Professional Documents

Culture Documents

7-2500 TDS PDF

Uploaded by

dakidofdaboomOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7-2500 TDS PDF

Uploaded by

dakidofdaboomCopyright:

Available Formats

Technical Information Sheet

Product Number: 7-2500

Application: Pipe Coating

Introduction:

Nap-Gard Product No. 7-2500 is a thermosetting epoxy powder designed as a coating for underground and subsea pipeline service. In

buried service, the coating is capable of withstanding continuous operating temperatures of 107C (225F). This product has been certified to

meet the requirements of CSA Z245.20-06, NACE RP-0394 and NSF 61 for Potable Water Services. This product is also recommended for

valves and fittings at an average film thickness of 8 mils per the NSF requirement and for use as a primer on multi-layer systems at

recommended 8 12 mils.

POWDER PROPERTIES

2

Color: Reddish Brown Theoretical Coverage: 134 Ft /lb/mil

Specific Gravity: 1.44 .05 Typical Gel Time: 22 4 Sec.

@ 205C (401F) CSA

Density: 1440 50 g/L Shelf Life @ 25C (77F): 12 months

CSA Z245.20-06 (Section 12.6.2.3) @50% RH

Thermal Characteristics: Tg1 = 58 5C

CSA Z245.20-06 Tg2 = 106 6C

H = 68 10 (J/g)

TYPICAL PROPERTIES OF APPLIED FILM

Recommended Film Thickness: 350m (14 mils) Average DSC glass transition temperature Tg3 = 110C (230F)

300m (12 mils) Minimum CSA Z245.20-06

Impact Resistance:

ASTM G14-72 @ 25C (77F) 160 in.lbs. Hardness:

1/8" X 5" X 8" Steel Panels Barcol, ASTM D2583 61 avg.

CSA Z245.20-06 @-30C (-22F) > 1.5 J Pass Shore D, ASTM D2240-74 90 avg.

Elongation: Compressive Strength: 10230 psi (+/- 20%)

Modified ASTM D2370-98 @23C (73F) 10.96% ASTM D695-95

Bending:

CSA-Z245.20-06 @-30C (-22F) 3.0/pipe dia. Pass

API-RP-5L7 Passes all requirements

Tensile Strength: 9436 psi

ASTM D2370-98/D882-91

Performance depends on film thickness. Consult Nap-Gard Specialist for specific recommendations.

Revised 07/16/2007

DuPont Powder Coatings, U.S.A.

9800 Genard Rd.

Houston, TX 77041

Tel.: 713-939-4000

Fax: 713-939-4027

www.dupontpowder.com

WARRANTY POLICY: Seller certifies that all coatings delivered to Customer in unopened factory filled containers meet all pertinent quality standards presented in its current published literature. Since matters of

surface preparation, application procedures, curing procedures and other local factors that affect coating performance are beyond Sellers control, Seller assumes no liability for coating failure other than to supply

replacement material for a coating material proven to be defective. Customer will determine suitability of this product for its use and thereby assumes all risks and liabilities in connection therewith. Seller will not

be liable for any injuries, damages or other losses derived, directly or indirectly, from or as a consequence of Customers use of the product. SELLER DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

RELATING TO ITS PRODUCTS AND THEIR APPLICATION, INCLUDING BUT NOT LIMITED TO WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSES.

Nap-Gard is a registered trademark of E.I. du Pont de Nemours and Company

for its brand of Polymer Powder Coatings. Only DuPont makes Nap-Gard.

Shear Adhesion ASTM D1002-94: Hot Water Resistance CSA Z245.20-06: Rating

Average 6555 psi 75C, 24 hr. 1-2 Pass

Minimum 5934 psi

Maximum 7865 psi

Thermal Conductivity: 0.19 0.02 BTU/hr./ft2/ft./F

ASTM C177

Cathodic Disbondment:

CSA Z245.20-06

24 hr., 3.5 volts, 65C (150F) 2 - 4 mm radius Pass

28 days, 1.5 volts, 25C (77F) 3 - 5 mm radius Pass

Strained C.D. No Cracking Pass

TYPICAL ELECTRICAL PROPERTIES

Dielectric Strength: 1500 volts/mil @ 250m (10 mils) Breakdown voltage: 20000 volts @ 450 m (18 mils)

ASTM D149-97 ASTM D149-97

Dielectric Constant: 2.15 at 1 MHz Volume Resistivity: 3.3 X 1015 ohm-cm.

