Professional Documents

Culture Documents

00-099.terminal Replacement PDF

Uploaded by

Sherwin J. Dela Cruz0 ratings0% found this document useful (0 votes)

251 views12 pagesOriginal Title

00-099.Terminal Replacement.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

251 views12 pages00-099.terminal Replacement PDF

Uploaded by

Sherwin J. Dela CruzCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

HONDA. Service Bulletin 00-099

AeplesTe: ALL, December 49, 2000

Terminal Replacement Instructions

(Replaces 95-023, dated May 1, 1985)

‘These terminal replacement instructions apply to these | PARTS INFORMATION

kits and toots: Terminal inspection Feeler Tool Set:

‘+ Terminal Pin Kit A: T/N 07JAZ-0030008 TN 07XA-001000A

a : : ‘Terminal Pin Kit A: TIN 07JAZ-0030008, which

ere ee eee arene contains Pin Too! Set T/N 07JAZ-002000A, Crimper

*+ Terminal inspection Feeler Too! Set: TIN O7JAZ-001020A, and various terminals.

TIN 07XAJ-0010008 Terminal Pin Kit 8: TIN 07QAZ-0030208, which

contains Crimper Tool Set TIN O7NGZ-001010A (used

This bulletin covers these topics: ‘on splice connectors only), Heat Gun TN O7NGZ-

i Cane (0010204, various terminals, and splice connsctors.

adic lsd The following kit has been shipped to dealerships. This

+ How to Install New Terminals kits to be added to Terminal Pin Kit B, TIN O7QAZ-

+ How to Install Pigtail Terminals poeteee

i : Terminal Pin Update Kit, T/N 07XAZ-002000A

Saf area ermine Selecion Chae which includes 25 each of the following terminals:

I = Checking for Poor Fit of Terminals, PIN 07JAZ-0013208

PIN O7UAZ-001330A

WARRANTY CLAIM INFORMATION PIN O7JAZ-001340A

P/N 07JAZ-001350A,

PIN 07JAZ-001380A

PIN 07JAZ-001370A

P/N 07JAZ-001380A

PIN 074AZ-001400A,

PIN O7JAZ-001410A

11 pe inner and outer label for Terminal Pin

Kit B: TIN 07Q42-003020B.

Replacement terminals, wire seals, and splice

connectors are listed on the inside lid of each terminal

pin kit

Additional information on replacement connectors,

terminals, and pigtails is listed in the Honda Electrical

Connector Catalog (P/N 13CNNA-3).

None; this bulletin is for information only.

ELECTRICAL

CONNECTOR

CATALOG

O580S9 3 iibsser son

© esoorsser

© 208 Ara on Oo, ne. A at Reed ara 220 012) 10f12

‘CUSTOMER INFORMATION: Tho ifarmatonin hs balotn is tended fv use only by sled tachnidars who have ihe proper od, GGUS

‘and airing correctly ard salely mainiain your vehicle. These proceaures should not be attomoted by 'o-t-yoursctirs." and yeustould saleeeerns

ths bulin amples to your veico, or that your vehicle ha tne condition doeorbod. To determine whether this Inforelion spies, cotens oe

authorized Herda suerte dealer,

ee Serer PR eee eee aR eee setae eae eee ec

HOW TO REPLACE CONNECTOR TERMINALS

The terminal repair kts provide necessary tools and

materials (terminals, wire seals, and splice connectors)

to repair many damaged of fauity connector terminals.

However, not all terminals for all connectors are

available. Reler to the labels on the lids of the repair

kits for replacement terminal availabilty.

IMPORTANT SAFETY INFORMATIOI

‘On some models, the SRS wires are in a separate

harness. If the SRS harness is damaged, replace

the harness; do not repair it, On other models, wire

harnesses include yellow SRS wires. if any SRS

wire is damaged, replace the entire harness; do not

repair it.

