Professional Documents

Culture Documents

Pressure Vessel Interview

Uploaded by

عصمت ضيف الله0 ratings0% found this document useful (0 votes)

538 views4 pagesPressure Vessel Interview

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPressure Vessel Interview

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

538 views4 pagesPressure Vessel Interview

Uploaded by

عصمت ضيف اللهPressure Vessel Interview

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

- pressure vessel

A container or structural envelope in which material are processed, treated,

or stored which has been designed to operate at pressure above 15 Psi are

knows as pressure vessel.

- Types of Pressure vessels:

According to Orientation

Typical Pressure Vessel Spherical Pressure vessel Horizontal

supports for vessel

Vessel have to be supported by different methods. Vertical vessel is supported by

bracket, column and saddle support horizontal vessels. The choice of the type of

supports depends on the

Height and diameter of the vessel,

Available floor space,

Location of vessel

Types of supports which are commonly used

Skirt supports (column) (cylindrical shell)

Saddle supports (Horizontal) (for large thin ring used)

Bracket or lug supports (thick, to dead weight and wind load)

Leg supports (vertical) (angle, channels fillet welded, small vessels, local

stresses)

- Types of nozzle

Radial nozzle: a nozzle, which is perpendicular to base of the shell or dished

end lies on the orientation line is called radial nozzle.

Offset nozzle: a nozzle, which is similar to radial nozzle but offset form

orientation line, is called as offset nozzle.

Tangential nozzle: a nozzle, which is on any tangential line of the shell, is

called tangential nozzle.

Angular nozzle: a nozzle, which is at an angle form the reference line, is

called as angular nozzle

- Pressure vessel Internals:

Trays

Inlet Distributer

Baffles

Catalyst Bed Grid and support beams

Outlet collectors

Flow distribution Grid

Cyclone and Plenum chamber system

- Shall be consider during Design:

Need for corrosion allowance

Lethal Services

Need for PWHT

The degree of NDT

- Material for shell ASTM A 285

- LOADINGS:

Internal or External Design Pressure

Weight of the vessel and normal contents under operating and test condition

Superimposed static reactions from weight of attached equipment

The attachment of (Internals Vessel supports)

Cyclic and dynamic reactions (Wind snow)

Impact reactions (fluid shock)

Temperature gradients

- Longitudinal Joints (Circumferential stresses)

- Circumferential Joints (longitudinal stresses)

- Types of caps (Ellipsoidal, Tori spherical, Hemispherical , Toriconical , )

- Welded Joint Category & Lethal requirements:

- Design Pressure: the pressure at the top of the vessel.

- Design Temperature: shall be based on the actual metal temperature

expected under operating condition for the part considered at the designated

coincident pressure.

- Operating Pressure: is the pressure at the top of the vessel at which it

normally operators. The operating pressure shall not exceed the design

pressure and is usually kept at a suitable level below it to prevent the

frequent opening of the pressure relieving devices.

- Test Pressure: the pressure to be applied at the top of the vessel during the

test.

- Gaskets: Full face spiral Wound octagonal ring metal Jacketed

- Stress analysis: to insure stress in piping component in allowable

To solve dynamic problems

To solve problems due to higher or lower operating

temperature.

(axial stresses shear stresses Radial stresses Hoops

stresses)

- Valves: Selection: Handling, Fluid Nature, function, construction

material, disk type, stem type, bonnet type, body ends, cost

Function of Valves: - Isolation, Regulation, non-return, special

purposes.

Isolating Valves: Gate, Ball, Plug, piston, diaphragm, butterfly, pinch.

Regulation Valves: Globe, Needle, Butterfly, diaphragm, piston, pinch

Non-return Valve: Check valve

Special valves: multi-port, pressure relieve, flush bottom.

Pr

T= +c.a.

