Professional Documents

Culture Documents

Litewalk Steel Grating

Uploaded by

Dr Bugs TanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Litewalk Steel Grating

Uploaded by

Dr Bugs TanCopyright:

Available Formats

LITEWALK

GRATING PANELS

LIGHTER STRONGER COST-SAVER SAFER TO WALK ON

WWW.MASTEK-OT.COM.MY

LIGHT WEIGHT ANTI-SLIP GALVANIZED STEEL GRATING SYSTEM

The uniqueness of LITEWALK grating lies in the creative design of the

load bearing bar. This innovative design has resulted in making LITEWALK

grating to become significantly lighter in weight. And amazingly the

design has also improveD the overall integrity of the panel. LITEWALK

grating panel uses less amount of raw material to manufacture. hence,

making it more competitive. And more importantly, this innovative

ANTI-SLIP design gives you a GOOD GRIP on your foot when you step on

OIL PLATFORM Industrial factorIES walk ways

Lite Walk Flyers_6 FA.indd 1 4/21/17 5:38:01 PM

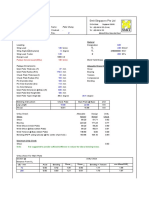

SIRIM LOAD TEST TABLE

Industrial Standard / Method of test:

BS 4592: Part 1: 1995 Industrial type flooring walkways and stair treads Part 1.

Specification for aluminium and steel open bar gratings

TEST TYPE OF TEST SPECIFICATION TEST RESULTS

Deflection 1/200 X

1st

Concentrated Load Test - 1.0kN/m2 Effective Span (4mm) or 0.63mm

Test

10mm whicever is lesser

Deflection 1/200 X

2nd

Uniformly Distributed Load Test - 5.0kN/m2 Effective Span (4mm) or 1.54mm

Test

10mm whicever is lesser EASY INSTALLATION

The test shows that LITEWALK grating conforms to the industrial standard as required in the oil & gas industry

WEIGHT ANALYSIS

Common Grating LITEWALK Grating

35% LIGHTER

WEIGHT WEIGHT LITEWALK Grating is

MODEL MODEL

kg/m2 kg/m2 Lighter by

a) A255msu 33.3 a) 35 x 15 x 1.5 x 30 22.3 a) 33%

b) A325msu 42.7 b) 45 x 15 x 1.5 x 30 27.7 b) 35%

c) A355msu 46.7 c) 50 x 15 x 1.5 x 30 30.3 c) 35%

d) A385msu 50.7 d) 55 x 15 x 1.5 x 30 33.3 d) 34% M-BRACKET

The test shows that LITEWALK grating is lighter by 33% to 35%

STRENGTH ANALYSIS 12% STRONGER

LITEWALK Grating Span Common Grating Span

35 x 15 x 1.5mm L = 1300mm 25 x 5mm L = 1300mm

UDL (kPA) Deflection UDL (kPA) Deflection

1.2 1.5mm 1 1.0mm

1.9 2.0mm 2 2.0mm

2.5 2.5mm 3 3.0mm

3.2 3.0mm 4 4.0mm

3.8 3.5mm 5 5.0mm CUT TO SHAPE

4.4 4.0mm

LITEWALK grating can take 12% more load

5.1 4.5mm than other common grating

5.6 5.0mm

SAFER TO CUT TO INTENSIVE LITEWALK LITEWALK

WALK ON! ANY SHAPE CORROSION TEST M BRACKETS J CLAMP

LITEWALK grating Worker who are used ASTM G44 - 99 2005 Specially designed The special designed

is the only grating to installing and cutting After 1,000 cycles M bracket to suit J Clamp can be used to

panel in the world common grating will (about 42 days) of LITEWALK grating fasten the LITEWALK

that is truly anti-slip. be able to handle this alternate immersion, installation, M panel onto the

It is safer to walk on LITEWALK grating easily. hot dip galvanized bracket is used to structural beam.

LITEWALK panel LITEWALK grating has the LITEWALKgrating are hold the LITEWALK

than any other types flexibility to be cut to any found to be resistance grating panel onto

of grating. shape in our factory or at to corrosion the structural beam.

the work site. - University of Malaya.

