Professional Documents

Culture Documents

25510-A New Calculation For Designing Multilayer Planar Spiral Inductors PDF PDF

Uploaded by

Anonymous Kti5jq5EJIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

25510-A New Calculation For Designing Multilayer Planar Spiral Inductors PDF PDF

Uploaded by

Anonymous Kti5jq5EJICopyright:

Available Formats

By J on se n se r Z hao P u ls e

A new calculation for

designing multilayer planar

spiral inductors

A new, simple, and accurate expression lets you calculate

the coupling factor between multilayer PCB inductors.

P

lanar spiral inductors are less expensive than ei- depending on layout (Table 1). Figure 2 defines DIN (inner

ther chip or coil inductors for PCB (printed-cir- diameter) and DOUT.

cuit-board)-based designs. Accuracy in design- A multilayer inductor creates mutual inductance, how-

ing a spiral inductor is important because it is ever, so 3-D-magnetic-simulation software cannot simulate

difficult to modify the inductor once you have a multilayer inductor. Even if it could, the process would take

built it on the PCB. Some formulas are avail- a long time, and the results would be inconsistent. Therefore,

able for calculating the spiral inductor for RF-IC applications you must use the following two equations for the coupling

with inductance of less than 100 nH on a single-layer design. value, KC, to obtain the total inductor value with a mutual in-

For the application of HPNA (Home ductance: LTOTAL=L1+L22M,

Phoneline Networking Alliance) or RF- and M=2KCL1L2.

telecom designs, which need inductances You can obtain another sim-

of more than 10 H, no published paper ple and accurate expression for

or report accurately calculates spiral in- the inductance of a planar spi-

ductors with a large value in multiple ral by approximating the sides

layers. of the spirals using symmetri-

Three options exist for designing large cal current sheets of equiva-

planar spiral inductors on a PCB: In- lent current densities (Refer-

crease the number of turns; increase the ence 1). Although the accu-

inner diameter, DIN; or add layers and racy of Equation 1 decreases

increase the coupling between multilay- as the ratio of space between

ers. The first two options occupy more traces to the trace width in-

area on the PCB, so the third option is creases, it exhibits a maximum

the best way to accommodate a large in- error of 8% for a space less

ductor when there is limited PCB area. than or equal to three times

Multilayer planar spiral inductors of- Figure 1 The traditional formula for calculating inductor the width. Note that design-

fer several advantages over other induc- size is accurate for single-layer planar spiral inductors ers typically build practical in-

tors. They have stable inductance, for ex- but does not calculate the inductance of those that tegrated spiral inductors with

ample, and, if the PCB has a fixed layout, employ multiple layers and connect with via holes. space less than or equal to the

their inductance tolerance is less than width because smaller spacing

2%. Further, spiral inductors cost less than chip inductors and improves the interwinding magnetic coupling and reduces

require a less complex manufacturing process, making them the area the spiral consumes. In PCB design, this practice is

easier to manufacture with low yield loss. not a concern because the intertrace spacing is normally less

The traditional formula for calculating inductor size is ac- than the trace width.

curate for single-layer planar spiral inductors, but it does not Analysis of these equations and experimenting with large

calculate the inductance for planar spiral inductors built on inductors shows that Equation 1 is accurate, and the increas-

multilayers and connected with via holes (Figure 1). ing value of the inductor does not affect the accuracy of these

You can calculate a single-layer inductors value using equations. The result shows an inductance close to the cal-

Equation 1: culated value, with the difference at high frequency due to

the actual distribution of parameters throughout the circuit

L=[(0N2DAVGC1)/2][ln(C2/)+C3+C42)], (1) rather than the lumped-parameter analysis of the model (Fig-

ure 3). Thus, you can use Equation 1 to calculate a large,

where N is the number of turns; 0 is the vacuum permeabil- single-layer inductor.

ity, 4107; is the fill ratio, (DOUTDIN)/(DOUT+DIN); DAVG Calculations for a multilayer coupled planar spiral inductor

is the average diameter, (DIN+DOUT)/2; and C1C2 are factors are more complex than those for a single-layer spiral inductor.

