Professional Documents

Culture Documents

Cycloid Drive - Replaced by Planocentric Involute Gearing PDF

Uploaded by

Max GrandeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cycloid Drive - Replaced by Planocentric Involute Gearing PDF

Uploaded by

Max GrandeCopyright:

Available Formats

JournaJof

Mechanical

Science and

Technology

Journal of Mechanical Science and Technology 21 (2007) 1172-1177

Development of Speed Reducer with Planocentric Involute

Gearing Mechanism

Moon-Woo Park'", Jae-Hoon Jeong", Jeong-Hyeon Ryu",

Hyoung-Woo LeeC, Noh-Gill Park"

aDepartment 0/ Mechanical Design Engineering, Graduate School, Pusan National University,

Jangjeon-Dong, Geumjeong-Gu, Busan, Korea

bSsangYong Motor Company, Chilkoi-Dong, Pyeongtaek, Gyeonggi-Do, Korea

cSchool ofMechanical Engineering, Pusan National University, Jangjeon-Dong, Geumjeong-Gu, Busan, Korea

(Manuscript Received December 18, 2006; Revised May 23, 2007; Accepted May 29,2007)

Abstract

A new speed reducer with the planocentric involutegearing mechanism,which can be replaced with a cycloid drive,

is developed. This speed reducer eliminates some significant disadvantages of the cycloid drive, which are difficulty

in not only designing and manufacturing the tooth profile but also meshing the gears to maintain an accurate center

distance. In this paper, to avoid tooth tip interference between internal and external gears and maximize a speed

reduction ratio, a pressure angle, a tooth height, a profile shifting factor and the number of teeth are simulated. We

manufacture a prototype based on these simulated results of the design specifications (the rated power of 350watts,

rated speed of 3600rpm and speed reduction ratio of41:1), of which the overall size is <DI46mm x95.2mm. A power

efficiency test of the prototype is carried out to compare with the cycloid drive.

Keywords: Gear; Speed reducer; Planetary gear; Planocentric; Involute; Cycloid drive

one of the planetary gear reducer. The designing and

1. Introduction machining process of the cycloid gear tooth are very

difficult and the manufacturing and assembly errors

Typical speed reducers used widely in industry,

which have not only relatively high speed reduction between the cycloid gears and pins (or rollers)

but compactness, have been known as the planetary seriously affects in a backlash; mesh to maintain an

gear reducer, cycloid drive and harmonic drive. The accurate center distance is important (Lai, 2006). The

planetary gear reducer has the advantage of easiness harmonic drive is used for precision mechanisms

of designing and machining the involute tooth profile required a more higher speed reduction ratio, a little

as well as little influence of the manufacturing and backlash and high compactness, but it has the large

assembly errors. However, it is difficult to maximize moment of inertia due to the wave generator

a speed reduction ratio because of the tooth tip operation and relatively low power effi-ciency.

interference (Lynwander, 1983). Whereas, the cycloid (Caison, 1985)

drive, which uses the planocentric cycloid gearing In this paper, we developed a new speed reducer

mechanism, has a higher speed reduction ratio than with the planocentric involute gearing mechanism

which can be replaced with the cycloid drive; the

speed reducer can not only have the advantages of the

'Corresponding author. Tel.: +82 51 SID 1475, Fax.: +82 51 5147640

E-mail address:munu@pusan.ac.kr planetary gear reducer but eliminate the above sig-

Moon-Woo Park et al./ Journal a/Mechanical Science and Technology 2/(2007j 1172-1177 1173

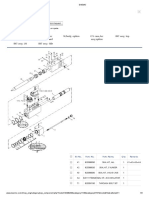

Ring Gear

nificant disadvantages of the cycloid drive. The key to

design the speed reducer is to avoid the tooth tip

Carrier Pin

interference between the internal and external gears

and maximize a speed reduction ratio. Therefore, the Carrier

objective function is to maximize a speed reduction

Output Shaft

ratio and the design constraints are considered to set

limits to the overall size, contact ratio and bending E--"~-

and contact stresses of the gears. A prototype of the

speed reducer with the rated power of 350watts, rated

speed of 3600rpm and speed reduction ratio of 41: 1 is

optimally designed and manufactured for industrial

robots. A power efficiency test of the prototype is

carried out to compare with the cycloid drive.