ASTM D150 ASTM D257

CHEMICAL RESISTANCE TESTS *

90-Day Immersion per CSA Z245.20-98

HCl inH2O**, 10% NaCl, H2SO4 in H2O**, 10% NaCl in H2O, Distilled Water, 5% NaOH in H2O **, MgCO3/CaCO3 in H2O ** No Blistering

* For additional information refer to Nap-Gard Products Catalog Chemical Resistance Chart.

**Distilled Water

GENERAL APPLICATION PARAMETERS

1. Grit blast to NACE Near-White specifications (Swedish Standard #Sa 2) and profile between 50m (2 mils) and

112m (4.5 mils).

2. Use phosphoric acid/deionized water rinse if water soluble salt contamination is suspected.

3. Preheat pipe to approximately 240C (464F).

4. Apply Nap-Gard 7-2500 powder to meet customer thickness specifications.

5. Follow recommended cure schedule (see below).

6. Electrically inspect for holidays and repair all found with Nap-Gard 7-1631S, 7-1847, or 7-1861.

Revised 07/16/2007

DuPont Powder Coatings, U.S.A.

9800 Genard Rd.

Houston, TX 77041

Tel.: 713-939-4000

Fax: 713-939-4027

www.dupontpowder.com

WARRANTY POLICY: Seller certifies that all coatings delivered to Customer in unopened factory filled containers meet all pertinent quality standards presented in its current published literature. Since matters of

surface preparation, application procedures, curing procedures and other local factors that affect coating performance are beyond Sellers control, Seller assumes no liability for coating failure other than to supply

replacement material for a coating material proven to be defective. Customer will determine suitability of this product for its use and thereby assumes all risks and liabilities in connection therewith. Seller will not

be liable for any injuries, damages or other losses derived, directly or indirectly, from or as a consequence of Customers use of the product. SELLER DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

RELATING TO ITS PRODUCTS AND THEIR APPLICATION, INCLUDING BUT NOT LIMITED TO WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSES.

Nap-Gard is a registered trademark of E.I. du Pont de Nemours and Company

for its brand of Polymer Powder Coatings. Only DuPont makes Nap-Gard .

GEL TIME & CURE SCHEDULE GUIDELINES

The cure schedule for Nap-Gard Product No. 7-2500 shows the minimum time at temperature required to achieve the typical performance

properties of the coating. Because pipe cooling rates vary so widely with pipe wall thickness, no allowance has been made for heat loss from

the pipe but this can be easily measured on the coating line and allowance made.

Recommended powder application temperature range is 226C (438F) to 253C (488F) for single/dual layer FBE and post heating is

not a normal requirement. The minimum post application curing temperature (as measured on the coated pipe), and the time to quench

may conform to the following cure schedule:

Gel Time (CSA Method)

Temperature Time (Seconds) Cure Schedule Time to Quench**

205C (401F) * 20 226C (438F) 120 Seconds

220C (428F) * 12 232C (450F) 80 Seconds

226C (438F) 10 239C (462F) 60 Seconds

232C (450F) 9

* For three layer primer applications only

**CAUTION** Recommended time to quench is based on the assumption that the listed temperature is maintained without any cool down

rate. Time to quench will vary with application parameters and pipe sizes. Therefore, the above information shall be used only as a

guideline by the applicator to develop proper time to quench. Cure should be verified by DSC or other methods. For multi-layer, the

optimum time for adhesive application is between 30-70% cure of the FBE. This has to be developed by the applicator based on the

plant layout.

Revised 07/16/2007

DuPont Powder Coatings, U.S.A.

9800 Genard Rd.

Houston, TX 77041

Tel.: 713-939-4000

Fax: 713-939-4027

www.dupontpowder.com

WARRANTY POLICY: Seller certifies that all coatings delivered to Customer in unopened factory filled containers meet all pertinent quality standards presented in its current published literature. Since matters of

surface preparation, application procedures, curing procedures and other local factors that affect coating performance are beyond Sellers control, Seller assumes no liability for coating failure other than to supply

replacement material for a coating material proven to be defective. Customer will determine suitability of this product for its use and thereby assumes all risks and liabilities in connection therewith. Seller will not

be liable for any injuries, damages or other losses derived, directly or indirectly, from or as a consequence of Customers use of the product. SELLER DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

RELATING TO ITS PRODUCTS AND THEIR APPLICATION, INCLUDING BUT NOT LIMITED TO WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSES.

Nap-Gard is a registered trademark of E.I. du Pont de Nemours and Company

for its brand of Polymer Powder Coatings. Only DuPont makes Nap-Gard .

