Professional Documents

Culture Documents

Technical Specification BIBO 2201.320: Product Material Rating

Uploaded by

Naw AzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Specification BIBO 2201.320: Product Material Rating

Uploaded by

Naw AzCopyright:

Available Formats

Technical specification BIBO 2201.

320

50 Hz

Shaft Power [hp] / [kW]

50 276, ST 277, ST

40 30 233, HT

275, ST 231, MT

30

20

20

10

10

0 0

Head [ft] / [m]

450

275, ST

400 120

1050

350

1200 mm 100

276, ST

300

250 80

200 60 277, ST

150

40

100

20

50 231, MT

233, HT

0 0

0 20 40 60 80 100 120 140

434 640 mm

0 500 1000 1500 2000 2500

Capacity [l/s] / [usgpm]

Product Material Rating

Submersible pump for dewatering con- Outer casing ________________ Cast iron 3~

struction sites, draining water in flooded Impeller, MT _________ Alloyed white iron Rated output ____________________ 37 kW

areas, handling water in mines or on oil HT _ Spring steel, Stainless steel Speed of rotation _____________ 2930 rpm

platforms and other similar applications. ST ____ Ni hard nickel-chromium

Rated Starting

The pump can handle water containing alloyed white iron Voltage current current

relatively abrasive solides. Wear parts _______________ Nitrile rubber V A A

Stator housing _________________ Cast iron

Denomination Strainer _______________ Galvanized steel

380 67 405

Shaft ___________________ Stainless steel 400 64 335

Product code _________________ 2201.320

O-rings __________________ Nitrile rubber 415 62 350

Installation ___________________________ S

440 59 375

Impeller characteristic _______ MT, HT, ST

Discharge connection __________ 4", 6", 8"

Mechanical face seals 500 51 271

Inner __ Corrosion resistant cemented carbide 550 47 305

Process data Outer _ Corrosion resistant cemented carbide

Liquid temp. _______________ max +40 C

Depth of immersion __________ max 20 m

Weight

The pH of the pumped liquid __ pH 6 - 13 Total (excl. cable) __________ 350 - 460 kg

Liquid density __________ max 1100 kg/m3

Strainer hole size,MT ____ 15 mm x 45 mm Options

HT ____ 10 mm x 10 mm Polyurethane-lined wear parts _ POLY-LIFE

Impeller (HT) ____________ Stainless steel

Motor data Discharge connector with coupling A

Squirrel cage 3-phase induction motor. O-rings __________________________ Viton

Frequency ________________________ 50 Hz Warm liquid version

Insulation class _____________ H (+180 C) Various cable sizes

Voltage variation Zinc anodes

- continuously running ________ max 5% Tandem connection

- intermittent running _______ max 10%

Voltage imbalance between phases max 2% Accessories

No. of starts/hour _______________ max 15 Adapters, hose connections and other me-

chanical accessories.

Cable Electrical accessories such as pump control-

Direct-on-line and Y/D start _____ SUBCAB ler, control panels, starters, monitoring re-

lays, cables.

Monitoring equipment

Thermal contacts

You might also like

- CRSI - Field Inspection of Reinforcing BarsDocument8 pagesCRSI - Field Inspection of Reinforcing BarsgonzaloNo ratings yet

- Csa G40.21 PDFDocument4 pagesCsa G40.21 PDFmecano1No ratings yet

- Anchor Channel Typical Product Catalogue 2019.4.9 PDFDocument43 pagesAnchor Channel Typical Product Catalogue 2019.4.9 PDFSultana KhanumNo ratings yet

- Installation Operating Manual SewatecDocument82 pagesInstallation Operating Manual SewatecMouayed Zeadan100% (1)

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- Water Pipe SizingDocument40 pagesWater Pipe SizingAfzal Khan100% (2)

- Brochure Sheet PilesDocument2 pagesBrochure Sheet PilesdadNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Calulating Submerged WeightDocument5 pagesCalulating Submerged WeightDoug Gould67% (6)

- 09bill of Quantities (Office-Showroom Fit-Out) PDFDocument15 pages09bill of Quantities (Office-Showroom Fit-Out) PDFAugust PongeNo ratings yet