Fig. I. A kinematic diagram of the planocentric speed reducer.

2. Mechanism layout

2.1 Kinematic diagram

The mechanism of the new speed reducer is similar

to one of the cycloid drive, because the planocentric

gearing mechanism is used. The input shaft has two

cranks with phase difference of 180, which are

inserted into bearings of the two planetary gears,

respectively. The ring gear is fixed to the case. The

carrier assembly, which consists of the carrier pins,

carrier and its output shaft, is designed to transfer a

pure rotation of the planetary gears to the central axis Fig. 2. Checking the tooth tip interference.

of the output shaft. Bearings are installed at the

branches between the front of the input shaft and 2.2 Geometrical considerations in design

frontal case, between the frontal crankshaft and fron- The geometric relationship of the tooth tip inter-

tal planetary gear, between the rear crankshaft and ference between the ring and planetary gears can be

rear planetary gear, and between the rear of the input shown in Fig. 2. The tooth tip interference occurs

shaft and case. The case is fixed to a frame or an during engagement and disengagement gearing. To

external structure. prevent a possibility that the tooth tip interference

For the speed reducer, a speed reduction ratio can occurs, the path of AT! must clear the point of An by

be deduced as (Maiti et al., 1996) adequate margin. The AT l and An are the intercepted

points between the tip circles ofthe ring and planetary

. zp gears. Thus, a condition that tooth tip interference

l[2=---- (I)

Zr -zp doesn't occur is determined by arc length between the

points of AT! and An which is more than 0.05 times

Where as much as the gear module. (Colbourne, 1987)

Zp: the number of teeth of the planetary gear

z.: the number of teeth of the ring gear (2)

To maximize a speed reduction ratio, the number of Where

teeth of the planetary gear should be large as many as Rn : Radius of the tip circle of the gear

possible and the difference of the teeth number 0T2 : Polar angle ofthe point Aj-,

between the ring and planetary gears should be small 2

: Polar angle of the point AT! relative to the ring

as many as possible. gear

1174 Moon-Woo Park et af. / Journal ofMechanical Science and Technology 21(2007) 1172-1177

y To: torque acting on the output shaft

r p : a pitch circle radius ofthe planetary gear

rc : a pitch circle radius of the carrier pins

The relationship of the force and deformation

between the carrier pins and pin holes is based on the

Hertzian contact theory. (Pillkey, 1994)

(6)

Where

Using Eqs. (3)-(6), the bearing reaction force is

Fig. 3. A free body diagram of the frontal planetary gear. given as follows;

The variables (R n , BT 2 and B2 ) of the Eq. (2) are

functions of the gearing parameters which are the (7)

pressure angle, gear module, number of teeth, profile

shifting factors, tooth height, etc for the ring and

planetary gears. From the Eq. (2), tooth tip inter- Where;

ference is verified if these gearing parameters are

given. N/2

Lsinr+1(iA.-)

2.3 Strength analysis 7J = -'.i""-I':-:- _

L sin" (iA. - )

N /2

Figure 3 shows a free body diagram of the frontal

planetary gear on loading. The transmitted forces (Frb i=l

Frn) are acting on the line of action of the gear pair. In

addition, the bearing reaction forces (Fsts FS1J are Bending stresses (Sr) of the tooth root fillet and

generated from the frontal crankshaft. The reaction contact stresses (Sc) on the surface of the gear teeth

forces (f;, i=I,2, ...N/2) are applied from the carrier are calculated by the following AGMA stress

pins of which total number is N. Neglecting inertia equations.

forces, we have three force and moment equilibrium

conditions as follows; St = W;Ks 1.0 KsKrnK S (8)

