Professional Documents

Culture Documents

Infinity Supported Application Toyota 1993-1997 Supra Turbo

Uploaded by

manyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Infinity Supported Application Toyota 1993-1997 Supra Turbo

Uploaded by

manyCopyright:

Available Formats

Instruction

Manual

Infinity Supported Application

19931998 Toyota Supra MKIV Twin Turbo

STOP!

THIS PRODUCT HAS LEGAL RESTRICTIONS.

READ THIS BEFORE INSTALLING/USING!

THIS PRODUCT MAY BE USED SOLELY ON VEHICLES USED IN SANCTIONED COMPETITION WHICH MAY NEVER BE USED UPON A

PUBLIC ROAD OR HIGHWAY, UNLESS PERMITTED BY SPECIFIC REGULATORY EXEMPTION. (VISIT THE EMISSIONS PAGE AT HTTP://

WWW.SEMASAN.COM/EMISSIONS FOR STATE BY STATE DETAILS.)

IT IS THE RESPONSIBILITY OF THE INSTALLER AND/OR USER OF THIS PRODUCT TO ENSURE THAT IT IS USED IN COMPLIANCE WITH

ALL APPLICABLE LAWS AND REGULATIONS. IF THIS PRODUCT WAS PURCHASED IN ERROR, DO NOT INSTALL AND/OR USE IT. THE

PURCHASER MUST ARRANGE TO RETURN THE PRODUCT FOR A FULL REFUND.

THIS POLICY ONLY APPLIES TO INSTALLERS AND/OR USERS WHO ARE LOCATED IN THE UNITED STATES; HOWEVER CUSTOMERS

WHO RESIDE IN OTHER COUNTRIES SHOULD ACT IN ACCORDANCE WITH THEIR LOCAL LAWS AND REGULATIONS.

WARNING: This installation is not for the tuning novice! Use this system with EXTREME caution! The AEM

Infinity Programmable EMS allows for total flexibility in engine tuning. Misuse or improper tuning of this

product can destroy your engine! If you are not well versed in engine dynamics and the tuning of engine

management systems DO NOT attempt the installation. Refer the installation to an AEM-trained tuning

shop or call 800-423-0046 for technical assistance.

NOTE: All supplied AEM calibrations, Wizards and other tuning information are offered as potential

starting points only. IT IS THE RESPONSIBILITY OF THE ENGINE TUNER TO ULTIMATELY CONFIRM IF THE

CALIBRATION IS SAFE FOR ITS INTENDED USE. AEM holds no responsibility for any engine damage that

results from the misuse or mistuning of this product!

AEM Performance Electronics

AEM Performance Electronics, 2205 126th Street Unit A, Hawthorne, CA 90250

Phone: (310) 484-2322 Fax: (310) 484-0152

http://www.aemelectronics.com

Instruction Part Number:

Document Build 1/6/2015

2

OVERVIEW

The AEM Infinity EMS can be adapted to most fuel injected engines. The base configuration files

available for the Infinity ECU are starting points only and will need to be modified for your specific

application. This manual lists the files available and suggested changes for your engine. It also includes

a pinout with suggestions for adapting the Infinity ECU to your engine harness. It is the responsibility of

the installer to verify this information before starting the engine.

MODELS

Toyota

19931998 MKIV Supra Twin Turbo

DOWNLOADABLE FILES

Files can be downloaded from www.aeminfinity.com. An experienced tuner must be available to configure

and manipulate the data before driving can commence. The Quick Start Guide and Full Manual describe

the steps for logging in and registering at www.aeminfinity.com. These documents are available for

download in the Support section of the AEM Electronics website: http://www.aemelectronics.com/

products/support/instructions.

FILES

Downloadable files for MKIV Toyota Supra Twin Turbo

7100-XXXX-62 Infinity-10 (XXXX = serial number)

7101-XXXX-63 Infinity-8 (XXXX = serial number)

To properly control your engine, the application specific settings listed in this document MUST be

confirmed or changed to the given settings. Failure to do so may result in improper function and possible

ECU damage.

2015 AEM Performance Electronics

Infinity Supported Application 3

ADAPTER HARNESS OPTIONS

30-3500 Harness, Plug & Play

Plug & Play harnesses are available for specific applications and are sold separately. Specific model

files must be used with each harness. Contact AEM for more information.

30-3702 Harness, Mini Lead

This harness includes a fused power distribution center with main relay. Pre-terminated connectors are

available for the internal UEGO sensors and AEMNet. A bag of multi-color flying leads is included to

simplify custom harness builds.

30-3701 Connector Kit

This kit includes mating connectors and terminals for the Infinity. It also includes a main relay kit which

is necessary for proper power distribution. This kit is best suited for experienced installers who want to

build their own harness.

30-3600 O2 Sensor Extension Harness

30-3601 IP67 Comms Cable

30-3602 IP67 Logging Cable

2015 AEM Performance Electronics

4

IMPORTANT APPLICATION SPECIFIC SETTINGS

Infinity Tuner Wizard Setup

Engine

In the Wizard Engine tab confirm the following settings:

Number of Cylinders = 6

Engine Cycle Type = 4 Stroke

Ignition Type = Sequential (Coil On Plug)

Firing Order = 1-5-3-6-2-4

Cam/Crank

In the Wizard Cam/Crank tab confirm the following setting:

Toyota Supra (19931998 Turbo)

Open the Advanced Setup tab and set the following:

Crank Noise Cancellation = 70

Cam 1 Noise Cancellation = 70

Add the 1-Axis Lookup Table VR_PwmDuty [%] to your layout. Set the following:

Ignition Sync

Add a text grid control to your layout and select the following channels. Make sure their values match

the settings below for initial timing sync.

TrigOffset [degBTDC] = 23.00

CamSyncAdjustment = 11.00

See QuickStart Guide section Setup: Ignition Sync for instructions on timing sync.

Idle Stepper Max Steps

Go to Setup Wizard Idle page and confirm the following setting:

Idle Stepper Max Steps = 33

2015 AEM Performance Electronics

Infinity Supported Application 5

AC Input Switch

Go to Setup Wizard Input Function Assignment page and confirm the following setting:

AC Input Switch Setup = Analog17[V]

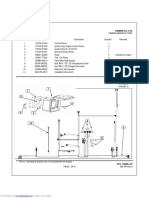

MAIN RELAY/FUEL PUMP SCHEMATIC

The 19931998 Toyota Supra Infinity patch harness requires a harness relay and fuel pump control to be

wired exactly as pictured below. Failure to do so may result in an unresponsive ECU and/or a no-start

condition.