- Vol-I - Main Report - PKG 2 - 9.13 KMDocument357 pagesVol-I - Main Report - PKG 2 - 9.13 KMKARAN TRIVEDI100% (1)

- Wcms 164653Document154 pagesWcms 164653Joshua TroglioNo ratings yet

- Wcms 164653Document154 pagesWcms 164653Joshua TroglioNo ratings yet

- MSRA-Site Office Mobilisation-00Document27 pagesMSRA-Site Office Mobilisation-00anwarNo ratings yet

- Dk294j-Parts ManualDocument4 pagesDk294j-Parts ManualJorge Alonso Fernandez50% (2)

- 5.Pc Sheet PilesDocument2 pages5.Pc Sheet PilesAnonymous 6S9tcbhNo ratings yet

- Duct System TypesDocument12 pagesDuct System TypesRahul DubeyNo ratings yet

- EngineerDocument11 pagesEngineerphaindikaNo ratings yet

- Primary TreatmentDocument22 pagesPrimary TreatmentEmil AbdoNo ratings yet

- Technical Specification BIBO 2102.041: Product Material RatingDocument1 pageTechnical Specification BIBO 2102.041: Product Material RatingSebastian Amézaga ZegarraNo ratings yet

- Typical Edge Section E-E: 4Ø12 Stø8C/C250 L-740 400 2Ø14 +2Ø12 2Ø14 +2 Ø12Document1 pageTypical Edge Section E-E: 4Ø12 Stø8C/C250 L-740 400 2Ø14 +2Ø12 2Ø14 +2 Ø12metsihafeNo ratings yet

- Bye Pass Rotameter: Eureka Industrial Equipments Pvt. LTDDocument2 pagesBye Pass Rotameter: Eureka Industrial Equipments Pvt. LTDArunasis KarmakarNo ratings yet

- BHR 35 - 30 4 Stg.Document3 pagesBHR 35 - 30 4 Stg.Maknan SteelNo ratings yet

- BV204VDocument1 pageBV204VFAIYAZ AHMEDNo ratings yet

- Presion Neumaticos 931Document1 pagePresion Neumaticos 931kathy fernandezNo ratings yet

- H: 60 Normal Type Cable Tray Load GraphDocument6 pagesH: 60 Normal Type Cable Tray Load GraphMaria TimofteNo ratings yet

- ETNA Vertical Multistage Pumps Technical Leaflet PDFDocument40 pagesETNA Vertical Multistage Pumps Technical Leaflet PDFkhairalla mohamedNo ratings yet

- Content (SG) PDFDocument88 pagesContent (SG) PDFshare irgaNo ratings yet

- Etech EH SeriesDocument16 pagesEtech EH SeriesZeina FarhatNo ratings yet

- 8K Series Pumps: Stainless Steel Multistage Centrifugal PumpsDocument12 pages8K Series Pumps: Stainless Steel Multistage Centrifugal PumpsSandro ChiliquingaNo ratings yet

- Pages From Pedestal Catalogue LowDocument1 pagePages From Pedestal Catalogue Lowهانى الشيخNo ratings yet

- PC Sheet Piles: DescriptionDocument1 pagePC Sheet Piles: DescriptionKarim Ryma100% (1)

- PC Sheet Piles: DescriptionDocument1 pagePC Sheet Piles: Descriptionganiardiansyah adam100% (1)

- Manual Wire Rope Winches Wall-Mounted Wire Rope Winch SW-W: Equipment and ProcessingDocument1 pageManual Wire Rope Winches Wall-Mounted Wire Rope Winch SW-W: Equipment and Processingdrg gocNo ratings yet

- Wil o 419065Document25 pagesWil o 419065Youghorta TirNo ratings yet

- Dimensional DrawingDocument9 pagesDimensional DrawingHery MukhlisNo ratings yet

- WBSELTxxx WWDocument2 pagesWBSELTxxx WWocsosramNo ratings yet

- Fittings & Flanges For Pipe Series 2432 and 3432: Bondstrand Product DataDocument12 pagesFittings & Flanges For Pipe Series 2432 and 3432: Bondstrand Product DataDanilo FornaroNo ratings yet