Ky Fm J

Frn + Fe = FSI1 (3) 1/2

Frt = Fst (4) s, = Cp[W;Ca <. CrnC f] (9)

c; dpF 1

2: Pi

N /2

F,trp = Fcrc sin(iA - ) (5)

i=l

Where

Where

3. Conceptual design

3.1 Optimal design process

To maximize a speed reduction ratio, design para-

Moon-Woo Park et al. / Journal ofMechanical Science and Technology 21(2007) 1172-1177 ll75

meters listed in Table 1 are considered. The speci- 3.2 Design results

fications to design the new speed reducer are con-

With difference of the teeth number of 4; the 171

sidered as the same specifications as the cycloid drive

teeth number of the ring gear and 167 teeth number of

named by Sumitomo CNH-6095-43 listed in Table 2.

the planetary gear, the new speed reducer having the

The overall size is limited to be <1>160 mmx l lu rnrn

speed reduction ratio of 41: 1 is designed as listed in

as referred to Sumitomo CNH-6095-43. Efficiency is

Table 4. The significant performances of the designed

available in case of over 80% and allowable bending

speed reducer are compared with ones of the

and contact stresses of gears, which are ones of the

benchmark cycloid drive (CNH-6095-43) in Table 5.

chromium-molybdenum alloy steel (AISI4140), are

The contact and bending stresses of the designed

limited to be 30 kgf/mm' and 77 kgf/mrn", respec-

speed reducer listed in Table 5 are calculated by the

tively. (Harvey, 1985)

AGMA stress equations [Eqs. (8) and (9)]. The

Design of the new speed reducer is carried out by

contact stress and bearing reaction force of the

the algorithm of the simple optimal design checking

cycloid drive are calculated by the research of Sung-

the tooth tip interference, stresses, contact ratio, etc.

Chul Lee et al. (1987). The contact stress is nearly

The detail procedure is listed in Table 3.

twice high but the bearing reaction force has

Table I. Design parameters. decreased by 19% and the overall size is about the

same.

Module m

The weak points of stresses are checked by the

Pressure angle a

finite element method (FEM) software (ANSYS).

Teeth numbers ofgears

Gears Figure 4 shows the bending stress of the tooth root

Addendum and dedendum

Profile shift factosr fillet on condition that the maximum load is acting on

Face width the pitch point of the planetary gear. The maximum

Number of carrier pins bending stress of the tooth fillet is 23.25 kgf/mrn', in

Radius of carrier pin r, addition, Fig. 5 shows a contact stress between the

Carrier I,

Length of carrier pin planetary and ring gear and the maximum contact

Pitch circle radius of carrier pin

Table 4. Design results.

Table 2. Design specifications.

Gears Carrier

Speed ratio 41:1

Rated power (Watt) 350 m 0.75 mm 4

Rated input speed (rpm) 3600 a 30 0 10mm

167 50mm

171 42mm

Table 3. Design algorithm.

0.75 mm

I. choose the teeth numbers 0.75 mm

2. calculate a speed reduction ratio and skip if it is larger than o

specified one 0.05

3. choose common parameters (module and pressure angle) with 12mm

prescribed ranges of the rack, tooth height and profile shifting

factors for the gears

Table 5. Comparisons to the cycloid drive.

4. check the tooth tip interference and skip if Eq. (2) is not

satisfied. Designed Speed Cycloid Drive

5. check a contact ratio and skip if it is less than 1.2 Reducer (CNH-6095-43)

6. calculate the transmitted force acting on the planetary gear for

the rated power and input speed listed in Table I. Bending stress of

21.1 -

7. choose the width of the planetary gear gears (kgf/mnr')