JULY 29, 2010 | EDN 37

Table 1 Layout- W

S

dependent coefficientS W

S

Layout C1 C2 C3 C4

Square 1.27 2.07 0.18 0.13

Hexagonal 1.09 2.23 0 0.17

DIN DOUT

Octagonal 1.07 2.29 0 0.19 DIN

Circle 1 2.46 0 0.2

DOUT

Table 2 Inductor turns

A B C D

0.184 0.525 1.038 1.001

(a) (b)

The coupling between the inductors W

on each layer is difficult to simulate S

because the coupling value depends

on the number of turns of the induc-

tor and the distance between the two

layers. Experimenting over the range

of inductor turns, N, with N equal to DIN

a 5- to 20-turns ratio, and the distance W

DIN

S

between the inductors on the two lay- DOUT

ers, X, with X equal to a 0.75- to 2-mm

distance, yields Equation 2 to calcu-

late the coupling factor:

KC=[N2/(AX3+BX2+CX+D) DOUT

(1.67N25.84N+65)0.64], (c) (d)

(2)

Figure 2 The C1C4 factors depend on layout: square (a), hexagonal (b), octagonal (c),

where X is the distance in millime- and circle (d).

ters between the inductors on the two

layers and N is the number of inductor turns that Figure 2 spacing, 1.0922-mm (43-mil) DIN, and 0.75-mm inter-

defines. The inductor turns of both layers must be the same layer distance. First, you must analyze the circular lay-

(Table 2). out to find DOUT and DAVG to obtain the single-layer in-

With the coupling factor from Equation 2 and the single ductance, LS, and the coupling factor, KC: DOUT=DIN+2

planar-spiral-inductor calculation from Equation 1, you can W+(W+S)(2N1)=8.9972; DAVG=(DIN+DOUT)/2=5.0927;

figure the total inductance of a two-layer inductor by using =(DIN+DOUT)/(DOUT+DIN)=0.7855; LS=[(N2DAVGC1)/2]

the mutual-inductance formula (Reference 2).

On a two-layer coupled inductor, you can calculate CH1 LS 10.01 H/REF 0H 0 52.772 H

the total inductance with the following layout informa- 113.359120598 MHz

tion: 15.75 turns, 0.127-mm (5-mil) width and trace

COR

1 2 3 4 5 6 7

4.1

3.1 HLD

INDUCTANCE IF BW 300 Hz POWER 0 dBm SWP 12.04 SEC

(H) START 100 kHz STOP 500 MHz

2.1

NO. FREQUENCY VALUE

0 113.359120598 MHz 52.772 H

1.1 1 100 kHz 1.1618 H

2 1 MHz 1.1197 H

3 5 MHz 1.108 H

0.1 4 10 MHz 1.1071 H

0.1 1 10 100

5 15 MHz 1.1137 H

BANDWIDTH (MHz) 6 20 MHz 1.1267 H

MEASURED CALCULATED 7 30 MHz 1.1703 H

Figure 3 An analysis of the equations shows an inductance Figure 4 The measured inductors frequency response is close

close to the calculated value. to the theoretical calculation to a frequency as high as 100 MHz.

38 EDN | JULY 29, 2010

Table 3 Four-layer-stack structure CH1 Q 20 U/REF 200 U 921.51 m

113.359120598 MHz

Layer 1 Spiral inductor 1 mil 0.025 mm

Layer 2 Substrate 34 mils 0.85 mm COR

Spiral inductor 1 mil 0.025 mm

6 7

Layer 3 Substrate 34 mils 0.85 mm 4 5

3

Spiral inductor 1 mil 0.025 mm 1 2 0

HLD

Layer 4 Substrate 34 mils 0.85 mm IF BW 300 Hz POWER 0 dBm SWP 12.04 SEC

START 100 kHz STOP 500 MHz

Spiral inductor 1 mil 0.025 mm

NO. FREQUENCY VALUE

0 113.359120598 MHz 921.51 m

1 100 kHz 1.1373 m

(ln(C2/)+C3+C42)]=106H=1 H; KC=0.64. Per the mu- 2 1 MHz 10.032 m

tual-inductance connection equations, the total inductance 3 5 MHz 31.196 m

is L1+L2+2KC=L1L2=3.28 H. 4 10 MHz 45.67 m

5 15 MHz 55.195 m

In a design with more than two layers, there are more cou- 6 20 MHz 61.729 m

pling factors between any two layers. You can use the same 7 30 MHz 71.491 m

method to obtain each coupling factor and then use the to- Figure 5 The self-resonant frequency is better than that of a chip

tal inductance per the mutual-inductance connection formu- inductor with the same value.