You might also like

- Technical Information Sheet: 7-2508 Pipe CoatingDocument3 pagesTechnical Information Sheet: 7-2508 Pipe Coatingreza329329No ratings yet

- Nap-Gard 7-2500 PDFDocument2 pagesNap-Gard 7-2500 PDFPietro ViganNo ratings yet

- Nap-Gard 7-2504 Gold-Dual Powder System: Technical Data SheetDocument3 pagesNap-Gard 7-2504 Gold-Dual Powder System: Technical Data Sheetlong chanNo ratings yet

- Nap-Gard 7-2514 PDFDocument2 pagesNap-Gard 7-2514 PDFPietro ViganNo ratings yet

- TDS - 7-0008 - Internal Pipe Coating - EngDocument3 pagesTDS - 7-0008 - Internal Pipe Coating - Englong chanNo ratings yet

- Fbe Dual Rock - Tds 7-2610Document3 pagesFbe Dual Rock - Tds 7-2610Jair PadillaNo ratings yet

- Karumel Ex4412: KCC CorporationDocument4 pagesKarumel Ex4412: KCC CorporationABAID ULLAHNo ratings yet

- PPSC - Product Data Sheet 3lpeDocument1 pagePPSC - Product Data Sheet 3lpejulianpirahNo ratings yet

- Epofine 556 FR/ FInehard 951Document3 pagesEpofine 556 FR/ FInehard 951Karishma Prabhu100% (1)

- 3496445985Document2 pages3496445985yosep gomezNo ratings yet

- Kocetal K700 Property DataDocument1 pageKocetal K700 Property DataRanjan GnanaoliNo ratings yet

- PPSC - Product Data Sheet 3lppDocument1 pagePPSC - Product Data Sheet 3lppjulianpirahNo ratings yet

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Document4 pagesF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- VISCOWRAP-HT Product Data Sheet EnglishDocument2 pagesVISCOWRAP-HT Product Data Sheet EnglishJA BustosNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- Properties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCDocument1 pageProperties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCsidsaleemNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Scotch Heavy Duty Mining Tape 31: Data Sheet June 2013Document2 pagesScotch Heavy Duty Mining Tape 31: Data Sheet June 2013Kishan MohtaNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- Epofine 556 - Finehard 22962Document5 pagesEpofine 556 - Finehard 22962Karishma PrabhuNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- 226NDocument2 pages226NUmaibalanNo ratings yet

- Typical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesDocument2 pagesTypical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesAdnan KhanNo ratings yet

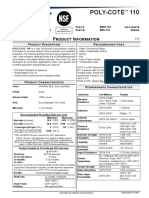

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- Hanwha LLDPE 7635Document1 pageHanwha LLDPE 7635M. Kürşad ArslanNo ratings yet

- CPVC PipesDocument24 pagesCPVC Pipeschaudhary osamaNo ratings yet

- RX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourDocument1 pageRX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourEetu SatosalmiNo ratings yet

- (201207) (PDS) Ex4700Document3 pages(201207) (PDS) Ex4700Abdelrahman AwadallahNo ratings yet

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackNo ratings yet

- Engineering Plastics Polybutylene Terephthalate Technical DataDocument2 pagesEngineering Plastics Polybutylene Terephthalate Technical Dataavinashchauhan2695No ratings yet

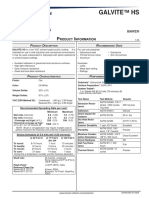

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- Sikadur 42LE Epoxy Grout DatasheetDocument5 pagesSikadur 42LE Epoxy Grout DatasheetJoshua HobsonNo ratings yet

- Sikadur®-42 MP Slow HC: Product Data SheetDocument4 pagesSikadur®-42 MP Slow HC: Product Data SheetAmnart KhampanitNo ratings yet

- Sikadur®-42 MP Slow - PDS - GCC - AE - (07-2016) - 1 - 1Document5 pagesSikadur®-42 MP Slow - PDS - GCC - AE - (07-2016) - 1 - 1邢焕震No ratings yet

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetArmanda SiryogiawanNo ratings yet

- KOPA KN126 enDocument1 pageKOPA KN126 enJagadeesh WaranNo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- Pds CPD Sikadur55SLV UsDocument2 pagesPds CPD Sikadur55SLV UsMikeNo ratings yet

- Tecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)Document1 pageTecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)David Matthew Kurniawan BEngNo ratings yet

- tds12 19 2019 - 10 49 12Document1 pagetds12 19 2019 - 10 49 12Camilo DazaNo ratings yet