8. check a bending and contact stresses of the gears and skip if

these are larger than prescribed allowable ones, respectively. Contact stress of

28.2 12.9

9. calculate the overall diameter of the ring gear and skip if it is gears (kgfzrrmr')

larger than prescribed one Bearing reaction

10. Among the selected feasible solution, choose the design 125.0 154.9

force (kgf)

parameters to maximize the speed reduction ratio and

minimize the overall size. Overall size (mm) <l>146x95.2 <l>145x100

1176 Aloon-Woo Park et al. / Journal ofMechanical Science and Technology 21(2007) 1172-1177

Reller Bush

l'I'l'IU""'l

~~~~

O',~S,H I

I

:!'Ue"!.

T:KPcI.

~:IKrV (A\'<)}

t>1U ~.;:Ii)lt--U .:znt-G!'>

.'!'IN ... 11'J.~~

2.!o3.'

I

.1,," w:) :~

S.167

Fig. 4. A bending stress of the planetary gear,

Fig. 6. A solid model of the planocentric speed reducer.

Ring gear Planetary gear Collar

Fig. 5. A contact stress between the planetary and ring gears.

stress is 30.44 kgf/rnrrr'. These stresses are similar to

Fig. 7. Manufactured components of the planocentric speed

calculated values by the AGMA stress equations so reducer.

that the speed reducer is safely designed.

Motor(f)ower source) Speed reducer

\ Dynamo meter

4. Prototype evaluation

4.1 Detail design for prototype

Based on the results of the conceptual design listed

in Table 4, we have done a detail design. The input

shaft having a crankshaft with eccentricity of 1.5mm

and output shaft connected to the carrier are designed.

Fig. 8. The test-bench for the planocentric speed reducer.

We used the software of COBRA (Advanced rotating

machinery Dynamics, 1994) to verify the fatigue life

4.2 Prototype manufacturing

of the five bearings according to the calculated

bearing radial forces. Based on the reaction forces, the Figure 7 shows manufactured components of the

four carrier pins inserted into roller bushes (dry speed reducer. The major components; the planetary

bearings) which are in contact with pin holes of the and ring gears are machined by a typical hobbing

planetary gears are designed. A solid model is machine. The input shaft (the crankshaft), output shaft

constructed as shown in Fig. 6 by commercial CAD (the carrier) and carrier pins are machined by CNC

software. (Pro/Engineer) machine tools and the other components are ma-

Aloon-Woo Park et af.! Journal of Mechanical Science and Technology 21(2007) 1172-1177 lin

- (I) Within the overall size of <1> 146 mrn x95.2 mm, the

I

100 Cycloid drive

. . New Speed Reducer

speed reducer with rated power 350 watt, rated

speed 3600 rpm, and a speed reduction rate of

41: I can be designed.

*s

:;:; 60

(2) The module and teeth numbers of the ring and

planetary gears are 0.75,171 and 167, respectively.

.

'0 40 The pressure angle is determined to be 30 to

~ avoid the tooth tip interference.

(3) The power efficiency of the prototype is measured

20

as high as 80%. A difference of the efficiency

between the prototype and cycloid drive is about

a +-~-,.--I--.--IfJ.---r~---'I'-~-r-~-,.---.---,

5 10 15 20 25 30 35 40 5%, which is slight. The prototype is suitable to be

Operation Speed(RPMx10'j replaced with the cycloid drive.

Fig. 9. A comparison of measured efficiency between the (4) The key point of the new model is regarded as to

planocentric speed reducer and cycloid drive. be economic to manufacture due to little influence