- Blanking Die Design Part DWG 1Document1 pageBlanking Die Design Part DWG 1taditya659No ratings yet

- Base Flow Seperation Numerical Problem ExampleDocument6 pagesBase Flow Seperation Numerical Problem Exampletom meeteiNo ratings yet

- 6 SheetpileDocument2 pages6 SheetpileIwan Dirgantara100% (2)

- Honeywell YStrainerV2 YST A150Document1 pageHoneywell YStrainerV2 YST A150samiao90No ratings yet

- Vosa Equilibrium Float ValveDocument2 pagesVosa Equilibrium Float ValveDota NgNo ratings yet

- Fittings & Flanges For Pipe Series 2410 and 3410 Using The TaperTaper Adhesive-Bonded Joint FP657-10 0898Document40 pagesFittings & Flanges For Pipe Series 2410 and 3410 Using The TaperTaper Adhesive-Bonded Joint FP657-10 0898nidhinNo ratings yet

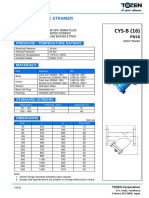

- Cys-B (16) (TM) (V1016)Document1 pageCys-B (16) (TM) (V1016)Azwan SunlineNo ratings yet

- 05 - 14 Steel RepairsDocument1 page05 - 14 Steel Repairsmaxuya2001No ratings yet

- 05 - 14 Steel RepairsDocument1 page05 - 14 Steel Repairsmaxuya2001No ratings yet

- C:/Tricomponente 08-05-2019/acetaminofen - Dat, DAD-280 NM: Retention Time Name Area (Group) Name AreaDocument1 pageC:/Tricomponente 08-05-2019/acetaminofen - Dat, DAD-280 NM: Retention Time Name Area (Group) Name AreaMaria Del Pilar Hurtado SanchezNo ratings yet

- Application Deep Well Turbine Pumps: Product Introduction 2361.1x/01-10G3Document4 pagesApplication Deep Well Turbine Pumps: Product Introduction 2361.1x/01-10G3FawadNo ratings yet

- 42crmo4 EnglishDocument3 pages42crmo4 Englisheduardomanar1224No ratings yet

- Type J Kerb Product Information Sheet 1Document2 pagesType J Kerb Product Information Sheet 1ariNo ratings yet

- CSG Vietwater22 BrochureDocument33 pagesCSG Vietwater22 BrochureTukang InsinyurNo ratings yet

- Centru de Conferinte: Gspublisherengine 0.5.100.100Document1 pageCentru de Conferinte: Gspublisherengine 0.5.100.100AnnIttNo ratings yet

- B - Boehler FOX SPE - Se - en - 5Document1 pageB - Boehler FOX SPE - Se - en - 5panait trofinNo ratings yet

- EL 60 A B DRAGFLOW-schede-EL-50Hz-ENGDocument2 pagesEL 60 A B DRAGFLOW-schede-EL-50Hz-ENGCarlos Picaluga CerveiraNo ratings yet

- DCP CBR and Soil ProfileDocument1 pageDCP CBR and Soil ProfileKarenForeroNo ratings yet

- Dismantling Joints With 3 Flanges, PN 64Document2 pagesDismantling Joints With 3 Flanges, PN 64Mohd AmirNo ratings yet

- Böhler Fox Eti: Rutile Stick Electrode, UnalloyedDocument1 pageBöhler Fox Eti: Rutile Stick Electrode, UnalloyedMiroslav MiladinovićNo ratings yet

- Valvotubi Dismantling Joints PN 63Document2 pagesValvotubi Dismantling Joints PN 63M MNo ratings yet

- Ti Mi 0035 Rev 1, 09-2001Document4 pagesTi Mi 0035 Rev 1, 09-2001Suresh MeenaNo ratings yet

- Katalog Ace Hammer Breaker LKPDocument16 pagesKatalog Ace Hammer Breaker LKPabdulloh faqihNo ratings yet

- Analysis of Phase Transformations in Eutectoid Zn-Al AlloysDocument6 pagesAnalysis of Phase Transformations in Eutectoid Zn-Al Alloysshahin azNo ratings yet

