Professional Documents

Culture Documents

Din en 14399-6 (2005.06) PDF

Uploaded by

Marco Cruz0 ratings0% found this document useful (0 votes)

165 views8 pagesOriginal Title

DIN EN 14399-6 (2005.06).pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

165 views8 pagesDin en 14399-6 (2005.06) PDF

Uploaded by

Marco CruzCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

mormCD- Stand 2006-1

DEUTSCHE NORM Sune 2005

DIN EN 14399-6

{cs 21,060.30 Supersedes

DIN 6916, October 1989 edition.

High-strength structural bolting assemblies for preloading

Part 6: Plain chamfered washers

English version of DIN EN 14399-5

Hochteste planmaBig vorspannbare Schraubenverbindungen fur don Metallbau - Teil 6: Flache Scheiben

mit Fase

National foreword

This standard has been prepared by CEN/TC 185 ‘Threaded and non-threaded mechanical fasteners and

accessories’ (Secratariat: Germany).

Tho responsible German body involved in its preparation was the Normenausschuss Mechanische

Verbincungselemente (Fasteners Standards Committee), Technical Committee FMV-AA 3.7 Stahlbauver-

schraubungen.

Details regarding the allocation of washers conforming to this standard to system HR or system HV bolt/aul/

washer assemblies are given in the introduction,

Amendments

This standard differs from DIN 6916, October 1989 edition, as follows.

a} The title has been amended.

b) The scope has been amended,

¢} References have been updated.

i} The nominal thread diameter of the associated bolt has been specified as nominal dimension.

¢) Dimension ¢ for nominal size 36 has been amended.

A) For dimension ¢, limiting values have been specified.

9) The designation has been amended.

Previous editions

DIN 6916: 1962-08, 1970-12, 1979-03, 1989-10.

Document comprises 8 pages.

(© napa ot is sandara ray ba reroducad wiwan ne pr aon ct Engi pice grouD 7?

‘Bn Dactsches sina fr Marron. Base, Baud Very Gro 10772 Borin, Germany, ‘ween de

‘ha te excise ight of ele or Gama Star (ON Nema. wore Bowne

onsoret

Normco- Stand 2005-11

EUROPEAN STANDARD EN 14399-6

NORME EUROPEENNE

EUROPAISCHE NORM March 2005

Ics 21.080.90

English version

High-strength structural bolting assemblies

for preloading

Part 6: Plain chamfered washers

Boulonnerie de construction métal- __Hochfeste planmaGig vorspannbare

fique & haute résistance apte ala pré- Schraubenverbindungen fur den Me

contrainte - Partie 6: Rondelles plates tallbau~ Teil 6: Flache Scheiben mit

chantreinges: Fas

This European Standard was approved by CEN on 2004-04-30.

CEN members are bound to comply with the CEN/CENELEC internal Regulations

which stipulate the conditions for giving this European Standard the status of a

national standard without any alteration

Up-to-date lists and bibliographical references concerning such national stand-

ards may be obtained on application to the Management Gentre or to any

CEN member.

‘The European Standards existin three official versions (English, French, German),

Aversion in any other language made by translation under the responsibility of a

CEN member into its own language and notified to the Management Centre has

the same status as the official versions.

CEN members are the nalional standards bodies of Austria, Belgium, Cyprus. the

Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary,

leeland, Wreland, Italy, Latvia, Lithuania, Luxembourg. Malta, the Netherlands,

Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland, and

the United Kingdom,

CEN

European Committee for Standardization

Comite Euranéen de Normalisation

Europiisches Komitee flr Normung

Management Centre: rue de Stassart, 36 B-1050 Brussels

(© 2005. CEN ~ Af rights of exploitation in any form and by any means fot. No, EN 14399-6:2005

reserved worldwide for CEN rational momber.

‘NormcO - Stand 20811

Pago?

EN 14399-6:2005

Contents Page

Foreword...

Introduetlon een

Scope

Normative references.

Dimensions...

Specification and reference standards...

Designation

Marking.