2015 AEM Performance Electronics

6

IMPORTANT IDLE AIR CONTROL VALVE REQUIREMENTS

Many Toyota, Mitsubishi, and other vehicles use an Idle Air Control Valve with a Unipolar Stepper Motor

(6-pin connector) and MUST be modified. See instructions below. A Bipolar Stepper Motor (e.g., GM)

will have a 4-pin connector and DOES NOT need to be modified.

*This info does not apply to vehicles that utilize IACV solenoids.

The 2 center pins (Black-Red wires) supply 12V power to the stepper motor in the factory setup,

however these pins MUST BE DISCONNECTED before powering the AEM Infinity ECU.

2015 AEM Performance Electronics

Infinity Supported Application 7

Step 1: Disconnect connector from IACV housing and gently remove the retainer from the connector.

Step 2: Use a small flat-blade screwdriver/pick to move the terminal locks while pulling the Black-Red

wires out from the backside of the connector.

2015 AEM Performance Electronics

8

Step 3: Use heat shrink to insulate both 12V wires, and then zip-tie the insulated wires to a nearby

loom.

Step 4: Reinstall the retainer, and then plug the connector back into the IACV.

2015 AEM Performance Electronics

Infinity Supported Application 9

ECU COVER MODIFICATIONS

It is recommend that the OEM ECU cover panel be modified and reinstalled with the AEM Infinity EMS

when utilizing the mounting bracket. Failure to properly clearance and reinstall this panel (Toyota

PN#55199-14020) could potentially result in damage to the ECU, adapter harness, ECU connectors and/

or USB cables and connectors.

Please note clearance modifications below. These modifications should be performed with a die grinder,

90-degree sander, or plastic shears.

Step 1: Remove the four ribs located near the center of the cover as highlighted below.

Step 2: Trim the center support leg as outlined. Test fit, note, and trim any additional areas required.

2015 AEM Performance Electronics

10

PINOUTS

Infinity Pinouts

Dedicated and not

Dedicated reconfigurable

Assigned Assigned but reconfigurable

Available Available for user setup

Not Applicable Not used in this configuration

Required Required for proper function

7100-XXXX-62

Infinity

Hardware Reference 7101-XXXX-63 Hardware Specification Notes

Pin

Function

Lowside switch, 4A max, NO See "LowSide Assignment Tables" f or output

C1-1 LowsideSwitch_4 A/C Relay Control

internal f ly back diode. assignment.

Lowside switch, 4A max with

See Setup Wizard Page "LowSide

internal f ly back diode. Inductiv e

C1-2 LowsideSwitch_5 LS5 Assignment Tables" f or output assignment

load should NOT hav e f ull time

and 2D table "LS5_Duty [%]" f or activ ation.

power.

Lowside switch, 4A max with

See Setup Wizard Page "LowSide

internal f ly back diode. Inductiv e

C1-3 LowsideSwitch_6 LS6 Assignment Tables" f or output assignment

load should NOT hav e f ull time

and 2D table "LS6_Duty [%]" f or activ ation.

power.

Lowside switch f or UEGO heater control.

Connect to pin 4 of Bosch UEGO sensor.

C1-4 UEGO 1 Heat UEGO 1 Heat NOTE that pin 3 of the Sensor is heater (+)

and must be power by a f used/switched

12V supply .

Trim Current signal. Connect to pin 2 of

C1-5 UEGO 1 IA UEGO 1 IA

Bosch UEGO controller Bosch UEGO sensor.

Pumping Current signal. Connect to pin 6 of

C1-6 UEGO 1 IP UEGO 1 IP

Bosch UEGO sensor.

Nernst Voltage signal. Connect to pin 1 of

C1-7 UEGO 1 UN UEGO 1 UN

Bosch UEGO sensor.

Virtual Ground signal. Connect to pin 5 of

C1-8 UEGO 1 VM UEGO 1 VM

Bosch UEGO sensor.

Not usually needed f or automatic f irmware

updates through Inf inity Tuner. If

connection errors occur during update,

C1-9 Flash_Enable Flash Enable 10K pulldown

connect 12 v olts to this pin bef ore

proceeding with upgrade. Disconnect the 12

v olts signal af ter the update.

Full time battery power. MUST be powered

Dedicated power management

C1-10 +12V_R8C_CPU Battery Perm Power bef ore the ignition switch input is triggered.

CPU

(See C1-65.)

05V Falling edge f ire. DO NOT connect

directly to coil primary . Must use an ignitor

C1-11 Coil 4 Coil 4 25 mA max source current

OR CDI that accepts a FALLING edge f ire

signal.

05V Falling edge f ire. DO NOT connect

directly to coil primary . Must use an ignitor

C1-12 Coil 3 Coil 3 25 mA max source current

OR CDI that accepts a FALLING edge f ire

signal.

2015 AEM Performance Electronics

Infinity Supported Application 11

7100-XXXX-62

Infinity

Hardware Reference 7101-XXXX-63 Hardware Specification Notes

Pin

Function

05V Falling edge f ire. DO NOT connect

directly to coil primary . Must use an ignitor

C1-13 Coil 2 Coil 2 25 mA max source current

OR CDI that accepts a FALLING edge f ire

signal.

05V Falling edge f ire. DO NOT connect

directly to coil primary . Must use an ignitor

C1-14 Coil 1 Coil 1 25 mA max source current

OR CDI that accepts a FALLING edge f ire

signal.

05V Falling edge f ire. DO NOT connect

directly to coil primary . Must use an ignitor

C1-15 Coil 6 Coil 6 25 mA max source current

OR CDI that accepts a FALLING edge f ire

signal.

05V Falling edge f ire. DO NOT connect

directly to coil primary . Must use an ignitor

C1-16 Coil 5 Coil 5 25 mA max source current

OR CDI that accepts a FALLING edge f ire

signal.

Lowside switch, 4A max, NO See "LowSide Assignment Tables" f or output

C1-17 LowsideSwitch_2 Coolant Fan 1 Control

internal f ly back diode. assignment.

See Wizard page "LowSide Assignment

Tables" f or output assignment.

MIL Activ ates when any of the f ollowing

Lowside switch, 4A max with

f lags are true: ErrorAirTemp, ErrorBaro,

internal f ly back diode. Inductiv e

C1-18 LowsideSwitch_3 MIL Output ErrorCoolantTemp, ErrorEBP,

load should NOT hav e f ull time

ErrorFuelPressure, UEGO_0_Diag_error,

power.