SE-0.6p

You might also like

- PV Elite and CodeCalcDocument102 pagesPV Elite and CodeCalcRaúl R Rojas Torres100% (1)

- Inspection HandbookDocument126 pagesInspection Handbooksteffy18295% (21)

- Pressure Vessel Inspection and DesignDocument48 pagesPressure Vessel Inspection and DesignMohammed Raje100% (2)

- ASME VIII Div.1 PresentationDocument282 pagesASME VIII Div.1 Presentationmarforall5205100% (12)

- Asme Section Viii Div-1,2,3Document73 pagesAsme Section Viii Div-1,2,3me2437090% (39)

- Piping Interview QuestionsDocument22 pagesPiping Interview Questionsmsaad288% (34)

- Guide To ASME Code VIII Division 1 Pressure VesselsDocument16 pagesGuide To ASME Code VIII Division 1 Pressure VesselsSaâd Eddine Atif0% (1)

- Code-compliant vessel design requirementsDocument90 pagesCode-compliant vessel design requirementsعصمت ضيف الله83% (12)

- Moldavite Ukazka PDFDocument15 pagesMoldavite Ukazka PDFNeven Žižić100% (1)

- Pressure VesselDocument40 pagesPressure VesselPrt00789% (18)

- Industrial Valves Types, Standards & Testing GuideDocument70 pagesIndustrial Valves Types, Standards & Testing GuideGOUTHAM RATHINAM50% (2)

- ASME Sec VIII - AwarenessDocument33 pagesASME Sec VIII - AwarenessNirmal100% (4)

- ASME CourseDocument283 pagesASME Courseeng_far100% (5)

- Weld Joint EfficienciesDocument5 pagesWeld Joint EfficienciesMohd Idris MohiuddinNo ratings yet

- Asme Sec Viii Div 1 Vs Asme Viii Div 2Document3 pagesAsme Sec Viii Div 1 Vs Asme Viii Div 2Jignesh ShahNo ratings yet

- Standards and Codes: Asme Section ViiiDocument44 pagesStandards and Codes: Asme Section ViiiNitin LuhadiyaNo ratings yet

- Fractional Flow Analysis of WaterfloodDocument11 pagesFractional Flow Analysis of WaterfloodBagus PrihardianNo ratings yet

- Temporary Repair RegisterDocument6 pagesTemporary Repair Registerعصمت ضيف اللهNo ratings yet

- Summary of ASME Section VIIIDocument3 pagesSummary of ASME Section VIIIAMALENDU PAUL100% (2)

- Marine Pressure Vessel Design Code ComparisonDocument0 pagesMarine Pressure Vessel Design Code ComparisonSaid Alauddeen FaiszNo ratings yet

- Oil & Gas Valve Types: Gate, Globe, Check, Ball & Butterfly DesignsDocument12 pagesOil & Gas Valve Types: Gate, Globe, Check, Ball & Butterfly DesignsMAHESH CHANDNo ratings yet

- Asme Section Ix Practice QuestionsDocument12 pagesAsme Section Ix Practice QuestionsAnonymous 2zpiaauYat50% (6)

- Asme Sec Viii HighlightsDocument10 pagesAsme Sec Viii HighlightsANILNo ratings yet

- Pressure Vessel Dimension InspectionDocument12 pagesPressure Vessel Dimension Inspectionalokbdas100% (3)

- Pressure Vessels Field Manual: Common Operating Problems and Practical SolutionsFrom EverandPressure Vessels Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (12)

- ASME Pressure Vessel JointDocument5 pagesASME Pressure Vessel JointRodrigo CarneiroNo ratings yet

- ASME VIII Div. 1 - 5 External PressureDocument32 pagesASME VIII Div. 1 - 5 External Pressureعصمت ضيف الله100% (2)

- ASME VIII Div. 1 - 5 External PressureDocument32 pagesASME VIII Div. 1 - 5 External Pressureعصمت ضيف الله100% (2)

- ASME Impact Test RequirementDocument6 pagesASME Impact Test RequirementgaurangNo ratings yet

- Static Equipment PDFDocument37 pagesStatic Equipment PDFMedinaNo ratings yet

- ASME Sec VIII Div 1Document120 pagesASME Sec VIII Div 1kanchanabalaji96% (23)

- Asme Standards Specifications-1Document72 pagesAsme Standards Specifications-1DHAVAL PANCHAL100% (1)