Before you begin, inspect the wire you are about to

repair for damage and length. Make sure the wire will

be long enough to make a terminal repair without

stretching it when you reinstall the terminal in the

‘connector. If the wire Is too short, or if access to the

‘connector is too restricted to make a terminal repair,

you may need to installa pigtail terminal (a short length

of wire with a factory-crimped terminal on it). Refer to

HOW TO INSTALL PIGTAIL TERMINALS.

Removing the Terminal

Use the tools from Pin Tool Set T/N 07JAZ-002000A.

First, check the connector that you are about to repair.

* Itithas a secondary terminal lock, go to Connectors

With a Secondary Lock. A secondasy lock, found on

most connectors on some models, is an additional

locking device on the connector housing as a backup

for the primary lock on the terminal.

+ Ifthe connector does not have a secondary lock, go

to Connectors Without a Secondary Lock.

2of 12

Connectors With a Secondary Lock

All examples are shown with the connector lock facing

up. The illustrations are examples of the secondary

terminal locks; however, the connector you are

repairing may vary in size. Identify the connector by the

type of secondary lock, not by the number of terminal

cavities.

EXAMPLE A:

1. Release the secondary lock.

inserta small

screweriver here.

Lift up on the screwdriver and

‘he lock will “snap* upward.

2, Remove the terminal.

Insert the too! inthis

Push tho wire into the zityebove te

‘connector torelieve tension —_terminal until it seats.

‘on the terinal lock.

PIN TOOL A

‘O7JAZ-0020108

ul the terminal out

of the connector

3, Go to HOW TO INSTALL NEW TERMINALS.

EXAMPLE B:

1, Remove the secondary lock from the male terminal

halt,

Male Terminal Hatt

Pull the lock straight out

of the connector wth

reecle-nose piers.

ws

2. Remove the secondary lock from the female

terminal halt.

~ Female Terminal Halt

PINTOOLE

‘07az-0020508

3. Remove the terminal (same procedure for male and

female).

Push tho wire into th

‘connector to roleve the

tension on the primary lock.

ul the terminal out

‘of the connector. Insert the tool under the

terminal, and it up.

4. Goto HOW TO INSTALL NEW TERMINALS.

00-099

EXAMPLE C:

1. Remove the secondary lock.

focc outolMe conmector

ial from the female halt.

— Female Terminal Half

Push the wire into the

‘connector to relieve the

jencion on the primary

Insert the t001 atthe middle of

the terminal, and itt up-on the

primary look.

3. Remove the terminal from the maie half.

Male Terminal Half

Push the wire into the

connector to relieve the

‘tension on the primary lock

\Z

Pull the terminal out

‘of tie connactar.

ee

YY

Ssy7]

Ingort the tool under the

‘primary lock, and it up.

4. Go to HOW TO INSTALL NEW TERMINALS.

3of12

EXAMPLE D:

1. Remove the secondary locks.

Pry cut on the tabs

onboth sides.

FRotithe upper and

lowor locks in the

direction of the arrows,

2, Remove the terminal (same procedure for male and

femaie).

Insert the too into

Push the wire into thes

‘upper half of the

the connector to t

ralieve the tension {terminal caviy,

‘on the primary lock.

Pm TOOL A,

Pullthe terminal out

uate terrioel ‘O7JAZ0020108

3. Goto HOW TO INSTALL NEW TERMINALS.

4oti2

EXAMPLE E:

1. Remove the secondary locks.

Ge on the back ot

fe'secondarytemna ose

Roll the secondary lock

Up so the lugs cf the lock

ate free of

2. Remove the terminal (same procedure for male and

female).

Insert tcl na the

Push the wire into the temereee nine fee at

‘connector to relieve the heen

fongion onthe primary

3. Go to HOW TO INSTALL NEW TERMINALS.

EXAMPLE F:

1. Remove the secondary locks,

Pull back on the lock, then.

Itt up so ts lugs are free

‘of the connector.

Gently pry up on the back

cof the upger or lower

Secondary terminal look.