las. You can also calculate a four-layer spiral inductor with

15.75 turns, a 5-mil-wide trace, a 5-mil trace spacing, and

a 43-mil circular inner diameter. Table 3 shows the stack Several samples with different sizes and structures verify

structure of the PCB. You must first calculate the single-layer the new calculation and measure and compare samples. To

inductance, LS, which is 1 H. It has six coupling factors: perform the verification, you must first increase the size of

KC12, KC13, KC14, KC23, KC24, and KC34. KC12=KC23=KC34=0.618, the single-layer planar inductor and then increase the num-

KC13=KC24=0.459, and KC14=0.294. So the total inductance ber of turns from four or five to 15. You must also increase the

is: L1+L2+L3+L4+(2KC12+2KC13+2KC14+2KC23+2KC24+ track width from 4 to 200 microns and increase DIN from 100

2KC34)L1=10.132 H. The four-layer inductor has a 10.1- to 2400 microns. The inductance calculated using Equation

H inductance. 1 is 1.1 H. Figure 4 shows the measured inductor frequency

JULY 29, 2010 | EDN 39

CH1 LS 10.01 H/REF 0H 29.403 H

0 40 MHz

COR

1 2 3 4 56 7

HLD

IF BW 300 Hz POWER 0 dBm SWP 12.04 SEC

START 100 kHz STOP 500 MHz

NO. FREQUENCY VALUE

0 40 MHz 29.403 H

1 100 kHz 3.8144 H

2 1 MHz 3.7903 H

3 5 MHz 3.7677 H

4 10 MHz 3.8956 H

5 15 MHz 4.1822 H

6 20 MHz 4.6846 H

7 30 MHz 7.1989 H

Figure 8 You can build a fifth-order, lowpass filter with a two-

Figure 6 The frequency response for the spiral inductor is better layer, coupled spiral inductor.

than that of a chip inductor with the same value.

CH2 S21 LOG 20 dB/REF 60 dB 5: 71.551 dB

CH1 Q 5 U/REF 20 U 4 5 160.95 m CH4 MEM LOG 5 dB/REF 15 dB 5: 0.03330 dB

6 50 MHz CH2 MARKERS

3 42.668537658 MHz * 1: .47690 dB

1 3 4 5 30 kHz

COR 7 2: .40430 dB

2 2 MHz

2

3: .45610 dB

2.2 MHz

1 0 4: 67.072 dB

12 MHz

4 5

CH4 MARKERS

IF BW 300 Hz POWER 0 dBm SWP 12.04 SEC PRM 3 1: 30.965 dB

START 100 kHz STOP 500 MHz 30 kHz

COR

NO. FREQUENCY VALUE 2 2: 23.042 dB

0 42.668537658 MHz 160.95 m 1 2 MHz

1 100 kHz 2.0236 m COR 3: 21.310 dB

2 1 MHz 16.411 m 2.2 MHz

3 5 MHz 34.595 m 4: .14550 dB

4 10 MHz 42.162 m 12 MHz

5 15 MHz 42.886 m START .030 MHz STOP 100 MHz

6 20 MHz 38.899 m 2 INSERTION LOSS 4 RETURN LOSS

7 30 MHz 22.878 m

Figure 9 The performance of the filter matches the simulation

Figure 7 Two-layer planar spiral inductors have better Q and result.

self-resonant frequency than does a chip inductor.

ACKNOWLEDGMENT

response, which is close to the theoretical calculation to a The author would like to thank Homer Feng, KB Ong, Paul

frequency as high as 100 MHz. The Q value and self-reso- Doyle, Andrew Zhang, and Bino Zhu for their valuable input and

nant frequency in figures 4 and 5 are better than that of the technical support during this project.

same-value chip inductor. Normally, the chip inductors Q

value is only 15 to 20. REFERENCES

To verify the coupling factor, you build two equally sized, 1 Rosa, Edward B, Calculation of the self-inductances of

1.1-H planar spiral inductors on a two-layer PCB substrate single-layer coils, Bulletin of the Bureau of Standards, Vol-

with a thickness of 0.8 mm. The calculated inductor value us- ume 2, No. 2, 1906, pg 161, http://bit.ly/9YpeeX.

ing Equation 2 is 3.8 H. Figures 6 and 7 show the frequency 2 Nilsson, James W, and Susan A Riedel, Electric Circuits,

response. The two-layer planar spiral inductors Q and self-res- Seventh Edition, Prentice Hall, May 17, 2004, ISBN

onant frequency are better than that of a chip inductor with 0131465929.

the same value.