- Pressure Vessel PD Week 9.1Document18 pagesPressure Vessel PD Week 9.1Muzzamil Abbasi100% (1)

- Asset Integrity Daily ReportDocument1 pageAsset Integrity Daily Reportعصمت ضيف اللهNo ratings yet

- 3) Piping Interview QuestionnaireDocument5 pages3) Piping Interview QuestionnaireAjaz MalikNo ratings yet

- ASME Code General ReviewDocument33 pagesASME Code General Reviewaike_5No ratings yet

- Piping QuestionsDocument57 pagesPiping Questionsnavee_200875% (4)

- Welcome To: Training Program On ASME Sec. VIII Div. 1Document120 pagesWelcome To: Training Program On ASME Sec. VIII Div. 1Wilson Wilfredo Yucra Paco100% (1)

- Introduction To ASMEDocument33 pagesIntroduction To ASMEFajar Sri Lestari PangukirNo ratings yet

- Asme Awareness Program - DesignDocument126 pagesAsme Awareness Program - DesignGaurav KhamkarNo ratings yet

- ASME VIII Pressure Vessel MasterclassDocument6 pagesASME VIII Pressure Vessel MasterclassKmt_AeNo ratings yet

- Casti Guidebook Pressure VesselDocument3 pagesCasti Guidebook Pressure VesselQuangTiên0% (1)

- Pvii Study Notes English TestDocument21 pagesPvii Study Notes English Testanon_660004464100% (1)

- Confined Space EntryDocument15 pagesConfined Space EntryEnginnering Section100% (1)

- Piping Interview QuestionnaireDocument9 pagesPiping Interview QuestionnaireRakesh RanjanNo ratings yet

- ASME Pressure Vessel Joint Efficiencies and RT RequirementsDocument5 pagesASME Pressure Vessel Joint Efficiencies and RT RequirementsalokbdasNo ratings yet

- Tanks - Specification For Tank Hydrotest PDFDocument24 pagesTanks - Specification For Tank Hydrotest PDFعصمت ضيف اللهNo ratings yet

- ASME VIII Div 1 ReportDocument12 pagesASME VIII Div 1 ReportAmir Zamri100% (2)

- Analyzer Sample Systems Ver HappenDocument12 pagesAnalyzer Sample Systems Ver HappenIñaki Eseberri100% (1)

- PRESSURE VESSEL DESIGNDocument51 pagesPRESSURE VESSEL DESIGNssfoodtech100% (1)

- Piping Study Guide ASME Codes Standards MaterialsDocument15 pagesPiping Study Guide ASME Codes Standards MaterialsnandajntuNo ratings yet

- ASME Pressure Vessel Inspections GuideDocument43 pagesASME Pressure Vessel Inspections GuidepvvyesubabuNo ratings yet

- FFS SheetDocument28 pagesFFS Sheetعصمت ضيف الله50% (2)

- Slides Project Management Professional (Pmi) Study GuideDocument270 pagesSlides Project Management Professional (Pmi) Study Guideapi-27145250100% (7)

- PMP CH 4 IntegrationDocument102 pagesPMP CH 4 Integrationعصمت ضيف اللهNo ratings yet

- Aetheric Battery - Copy #1Document6 pagesAetheric Battery - Copy #1Keresztúri FerencNo ratings yet

- ASME VIII Div. 1 - 6 Pressure TestingDocument26 pagesASME VIII Div. 1 - 6 Pressure Testingعصمت ضيف الله75% (4)

- ASME VIII Div. 1 - 6 Pressure TestingDocument26 pagesASME VIII Div. 1 - 6 Pressure Testingعصمت ضيف الله75% (4)

- QAQC Manager, Authorized APIDocument3 pagesQAQC Manager, Authorized APIعصمت ضيف اللهNo ratings yet

- Asme Viii Div. 1 - 3 StaticheadDocument35 pagesAsme Viii Div. 1 - 3 Staticheadعصمت ضيف الله100% (2)

- Asme Viii Div. 1 - 3 StaticheadDocument35 pagesAsme Viii Div. 1 - 3 Staticheadعصمت ضيف الله100% (2)