of a manufacturing and assembly errors.

chined by a generic lathe and milling machine.

References

4.3 Performance test

Advanced Rotating Machinery Dynamics (Rotor

Figure 8 shows a test-bench to measure power bearing, Technology & Software), 1994, "COBRA,"

transmission efficiency of the prototype. The test-

USA.

bench consists of a power source (AC servo motor),

AGMA, 1988, "Fundamental Rating Factors and

torque-sensor and dynamometer. The input shaft of

Calculation Methods for Involute Spur and Helical

the prototype is directly connected to the torque-

Gear Teeth," ANSI/AGMA 200 I-B886.

sensor and the output shaft is also directly connected

AGMA, 1989, "Geometry Factors for Determining

to the dynamometer. A test to measure power

the Pitting Resistance and bending Strength of Spur,

efficiency of the prototype is carried out under

Helical and Herringbone Gear Teeth," AGMA 908-

condition of constant output torque (dynamometer

B89.

brake torque) of 38N-m and variable input speeds.

CaIson, J. H., 1985, "Harmonic Drive for Servo

Figure 9 shows efficiency of the prototype and

Mechanisms," Machine Design, Vol. 6 pp. 102-106.

benchmark cycloid drive (CNH-6095-43) measured

Colbourne, 1. R., 1987, "The Geometry of Involute

on the same condition. The power efficiency of the

Gears," Springer-Verlag New York.

prototype is measured as high as 80%. According to a

Peter Lynwander, 1983, "Gear Drive Systems,"

comparison of the efficiency between the prototype

Marcel Dekker, Inc., pp.293~323.

and cycloid drive, a difference of the efficiency is

Philip, D. Harvey and Editors, 1985, "Engineering

about 5%, which is slight. Therefore, we consider that

Properties of Steel," American Society for Metals,

the new speed reducer is suitable to be replaced with

Metals Park, Ohio 44073, second printing.

the cycloid drive and used widely in industry.

MAITI, R. and ROY, A.K., 1996, "Minimum Tooth

Difference in Internal-external Involute Gear Fair,"

5. Conclusion Mech. Mach. Theory Vol. 31. No.4, pp. 475-485.

We developed the new speed reducer with the Lee, Sung-Chul, Oh, Park-Kyoun and Kwon, Oh-

planocentric involute gearing mechanism, which can Kwan, 1987, "A Study on the Design of the Torque

be replaced with the cycloid drive. To avoid the tooth Driver Used in Industrial Robot," Journal of the

tip interference and maximize a speed reduction ratio, KSLE, Vol. 3, No.2, pp. 72-80.

a pressure angle, a tooth height, a profile shifting factor Ta-Shi Lai, 2006, "Design and Machining of the

and the number of teeth are simulated. We manu- Epicycloid Planet Gear of Cycloid Drives," Int. J

factured the prototype with these simulated results for Adv ManufTechnol, Vol. 28, pp. 665-670.

the design specifications and carried out its efficiency Walter D. Pillkey, 1994, "Formulas for Stress,

test to compare with the cycloid drive. (RV-20) Strain and Structual Matrices," J Wiley New York.

You might also like

- Cycloid Drive - Replaced by Planocentric Involute GearingDocument6 pagesCycloid Drive - Replaced by Planocentric Involute GearingMax GrandeNo ratings yet

- Design and Analysis of Planetary Gearbox For All-Terrain VehicleDocument10 pagesDesign and Analysis of Planetary Gearbox For All-Terrain VehicleIJRASETPublications100% (1)