- TecamidDocument2 pagesTecamidTejas HuddarNo ratings yet

- LG Chem TDS SP988 EnglishDocument1 pageLG Chem TDS SP988 EnglishSérgio BarbosaNo ratings yet

- Pao 100Document2 pagesPao 100Антон СтепураNo ratings yet

- PDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFDocument3 pagesPDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFMohamed NouzerNo ratings yet

- NorylDocument1 pageNorylAnonymous P8Bt46mk5INo ratings yet

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 pagesLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanNo ratings yet

- Elite NG 5401BDocument3 pagesElite NG 5401BAbdo WalidNo ratings yet

- Wonderloy PC 540Document2 pagesWonderloy PC 540Phung LucNo ratings yet

- Solar Roll PE55 PDFDocument2 pagesSolar Roll PE55 PDFLong TomahawkNo ratings yet

- Ptfe Data SheetDocument1 pagePtfe Data SheetEko PrastyoNo ratings yet

- MolykoteDocument2 pagesMolykoteRafael FrançaNo ratings yet

- Sikadur®-42 MP Slow HC: Product Data SheetDocument4 pagesSikadur®-42 MP Slow HC: Product Data SheetCbeztNo ratings yet

- Viscowrap-Ht: Product Data SheetDocument2 pagesViscowrap-Ht: Product Data SheetFarid HarisNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- ASME B16.5 Flanges PDFDocument50 pagesASME B16.5 Flanges PDFPedro De Mesquita Soares CamposNo ratings yet

- American Society For Testing and Materials Specification: Astm - AMS - Aerospace MaterialDocument10 pagesAmerican Society For Testing and Materials Specification: Astm - AMS - Aerospace MaterialjleonosNo ratings yet

- Cortadora en FrioDocument4 pagesCortadora en FriojleonosNo ratings yet

- Cross Reference of ASTM Material SpecificationsDocument2 pagesCross Reference of ASTM Material SpecificationsjleonosNo ratings yet

- P4lno41003f PDFDocument6 pagesP4lno41003f PDFjleonosNo ratings yet

- ASME B16.5 Flanges PDFDocument50 pagesASME B16.5 Flanges PDFPedro De Mesquita Soares CamposNo ratings yet

- Paints and Varnishes 3Document8 pagesPaints and Varnishes 3jleonos100% (1)

- Ansi - Isa-75 08 01-2002Document18 pagesAnsi - Isa-75 08 01-2002jleonosNo ratings yet

- Torque WrenchesDocument12 pagesTorque WrenchesjleonosNo ratings yet

- Barko 920 Industrial TractorDocument2 pagesBarko 920 Industrial Tractorjleonos0% (2)

- Ansi - Isa-75.01.01-2012 (60534-2-1 Mod)Document70 pagesAnsi - Isa-75.01.01-2012 (60534-2-1 Mod)jleonos100% (4)

- Poseidon I Barge SpecsDocument2 pagesPoseidon I Barge SpecsjleonosNo ratings yet

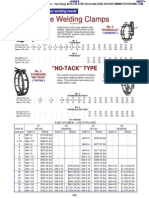

- Alineadores ManualesDocument1 pageAlineadores ManualesjleonosNo ratings yet

- Liqua-Blaster 100 Series BrochureDocument4 pagesLiqua-Blaster 100 Series BrochurejleonosNo ratings yet

- C 9Document4 pagesC 9jleonosNo ratings yet

- Brederoshaw Pds 3lpeDocument2 pagesBrederoshaw Pds 3lpejleonosNo ratings yet

- Ice 216 175C 1198Document89 pagesIce 216 175C 1198jleonosNo ratings yet

- 2485 FlukeDocument3 pages2485 FlukejleonosNo ratings yet

- Flange CatalogDocument76 pagesFlange CatalogSantosh ShettyNo ratings yet

- Tamsa TuberiaDocument2 pagesTamsa TuberiajleonosNo ratings yet

- Calculator ASME B31 4Document9 pagesCalculator ASME B31 4jleonos100% (3)

- Poseidon I Barge SpecsDocument2 pagesPoseidon I Barge SpecsjleonosNo ratings yet

- Deuda de Mexico 2011Document2 pagesDeuda de Mexico 2011jleonosNo ratings yet

- 3056 3054Document10 pages3056 3054jleonos100% (1)

- DL45 SpecificationsDocument1 pageDL45 Specificationsjleonos0% (1)

- Tksa20 Datasheet enDocument2 pagesTksa20 Datasheet enjleonosNo ratings yet

- Honda IzyDocument16 pagesHonda IzyTerry FordNo ratings yet

- Cultural Sensitivity BPIDocument25 pagesCultural Sensitivity BPIEmmel Solaiman AkmadNo ratings yet