Bibliography

Foreword

‘This document (EN 14399-6:2005) has been prepared by Technical Committee CEN /TC 185 “Threaded and

nnon-threaded mechanical fasteners and accessories", the secretariat of which is held by DIN.

‘This European Standard shall be given the status of a national standard, either by publication of an identical text or

by endorsement, at tho latest by September 2005, and conflicting netional standards shall be withdrawn at the

latest by September 2005.

‘This document includes @ Bibfiography.

‘According 19 the CEN/CENELEC Internal Regulations, the national standards organizations of the following

counivies are bound to implement this European Standard: Aust, Gelgium, Cyprus, Czech Republic, Denmark,

Estonia, Finland, France, Germany, Greece, Hungary, Iceland, reland, Naty, Latvia, Lihuanla, Luxembourg, Malta,

‘Nethertands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzertand and United Kingdom.

‘Nowe - Stand 205-1

Page 3

EN 14399-6:2005,

Introduction

This document on structural bolting reflects the situation in Europe where two technical solutions exist to achieve the

necessary duciity of boltnutwasher assemblies. These solutions ullize diferent sysiems (HR and HV) of

bolunulwasher assemblies, sea Table 1. Both systems are well proved and it is up to the experts responsible for

structural bolting whether they use the one or the other system.

is, however, important for the performance of the assembly to avoid mixing up the components of both systems.

Therefore, bolts and nuts for both systems are standardized in one single part of this European Standard each and

the rnarking of the components of the same system is uniform.

Table — Systems of boltinuttwashor assemblies

Beniwaohe Bairaiwashe

sery sven

Sper He Sytem

seaemant atin

Belunat ose en Hao83 esas

waning Es HW

Prove cesses co war aro

Washer(s) EN 14399-5 or EN 14399-8 EN 14399-5 of EN 143996

Manin zl i

Setaara eee Lt en 1390.2 en 19902

Preloaded bolled assembles are very sensitive to differences in manufacture and lubrication. Therefore itis important

thal the assembly is supplied by one manufacturer who is always responsible forthe function of the assembly.

For the same reason itis important that coating of the assembly is under the control of one manufacturer.

Beside the mechanical properties of the components the functionality of the assembly requires that the specified

preload can be achieved if the assembly is tightened with a suitable procedure. For this purpose a test method for the

suitabilly of the components for preloading was created which will demonstrate whether the function of the assembly

is fufled

'W should be pointed out that compared to 1S0 272 the widths across flats (large series) for M12 and M20 have been

changed to 22 mm and 32 mm respectively. These changes are justified by the following reasons,

Under the specific conditions of structural boting the compressive stresses under the bott head or nut for the sizes

M12 may become (00 large with the width across fats of 21 mm, especialy if the washer is fitted excentrically to the

bolt axis.

For the size M20, the width across flats of 34 mm is very difficult to be produced. The change to 32 mm is primanly

‘motivated by economics but it should also be pointed out thal the width across flats of 32 mm is already common

practice in Europe.

For the time being, the product standards EN 14399-3 to EN 14398-6 are the only European Standards which have

regard to the general requirements of EN 14399-1. However, further product standards on

— Moots,

— countersunk head bolts, and

— [oad indicating washers:

for the use in high strength structural bolting or preloading are under preparation.

Norm «Stand 2008-11

Page 4

EN 14399-6:2005

1 Scope

‘This document specifies, together with EN 14399-1, hardened and tempered plain washers with chamfer intended

{or assembly with large series hexagon high-strength structural bolts and nuts with thread sizes from M12 to M36

inclusive.

NOTE Attention is drawn to the importance of ensuring thal tho washers are correclly used if salistactoy results pre to be

‘bined. For rocommendations concorning propor sppicalin, reference to ENV 1090-1 is made.

2 Normative references

‘The following referenced documents are indispensable for the application of this document. For dated references,

‘only the edition cited applies. For undated references, the latest edition of the referenced document (including any

amendments) appiies.