Figure 8 shows a fifth-order lowpass filter with two-layer A u t h or s b i ogra p h y

coupled planar spiral inductors using the new calculation for Jonsenser Zhao is a senior design engineer at the

the design of this filter. The performance of the filter match- network division of Pulses Chinese development

es the simulation result and works for HPNA and other tele- center, where he is responsible for transformer, fil-

communication applications (Figure 9). The simplicity and ter, and splitter design. Zhao has a bachelors degree

robustness of these calculations simplify circuit design and in electronics from the Air Force Missile College

optimization applications, which you can incorporate into (Shaanxi, China). His interests include developing

the computer-circuit model for spiral inductors.EDN designs for telecommunications applications.

40 EDN | JULY 29, 2010

You might also like

- Battery Charger Circuit Using SCRDocument25 pagesBattery Charger Circuit Using SCRankit50% (2)

- Understanding Shaft Voltage and Grounding Currents of Turbine GeneratorsDocument12 pagesUnderstanding Shaft Voltage and Grounding Currents of Turbine GeneratorsArni 2020No ratings yet

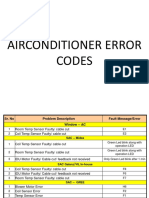

- Ac Error Codes & Trouble ShootingDocument14 pagesAc Error Codes & Trouble ShootingPrantik Padhy60% (5)

- Pedal Operated HacksawDocument2 pagesPedal Operated HacksawvasanthavananNo ratings yet

- Industrial DrivesDocument1 pageIndustrial DrivesSatish NurukurthiNo ratings yet

- RF PCB Design GuideDocument2 pagesRF PCB Design GuideSalman ShahNo ratings yet

- Ind 310Document166 pagesInd 310Jaime Carrillo Llontop100% (2)

- Wireless Power Transfer For Electric Vehicle Battery Charging MiniprojectDocument20 pagesWireless Power Transfer For Electric Vehicle Battery Charging MiniprojectAlisha AnjumNo ratings yet

- Zinc Air BatteryDocument14 pagesZinc Air BatteryAnonymous Kti5jq5EJINo ratings yet

- Stepper Motor and DrivesDocument8 pagesStepper Motor and DrivesLasantha Abeykoon100% (2)

- The Basics of Stepping MotorsDocument6 pagesThe Basics of Stepping MotorsSherif EltoukhiNo ratings yet

- A Novel AC To AC Wireless Power Transfer SystemDocument6 pagesA Novel AC To AC Wireless Power Transfer Systemarunkumarmurugesan88No ratings yet

- Dcmotors and Their RepresentationDocument61 pagesDcmotors and Their RepresentationSoeprapto AtmariNo ratings yet

- Parallel Driving of Synchronous GeneratorDocument7 pagesParallel Driving of Synchronous GeneratorMKIBETUNo ratings yet

- Diagrama de Modular Sony HCD-GNX880Document88 pagesDiagrama de Modular Sony HCD-GNX880Antonio Chavez100% (1)

- Modelling of IM Using DQ TransformationDocument64 pagesModelling of IM Using DQ Transformationdivinelight100% (1)

- Schematic 0G 00005516 SAMD21 MINIDocument1 pageSchematic 0G 00005516 SAMD21 MINIAnonymous Kti5jq5EJINo ratings yet

- Induction MotorDocument13 pagesInduction MotorJobin VargheseNo ratings yet

- Mototrbo SL Series Sl1K Portables: Detailed Service ManualDocument80 pagesMototrbo SL Series Sl1K Portables: Detailed Service ManualViorel AldeaNo ratings yet

- Dynamic Modeling of PMSMDocument10 pagesDynamic Modeling of PMSMHisham Magdi El DeebNo ratings yet

- Induction Motor: Navigation SearchDocument8 pagesInduction Motor: Navigation SearchSoni Mishra TiwariNo ratings yet

- Doubly Fed Electrical MachinesDocument282 pagesDoubly Fed Electrical MachinesjalilemadiNo ratings yet

- Active Disturbance Rejection Control for Nonlinear Systems: An IntroductionFrom EverandActive Disturbance Rejection Control for Nonlinear Systems: An IntroductionNo ratings yet