UEGO_1_Diag_error, ErrorMAFAnalog,

ErrorMAFDigital, ErrorMAP,

ErrorOilPressure, ErrorThrottle.

C1-19 AGND_1 Sensor Ground Dedicated analog ground Analog 05V sensor ground

C1-20 AGND_1 Sensor Ground Dedicated analog ground Analog 05V sensor ground

Crankshaf t Position Crankshaf t Position 10K pullup to 12V. Will work with See Setup Wizard page Cam/Crank f or

C1-21

Sensor Hall Sensor Hall ground or f loating switches. options.

Camshaf t Position Sensor Camshaf t Position 10K pullup to 12V. Will work with See Setup Wizard page Cam/Crank f or

C1-22

1 Hall Sensor 1 Hall ground or f loating switches. options.

Camshaf t Position 10K pullup to 12V. Will work with See Setup Wizard page Cam/Crank f or

C1-23 Digital_In_2

Sensor 2 Hall ground or f loating switches. options.

See Setup Wizard page Input Function

10K pullup to 12V. Will work with Assignment f or calibration constant.

C1-24 Digital_In_3 Turbo Speed Hz

ground or f loating switches. TurboSpeed [RPM] = Turbo [Hz] * Turbo

Speed Calibration.

10K pullup to 12V. Will work with See Setup Wizard page Input Function

C1-25 Digital_In_4 Vehicle Speed Sensor

ground or f loating switches. Assignment f or calibration constant.

10K pullup to 12V. Will work with See channel FlexDigitalIn [Hz] f or raw

C1-26 Digital_In_5 Flex Fuel

ground or f loating switches. f requency input data.

Dedicated knock signal See Setup Wizard page Knock Setup f or

C1-27 Knock Sensor 1 Knock Sensor 1

processor options.

Dedicated knock signal See Setup Wizard page Knock Setup f or

C1-28 Knock Sensor 2 Knock Sensor 2

processor options.

0.7A max ground sink f or external Will activ ate at key on and at key of f

C1-29 +12V_Relay _Control +12V Relay Control

relay control according to the conf iguration settings.

C1-30 Power Ground Ground Power Ground Connect directly to battery ground.

Recommend twisted pair (one twist per 2")

Dedicated High Speed CAN

C1-31 CANL_Aout AEMNet CANL with terminating resistor. Contact AEM f or

Transceiv er

additional inf ormation.

2015 AEM Performance Electronics

12

7100-XXXX-62

Infinity

Hardware Reference 7101-XXXX-63 Hardware Specification Notes

Pin

Function

Recommend twisted pair (one twist per 2")

Dedicated High Speed CAN

C1-32 CANH_Aout AEMNet CANH with terminating resistor. Contact AEM f or

Transceiv er

additional inf ormation.

Lowside switch, 4A max with

See Setup Wizard page Boost Control f or

internal f ly back diode. Inductiv e

C1-33 LowsideSwitch_1 Boost Control options. Monitor BoostControl [%] channel

load should NOT hav e f ull time

f or output state.

power.

Lowside switch, 4A max, NO Switched ground. Will prime f or 2 seconds

C1-34 Lowside Fuel Pump driv e Fuel Pump

internal f ly back diode. at key on and activ ate if RPM > 0.

05V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as

the low ref erence. Do not connect signals

Throttle Position ref erenced to +12V as this can permanently

C1-35 Analog_In_7 12 bit A/D, 100K pullup to 5V

Sensor damage the ECU. See the Setup Wizard Set

Throttle Range page f or automatic min/max

calibration. Monitor the Throttle [%] channel.

Also DB1_TPSA [%] f or DBW applications.

05V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as

the low ref erence. Do not connect signals

C1-36 Analog_In_8 MAP Sensor 12 bit A/D, 100K pullup to 5V ref erenced to +12V as this can permanently

damage the ECU. See the Setup Wizard Set

Manif old Pressure page f or setup and

calibration. Monitor the MAP [kPa] channel.

05V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as

the low ref erence. Do not connect signals

ref erenced to +12V as this can permanently

C1-37 Analog_In_9 Fuel Pressure 12 bit A/D, 100K pullup to 5V

damage the ECU. See the Setup Wizard

Fuel Pressure page f or setup and

calibration. Monitor the FuelPressure [psig]

channel.

05V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as

the low ref erence. Do not connect signals

ref erenced to +12V as this can permanently

C1-38 Analog_In_10 Baro Sensor 12 bit A/D, 100K pullup to 5V

damage the ECU. See the Setup Wizard

Barometric Pressure page f or setup and

calibration. Monitor the BaroPress [kPa]

channel.

05V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as

the low ref erence. Do not connect signals

ref erenced to +12V as this can permanently

C1-39 Analog_In_11 Shif t Switch Input 12 bit A/D, 100K pullup to 5V

damage the ECU.

See the 1D lookup table 'Shif tSwitch' f or

setup. Also assignable to multiple f unctions.

See Setup Wizard f or details.

05V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as

the low ref erence. Do not connect signals

ref erenced to +12V as this can permanently

damage the ECU.

C1-40 Analog_In_12 Mode Switch 12 bit A/D, 100K pullup to 5V See the 1D lookup table 'ModeSwitch' f or

input state.

A multi-position rotary switch such as AEM

P/N 30-2056 is recommended.

Also assignable to multiple f unctions. See

Setup Wizard f or details.

Regulated, f used +5V supply f or

C1-41 +5V_Out_1 +5V Out Analog sensor power

sensor power

Regulated, f used +5V supply f or

C1-42 +5V_Out_1 +5V Out Analog sensor power

sensor power

2015 AEM Performance Electronics

Infinity Supported Application 13

7100-XXXX-62

Infinity

Hardware Reference 7101-XXXX-63 Hardware Specification Notes

Pin

Function

See Setup Wizard page 'HighSide

0.7A max, High Side Solid State Assigment Tables' f or conf iguration options.

C1-43 HighsideSwitch_1 HS1 (switched 12V)

Relay See 2D lookup table 'HS1_Table' f or

activ ation settings.

See Setup Wizard page 'HighSide

Assigment Tables' f or conf iguration options.

0.7A max, High Side Solid State See 2D lookup table 'HS0_Table' f or

C1-44 HighsideSwitch_0 VTEC

Relay activ ation settings.

See Setup Wizard page 'VTEC' f or def ault

activ ation criteria.