- Week - 2 Lab - 1 - Part I Lab Aim: Basic Programming Concepts, Python InstallationDocument13 pagesWeek - 2 Lab - 1 - Part I Lab Aim: Basic Programming Concepts, Python InstallationSahil Shah100% (1)

- Exponential Smoothing - The State of The ArtDocument28 pagesExponential Smoothing - The State of The ArtproluvieslacusNo ratings yet

- BÀI TẬP LESSON 7. CÂU BỊ ĐỘNG 1Document4 pagesBÀI TẬP LESSON 7. CÂU BỊ ĐỘNG 1Yến Vy TrầnNo ratings yet

- Lesser Known Homoeopathic Medicines of Alopecia Areata.20200718115446Document9 pagesLesser Known Homoeopathic Medicines of Alopecia Areata.20200718115446BruntNo ratings yet

- SavannahHarbor5R Restoration Plan 11 10 2015Document119 pagesSavannahHarbor5R Restoration Plan 11 10 2015siamak dadashzadeNo ratings yet

- WBCS 2023 Preli - Booklet CDocument8 pagesWBCS 2023 Preli - Booklet CSurajit DasNo ratings yet

- Procter and Gamble - MarketingDocument10 pagesProcter and Gamble - MarketingIvana Panovska100% (5)

- PreviewpdfDocument29 pagesPreviewpdfSoemarlan ErlanNo ratings yet

- IQAc 04-05Document10 pagesIQAc 04-05ymcacollegewebsiteNo ratings yet

- Introduction To Password Cracking Part 1Document8 pagesIntroduction To Password Cracking Part 1Tibyan MuhammedNo ratings yet

- Project ProposalDocument4 pagesProject Proposaljiaclaire2998100% (1)

- 21 Tara Mantra-Wps OfficeDocument25 pages21 Tara Mantra-Wps OfficeAlteo FallaNo ratings yet

- Operator'S Manual Diesel Engine: 2L41C - 2M41 - 2M41ZDocument110 pagesOperator'S Manual Diesel Engine: 2L41C - 2M41 - 2M41ZMauricio OlayaNo ratings yet

- Angel C. Delos Santos: Personal DataDocument8 pagesAngel C. Delos Santos: Personal DataAngel Cascayan Delos SantosNo ratings yet

- Vieworks DR Panel BrochureDocument8 pagesVieworks DR Panel Brochuretito goodNo ratings yet

- CRISTIAN COLCERIU - PERSONALITATI CLUJENE Prof - Dr.ing - POMPILIU MANEADocument21 pagesCRISTIAN COLCERIU - PERSONALITATI CLUJENE Prof - Dr.ing - POMPILIU MANEAcristian colceriu100% (2)

- Aero Ebook - Choosing The Design of Your Aircraft - Chris Heintz PDFDocument6 pagesAero Ebook - Choosing The Design of Your Aircraft - Chris Heintz PDFGana tp100% (1)

- Raksha Mantralaya Ministry of DefenceDocument16 pagesRaksha Mantralaya Ministry of Defencesubhasmita sahuNo ratings yet

- Rights of Parents in IslamDocument11 pagesRights of Parents in Islamstoneage989100% (2)

- 4B - Urp - Shavya's FarmDocument22 pages4B - Urp - Shavya's FarmSnehansh KishoreNo ratings yet

- Case Study - Montana Mountain BikingDocument6 pagesCase Study - Montana Mountain Bikingbonny MishNo ratings yet

- PNP Ki in July-2017 AdminDocument21 pagesPNP Ki in July-2017 AdminSina NeouNo ratings yet

- E-Mobility and SafetyDocument77 pagesE-Mobility and SafetySantosh KumarNo ratings yet

- Natural Cataclysms and Global ProblemsDocument622 pagesNatural Cataclysms and Global ProblemsphphdNo ratings yet

- Getting Started With Citrix NetScalerDocument252 pagesGetting Started With Citrix NetScalersudharaghavanNo ratings yet

- Nescom Test For AM (Electrical) ImpDocument5 pagesNescom Test For AM (Electrical) Impشاہد یونسNo ratings yet

- Lesson 1: Composition: Parts of An EggDocument22 pagesLesson 1: Composition: Parts of An Eggjohn michael pagalaNo ratings yet

- Electrical Engineering Lab Vica AnDocument6 pagesElectrical Engineering Lab Vica Anabdulnaveed50% (2)