MASTEK OIL TOOLS SDN BHD

Suite 3B-2-3, Level 2, Block 3B, Plaza Sentral, Jalan Stesen Sentral 5, Kuala Lumpur Sentral, 50470 Kuala Lumpur,Malaysia

T. +603 2273 4534/36 F. +603 2272 2844 E. sales@mastek-ot.com.my www.mastek-ot.com.my

Lite Walk Flyers_6 FA.indd 2 4/21/17 5:38:02 PM

You might also like

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionFrom EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo ratings yet

- Access Flooring and Handrail CatalogueDocument10 pagesAccess Flooring and Handrail CatalogueSaravan KumarNo ratings yet

- Tolerance Chart: (Maximum Permissible Error)Document3 pagesTolerance Chart: (Maximum Permissible Error)arufatoNo ratings yet

- Casing Types, Functions, and ClassificationsDocument71 pagesCasing Types, Functions, and ClassificationsPeterMarkNo ratings yet

- Field Manual For Structural Bolting 5 5x8 5pdf 468332 7Document50 pagesField Manual For Structural Bolting 5 5x8 5pdf 468332 7Mahmoud FawzyNo ratings yet

- Wire Rope (Trawl Rope) - Galvanized, Bright, Stainless, IWRC, Fillerwire & RDocument6 pagesWire Rope (Trawl Rope) - Galvanized, Bright, Stainless, IWRC, Fillerwire & RralishNo ratings yet

- Live Load Distribution Factor CalculationsDocument5 pagesLive Load Distribution Factor CalculationsBunkun15No ratings yet

- Christie Bolt Torque Loads With LubricantDocument2 pagesChristie Bolt Torque Loads With Lubricantsllim776100% (1)

- 16542Document7 pages16542Cnc CamNo ratings yet

- C P & C I .: Cema B4, B5, C5, C6, D6 & E7 Class IdlersDocument20 pagesC P & C I .: Cema B4, B5, C5, C6, D6 & E7 Class IdlersArdian20No ratings yet

- Facilities On Offshore Installations: Guide For Building and ClassingDocument209 pagesFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyNo ratings yet

- Structural Framing Design AppraisalDocument31 pagesStructural Framing Design AppraisaltimsykiNo ratings yet

- Connectorsubsea 20502 0210 CSS Split Sleeve Repair ClampsDocument2 pagesConnectorsubsea 20502 0210 CSS Split Sleeve Repair ClampsTTNo ratings yet

- Pade EyeDocument2 pagesPade EyeAzwar Maiza PutraNo ratings yet

- Bethlehem Structural Shapes Catalogue 1911Document122 pagesBethlehem Structural Shapes Catalogue 1911Alberto ChazarretaNo ratings yet

- Long Radius Steel Elbows - 3D, 5D and 6D: Product DescriptionDocument3 pagesLong Radius Steel Elbows - 3D, 5D and 6D: Product Descriptionbadesharamk100% (2)

- Torque-Tension Relationship For ASTM A193 B7 Bolts and StudsDocument1 pageTorque-Tension Relationship For ASTM A193 B7 Bolts and StudsSiva Krishna ChaudharyNo ratings yet

- Marine Propulsion System Failures-A Review: Marine Science and EngineeringDocument14 pagesMarine Propulsion System Failures-A Review: Marine Science and EngineeringDavid NuñezNo ratings yet

- TorqueDocument2 pagesTorquestaedtlerpNo ratings yet

- #160 Lifting Fixture 38tons 020807Document14 pages#160 Lifting Fixture 38tons 020807halder_kalyan9216No ratings yet

- KLELINE hoses for offshore vertical installation and CALM buoy configurationsDocument24 pagesKLELINE hoses for offshore vertical installation and CALM buoy configurationsJorge GonzalezNo ratings yet

- Parallel Flange Channels (ALL Sections) : DiagramDocument1 pageParallel Flange Channels (ALL Sections) : Diagramalvin_tanNo ratings yet

- Securing Straps & RatchetsDocument2 pagesSecuring Straps & RatchetsKhurram S. MuzammilNo ratings yet

- Star Core 6Document2 pagesStar Core 6jmur10No ratings yet

- 28.GOMA Pump T-8000 CatalougeDocument2 pages28.GOMA Pump T-8000 Catalougeramesh babuNo ratings yet

- Offshore & Structural Plate SizeDocument4 pagesOffshore & Structural Plate Sizelaleye_olumideNo ratings yet

- Fortress Timber & Metal SDS Screws 2017 WebDocument36 pagesFortress Timber & Metal SDS Screws 2017 WebGabriel MacedoNo ratings yet

- kλ Beam Spread D: 19.5 mm Near Zone =Document6 pageskλ Beam Spread D: 19.5 mm Near Zone =Malcolm DowNo ratings yet

- Alloy Master LinksDocument1 pageAlloy Master LinksAnonymous 48jYxR1C0% (1)