EN 14399-1, High-strength structural bolting assemblies for preloading — Part 1: General requirements.

EN 1SO 3269, Fasteners — Acceptance inspection (iSO 3269:2000).

EN 1S0 4759-3, Tolerances for fasteners — Part 3: Plain washers for bolts, screws and nuts — Products grades A

and C (ISO 4789-3:2000).

EN 1SO 10684, Fasteners — Hot alp galvanized coatings (ISO 10684:2004).

ormcD - Steno 2008-19

Page 5

EN 14999-6:2005

3 Dimensions

‘See Figure 4 and Table 2.

SF

Figure 1 — Dimensions

Table 2— Dimensions

Dimensions in itimetres

Nominal size

trominatinens | 12 | aap | 16 | cree | 20 | 22 | 2a | ar | ao | oe

ciameter of

associated bots)

7 mm [@ | |v | [a [a |o [we |a |o

imox_| 1327 | 1827 | 1727| 19.33 | 2133 | 239 | 26.93 | 2052 | s162 | 3762

7 wm_| 2348 | 27.48 | 2040 | 29.98 36.08 | 90.38 | 4938 | «2 | S40 | 60.60

mx [a |e | 30 |m jar | a | [so | oe | 66

mis fs [ste [se {els ts [s [es

+ me | 27 | a7 | a7 | a7 | a7 | a7 | ar | aa | 4a | sa

mm | 33 | 33 | 43] aa | 43 | 43 | 43 | 56 | 56 | 66

vom=mn | 05 | 05 | o75[ o76| 075| 075{ o7s| 1 | 1 | 125

+ mm | 10 | 10 |] 160] 150] t60[ 180] 160| 2 | 2 | 250

mm | 16 | 16 | 16 | 2 | 20 | 20 | 20 | 28 | 25 | 25 |

7 om | 19 | 19 | 19 | 25 [25 [ 25 | 25 [ 30 | 30 | 30 |

NOTE For hol dip galvanizad washers the above dimensions apply prior to galvanizing

‘Sizes in brackets are non-pelered sizes,

NormcO » Stand 2005-11

Page 6

EN 14389-6:2005

4 Specification and reference standards

Table 3 — Specifications and reference standards

Matoriat Steel

Gonaral requirements EN 14306-4

‘Mechanical properties Hardness range 300 HV to 370 HV

Product grade A

Tolerances ————

International Standard EN 180 4759-3

normal ‘as processed?

Surface finish® hot dip galvanized EN ISO 10684

others tobe agreed

arts shall be uniform and free of irreguianties or

Workmanship detrimental defects. No protroding burs shall appear on

the wash

For acceptance procedure, see EN (SO 3289.

‘Acceptability

‘Allenton is drawn to the need to consider the risk of hydrogen embrittlement when selecting an appropriate surface

treaiment process (e.g. cleaning and coating), see the relevant coating standards,

“As processed" means the normal fnish resulting from heat treatment with alight coating of ol

‘thor coatings may be negotiated between the purchaser end the manufacturer provided they do Act impair tho

‘mechanical properties or the funcional charactersties. Coatings of cadmium or cadmium atioys are not permed.

5 Designation

EXAMPLE Alhardened and tempered chamfered plain washer, nominal size d = 18 mm, for high-strength structure! bolting

{or preloading is designated as follows:

Washer EN 14399-6 — 16

6 Marking

Hardened and tempered chamfered washers shall be marked with the manutacturer’s trade (identification) mark and

{he fetter H. The marking shall be indented on the non-chamfered side.

Key

1. Identification mark of the manufacturer of the assembly.

Figure 2— Marking

Normc0- Stand 200s-t1

i

ia}

Page 7

EN 14399-6:2005

Bibliography

ENV 1090-1, Execution of stea! structures — Part 1: Generel rules and rules for buildings.

