FireSrinivasan RajenderanNo ratings yet

- CV Johannes K - CophiDocument3 pagesCV Johannes K - CophiA A Ichsan CrNo ratings yet