- Allen Ginsberg and The Prajna Paramita SutraDocument3 pagesAllen Ginsberg and The Prajna Paramita SutraAnonymous Kti5jq5EJINo ratings yet

- Cummins EFC Speed ControlDocument54 pagesCummins EFC Speed ControlRicharson Ochoa100% (2)

- Power System Stabliser: A ReviewDocument71 pagesPower System Stabliser: A ReviewPiyush AgnihotriNo ratings yet

- Parameter Identification of Induction Motor PDFDocument65 pagesParameter Identification of Induction Motor PDFsalah eddineNo ratings yet

- Integration of Green and Renewable Energy in Electric Power SystemsFrom EverandIntegration of Green and Renewable Energy in Electric Power SystemsNo ratings yet

- Wind Energy Generation Modelling and ControlDocument8 pagesWind Energy Generation Modelling and Controljuniorj123No ratings yet

- Hysteresis MotorDocument27 pagesHysteresis MotorSubham GhoshNo ratings yet

- Solid State Drives Short BookDocument48 pagesSolid State Drives Short BookGomathi Raja MNo ratings yet

- Sample 22289 PDFDocument16 pagesSample 22289 PDFVarun DuggalNo ratings yet

- Psoc Course FileDocument14 pagesPsoc Course Filecholleti sriramNo ratings yet

- Super-High Frequency Models and Behaviour PDFDocument23 pagesSuper-High Frequency Models and Behaviour PDFalokinxxNo ratings yet

- Analysis of Electrical MachineryDocument66 pagesAnalysis of Electrical Machineryzabig100% (1)

- Multi LVL DC DC BoostDocument9 pagesMulti LVL DC DC BoostDurga PrathibhaNo ratings yet

- Wound-Field Synchronous Machine DrivesDocument62 pagesWound-Field Synchronous Machine DrivesKorlpate BhaskarNo ratings yet

- Repulsion MotorDocument10 pagesRepulsion MotorAhmed Abd El MoatiNo ratings yet

- DC Motor Speed Control Using PWMDocument14 pagesDC Motor Speed Control Using PWMVincent KorieNo ratings yet

- Induction MotorsDocument25 pagesInduction Motorsapi-3827132100% (2)

- Basic SVPWMDocument6 pagesBasic SVPWMVAMSIKRISHNAEEENo ratings yet

- DC MachinesDocument52 pagesDC MachinesArun Kumar100% (1)

- DC Motor Speed ControllerDocument22 pagesDC Motor Speed ControllerShafqt MbrkNo ratings yet

- Electric Machinery Fundamentals Fourth EDocument26 pagesElectric Machinery Fundamentals Fourth EZeeshan RafiqNo ratings yet

- DC Link CurrentDocument8 pagesDC Link CurrentsubbannaNo ratings yet

- Special - Electrical - Machines QBDocument25 pagesSpecial - Electrical - Machines QBVel MuruganNo ratings yet

- Wireless Power Transfer SynopsisDocument3 pagesWireless Power Transfer Synopsisa d100% (1)

- Novel Dual-Excitation Permanent Magnet Vernier Machine: Akio Toba Thomas A. LipoDocument6 pagesNovel Dual-Excitation Permanent Magnet Vernier Machine: Akio Toba Thomas A. LipoNenad Kostadinovic50% (2)

- EE2403 Special Electrical MachinesDocument19 pagesEE2403 Special Electrical MachinesvasanthavananNo ratings yet

- Damper Winding Influence On UMPDocument8 pagesDamper Winding Influence On UMPSrinivas KamarsuNo ratings yet

- 4 - Rotating - Machines - Intro PDFDocument107 pages4 - Rotating - Machines - Intro PDFSantiago Sanchez SotoNo ratings yet

- 2015 Summer Model Answer PaperDocument32 pages2015 Summer Model Answer PaperIvan-Jeff AlcantaraNo ratings yet

- Design of The Rotor Blades of A Mini Hydraulic Bulb-TurbineDocument9 pagesDesign of The Rotor Blades of A Mini Hydraulic Bulb-TurbineuroskNo ratings yet

- DTCDocument26 pagesDTCMELVINNo ratings yet

- Problem Set 1Document9 pagesProblem Set 1jerry tranNo ratings yet

- Distribution SystemDocument3 pagesDistribution SystemSouvik100% (1)