- Wire Rope Identification and Construction GuideDocument3 pagesWire Rope Identification and Construction GuideSorinNo ratings yet

- Welded JointsDocument30 pagesWelded JointsOmkar Kumar JhaNo ratings yet

- Mini ContainerDocument1 pageMini ContainerRezza AdityaNo ratings yet

- Jis g3456 Grade STPT 410 Pipes PDFDocument1 pageJis g3456 Grade STPT 410 Pipes PDFMitul MehtaNo ratings yet

- Enron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsDocument2 pagesEnron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsLorenaNo ratings yet

- Eccentric Column BucklingDocument10 pagesEccentric Column BucklingMukeshChopraNo ratings yet

- 4 EyeBolts-HoistRings-LiftingSlings - US PricingDocument5 pages4 EyeBolts-HoistRings-LiftingSlings - US PricingJohn MuellerNo ratings yet

- Trapezoidal ThreadsDocument5 pagesTrapezoidal ThreadsSaraswantoNo ratings yet

- Hot Rolled Carbon Steel Structural Shapes 1948 PDFDocument73 pagesHot Rolled Carbon Steel Structural Shapes 1948 PDFAmmar AyubNo ratings yet

- Russel Metals Grating PDFDocument51 pagesRussel Metals Grating PDFtylerlhsmithNo ratings yet

- Lifting Lug Stress - Typ FactorsDocument1 pageLifting Lug Stress - Typ FactorsDipak ZopeNo ratings yet

- Bridon Offshore ExplorationDocument44 pagesBridon Offshore ExplorationAthox QhurienNo ratings yet

- Har-Bach Marketing, Inc. Padeye Evaluation Safety Warnings/Instructions Project 21721Document12 pagesHar-Bach Marketing, Inc. Padeye Evaluation Safety Warnings/Instructions Project 21721Damar Budi LaksonoNo ratings yet

- Padeyes: Engineered & CertifiedDocument4 pagesPadeyes: Engineered & CertifiedMahmoudNo ratings yet

- Steel Castings, Carbon, For General ApplicationDocument4 pagesSteel Castings, Carbon, For General Applicationsharon blushteinNo ratings yet

- 2022.02-Chemical Corrosion Guide-FinalDocument52 pages2022.02-Chemical Corrosion Guide-FinalEdward Alejandro Avendaño BeltranNo ratings yet

- DNVGL RU SHIP Pt3Ch10Document63 pagesDNVGL RU SHIP Pt3Ch10KenginNo ratings yet

- Stress Strain Laws - Lect05Document16 pagesStress Strain Laws - Lect05Manoj VermaNo ratings yet

- Basic PV Elite TrainingDocument54 pagesBasic PV Elite TrainingcayovinNo ratings yet

- Shear Strength of High-Strength BoltsDocument61 pagesShear Strength of High-Strength Boltsloox600No ratings yet

- Whip Check HosesDocument49 pagesWhip Check Hosesprayitno_bsantosoNo ratings yet

- Froude-Krylov Force CoefficientDocument20 pagesFroude-Krylov Force CoefficientLazaros NtoanidisNo ratings yet

- Padeye Design AnalysisDocument8 pagesPadeye Design AnalysisMyatmyat SwewinNo ratings yet

- Padeye Calculator (Shackle Compatibility & Design Capacity) : Home About... Products Terms Contact UsDocument5 pagesPadeye Calculator (Shackle Compatibility & Design Capacity) : Home About... Products Terms Contact UsKarun Das0% (1)

- Rotabolt 007 eDocument15 pagesRotabolt 007 eShailesh KhodkeNo ratings yet

- Table of Contents for Bag Filtration Equipment ManualDocument13 pagesTable of Contents for Bag Filtration Equipment Manualsantiago pomasoncoNo ratings yet

- Premier Coatings Premcote 500Document2 pagesPremier Coatings Premcote 500Im ChinithNo ratings yet

- Denso Densopol 60 TapeDocument2 pagesDenso Densopol 60 TapeDwi SutiknoNo ratings yet

- XLam Cross Laminated Timber Site SolutionsDocument2 pagesXLam Cross Laminated Timber Site Solutionssant1411No ratings yet

- Gantry Chain Weight Www-Liftingsafety-Co-Uk-ProductDocument2 pagesGantry Chain Weight Www-Liftingsafety-Co-Uk-ProductMark ManayonNo ratings yet