- Pressure Vessel InspectionDocument44 pagesPressure Vessel Inspectionأحمد صبحى100% (4)

- In Servicepressurevesselinspectionaccordingtoapi 51010theditionoverview 180328042225 PDFDocument33 pagesIn Servicepressurevesselinspectionaccordingtoapi 51010theditionoverview 180328042225 PDFKrishna Vacha100% (2)

- Hydrocarbon Migration and Trapping MechanismsDocument51 pagesHydrocarbon Migration and Trapping MechanismsReddy Setyawan100% (3)

- Welder and Procedure QualificationDocument26 pagesWelder and Procedure Qualification'Izzad AfifNo ratings yet

- Valves Guide: Types, Parts, Standards & SpecificationsDocument141 pagesValves Guide: Types, Parts, Standards & SpecificationsrichardNo ratings yet

- Cswip 2015 Q& ADocument61 pagesCswip 2015 Q& ANaga Jothi50% (2)

- My ASME VIII Div 2 Vessels Are at the End of Their Life! What NowDocument56 pagesMy ASME VIII Div 2 Vessels Are at the End of Their Life! What NowRanjit Koshy Alexander100% (1)

- Asme Section Viii Div 1 2 3Document73 pagesAsme Section Viii Div 1 2 3Sakthi Pk100% (3)

- ASME VIII Div. 1 - 2 Joint EfficiencyDocument28 pagesASME VIII Div. 1 - 2 Joint Efficiencyعصمت ضيف الله89% (9)

- ASME VIII Div. 1 - 2 Joint EfficiencyDocument28 pagesASME VIII Div. 1 - 2 Joint Efficiencyعصمت ضيف الله89% (9)

- Chem Note SS1 1st TermDocument32 pagesChem Note SS1 1st TermVictor Okosun94% (16)

- Biocide Selection Guide: Oil and GasDocument8 pagesBiocide Selection Guide: Oil and GasJOSEANTONIO2001100% (1)

- Calculation Cover Sheet: ClientDocument8 pagesCalculation Cover Sheet: Clientanamaria ursuNo ratings yet

- Piping CodesDocument32 pagesPiping Codesengrabrar100% (3)

- Preguntas Practicas ASME B31.3Document25 pagesPreguntas Practicas ASME B31.3Andres BermudezNo ratings yet

- Module 6Document86 pagesModule 6Ahmed Abd ElmegeedNo ratings yet

- ASME Pressure Vessel Joint EfficienciesDocument4 pagesASME Pressure Vessel Joint EfficienciesliamcsNo ratings yet

- NTIW Tube Sheet PaperDocument10 pagesNTIW Tube Sheet PaperPankaj SinglaNo ratings yet

- Valve Components and Design Explained in DetailDocument19 pagesValve Components and Design Explained in DetailIzziyyahNo ratings yet

- Types of ValvesDocument6 pagesTypes of ValvesersgdNo ratings yet

- Chapter 4Document29 pagesChapter 4Engineers GalleryNo ratings yet

- Oil & Gas Surface Facilities: Presented by Carlos 6 March 2015Document53 pagesOil & Gas Surface Facilities: Presented by Carlos 6 March 2015Oscar YañezNo ratings yet

- ASSET INTEGRITY SECTION DAILY REPORTDocument1 pageASSET INTEGRITY SECTION DAILY REPORTعصمت ضيف اللهNo ratings yet

- Pmbok 5thDocument5 pagesPmbok 5thfloayzav5684No ratings yet

- PMP FormulasDocument3 pagesPMP FormulasMohyuddin A MaroofNo ratings yet

- Pmbok 5thDocument5 pagesPmbok 5thfloayzav5684No ratings yet

- Welder MatrixDocument12 pagesWelder Matrixعصمت ضيف اللهNo ratings yet

- C.V. Summary of QA/QC Manager with 17+ Years ExperienceDocument8 pagesC.V. Summary of QA/QC Manager with 17+ Years Experienceعصمت ضيف اللهNo ratings yet

- Answer of Cswip-2015Document2 pagesAnswer of Cswip-2015عصمت ضيف اللهNo ratings yet