- Numerical Methods For EngineersDocument160 pagesNumerical Methods For EngineersJugJyoti BorGohainNo ratings yet

- Slotless Permanent Magnet Ind-Synmotor: in Modern Industrialized Country, About 65% of Electrical Energy IsDocument11 pagesSlotless Permanent Magnet Ind-Synmotor: in Modern Industrialized Country, About 65% of Electrical Energy IsRahmathullah Saleem Basha0% (1)

- Chapter 1 Appeal DraftDocument10 pagesChapter 1 Appeal DraftJessie JulongbayanNo ratings yet

- Modeling and Analysis of 6 Phase Synchronous MotorDocument14 pagesModeling and Analysis of 6 Phase Synchronous MotorArif IqbalNo ratings yet

- Generator Load ModelDocument3 pagesGenerator Load Modelsrikaanth06No ratings yet

- Design of Igbt Based LLC Resonant InverterDocument7 pagesDesign of Igbt Based LLC Resonant InverterdhruvNo ratings yet

- شرح مخطط كارنوفDocument65 pagesشرح مخطط كارنوفzoherofNo ratings yet

- Differential Transformation Method for Mechanical Engineering ProblemsFrom EverandDifferential Transformation Method for Mechanical Engineering ProblemsNo ratings yet

- A New Calculation For Designing Multilayer Planar Spiral InductorsDocument4 pagesA New Calculation For Designing Multilayer Planar Spiral Inductorsagmnm1962No ratings yet

- Software Defined Radio Handbook PDFDocument62 pagesSoftware Defined Radio Handbook PDFAnonymous Kti5jq5EJINo ratings yet

- Some Measurements On E4000 and R820 TunersDocument8 pagesSome Measurements On E4000 and R820 TunersAnonymous Kti5jq5EJINo ratings yet

- Microwave SchematicDocument2 pagesMicrowave SchematicJason Strohsal100% (1)

- Electrolux MCC4060EDocument43 pagesElectrolux MCC4060EloagerNo ratings yet

- 0400 - Micro PicscopeDocument10 pages0400 - Micro PicscopeAnonymous Kti5jq5EJINo ratings yet

- Readme2 VscopeDocument1 pageReadme2 VscopeAnonymous Kti5jq5EJINo ratings yet

- Heart Rate Measurement From FingertipDocument8 pagesHeart Rate Measurement From FingertipNatasha PillaiNo ratings yet

- Simple Digital Geiger CounterDocument9 pagesSimple Digital Geiger CounterAnonymous Kti5jq5EJINo ratings yet

- 0400 - Micro PicscopeDocument10 pages0400 - Micro PicscopeAnonymous Kti5jq5EJINo ratings yet

- Micropower Circuit Monitors Positive Supply CurrentDocument1 pageMicropower Circuit Monitors Positive Supply CurrentAnonymous Kti5jq5EJINo ratings yet

- Using Fixed Voltage ReferenceDocument7 pagesUsing Fixed Voltage ReferenceAnonymous Kti5jq5EJINo ratings yet

- RF Remote ControllerDocument37 pagesRF Remote ControllerAnonymous Kti5jq5EJINo ratings yet

- Datasheet Tlp434a Rlp434aDocument2 pagesDatasheet Tlp434a Rlp434ajorge_gcaNo ratings yet

- Heart Rate Measurement From FingertipDocument8 pagesHeart Rate Measurement From FingertipNatasha PillaiNo ratings yet

- Chapt 15 PDFDocument44 pagesChapt 15 PDFfcoespinosaNo ratings yet

- Workshop3 PDFDocument7 pagesWorkshop3 PDFAnonymous Kti5jq5EJINo ratings yet

- Shield AC OnlyDocument1 pageShield AC OnlyAnonymous Kti5jq5EJINo ratings yet

- Secret Life of CapacitorsDocument11 pagesSecret Life of CapacitorsAni VinNo ratings yet

- Tips in Electronic PDFDocument10 pagesTips in Electronic PDFapi-3755845No ratings yet

- Loetfibel Ekorrds 040805Document17 pagesLoetfibel Ekorrds 040805Anonymous Kti5jq5EJINo ratings yet