- Stopefuse® & Durafuse®: Capped Fuse SystemsDocument1 pageStopefuse® & Durafuse®: Capped Fuse SystemsAlexander OpazoNo ratings yet

- 2020 Accolade and Testimony Bugs TanDocument40 pages2020 Accolade and Testimony Bugs TanDr Bugs TanNo ratings yet

- Test Result For Slip Resistence For Litewalk C3515Document2 pagesTest Result For Slip Resistence For Litewalk C3515Dr Bugs TanNo ratings yet

- 2020 Accolade and Testimony Bugs TanDocument40 pages2020 Accolade and Testimony Bugs TanDr Bugs TanNo ratings yet

- Novel Coronavirus Landscape Covid 19Document12 pagesNovel Coronavirus Landscape Covid 19Dr Bugs TanNo ratings yet

- The Science of DeathDocument24 pagesThe Science of DeathDr Bugs TanNo ratings yet

- Eulogy For Venerable Dr. Madawela PunnajiDocument3 pagesEulogy For Venerable Dr. Madawela PunnajiDr Bugs TanNo ratings yet

- 2019 DR Bugs at Dhamma Minders 5Document29 pages2019 DR Bugs at Dhamma Minders 5Dr Bugs TanNo ratings yet

- An Expert in Creativity & Innovation - Dr. Bugs TanDocument8 pagesAn Expert in Creativity & Innovation - Dr. Bugs TanDr Bugs TanNo ratings yet

- Notes For The Retreat by Maechee PunnisaDocument9 pagesNotes For The Retreat by Maechee PunnisaDr Bugs TanNo ratings yet

- DR Bugs Tan INTI Ind Adjunct Faculty MemberDocument2 pagesDR Bugs Tan INTI Ind Adjunct Faculty MemberDr Bugs TanNo ratings yet

- 2019 Litewalk Grating ProjectsDocument17 pages2019 Litewalk Grating ProjectsDr Bugs TanNo ratings yet

- Dr. Bugs Tan at ADIPEC 2017Document2 pagesDr. Bugs Tan at ADIPEC 2017Dr Bugs TanNo ratings yet

- About The Author DR Bugs TanDocument1 pageAbout The Author DR Bugs TanDr Bugs TanNo ratings yet

- Forest Fire in Southeast AsiaDocument2 pagesForest Fire in Southeast AsiaDr Bugs TanNo ratings yet

- Dr. Bugs Tan Appointment As AdjudicatorDocument6 pagesDr. Bugs Tan Appointment As AdjudicatorDr Bugs TanNo ratings yet

- Certificate For Slip Resistance For Litewalk C3515Document1 pageCertificate For Slip Resistance For Litewalk C3515Dr Bugs TanNo ratings yet

- Cr8tivity & Innovation Workshop 8th July 2017Document2 pagesCr8tivity & Innovation Workshop 8th July 2017Dr Bugs TanNo ratings yet

- Dr. Bugs Tan ADIPEC Conference PaperDocument23 pagesDr. Bugs Tan ADIPEC Conference PaperDr Bugs Tan100% (1)

- 2017 Last Days of The BuddhaDocument44 pages2017 Last Days of The BuddhaDr Bugs TanNo ratings yet

- Litewalk PosterDocument1 pageLitewalk PosterDr Bugs TanNo ratings yet

- Certificate For Slip Resistance For Litewak Grating B3538Document2 pagesCertificate For Slip Resistance For Litewak Grating B3538Dr Bugs TanNo ratings yet

- Thank You Letter From Petronas For DR Bugs TanDocument1 pageThank You Letter From Petronas For DR Bugs TanDr Bugs TanNo ratings yet

- Development and Managing Cre8tivity & InnovationDocument9 pagesDevelopment and Managing Cre8tivity & InnovationDr Bugs TanNo ratings yet

- 2016 Accolade and Testimony Bugs TanDocument25 pages2016 Accolade and Testimony Bugs TanDr Bugs TanNo ratings yet

- ICDI 2016 HandbookDocument16 pagesICDI 2016 HandbookDr Bugs TanNo ratings yet

- The Roti Canai StoryDocument5 pagesThe Roti Canai StoryDr Bugs TanNo ratings yet

- The Feisty Little Tea PotDocument4 pagesThe Feisty Little Tea PotDr Bugs TanNo ratings yet

- Pokok Daud MenariDocument3 pagesPokok Daud MenariDr Bugs TanNo ratings yet

- Robot BolehDocument6 pagesRobot BolehDr Bugs TanNo ratings yet

- Ribbed Slab DesignDocument4 pagesRibbed Slab Designyusuf abdinasir100% (1)