Crankshaf t Position Crankshaf t Position See Setup Wizard page Cam/Crank f or

C1-45

Sensor VR+ Sensor VR+ Dif f erential Variable Reluctance options.

Crankshaf t Position Crankshaf t Position Zero Cross Detection See Setup Wizard page Cam/Crank f or

C1-46

Sensor VR- Sensor VR- options.

Camshaf t Position Sensor Camshaf t Position See Setup Wizard page Cam/Crank f or

C1-47

1 VR- Sensor 1 VR- Dif f erential Variable Reluctance options.

Camshaf t Position Sensor Camshaf t Position Zero Cross Detection See Setup Wizard page Cam/Crank f or

C1-48

1 VR+ Sensor 1 VR+ options.

Non Driv en Lef t See Non Driv en Wheel Speed Calibration in

C1-49 VR+_In_2 Wheel Speed Sensor the Setup Wizard Input Function

+ Dif f erential Variable Reluctance Assignment page.

Zero Cross Detection

Non Driv en Lef t

C1-50 VR-_In_2

Wheel Speed Sensor -

See Driv en Wheel Speed Calibration in the

Driv en Lef t Wheel

C1-51 VR-_In_3 Setup Wizard Input Function Assignment

Speed Sensor - Dif f erential Variable Reluctance

page.

Zero Cross Detection

Driv en Lef t Wheel

C1-52 VR+_In_3

Speed Sensor +

DBW Motor Control 5.0A max Throttle Control Hbridge

C1-53 DBW1 Motor - +12V to close

Close Driv e

DBW Motor Control 5.0A max Throttle Control Hbridge

C1-54 DBW1 Motor + +12V to open

Open Driv e

C1-55 Power Ground Ground Power Ground Connect directly to battery ground.

Saturated or peak and hold, 3A

C1-56 Injector 6 Injector 6 Injector 6

max continuous

Saturated or peak and hold, 3A

C1-57 Injector 5 Injector 5 Injector 5

max continuous

Saturated or peak and hold, 3A

C1-58 Injector 4 Injector 4 Injector 4

max continuous

Saturated or peak and hold, 3A

C1-59 Injector 3 Injector 3 Injector 3

max continuous

C1-60 Power Ground Ground Power Ground Connect directly to battery ground.

12 v olt power f rom relay . Relay must be

C1-61 +12V +12V In 12 v olt power f rom relay controlled by +12V Relay Control signal, pin

C1-29 abov e.

Saturated or peak and hold, 3A

C1-62 Injector 2 Injector 2 Injector 2

max continuous

Saturated or peak and hold, 3A

C1-63 Injector 1 Injector 1 Injector 1

max continuous

12 v olt power f rom relay . Relay must be

C1-64 +12V +12V In 12 v olt power f rom relay controlled by +12V Relay Control signal pin

C1-29 abov e.

Full time battery power must be av ailable at

C1-65 +12V_SW Ignition Switch 10K pulldown

C1-10 bef ore this input is triggered.

See "Coolant Temperature" Setup Wizard f or

C1-66 Analog_In_Temp_1 Coolant Temp Sensor 12 bit A/D, 2.49K pullup to 5V

selection.

2015 AEM Performance Electronics

14

7100-XXXX-62

Infinity

Hardware Reference 7101-XXXX-63 Hardware Specification Notes

Pin

Function

Intake Air See "Air Temperature" Setup Wizard f or

C1-67 Analog_In_Temp_2 12 bit A/D, 2.49K pullup to 5V

Temperature selection.

See 1D table OilTempCal table f or

Harness_Analog_In_Temp Oil Temperature

C1-68 12 bit A/D, 2.49K pullup to 5V calibration data and OilTemp [C] f or channel

_3 Sensor

data.

Be sure that each internal coil of the

Automotiv e, Programmable

stepper motor are properly paired with the

C1-69 Stepper_2A Stepper 2A Stepper Driv er, up to 28V and

1A/1B and 2A/2B ECU outputs. Supports Bi-

1.4A

Polar stepper motors only .

Be sure that each internal coil of the

Automotiv e, Programmable

stepper motor are properly paired with the

C1-70 Stepper_1A Stepper 1A Stepper Driv er, up to 28V and

1A/1B and 2A/2B ECU outputs. Supports Bi-

1.4A

Polar stepper motors only .

Be sure that each internal coil of the

Automotiv e, Programmable

stepper motor are properly paired with the

C1-71 Stepper_2B Stepper 2B Stepper Driv er, up to 28V and

1A/1B and 2A/2B ECU outputs. Supports Bi-

1.4A

Polar stepper motors only .

Be sure that each internal coil of the

Automotiv e, Programmable

stepper motor are properly paired with the

C1-72 Stepper_1B Stepper 1B Stepper Driv er, up to 28V and

1A/1B and 2A/2B ECU outputs. Supports Bi-

1.4A

Polar stepper motors only .

C1-73 Power Ground Ground Power Ground Connect directly to battery ground.

DBW Motor Control 5.0A max Throttle Control Hbridge

C2-1 DBW2 Motor + +12V to open

Open Driv e

DBW Motor Control 5.0A max Throttle Control Hbridge

C2-2 DBW2 Motor - +12V to close

Close Driv e

C2-3 Power Ground Ground Power Ground Connect directly to battery ground.

Saturated or peak and hold, 3A

C2-4 Injector 7 Injector 7 Injector 7

max continuous

Saturated or peak and hold, 3A

C2-5 Injector 8 Injector 8 Injector 8

max continuous

Saturated or peak and hold, 3A

C2-6 Injector 9 Injector 9 Injector 9

max continuous

Saturated or peak and hold, 3A

C2-7 Injector 10 Injector 10 Injector 10

max continuous

C2-8 Power Ground Ground Power Ground Connect directly to battery ground.

12 v olt power f rom relay . Relay must be

C2-9 +12V +12V In 12 v olt power f rom relay controlled by +12V Relay Control signal, pin

C1-29 abov e.

Saturated or peak and hold, 3A

C2-10 Injector 11 Injector 11 Not used

max continuous

Saturated or peak and hold, 3A

C2-11 Injector 12 Injector 12 Not used

max continuous

05V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as

the low ref erence. Do not connect signals

ref erenced to +12V as this can permanently

C2-12 Analog_In_17 A/C Analog Request 12 bit A/D, 100K pullup to 5V

damage the ECU. See Setup Wizard Input

Functions page f or input selection. See

AC_Request_In 1-axis table f or activ ation

logic.