- Lowara z8 z10 z12 Technical Datasheet PDFDocument108 pagesLowara z8 z10 z12 Technical Datasheet PDFArif MahendraNo ratings yet

- BALL VALVES-Global ControlsDocument15 pagesBALL VALVES-Global ControlsWESHIMNo ratings yet

- BHR 28 - 30 3 Stg.Document3 pagesBHR 28 - 30 3 Stg.Maknan SteelNo ratings yet

- Separable Connectors MV Medium VoltageDocument4 pagesSeparable Connectors MV Medium VoltageEduleofNo ratings yet

- NewsReleaseEDocument2 pagesNewsReleaseEcahaya subuhNo ratings yet

- Wika CLTDocument2 pagesWika CLTYuly Elizabeth AryatnieNo ratings yet

- Molded-Case Circuit Breaker Design: Frame Size A Interrupting Capacity A Continuous Current Ratings, ADocument16 pagesMolded-Case Circuit Breaker Design: Frame Size A Interrupting Capacity A Continuous Current Ratings, AGlenn GregorioNo ratings yet

- Rebar Cold Bend Testing Machine: LWS Series LWS-200/3 00Document2 pagesRebar Cold Bend Testing Machine: LWS Series LWS-200/3 00daniel enrique romero robayoNo ratings yet

- Swing Type Manual Fire HosereelDocument2 pagesSwing Type Manual Fire Hosereelvin ssNo ratings yet

- Tubos Comparativo de Diametros Nominais e ExternosDocument1 pageTubos Comparativo de Diametros Nominais e ExternosFábio Da Silva AlanoNo ratings yet

- Revo Uninstaller 2 User's Guide: (Document Last Update - 06 June 2019)Document34 pagesRevo Uninstaller 2 User's Guide: (Document Last Update - 06 June 2019)Yogesh PatilNo ratings yet

- HW5 SolnsDocument11 pagesHW5 SolnsNaw AzNo ratings yet

- AsdDocument1 pageAsdNaw AzNo ratings yet

- Rwg4020 Aus Einbau enDocument1 pageRwg4020 Aus Einbau enNaw AzNo ratings yet

- Methods of Y InstallationsDocument1 pageMethods of Y InstallationsNaw AzNo ratings yet

- HLTV ReadmeDocument9 pagesHLTV Readmewillquem16100% (4)

- CD KeyDocument1 pageCD KeyTavi PetrisorNo ratings yet

- Equal-Friction-Method (From Engineering Toolbox)Document2 pagesEqual-Friction-Method (From Engineering Toolbox)Naw AzNo ratings yet

- Equal Pressure BookDocument1 pageEqual Pressure BookNaw AzNo ratings yet

- EHGASHRAENoiseVsVelocity PDFDocument1 pageEHGASHRAENoiseVsVelocity PDFNaw Az100% (1)

- Arora LinkDocument1 pageArora LinkNaw AzNo ratings yet

- Lec1 (4) MMDocument21 pagesLec1 (4) MMPradeep DahiyaNo ratings yet

- 003 Sewatec KSBDocument52 pages003 Sewatec KSBClovis_sccp100% (1)

- Avk Dismantling Joint, Pn10/16/25 265/30Document2 pagesAvk Dismantling Joint, Pn10/16/25 265/30Naw AzNo ratings yet

- Waste Water Treatment MixerDocument8 pagesWaste Water Treatment MixerNaw AzNo ratings yet

- Guia Diseño RejasDocument10 pagesGuia Diseño RejasJose Alberto Muñoz FloresNo ratings yet

- SB 285p BuoyDocument4 pagesSB 285p BuoyNaw AzNo ratings yet

- Wastewater: Lowara Solutions For Building ServicesDocument8 pagesWastewater: Lowara Solutions For Building ServicesNaw AzNo ratings yet

- Large Propeller Submersible MixerDocument4 pagesLarge Propeller Submersible MixerNaw AzNo ratings yet

- Flange Data ComparisonDocument21 pagesFlange Data ComparisonRiki FernandesNo ratings yet