2. Remove the terminal from the female halt

— Female Terminal Hai

On the top row, insert the

tool below ihe terminal

(On the bottom row, Insert

2 tool above the terminal)

Push the wire into the

‘sonnector 10 relieve the

fenson onthe primary

lec

Pullthe terminal cut PINTOOLF — Pullupon the

of tha connector. 97JAZ-002060A tool to push down

the primary lock.

3. Remove the terminal from the male half

=Male Terminal Half

On the top row, insert the

too above tho terminal (On

the bottom row, insert the

tool below the terminal)

Push the wire into the

‘connector 19 rellove the

tension onthe primary

Push down on

{ho too! to it the

primary lock,

Pull the terminal out

‘ofthe connector.

4. Goto HOW TO INSTALL NEW TERMINALS.

00-089

Connectors Without a Secondary Lock

All examples are shown with the connector lock facing

Up. The illustrations are examples of connector

terminals without a secondary lock; however, the

connector you are repairing may vary in size and

shape.

EXAMPLE A:

1. Remove the terminal.

Push the wie into the

‘connector to relieve the

Ee meet an

poenermay’ perspe

PINTOOL A

O7JAZ-0020108

t

ull up onthe toot

to push down the

primary lock

Pull the terminal out

‘of the connecter.

2. Goto HOW TO INSTALL NEW TERMINALS.

EXAMPLE B:

1. Remove the terminal.

Push the wie into the

amerorigrelevethe rear eto othe

eats Primary tthe connector.

PIN TOOL B

oraz o0a0208

ul the torminal out

etna comment Push the tool in

‘to reloase the

primary lock,

2. Go to HOW TO INSTALL NEW TERMINALS,

Sof t2

EXAMPLE C:

1. Remove the terminal.

Insert the tool into

PMTOOLC the access slot

Push the wire into q7JAz-o0z0s0 above the terminal,

the connector 19

rolleve the tension

‘on the primary 10ck,

Pull the terminal out

of the connector.

Slide the too into

‘the primary lock.

2. Goto HOW TO INSTALL NEW TERMINALS.

EXAMPLE D:

1. Remove the terminal.

PINTOOLD —_Insort tho toot inta

Push the wire into 07Jaz-002040A the access slo!

the connector to above the terminal,

religve the tension

(on the primary tock,

Twist 90° to

release the lock,

Slide the too! into

the primary lock.

Pull the terminal out

of the connector.

2, Goto HOW TO INSTALL NEW TERMINALS.

Bot12

EXAMPLE

1. Remove the terminal

Push the wire into the

connector Io relieve the

fension onthe primary

PIN TOOL E.

7

+

®

Lift up on the tool

torelease the

primary tec:

Insert the tool a

Below the terminal

Pull the torminal out

ofthe connector.

2. Go to HOW TO INSTALL NEW TERMINALS.

EXAMPLE F:

1, Remave the terminal.

Push the wiro into the

gomeco: 9 releve the

ee PINTOOL F

1974102-0020608,

Pull the terminal out

ofthe comecr.

Lit ub on the

fev ase

primary ioc.

Insert the tool iad

below the terminal.

2, Go to HOW TO INSTALL NEW TERMINALS,

00-098

EXAMPLE G:

1. Remove the terminal,

Push the wire into the Insert the too!

connector to relave the atthe middle of

tenson on the primary. fhe terial

Push down on the

too to it up on

the primary lock.

Pull the terminal out

of the connector.

2. Goto HOW TO INSTALL NEW TERMINALS,

00-099

HOW To INSTALL NEW TERMINALS

1. Garefully match the old terminal with @ new one

from the terminal repair kit. Choose the correct

replacement terminal based on the wire size range

the terminal will accommodate.

NOTE: If the replacement terminal quantitos are

low, reorder them by using the terminal part number

listed on the inside lid of the terminal repair kit

Replacement terminals are available through your

parts department using normal parts ordering

procedures.