05V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as

C2-13 Analog_In_18 DBW_APP1 [%] 12 bit A/D, 100K pullup to 5V the low ref erence. Do not connect signals

ref erenced to +12V as this can permanently

damage the ECU.

2015 AEM Performance Electronics

Infinity Supported Application 15

7100-XXXX-62

Infinity

Hardware Reference 7101-XXXX-63 Hardware Specification Notes

Pin

Function

05V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as

C2-14 Analog_In_19 DBW_APP2 [%] 12 bit A/D, 100K pullup to 5V the low ref erence. Do not connect signals

ref erenced to +12V as this can permanently

damage the ECU.

See ChargeOutTemp [C] table f or

Charge Out

C2-15 Analog_In_Temp_4 12 bit A/D, 2.49K pullup to 5V calibration data and ChargeOutTemp [C] f or

Temperature

channel data.

See AirboxTemp [C] table f or calibration

C2-16 Analog_In_Temp_5 Airbox Temperature 12 bit A/D, 2.49K pullup to 5V

data and AirboxTemp [C] f or channel data.

See FuelTemp [C] table f or calibration data

C2-17 Analog_In_Temp_6 Fuel Temperature 12 bit A/D, 2.49K pullup to 5V

and FuelTemp [C] f or channel data.

05V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as

the low ref erence. Do not connect signals

C2-18 Analog_In_13 Oil Pressure 12 bit A/D, 100K pullup to 5V ref erenced to +12V as this can permanently

damage the ECU. See Setup Wizard Oil

Pressure page f or setup options. See

OilPressure [psig] f or channel data.

05V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as

the low ref erence. Do not connect signals

Traction Control ref erenced to +12V as this can permanently

C2-19 Analog_In_14 12 bit A/D, 100K pullup to 5V

Mode / Sensitiv ity damage the ECU. See the TC_SlipTrgtTrim

[MPH] 1-axis table. A multi-position rotary

switch such as AEM P/N 30-2056 is

recommended.

05V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as

the low ref erence. Do not connect signals

Exhaust Back

C2-20 Analog_In_15 12 bit A/D, 100K pullup to 5V ref erenced to +12V as this can permanently

Pressure

damage the ECU. See Setup Wizard

Exhaust Pressure page f or setup options.

See EBPress [kPa] f or channel data.

05V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as

C2-21 Analog_In_16 DBW1_TPSB [%] 12 bit A/D, 100K pullup to 5V the low ref erence. Do not connect signals

ref erenced to +12V as this can permanently

damage the ECU.

Regulated, f used +5V supply f or

C2-22 +5V_Out_2 +5V Out Analog sensor power

sensor power

Regulated, f used +5V supply f or

C2-23 +5V_Out_2 +5V Out Analog sensor power

sensor power

Regulated, f used +5V supply f or

C2-24 +5V_Out_2 +5V Out Analog sensor power

sensor power

See Driv en Wheel Speed Calibration in the

Driv en Right Wheel

C2-25 VR+_In_5 Setup Wizard Input Function Assignment

Speed Sensor + Dif f erential Variable Reluctance

page.

Zero Cross Detection

Driv en Right Wheel

C2-26 VR-_In_5

Speed Sensor -

See Non Driv en Wheel Speed Calibration in

Non Driv en Right

C2-27 VR-_In_4 the Setup Wizard Input Function

Wheel Speed Sensor -

Dif f erential Variable Reluctance Assignment page.

Non Driv en Right Zero Cross Detection

C2-28 V R+_In_4 Wheel Speed Sensor

+

Lowside switch, 4A max with

internal f ly back diode, 2.2K 12V See Setup Wizard page Tacho f or

C2-29 LowsideSwitch_9 Tachometer

pullup. Inductiv e load should NOT conf iguration options.

hav e f ull time power.

2015 AEM Performance Electronics

16

7100-XXXX-62

Infinity

Hardware Reference 7101-XXXX-63 Hardware Specification Notes

Pin

Function

C2-30 AGND_2 Sensor Ground Dedicated analog ground Analog 05V sensor ground

C2-31 AGND_2 Sensor Ground Dedicated analog ground Analog 05V sensor ground

C2-32 AGND_2 Sensor Ground Dedicated analog ground Analog 05V sensor ground

05V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as

C2-33 Analog_In_20 Spare Analog Input 12 bit A/D, 100K pullup to 5V the low ref erence. Do not connect signals

ref erenced to +12V as this can permanently

damage the ECU.

05V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as

the low ref erence. Do not connect signals

C2-34 Analog_In_21 3 Step Enable Switch 12 bit A/D, 100K pullup to 5V

ref erenced to +12V as this can permanently

damage the ECU. See 3StepSwitch 1-axis

table f or setup.

05V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as

the low ref erence. Do not connect signals

ref erenced to +12V as this can permanently

C2-35 Analog_In_22 USB Logging Activ ate 12 bit A/D, 100K pullup to 5V

damage the ECU. See

USBLoggingRequestIn channel f or input

state. See Setup Wizard page USB Logging

f or conf iguration options.

05V analog signal. Use +5V Out pins as

power supply and Sensor Ground pins as

the low ref erence. Do not connect signals

ref erenced to +12V as this can permanently

C2-36 Analog_In_23 Charge Out Pressure 12 bit A/D, 100K pullup to 5V

damage the ECU. See ChargeOutPress

[kPa] channel f or input state. See Setup

Wizard page Charge Out Pressure f or

calibration options.

Input can be assigned to dif f erent pins. See

No pullup. Will work with TTL

C2-37 Digital_In_6 Spare Digital Input Setup Wizard page Input Function

signals.

Assignments f or input mapping options.

See ClutchSwitch 1-axis table f or setup

No pullup. Will work with TTL options. Input can be assigned to dif f erent

C2-38 Digital_In_7 Clutch Switch

signals. pins. See Setup Wizard page Input Function

Assignments f or input mapping options.

C2-39 Power Ground Ground Power Ground Connect directly to battery ground.

C2-40 Power Ground Ground Power Ground Connect directly to battery ground.

Dedicated High Speed CAN

C2-41 CanH_Bout CANH Not used

Transceiv er

Dedicated High Speed CAN

C2-42 CanL_Bout CANL Not used

Transceiv er

Activ ates if any of the f ollowing f lags are

Lowside switch, 4A max with true: OilPressProtectOut, LeanProtectOut,

Engine Protect internal f ly back diode. Inductiv e CoolantProtect. Output can be assigned to

C2-43 LowsideSwitch_8

Warning Out load should NOT hav e f ull time other f unctions. See Setup Wizard page

power. LowSide Assignment Tables f or additional

options.