- INSTALL AND SERVICE 21ST CENTURY LIGHTSDocument84 pagesINSTALL AND SERVICE 21ST CENTURY LIGHTSAnonymous D9bqxF100% (1)

- Indian Institute of Tecnology, Roorkee: AUTUMN SEMESTER:-2016-17Document20 pagesIndian Institute of Tecnology, Roorkee: AUTUMN SEMESTER:-2016-17Allyne CristinaNo ratings yet

- Ancient Asyut The First Synthesis After 300 Years of ResearchDocument6 pagesAncient Asyut The First Synthesis After 300 Years of ResearchaminNo ratings yet

- Service Manual RCF Art 500 ADocument3 pagesService Manual RCF Art 500 AFederico Torre0% (1)

- DSR Vol. 1-1Document234 pagesDSR Vol. 1-1Charan Electricals100% (2)

- Multi Storey Car ParksDocument6 pagesMulti Storey Car ParksRifat Türkkan0% (1)

- The Betyls of Petra. Robert WenningDocument17 pagesThe Betyls of Petra. Robert WenningRubén Montalbán LópezNo ratings yet

- CETA-RAM machine produces hollow cement blocksDocument17 pagesCETA-RAM machine produces hollow cement blockstoacaminho0% (1)

- Food Tenant Cooling Load CapacityDocument18 pagesFood Tenant Cooling Load CapacityVanne Jo PajoNo ratings yet

- Victims Analysis 2004-2009Document47 pagesVictims Analysis 2004-2009Peter HermannNo ratings yet

- Samridhi SharmaDocument10 pagesSamridhi SharmaSamridhi SharmaNo ratings yet

- How To Submit JCL From CICS ProgramDocument3 pagesHow To Submit JCL From CICS ProgramMainframe for everyone100% (2)

- EstimateDocument28 pagesEstimateKuruvaJanardhanNo ratings yet

- Architectural Supplemental ServicesDocument60 pagesArchitectural Supplemental ServicesLuwella GumallaoiNo ratings yet

- IBC 2016 TABLE 1604.3 DEFLECTION LIMITSDocument1 pageIBC 2016 TABLE 1604.3 DEFLECTION LIMITSMuhammad Najam AbbasNo ratings yet

- Lab Manual Exec System Call: A Family of Six FunctionsDocument9 pagesLab Manual Exec System Call: A Family of Six FunctionsMubeen ul hassanNo ratings yet

- Android: How It Benefits Application Developers in The Near FutureDocument5 pagesAndroid: How It Benefits Application Developers in The Near FutureTong Viet HIeuNo ratings yet

- SSRS Interview Question and Answers Basics Part 1Document3 pagesSSRS Interview Question and Answers Basics Part 1Venkat RatnakaramNo ratings yet

- Haries B. Garcia: Career SummaryDocument3 pagesHaries B. Garcia: Career SummaryHaries Bugarin GarciaNo ratings yet

- Adnan CVDocument3 pagesAdnan CVazharNo ratings yet

- High Performance Building GuidelinesDocument146 pagesHigh Performance Building GuidelinesMike Bello100% (1)

- Hsfi Winpak46 01 Uk (0618) Ds e PDFDocument2 pagesHsfi Winpak46 01 Uk (0618) Ds e PDFdeaironiNo ratings yet

- Service Manual LGDocument73 pagesService Manual LGMiguel Figueroa100% (1)

- Conf2015 MGough MalwareArchaelogy SecurityCompliance FindingAdvnacedAttacksAnd PDFDocument62 pagesConf2015 MGough MalwareArchaelogy SecurityCompliance FindingAdvnacedAttacksAnd PDFVangelis MitakidisNo ratings yet

- Energy Benefits of View Dynamic Glass in Workplaces: Energy Consumption by BuildingsDocument10 pagesEnergy Benefits of View Dynamic Glass in Workplaces: Energy Consumption by BuildingsPmb KmeNo ratings yet

- Session #103750 - Integrate PeopleSoft and SharePoint - C12 TemplateDocument27 pagesSession #103750 - Integrate PeopleSoft and SharePoint - C12 TemplatejlabrashNo ratings yet

- Wellesley Trails Gist Rail MapDocument1 pageWellesley Trails Gist Rail MapjaironarezNo ratings yet

- Concrete Cube QC FormDocument1 pageConcrete Cube QC Formneutron_870% (1)

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 31-Nov-2019 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 31-Nov-2019 CivilyazNo ratings yet