- Optimization of Gear Reduction Unit Through Ray DiagramDocument7 pagesOptimization of Gear Reduction Unit Through Ray Diagramأحمد دعبس100% (1)

- Design and Analysis Procedures For Shafts and Splines: Paul E. BurkeDocument21 pagesDesign and Analysis Procedures For Shafts and Splines: Paul E. BurkeBalasrinivasan Murugan100% (3)

- Tseng 2004 Mechanism and Machine TheoryDocument15 pagesTseng 2004 Mechanism and Machine TheoryKhanh VqNo ratings yet

- Agma 2002 b88Document48 pagesAgma 2002 b88Nursena SEVİNÇNo ratings yet

- Agma 914 b04Document45 pagesAgma 914 b04Nursena SEVİNÇNo ratings yet

- Gear TechnologyDocument52 pagesGear TechnologyJithinNo ratings yet

- Name: Roll No: AssignmentDocument6 pagesName: Roll No: Assignmentigualdi53No ratings yet

- Translated Copy of Translated Copy of DIN 58405-1Document30 pagesTranslated Copy of Translated Copy of DIN 58405-1venkatNo ratings yet

- Characteristics of Trochoids and Their Application To Determining Gear Teeth Fillet ShapesDocument14 pagesCharacteristics of Trochoids and Their Application To Determining Gear Teeth Fillet ShapesJohn FelemegkasNo ratings yet

- Effect of Increased Center Distance on Gear Teeth Contact Ratio and StressDocument21 pagesEffect of Increased Center Distance on Gear Teeth Contact Ratio and StressDavide MaranoNo ratings yet

- Helicoil Catalog - hc2000 Rev.5Document36 pagesHelicoil Catalog - hc2000 Rev.5Hugo CastroNo ratings yet

- Clutch DesignDocument7 pagesClutch DesignHla Min HtunNo ratings yet

- A Crowning Achievement For Automotive ApplicationsDocument10 pagesA Crowning Achievement For Automotive ApplicationsCan CemreNo ratings yet

- Gear DesignDocument83 pagesGear DesignmuhammadaminjamalmutNo ratings yet

- Design of Bevel and Worm Gear: Machine Element IIDocument60 pagesDesign of Bevel and Worm Gear: Machine Element IIkibromgidey12No ratings yet

- An Investigation of The Fatigue and Fretting PerformanceDocument19 pagesAn Investigation of The Fatigue and Fretting PerformanceKrishna PrasadNo ratings yet

- GEAR TOOTH PROFILESDocument5 pagesGEAR TOOTH PROFILESpremnathgopinathanNo ratings yet

- POWERTRAINDocument10 pagesPOWERTRAINarpitaNo ratings yet

- Agma 906 A94Document22 pagesAgma 906 A94Nursena SEVİNÇNo ratings yet

- Bonfiglioli Geared MotorDocument584 pagesBonfiglioli Geared MotorProdip SarkarNo ratings yet

- R.drago Publications ListDocument14 pagesR.drago Publications Listidontlikeebooks100% (1)

- The Application of Bevel GearsDocument6 pagesThe Application of Bevel GearsPrasanth ThiagarajanNo ratings yet

- GB/T 10095.2-2008 Cylindrical Gears Accuracy StandardDocument5 pagesGB/T 10095.2-2008 Cylindrical Gears Accuracy StandardtaghdirimNo ratings yet

- Face WidthDocument24 pagesFace WidthDipak100% (1)

- A Kinematic Analysis of Meshing Polymer Gear TeethDocument16 pagesA Kinematic Analysis of Meshing Polymer Gear TeethsandeepNo ratings yet

- 4 Dtic: Reliability and Life Prediction Methodology M60 Torsion BarsDocument60 pages4 Dtic: Reliability and Life Prediction Methodology M60 Torsion BarsTabiXh AahilNo ratings yet

- Rating of Asymmetric Tooth Gears: Alex L. Kapelevich and Yuriy V. ShekhtmanDocument6 pagesRating of Asymmetric Tooth Gears: Alex L. Kapelevich and Yuriy V. ShekhtmanDavide MaranoNo ratings yet

- Module IV: Gears and Gear TrainsDocument38 pagesModule IV: Gears and Gear TrainsSuraj VinayNo ratings yet