Lowside switch, 4A max with See Spare GPO1 Basic Setup section of

internal f ly back diode. Inductiv e User GPIOs and PWM Setup Wizard page

C2-44 LowsideSwitch_7 Spare GPO1

load should NOT hav e f ull time LowSide Assignment Tables f or additional

power. options.

Virtual Ground signal. Connect to pin 5 of

C2-45 UEGO 2 VM UEGO 2 VM Bosch UEGO Controller

Bosch UEGO sensor.

2015 AEM Performance Electronics

Infinity Supported Application 17

7100-XXXX-62

Infinity

Hardware Reference 7101-XXXX-63 Hardware Specification Notes

Pin

Function

Nernst Voltage signal. Connect to pin 1 of

C2-46 UEGO 2 UN UEGO 2 UN

Bosch UEGO sensor.

Pumping Current signal. Connect to pin 6 of

C2-47 UEGO 2 IP UEGO 2 IP

Bosch UEGO sensor.

Trim Current signal. Connect to pin 2 of

C2-48 UEGO 2 IA UEGO 2 IA

Bosch UEGO sensor.

Lowside switch f or UEGO heater control.

Connect to pin 4 of Bosch UEGO sensor.

C2-49 UEGO 2 HEAT UEGO 2 HEAT NOTE that pin 3 of the Sensor is heater (+)

and must be power by a f used/switched

12V supply .

Optional f ull time battery power. MUST be

Dedicated power management

C2-50 +12V_R8C_CPU Battery Perm Power powered bef ore the ignition switch input is

CPU

triggered. (See C1-65.)

05V f alling edge f ire. DO NOT connect

directly to coil primary . Must use an ignitor

C2-51 Coil 7 Coil 7 25 mA max source current

OR CDI that accepts a FALLING edge f ire

signal.

05V f alling edge f ire. DO NOT connect

directly to coil primary . Must use an ignitor

C2-52 Coil 8 Coil 8 25 mA max source current

OR CDI that accepts a FALLING edge f ire

signal.

05V Falling edge f ire. DO NOT connect

directly to coil primary . Must use an ignitor

C2-53 Coil 9 Coil 9 25 mA max source current

OR CDI that accepts a FALLING edge f ire

signal.

05V f alling edge f ire. DO NOT connect

directly to coil primary . Must use an ignitor

C2-54 Coil 10 Coil 10 25 mA max source current

OR CDI that accepts a FALLING edge f ire

signal.

Highside switch, 0.7A max, Solid

Highside Fuel Pump +12V High Side Driv e. Will prime f or 2

C2-55 Fuel Pump State Relay , NO internal f ly back

switch seconds at key on and activ ate if RPM > 0.

diode.

C2-56 Not used Not used Not used Not used

Toyota Pin Numbering

19931998 Toyota Supra ECU Connectors View ed from Wire Side

2015 AEM Performance Electronics

18

Infinity Pin Numbering

AEM Infinity Connectors View ed from Wire Side

2015 AEM Performance Electronics

Infinity Supported Application 19

12 MONTH LIMITED WARRANTY

Advanced Engine Management Inc. warrants to the consumer that all AEM High

Performance products will be free from defects in material and workmanship for a

period of twelve (12) months from date of the original purchase. Products that fail within

this 12-month warranty period will be repaired or replaced at AEMs option, when

determined by AEM that the product failed due to defects in material or workmanship.

This warranty is limited to the repair or replacement of the AEM part. In no event shall

this warranty exceed the original purchase price of the AEM part nor shall AEM be

responsible for special, incidental or consequential damages or cost incurred due to the

failure of this product. Warranty claims to AEM must be transportation prepaid and

accompanied with dated proof of purchase. This warranty applies only to the original

purchaser of product and is non-transferable. All implied warranties shall be limited in

duration to the said 12-month warranty period. Improper use or installation, accident,

abuse, unauthorized repairs or alterations voids this warranty. AEM disclaims any

liability for consequential damages due to breach of any written or implied warranty on

all products manufactured by AEM. Warranty returns will only be accepted by AEM when

accompanied by a valid Return Merchandise Authorization (RMA) number. Product

must be received by AEM within 30 days of the date the RMA is issued.

Please note that before AEM can issue an RMA for any electronic product, it is first

necessary for the installer or end user to contact the EMS tech line at 1-800-423-0046 to

discuss the problem. Most issues can be resolved over the phone. Under no

circumstances should a system be returned or a RMA requested before the above

process transpires.

AEM will not be responsible for electronic products that are installed incorrectly, installed

in a non-approved application, misused, or tampered with.

Any AEM electronics product can be returned for repair if it is out of the warranty period.

There is a minimum charge of $50.00 for inspection and diagnosis of AEM electronic

parts. Parts used in the repair of AEM electronic components will be extra. AEM will

provide an estimate of repairs and receive written or electronic authorization before

repairs are made to the product.

2015 AEM Performance Electronics

You might also like

- Installation Instructions For EMS P/N 30-6310Document15 pagesInstallation Instructions For EMS P/N 30-6310davidNo ratings yet

- 10-1030 For EMS - 30-1030Document12 pages10-1030 For EMS - 30-1030Javier RojasNo ratings yet

- Installation Instructions For EMS P/N 30-6320Document13 pagesInstallation Instructions For EMS P/N 30-6320davidNo ratings yet

- Installation Instructions For: EMS P/N 30-1300 1990-1994 Eclipse Turbo, Talon Tsi, Laser RS, Galant VR4Document6 pagesInstallation Instructions For: EMS P/N 30-1300 1990-1994 Eclipse Turbo, Talon Tsi, Laser RS, Galant VR4Ruben GomezNo ratings yet

- Installation Instructions 30-1810Document11 pagesInstallation Instructions 30-1810Michael AliNo ratings yet

- Installation Instructions EMS 30-1320 / 30-1320UDocument10 pagesInstallation Instructions EMS 30-1320 / 30-1320Urogerio100% (1)

- Manual Evo4-8Document12 pagesManual Evo4-8Azre mohd norNo ratings yet

- 10-6320 For EMS - 30-6320Document13 pages10-6320 For EMS - 30-6320Alexandru AvrigeanuNo ratings yet

- MSD 2900 ManualDocument28 pagesMSD 2900 Manualwoocash clabyshNo ratings yet

- 10-1002 For EMS - 30-1002Document7 pages10-1002 For EMS - 30-1002Javier RojasNo ratings yet