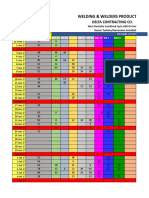

- Welding & Welders ActivitiesDocument4 pagesWelding & Welders Activitiesعصمت ضيف اللهNo ratings yet

- PMP CH 6-1 (Time Management)Document109 pagesPMP CH 6-1 (Time Management)عصمت ضيف اللهNo ratings yet

- Mandatory Minimum NondestructiveDocument1 pageMandatory Minimum Nondestructiveعصمت ضيف اللهNo ratings yet

- PMP FormulasDocument3 pagesPMP FormulasMohyuddin A MaroofNo ratings yet

- PMP CH 5-2Document76 pagesPMP CH 5-2عصمت ضيف اللهNo ratings yet

- 01 Introductiontoframework 101018053825 Phpapp01Document52 pages01 Introductiontoframework 101018053825 Phpapp01Uma KandukuriNo ratings yet

- 01 Introductiontoframework 101018053825 Phpapp01Document52 pages01 Introductiontoframework 101018053825 Phpapp01Uma KandukuriNo ratings yet

- Chapter 2 Fluid StaticsDocument13 pagesChapter 2 Fluid StaticsguhanNo ratings yet

- Laboratory Report on Emulsion ExperimentDocument14 pagesLaboratory Report on Emulsion Experimenteizat abasNo ratings yet

- AOAC 965.08 Kadar Air Pada PupukDocument3 pagesAOAC 965.08 Kadar Air Pada PupukDENI ARIFIYANTONo ratings yet

- Regulated explosive substances and articles documentDocument37 pagesRegulated explosive substances and articles documentJeyas LeoNo ratings yet

- DLSU-CE-Geotech Lab 2 Unconfined Compression Test ReportDocument5 pagesDLSU-CE-Geotech Lab 2 Unconfined Compression Test ReportAbigail Lorico100% (2)

- PO Pangling SalonDocument1 pagePO Pangling SalonArlin RomansyahNo ratings yet

- Laboratory Report CHM138 Experiment 1Document7 pagesLaboratory Report CHM138 Experiment 1Muhammad FaridNo ratings yet

- Growing shrimp and tilapia together in indoor aquacultureDocument13 pagesGrowing shrimp and tilapia together in indoor aquaculturetushar patelNo ratings yet

- Test # 12.1 Physics-Ii: Superb in EducationDocument8 pagesTest # 12.1 Physics-Ii: Superb in EducationKamran AliNo ratings yet

- LM Product BrochureDocument20 pagesLM Product BrochurekashishNo ratings yet

- Process Modeling Using Aspen HYSYSDocument2 pagesProcess Modeling Using Aspen HYSYSLinton WongNo ratings yet

- U4 - WeldingDocument59 pagesU4 - WeldingAnonymous LM9RaUA4yNo ratings yet

- The Reactivity Series NotesDocument8 pagesThe Reactivity Series NotesTHEVINESHNo ratings yet

- MCQ Gad 2Document8 pagesMCQ Gad 2AlhanNo ratings yet

- R717 (Ammonia) Pressure Temperature ChartDocument2 pagesR717 (Ammonia) Pressure Temperature ChartNeoZeruelNo ratings yet

- 100-800 HP Boiler Control System PLC HMI Safety FunctionsDocument4 pages100-800 HP Boiler Control System PLC HMI Safety FunctionssebaversaNo ratings yet

- FLuid LabDocument7 pagesFLuid LabArik EthanNo ratings yet

- NFL Corporate Presentation FinalDocument27 pagesNFL Corporate Presentation Finalnirmal singhNo ratings yet

- Predictive Wear Modelling of Lubricated Piston Rings in A Diesel EngineDocument14 pagesPredictive Wear Modelling of Lubricated Piston Rings in A Diesel EngineJoel E ValenciaNo ratings yet

- Data Sheet For Mixer M34Document5 pagesData Sheet For Mixer M34bingminNo ratings yet

- Dimensional Analysis ExerciseDocument2 pagesDimensional Analysis ExercisebiribiboiNo ratings yet