- Cable - XLPE-LSHF-SWB-LSHF-AT-AR 3GX 2.5MMDocument2 pagesCable - XLPE-LSHF-SWB-LSHF-AT-AR 3GX 2.5MMavanz7173No ratings yet

- SP43Document352 pagesSP43SourabhAdikeNo ratings yet

- Bridge Design Format For Rural Road NQM Project AssamDocument35 pagesBridge Design Format For Rural Road NQM Project Assamarif ahmedNo ratings yet

- Ivy Apartment Brochure 2022Document16 pagesIvy Apartment Brochure 2022Rory MurrayNo ratings yet

- InstallationManual - ThermoPower VDFDocument19 pagesInstallationManual - ThermoPower VDFSunMaxx SolarNo ratings yet

- Vyago Engineers: ISO 9001:2015 Certified CompanyDocument20 pagesVyago Engineers: ISO 9001:2015 Certified CompanyScripts TeamNo ratings yet

- PC VRF Systems 2Document50 pagesPC VRF Systems 2pallavNo ratings yet

- Mac-Bak-000525 - Rev D V1Document1 pageMac-Bak-000525 - Rev D V1Erikson JeremiasNo ratings yet

- Tasaki Instalation ManualDocument10 pagesTasaki Instalation ManualChalitha Nayana Hewawasam100% (1)

- Curing in ConstructionDocument7 pagesCuring in ConstructionNgissah NketiahNo ratings yet

- Dril-Flex® Structural Self-Drilling FastenersDocument4 pagesDril-Flex® Structural Self-Drilling FastenersPaulNo ratings yet

- Bsi BS en 12602+a1 - 2013Document190 pagesBsi BS en 12602+a1 - 2013alferedNo ratings yet

- Mechanical Services Particular SpecificationDocument12 pagesMechanical Services Particular SpecificationAhmed Mohamed AliNo ratings yet

- Ace Plast Ram Bs2Document1 pageAce Plast Ram Bs2pulakjaiswal85No ratings yet

- CPM - Construction PlanningDocument13 pagesCPM - Construction PlanningAnton_Young_1962No ratings yet

- 1001 Dawkins FP SubmissionDocument20 pages1001 Dawkins FP Submissionapi-621764856No ratings yet

- TJ-9001 - Trus Joist - Installation Guide For Floor and Roof Framing With TJI JoistsDocument20 pagesTJ-9001 - Trus Joist - Installation Guide For Floor and Roof Framing With TJI JoistsAdam GreenlawNo ratings yet

- Tijaarat Developers Limited: Canyon Views Developments Defence Housing Authorities Phase Ii (Ext) Islamabad, PakistanDocument9 pagesTijaarat Developers Limited: Canyon Views Developments Defence Housing Authorities Phase Ii (Ext) Islamabad, PakistanMuhammadIqbalMughalNo ratings yet

- Technical Regulations For RoadsDocument14 pagesTechnical Regulations For RoadsAlexe FloreaNo ratings yet

- Aman Case StudyDocument40 pagesAman Case Studyvandy nehaliaNo ratings yet

- Former Kyneton Primary School Draft Master Plan ConceptsDocument5 pagesFormer Kyneton Primary School Draft Master Plan ConceptsAnonymous TLKcJKUUWr100% (1)

- Eastman Industries - BoqDocument6 pagesEastman Industries - BoqcivilNo ratings yet

- 4 Ethekwini Design Manualmay 2008Document50 pages4 Ethekwini Design Manualmay 2008Roxy MansNo ratings yet

- 69-02 Queens Boulevard - 20180265 ZMQ, 20180266 ZRQ, 20180267 ZSQDocument38 pages69-02 Queens Boulevard - 20180265 ZMQ, 20180266 ZRQ, 20180267 ZSQChristina WilkinsonNo ratings yet

- D - 5368 - Qadnet-Motorized Smoke Damper-Ocr-26102022.Document3 pagesD - 5368 - Qadnet-Motorized Smoke Damper-Ocr-26102022.JomyJoseNo ratings yet

- BidimDocument5 pagesBidimrolandchalfounNo ratings yet