- 01-09 SigernesDocument5 pages01-09 SigernesAnonymous Kti5jq5EJINo ratings yet

- LM1575/LM2575/LM2575HV Simple Switcher 1A Step-Down Voltage RegulatorDocument28 pagesLM1575/LM2575/LM2575HV Simple Switcher 1A Step-Down Voltage Regulatorfernando1123No ratings yet

- 60 1 51Document8 pages60 1 51Anonymous Kti5jq5EJINo ratings yet

- 807 D5 F47 D 01Document4 pages807 D5 F47 D 01Wisdarmanto Erlangga100% (1)

- 6 334FinalProject-TungShenChew PDFDocument10 pages6 334FinalProject-TungShenChew PDFAnonymous Kti5jq5EJINo ratings yet

- Low Cost Led Driver For 1 Watt LedsDocument4 pagesLow Cost Led Driver For 1 Watt LedsAnonymous Kti5jq5EJINo ratings yet

- Different MPPT TechniquesDocument10 pagesDifferent MPPT TechniquesphanioletyNo ratings yet

- Electronic CircuitsDocument91 pagesElectronic Circuitsvinay Shastry100% (6)

- AcuLaserC9100 ADocument616 pagesAcuLaserC9100 ALukáš KadeřábekNo ratings yet

- PCB Fixture Data SheetDocument2 pagesPCB Fixture Data SheetAdrian HerskovicsNo ratings yet

- Evaluates: MAXM86146 MAXM86146 Evaluation System: General Description Quick StartDocument35 pagesEvaluates: MAXM86146 MAXM86146 Evaluation System: General Description Quick StartVenkatesh KamathNo ratings yet

- 6880309T87 AMobileDSMDocument265 pages6880309T87 AMobileDSMAyon BaxterNo ratings yet

- Ec 160 Service ManualDocument32 pagesEc 160 Service ManualNatalia MontañaNo ratings yet

- LG FFH 285axDocument36 pagesLG FFH 285axAlexNo ratings yet

- Methods To Reduce Radiated Emissions From Optical TransceiversDocument5 pagesMethods To Reduce Radiated Emissions From Optical TransceiversParthasarathi PalaiNo ratings yet

- Tds Solder Sn100cl enDocument2 pagesTds Solder Sn100cl enMarija JovanovicNo ratings yet

- STP 120 Manual PDFDocument56 pagesSTP 120 Manual PDFhamza shahNo ratings yet

- AEM6000 Based 50W Amp Construction NotesDocument22 pagesAEM6000 Based 50W Amp Construction NotesMortenGundersenNo ratings yet

- SIM300 Breakout Board - ManualDocument5 pagesSIM300 Breakout Board - ManualBejo JocobNo ratings yet

- Part List Commander 400Document38 pagesPart List Commander 400Gabino Ubilio MurilloNo ratings yet

- Suavizador Clack Ws Manual de ServicioDocument44 pagesSuavizador Clack Ws Manual de ServicioAlfredo FloresNo ratings yet

- SJ 4351x SMT SeriesDocument4 pagesSJ 4351x SMT SeriesCarlo ColloNo ratings yet

- CM2 User Manual 4 - 0 - OnlineDocument63 pagesCM2 User Manual 4 - 0 - OnlineDadang KurniaNo ratings yet

- Cssub 10: Date of Production: 2008Document19 pagesCssub 10: Date of Production: 2008JorgeNo ratings yet

- Jtagboundary Scantest Apracticalapproach Harrybleeker Petervandeneijnden Fransdejong Kluweracademic 130617173055 Phpapp01 PDFDocument241 pagesJtagboundary Scantest Apracticalapproach Harrybleeker Petervandeneijnden Fransdejong Kluweracademic 130617173055 Phpapp01 PDFTuyen DinhNo ratings yet

- Aqh 2213Document6 pagesAqh 2213johnbad36No ratings yet

- Printed Circuit Board Maintenance - Repair - and Testing GuideDocument194 pagesPrinted Circuit Board Maintenance - Repair - and Testing GuideSebastião Jorge dos SantosNo ratings yet

- GM338/GM398 Mobile Radios: Basic Service ManualDocument56 pagesGM338/GM398 Mobile Radios: Basic Service ManualWild ScreamNo ratings yet

- IED AwarenessDocument41 pagesIED AwarenessDebbieNo ratings yet

- Panasonic Sr-jhs18-Nsd Rice Cooker SMDocument42 pagesPanasonic Sr-jhs18-Nsd Rice Cooker SMBảo BìnhNo ratings yet