1S0 272, Festeners — Hexagon products - Widths across Nats.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Tapping DirectTappingDuctileIronPipeinPolyethylene PDFDocument7 pagesTapping DirectTappingDuctileIronPipeinPolyethylene PDFPn EkanayakaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Morecambe Marina Feasibility Study Main Report PDFDocument59 pagesMorecambe Marina Feasibility Study Main Report PDFharyanto99100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Design Criteria For RCCDocument7 pagesDesign Criteria For RCCAtifkhan132No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- S3-TL4 Bridge Railing PDFDocument1 pageS3-TL4 Bridge Railing PDFPn EkanayakaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Standard Construction Drawings - 20meg PDFDocument100 pagesStandard Construction Drawings - 20meg PDFPn EkanayakaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Angus MonitorsDocument16 pagesAngus Monitorsmuhammadtayyab_87No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Limit States Design in Structural Steel 8th EdDocument392 pagesLimit States Design in Structural Steel 8th EdPn EkanayakaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Mit - Concepte Cedare RCDocument9 pagesMit - Concepte Cedare RCRada IoanNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Lighting Structures PDFDocument30 pagesLighting Structures PDFScott TrainorNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Concrete Mix Design SpreadsheetDocument4 pagesConcrete Mix Design SpreadsheetSmith SivaNo ratings yet

- O 06 Dcty DFLCTNDocument9 pagesO 06 Dcty DFLCTNCarlos Rene Mamani TrujilloNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Beam On Flexible FoundationDocument4 pagesBeam On Flexible FoundationPn EkanayakaNo ratings yet

- Axial and Lateral Load Piles Fem v1.6Document60 pagesAxial and Lateral Load Piles Fem v1.6Shahab KhaledNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Chapter 4 - Slender ColumnsDocument26 pagesChapter 4 - Slender ColumnsMohamed Salah100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Concrete Floor Slabs On Grade Subjected To Heavy Loads PDFDocument57 pagesConcrete Floor Slabs On Grade Subjected To Heavy Loads PDFPn EkanayakaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Guide For Designing Energy Efficient Building EnclosuresDocument242 pagesGuide For Designing Energy Efficient Building EnclosuresPn EkanayakaNo ratings yet

- Watermain STD Dwgs-101101Document37 pagesWatermain STD Dwgs-101101Pn EkanayakaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Market Analysis Marina DevelopmentDocument88 pagesMarket Analysis Marina DevelopmentPn EkanayakaNo ratings yet

- Pile Cap Design - ColumnsDocument6 pagesPile Cap Design - Columnsntah8450% (2)

- Details of WDETAILS OF WATER SAMPLING STATION - Pdfater Sampling StationDocument31 pagesDetails of WDETAILS OF WATER SAMPLING STATION - Pdfater Sampling StationHong Leong KuNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Book Understanding Housing Defects Second Edition PDFDocument353 pagesBook Understanding Housing Defects Second Edition PDFPn Ekanayaka50% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Allowable Stress Design Method-Of-SolutionDocument11 pagesAllowable Stress Design Method-Of-SolutionPn EkanayakaNo ratings yet

- Annual Reports Grand Harbour Marina 2014Document90 pagesAnnual Reports Grand Harbour Marina 2014Pn EkanayakaNo ratings yet

- Yacht Marina ReviewDocument21 pagesYacht Marina ReviewPn EkanayakaNo ratings yet

- Request For Proposal Writing GuideDocument3 pagesRequest For Proposal Writing GuideSunilBhandari100% (1)

- SSB05 Detailed Design of Trusses 2010-03-22Document131 pagesSSB05 Detailed Design of Trusses 2010-03-22DN GHNo ratings yet

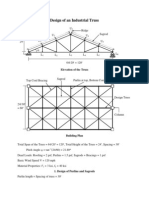

- Design of Industrial TrussDocument15 pagesDesign of Industrial TrussGurnam Singh Sodhi100% (3)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- MIAA Australian Marina Profile Report - Nov 2010Document13 pagesMIAA Australian Marina Profile Report - Nov 2010Pn EkanayakaNo ratings yet

- Facility StandardsDocument94 pagesFacility StandardsPn EkanayakaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)