2. Depending on the size of the wire you are repairing,

Use the proper size slot in the crimping tool.

orm £5 |

‘CRIMPER

‘07sAz-0010208,

3. Strip the insulation off the end of the wire so the

wire fits in the new terminal as shown. (If the wire

has a wire seal, replace it with a new one from the

kit)

NOTE: Aiter stripping the end of the wire, make

sure you did not cut any wire strands. If you did, cut

the wire off even with the insulation, and strip it

again.

wore

wsutaTion ORI

en

CT ce

[lle arcs dear

‘1 mm of insulation showing here

End of al 1 mm beyond

thetnaulaion cmp.

70112

4. Position the terminal in the crimping tool stot with

the solid portion of the terminal toward the anvil and

the open section toward the former.

5. Insert the wire in the terminal to the position shown

in step 3.

6. Squeeze the tool with both hands until the stops

make contact.

x

7. Crimp the insulation crimp.

+ Ifyou do not have a wire seal, then use the next

larger size crimp slot. Position the crimping tool

‘ver the insulation crimp section of the terminal,

then squeeze ths tool with both hands until the

stops make contact.

+ ltyou have a wire seal, position the insulation

crimp in the 5.5 crimping slot, then carefully

squeeze the crimp closed until its ends are

touching and making a full-circle shape.

Koop a circo shape.

aott2

8. Inspect the quality of the wite orimp. I it has any of

the following NO GOOD crimps, cut I of and start

over.

\Wire should be visible here,

oop

No coop

Loose strands of wire,

No Goon

Wire crimp not

imped evenly.

woo) peek

coon

Poor crimping, If one side

sticks out more, he terminal

‘may not fit into the connector.

9. Insert the terminal into the connector. Make sure

the wire seals are pushed all the way into the

connector. Light pull on the wires fo make sure

the terminal is locked into place.

10. Close or insert the secondary terminal lock, if

applicable, and reconnect the connector.

HOW TO INSTALL PIGTAIL TERMINALS

Pigtail terminals {short pieces of wire with a factory

crimped terminal) are used when the wire is too short

‘or when access to the connector is too restricted to

make a terminal repair. Refer to the selection chart on

page 11

00-099

NOTE: To replace just a connector terminal, go to How

to Replace Connector Terminals.

IMPORTANT SAFETY INFORMATION:

On some models, the SRS wires are in a separate

harness. If the SAS harness is damaged, replace

the harness; do not repair it. On other models, wire

harnesses include yellow SRS wires. If any SRS

wire is damaged, replace the entire harness; de not

repair it.

1. Rlemove the damaged or faulty terminal from the

connector. Use the proper removal tool from Pin

Tool Set TIN 07JAZ-002000A.

2. Cut off the wire about an inch back from where it

‘connects to the damaged or faulty terminal, then

strip about half of the insulation off that piece. This

will be used to size the wire end of the replacement

Pigta terminal.

NOTE: Ityou are not sure of the wire size, start with

a large enough hole on the stripper that will not nick

or cut off any strands of wires.

‘Cut the old wire here

then, ship ithere.

and match both ands to the

‘ends on a new pigtal terminal,

3. Select a pigtail terminal that matches the original

‘wire at both ends (same kind of terminal and same

diameter bare wire).

4. Select the smallest splice connector (yellow, pink,

r blue) that will ft onto the stripped end of the

original wire,

00-088

5. Insert the pigtail terminal into the connector cavity;

push it in until it locks in place.

ORIGINAL

WIRE

6. Lay the pigtail and the original wire side-by-side,

and cut off both ends at once. If you are making

more than one splice, do not cut each pigtail at the

same location; the resulting “lump” of splice

Connectors would interfere with rewrapping the

hamess. Instead, cut the first pigtall close enough

to the terminal so you will have room to make each

remaining out about 20 mm (3/4 inch) farther down

con the next pigtail.