- Home Search Collections Journals About Contact Us My IopscienceDocument8 pagesHome Search Collections Journals About Contact Us My IopscienceCan CemreNo ratings yet

- 0618 Gearsolutions PDFDocument64 pages0618 Gearsolutions PDFdesetekNo ratings yet

- CAD-based Simulation of The Hobbing ProcessDocument11 pagesCAD-based Simulation of The Hobbing ProcessGabriel MariusNo ratings yet

- Agma 927 A01pdfDocument38 pagesAgma 927 A01pdfNursena SEVİNÇNo ratings yet

- 4319B - Flank Modifications in Bevel Gears Using A UMCDocument22 pages4319B - Flank Modifications in Bevel Gears Using A UMCRaul PerezNo ratings yet

- Iso 13282013Document15 pagesIso 13282013Kailas KatharNo ratings yet

- Gear Grinding: SoftwareDocument68 pagesGear Grinding: SoftwareTungNo ratings yet

- Gearsand GearingDocument57 pagesGearsand Gearingcamohunter71No ratings yet

- Introduction To Direct Gear DesignDocument15 pagesIntroduction To Direct Gear DesignburaktuncerNo ratings yet

- APR11 Bearing Software BrochureDocument8 pagesAPR11 Bearing Software BrochureDagim GirmaNo ratings yet

- Contact Stress Analysis of Spur Gear Teeth Pair PDFDocument6 pagesContact Stress Analysis of Spur Gear Teeth Pair PDFCan CemreNo ratings yet

- Reverse Engineering of Spur GearDocument4 pagesReverse Engineering of Spur GearInaamNo ratings yet

- Boston Gear Helical GearsDocument14 pagesBoston Gear Helical GearssandchiNo ratings yet

- 5.1 Chordal Tooth Thickness MeasurementDocument20 pages5.1 Chordal Tooth Thickness Measurementsharma RISHINo ratings yet

- Machine Design & Drawing - II - GEARSDocument12 pagesMachine Design & Drawing - II - GEARSSenthil KumarNo ratings yet

- Metallurgical Aspects of Gear and Shaft DesignDocument7 pagesMetallurgical Aspects of Gear and Shaft DesignSivaraman VisvanathanNo ratings yet

- Thermal Lead Correction For High-Speed Gears: Sinto America, IncDocument92 pagesThermal Lead Correction For High-Speed Gears: Sinto America, IncRongbaaz BongNo ratings yet

- 0611 GearSolutionsDocument72 pages0611 GearSolutionspoorianaNo ratings yet

- Power Skiving PDFDocument11 pagesPower Skiving PDFmadhavikNo ratings yet

- Gear TrainDocument19 pagesGear TrainGthulasi78No ratings yet

- KissSoft Article GearAnalysisAndOptimization PDFDocument12 pagesKissSoft Article GearAnalysisAndOptimization PDFeng13No ratings yet

- How Hobbing Works: The Generating ProcessDocument1 pageHow Hobbing Works: The Generating ProcessPriyadarshini KrishnaswamyNo ratings yet

- Measurements & Metrology (English)Document29 pagesMeasurements & Metrology (English)Kumar SubramanianNo ratings yet

- Structural Health MonitoringFrom EverandStructural Health MonitoringDaniel BalageasNo ratings yet

- Guide to Load Analysis for Durability in Vehicle EngineeringFrom EverandGuide to Load Analysis for Durability in Vehicle EngineeringP. JohannessonRating: 4 out of 5 stars4/5 (1)

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet

- A Guide to Motor-Cycle Design - A Collection of Vintage Articles on Motor Cycle ConstructionFrom EverandA Guide to Motor-Cycle Design - A Collection of Vintage Articles on Motor Cycle ConstructionNo ratings yet

- PredkiDocument12 pagesPredkiMax GrandeNo ratings yet

- KrullDocument12 pagesKrullMax GrandeNo ratings yet

- Vibration and Noise Generation in Gear Units Caused by Gear Teeth ImpactsDocument12 pagesVibration and Noise Generation in Gear Units Caused by Gear Teeth ImpactsMax GrandeNo ratings yet