- AEM InstallManual30 1120Document6 pagesAEM InstallManual30 1120Danno NNo ratings yet

- Manual 3sgte II PDFDocument12 pagesManual 3sgte II PDFKhurram SarfrazNo ratings yet

- Installation Instructions For: EMS P/N 30-6100 1993-1998 Toyota Supra TTDocument12 pagesInstallation Instructions For: EMS P/N 30-6100 1993-1998 Toyota Supra TTAlexandru AvrigeanuNo ratings yet

- Installation Instructions ForDocument17 pagesInstallation Instructions Forkilofome05No ratings yet

- 10-1000 For EMS - 30-1000Document6 pages10-1000 For EMS - 30-1000Javier RojasNo ratings yet

- Installation & User Manual: Engine InterfaceDocument10 pagesInstallation & User Manual: Engine InterfaceErickGonzalezFrancoNo ratings yet

- 30-6030 Series 2 Plug & Play EMS-1Document17 pages30-6030 Series 2 Plug & Play EMS-1Teerajet ChumrunworakiatNo ratings yet

- Installation Instructions 30-6300Document12 pagesInstallation Instructions 30-6300Jose AbreuNo ratings yet

- 10-6050 For EMS - 30-6050 - Updated Nov 2009Document12 pages10-6050 For EMS - 30-6050 - Updated Nov 2009Alexandru AvrigeanuNo ratings yet

- Af49 1505Document9 pagesAf49 1505engineeringspecialtiesltdNo ratings yet

- 10-1010 For EMS - 30-1010Document7 pages10-1010 For EMS - 30-1010Roy CormierNo ratings yet

- Installation Instructions For:: EMS P/N 30-6820 2004 Subaru WRX STI (USDM 2.5L Turbo)Document21 pagesInstallation Instructions For:: EMS P/N 30-6820 2004 Subaru WRX STI (USDM 2.5L Turbo)Alexandru AvrigeanuNo ratings yet

- Instruction Manual: P/N 30-2860 B Series COP Conversion KitDocument22 pagesInstruction Manual: P/N 30-2860 B Series COP Conversion KitWhiro Opo Arief100% (1)

- 10-1001 For EMS - 30-1001Document6 pages10-1001 For EMS - 30-1001Javier RojasNo ratings yet

- 30-3250 Engine Position Module Puck PDFDocument6 pages30-3250 Engine Position Module Puck PDFAzaad HassamNo ratings yet

- 30-6060 Series 2 Plug & Play EMS PDFDocument12 pages30-6060 Series 2 Plug & Play EMS PDFJuan ContrerasNo ratings yet

- FRENIC Ace Solar Pumping ManualDocument78 pagesFRENIC Ace Solar Pumping ManualSINES FranceNo ratings yet

- 10-6053 For EMS - 30-6053Document21 pages10-6053 For EMS - 30-6053Alexandru AvrigeanuNo ratings yet

- MurphyDocument18 pagesMurphyRoger Pozo AriasNo ratings yet

- Installation Instructions For: EMS P/N 30-1010 00-01 Acura Integra 98-99 Acura 2.3CL 98-02 Honda Accord 99-00 Honda CivicDocument7 pagesInstallation Instructions For: EMS P/N 30-1010 00-01 Acura Integra 98-99 Acura 2.3CL 98-02 Honda Accord 99-00 Honda Civicadulfo03455No ratings yet

- Gen Set Replacement Control Panel MODEL 540: Installation - Operation ManualDocument13 pagesGen Set Replacement Control Panel MODEL 540: Installation - Operation ManualBrianHaze100% (1)

- LadderProg ManualDocument47 pagesLadderProg ManualJeny KissyouNo ratings yet

- Controlador de EmpilhadeiraDocument76 pagesControlador de EmpilhadeiraJosias100% (4)

- HAR-1005 LT1 Fuel Injection Wiring Harness InstructionsDocument14 pagesHAR-1005 LT1 Fuel Injection Wiring Harness InstructionsJacob Hernandez100% (2)

- AEM 30-6310 ManualDocument15 pagesAEM 30-6310 ManualCarlz0rNo ratings yet

- FUJI FRENIC-Ace User - S ManualDocument590 pagesFUJI FRENIC-Ace User - S Manualsantosh reddy dundigalNo ratings yet

- (See Below) : 2006 - Current Electronic Fuel Injection Wiring Harness W/ Manual or Non-Electronic Automatic TransmissionDocument15 pages(See Below) : 2006 - Current Electronic Fuel Injection Wiring Harness W/ Manual or Non-Electronic Automatic TransmissionDaniel Jue100% (1)

- Mega TorqueDocument354 pagesMega TorqueGuilherme AugustoNo ratings yet

- EPC Technical Reference ManualDocument19 pagesEPC Technical Reference Manualhibidder7775891No ratings yet

- DVIN0008 Mitsubishi M800 OEM EVO89 Installation NotesDocument18 pagesDVIN0008 Mitsubishi M800 OEM EVO89 Installation NotesRickyTongNo ratings yet

- SR-4 Microprocessor Control System For Trailer Single-Temp UnitsDocument429 pagesSR-4 Microprocessor Control System For Trailer Single-Temp UnitsIan McDaniel (Mc)100% (2)

- 2007 Chevrolet Equinox: Submodel: Engine Type: Liters: Fuel Delivery: FuelDocument2 pages2007 Chevrolet Equinox: Submodel: Engine Type: Liters: Fuel Delivery: FuelJorge GarciaNo ratings yet

- 812FJ Operations ManualDocument18 pages812FJ Operations ManualRenato Bautista100% (1)

- 1998-2002 GM LS1 / LS6 Drive by Cable EFI Wiring Harness HAR-1012 LS1 Harness InstructionsDocument13 pages1998-2002 GM LS1 / LS6 Drive by Cable EFI Wiring Harness HAR-1012 LS1 Harness InstructionsJacob HernandezNo ratings yet

- Gen Set Replacement Control Panel MODEL 540: Installation - Operation ManualDocument13 pagesGen Set Replacement Control Panel MODEL 540: Installation - Operation ManualBrianHazeNo ratings yet

- 4 TNV 84 TZDocument6 pages4 TNV 84 TZCarlos Rivera MontesNo ratings yet

- UI Bulletin 124jDocument22 pagesUI Bulletin 124jJoshNo ratings yet

- Spitronics TCU Manual - How To Tune PDFDocument32 pagesSpitronics TCU Manual - How To Tune PDFShivam KohliNo ratings yet