- FEM 1 001 Booklet 1 To 8 PDFDocument277 pagesFEM 1 001 Booklet 1 To 8 PDFMax GrandeNo ratings yet

- HandschuhDocument14 pagesHandschuhMax GrandeNo ratings yet

- Gear Geometry of Cycloid DrivesDocument13 pagesGear Geometry of Cycloid DrivesMax Grande100% (1)

- Design of Planetary-Cyclo-Drive Speed Reducer Cycloid StageDocument90 pagesDesign of Planetary-Cyclo-Drive Speed Reducer Cycloid StageDiego Silva100% (1)

- Alban, Systematic Analysis of Gear FailuresDocument241 pagesAlban, Systematic Analysis of Gear FailuresMax Grande100% (10)

- Spanner Selection For Metric and Imperial Hex BoltsDocument1 pageSpanner Selection For Metric and Imperial Hex BoltsMuhammad SaimNo ratings yet

- Sulzer-Rta76.part 2Document206 pagesSulzer-Rta76.part 2Long NguyễnNo ratings yet

- Rock Shiox 2013 2018 Reverb Stealth A2 and b1 Service ManualDocument50 pagesRock Shiox 2013 2018 Reverb Stealth A2 and b1 Service ManualDorian Theodor ClenciuNo ratings yet

- 9 Radiator Installation PDFDocument3 pages9 Radiator Installation PDFAnonymous aufoLkcwhZNo ratings yet

- Maintenance Nissan CWBDocument13 pagesMaintenance Nissan CWBEko Sunaryo100% (1)

- Cummins KT6TA 19 engine overhaul part listDocument2 pagesCummins KT6TA 19 engine overhaul part listTC Bengalon100% (1)

- Astra Z14xeDocument5 pagesAstra Z14xeCrV3n1No ratings yet

- Bicycle Parts Catalog & Bathroom ReaderDocument44 pagesBicycle Parts Catalog & Bathroom ReaderBillNo ratings yet

- Pins and BushingsDocument12 pagesPins and Bushingsluis delgadoNo ratings yet

- PMI-BA Tubing AnchorDocument5 pagesPMI-BA Tubing AnchorSajida QadeerNo ratings yet

- Removing Reinstalling and Aligning The Main Drive AssemblyDocument4 pagesRemoving Reinstalling and Aligning The Main Drive Assemblykostas sanNo ratings yet

- Automobile MCQ K SINGHDocument15 pagesAutomobile MCQ K SINGHAMOL JAGTAP100% (2)

- FemaDocument43 pagesFemaVenkatesha HebbarNo ratings yet

- 303-01 - 2.3L EcoBoost - Removal and Installation - Timing Chain TensionerDocument4 pages303-01 - 2.3L EcoBoost - Removal and Installation - Timing Chain TensionerCARLOS LIMADANo ratings yet

- Rigger Load Charts PDFDocument8 pagesRigger Load Charts PDFShafa Ullah Khan NiaziNo ratings yet

- Diagramas Caterpillar RENR1497Document2 pagesDiagramas Caterpillar RENR1497jorge antonio guillenNo ratings yet

- Seval KatalogDocument46 pagesSeval KatalogAra Akram0% (2)

- Arp & 4G63T SpecsDocument1 pageArp & 4G63T SpecsPUTRA SANINo ratings yet

- Catalogo Hubbell Lineas AereasDocument50 pagesCatalogo Hubbell Lineas AereassalazarjanNo ratings yet

- Voltage Drop - BussmannDocument3 pagesVoltage Drop - BussmannJoe SalvoNo ratings yet

- Rolling Shutter FileDocument12 pagesRolling Shutter FileArvinder Singh0% (1)

- HDF50 7SDocument311 pagesHDF50 7SDomingo BravoNo ratings yet

- Daemo DMB230 Parts ManualDocument3 pagesDaemo DMB230 Parts ManualVICTOR GARCIANo ratings yet

- 2,0l Motronic (AQY+APK)Document11 pages2,0l Motronic (AQY+APK)Tremalone SemionelaNo ratings yet

- Specifications Culender Head 3512 CatDocument16 pagesSpecifications Culender Head 3512 CatAngel Theran Pardo75% (4)

- Transmission TransaxleDocument59 pagesTransmission Transaxlenitin9860No ratings yet

- H2ADDocument27 pagesH2ADTatiana MirandaNo ratings yet

- Lme500c Yedek Parça 1986Document321 pagesLme500c Yedek Parça 1986onur tezman100% (1)

- 2014 Ef2400is 7CF3Document26 pages2014 Ef2400is 7CF3DaniHuToscanoNo ratings yet