- File 314 1241Document858 pagesFile 314 1241bigboss1017067No ratings yet

- 2013 Ski Doo REV XM XS SM 05620Document562 pages2013 Ski Doo REV XM XS SM 05620Maks100% (1)

- S2000 AEM PinoutDocument11 pagesS2000 AEM PinoutDionisis SpiliopoulosNo ratings yet

- Control Techniques Unidrive Control SystemDocument87 pagesControl Techniques Unidrive Control SystemJohn Bofarull GuixNo ratings yet

- Packaged Terminal Air Conditioner/Heat Pump Installation/Owner'S ManualDocument27 pagesPackaged Terminal Air Conditioner/Heat Pump Installation/Owner'S ManualMichael MartinNo ratings yet

- ES Series Hardware Manual170413Document64 pagesES Series Hardware Manual170413Oscar MontañezNo ratings yet

- HAR-1019 VORTEC Harness Instructions 9Document14 pagesHAR-1019 VORTEC Harness Instructions 9Jacob HernandezNo ratings yet

- Moog ServoDrives DS2000 Manual enDocument142 pagesMoog ServoDrives DS2000 Manual enBojan MarkovićNo ratings yet

- 10-6620 For EMS - 30-6620Document14 pages10-6620 For EMS - 30-6620Michael AliNo ratings yet

- Service Station Manual Aprilia Mojito 50ccDocument110 pagesService Station Manual Aprilia Mojito 50ccCatalin ChetanNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Combined Science: Trilogy: 8464/P/1F - Physics Paper 1 Foundation Tier Mark SchemeDocument14 pagesCombined Science: Trilogy: 8464/P/1F - Physics Paper 1 Foundation Tier Mark SchemeHassounii AlHakakNo ratings yet

- Manual of - Installation - Operation - Maintenance Light Oil and Biodiesel Burners Progressive and Fully Modulating Versions PG30 PG90 PG510 PG60 PG91 PG515 PG70 PG92 PG520 PG80 PG81Document52 pagesManual of - Installation - Operation - Maintenance Light Oil and Biodiesel Burners Progressive and Fully Modulating Versions PG30 PG90 PG510 PG60 PG91 PG515 PG70 PG92 PG520 PG80 PG81OSAMANo ratings yet

- 3 Mass Balance Agro1 PDFDocument28 pages3 Mass Balance Agro1 PDFLiam LagartoNo ratings yet

- L Series Actuator SpecificationDocument2 pagesL Series Actuator Specificationaung minhtetNo ratings yet

- Tropospheric Ducting TDMMDocument16 pagesTropospheric Ducting TDMMMuhammad JunaidNo ratings yet

- Genrator Dosent StartDocument21 pagesGenrator Dosent StartMohammad AmerNo ratings yet

- 1.1. Daftar Spek. Peralatan RigDocument61 pages1.1. Daftar Spek. Peralatan RigLavayrter100% (1)

- ClassiCool 12K To 72K - R410A - IOM - tcm478-51424Document88 pagesClassiCool 12K To 72K - R410A - IOM - tcm478-51424Dessouki SamakNo ratings yet

- CBIP Protection Guide 2016Document342 pagesCBIP Protection Guide 2016Sushant Yadav100% (5)

- UntitledDocument14 pagesUntitledSoorya Priya Gopala KrishnaNo ratings yet

- AOP605 Complementary Enhancement Mode Field Effect TransistorDocument7 pagesAOP605 Complementary Enhancement Mode Field Effect TransistorfrancicciusNo ratings yet

- Black Body Radiation-Online NotesDocument3 pagesBlack Body Radiation-Online NotesNeeraj Mosawa50% (4)

- Bicotest Model T272 - High Resistance Cable Fault LocatorDocument2 pagesBicotest Model T272 - High Resistance Cable Fault LocatorDEEPAK KUMARNo ratings yet

- Guidelines For Payment of Compensation Towards Damages in Regard To RoWDocument46 pagesGuidelines For Payment of Compensation Towards Damages in Regard To RoWclicknagpal100% (1)

- Operating Procedure ERLDCDocument154 pagesOperating Procedure ERLDCbramhanand vermaNo ratings yet

- Final Draft Business ProposalDocument8 pagesFinal Draft Business Proposalapi-384392869No ratings yet

- Control of Welding ConsumableDocument6 pagesControl of Welding ConsumableRaja Rathinam100% (1)

- Company Profile:: 1,624 Main Towns 8 Regional OfficesDocument8 pagesCompany Profile:: 1,624 Main Towns 8 Regional OfficesUsman SarwarNo ratings yet

- Jordan Toward A 100% Renewable Electricity SystemDocument14 pagesJordan Toward A 100% Renewable Electricity SystemMinh Pháp VũNo ratings yet

- BLDC 1500 2018 BC Building Code-Part 9 Single Family Dwelling BuildingsDocument12 pagesBLDC 1500 2018 BC Building Code-Part 9 Single Family Dwelling BuildingsHamza TikkaNo ratings yet

- Jack-Up Vessel Optimisation in Offshore Wind O&M by Generating Better For The Crown EstateDocument42 pagesJack-Up Vessel Optimisation in Offshore Wind O&M by Generating Better For The Crown EstateSally Shenton100% (1)

- Best Tech KoreanDocument8 pagesBest Tech KoreanUkay Dedi SukardiNo ratings yet

- .Fabrication of Solar Air Cooler For Remote AreaDocument4 pages.Fabrication of Solar Air Cooler For Remote AreaAnonymous Clyy9NNo ratings yet

- Electrical InstallationsDocument51 pagesElectrical InstallationsCinthia Lidia Hidrogo Paulino100% (1)

- Damper DatasheetDocument1 pageDamper DatasheetK P Vignesh RaoNo ratings yet

- Chemical Kinetics: The Iodine Clock Reaction: J. CortezDocument6 pagesChemical Kinetics: The Iodine Clock Reaction: J. CortezKyle CortezNo ratings yet

- SERVERON - Duval DGA Seminar - July 2016 (Summary)Document33 pagesSERVERON - Duval DGA Seminar - July 2016 (Summary)Cristian Méndez100% (1)

- Pegboard Meeting Minutes Nov14 FinalDocument2 pagesPegboard Meeting Minutes Nov14 FinalSuparman StNo ratings yet

- Siemens Loher Flameproof & Special Designed MotorsDocument21 pagesSiemens Loher Flameproof & Special Designed Motorspokiri100% (1)