7. Ifyou are using a yellow splice connector, strip

about 6 mm (1/4 inch) of insulation off the ends of

both wires. I you are using a pink or blue splice

connector, strip off about 8 mm (5/16 inch) of

insulation,

NOTE: if you nick or cut off any strands of wire, try

again with the next larger size hole on the stripper.

Ship 6 mn (1/8) for

ie YELLOW osm

| Sip 8 men 6/15) for

PINK or BLUE

comector.

Bot 12

8. Putthe splice connector in the proper size slot in

the Crimper Too!, T/N O7NGZ-001010A, slide it to

‘one end (where the flare begins), and close tho

crimper handles far enough to hold it in place. To

release the ratchet mechanism at any point after

the first click, squeeze the handles slightly and

push the release lever, then lot the handles open.

Do nat loosen or remove this screw;

‘has been set to release the ratchot

at proper crimping pressure.

CCRIMPER TOOL

CRIMPER

i O7NGZ-0010108

9. Insert one of the bare wires into the splice

connector end that is in the crimper jaws. Push the

wire all the way into the splice connector, and

squeeze the crimper handles. Keep squeezing until

the jaws touch, and hold it at that position until the

ratchet clicks again.

Laced CRMUPER

SAWS

T

SPLICE | BARE WIRE

CONNECTOR

10. Crimp the other wire in the same way into the other

end of the splice connector.

11. After crimping, gently pull on the wires in the

opposite directions to make sure they are secure in

the connector.

1008 12

12. Separate the other wires in the harness from the

repaired wire(s), and shield them with nonflamable

material.

NONFLAMMABLE

MATERIAL

REPAIRED WiRE

HEAT GUN

(7NGz-0030208

13. Plug in the heat gun, and turn it on. Start at the

middle ofthe splice connector, and move the gun

toward the ends as the tube shrinks. Apply heat

evenly by rotating the curved heat spreader around

the splice connector. Shrinking is complete when a

small amount of sealant appears at each end of the

‘ube.

NOTE: Be careful when working with the high heat

produced by the heat gun.

Shrinking’ complete

when sealer appears here

00-099

PIGTAIL TERMINAL SELECTION CHART

Wire Seal Type

Select the proper size pigtal terminal by matching the | srmea

replacement terminal part number and the wire size wine Sea

being repaired to the Coresponcing pigtal an Gs

part sumber. Then use the color (size) splice connector

Iisted In some instances you may alco have to match ses

the wie sea! style to select the proper pigtail terminal erie

Pigial terminals are available through your parts

department, in quantities of 10, using normal parts

ordering procedures

jacement | Wire Size Bein T ‘Splice Connector | Wire Seat |

TermnlPn |" Repaied” | Pita'Terinai pn | Slee Connector |” Wiese

GruRzTOTOAGA | 20 RNS a0 SPOR | eto i

TéAWG 04320-SP0-B00 Pink |

|“ craazaaroaon | 2a ai Ga220-SPO-G00 Yelowr a

Te AWG 32826-SPO-D00 Pink a

2OAWG 32320 SPOECO Yellow o

16 AWG (04820-SPO-FOO Pink 8

[Tamiazenroaoa ZO.AWG 04920 SPO-G00 Yellow

G7uAT-O0;680A | 20 ANG '04920-SP0-J00 Yalow

TeAWG 34320-SPO-HO0 Pik

‘O7JAZ-00 1260) 20 AWG (04520-SPO-A10 Yellow

TSAWG | O4080-30-NOO Fin

GHIA OOTEOR Teawe (01926 SFo-F00 Pini

O7uAz Daiza0A TS AWG caa20 SPO-POO. Pink al

F~orsaz-ooresoa ZANE #326-SF0-So0 Yelow

Tawa 04820.5P0-TO0 Pink

14 AWG 34980-SPOUDD Sue

TrIRZDSTEAOR 20AWG 04926 SOOO Yalow

| Te AWG 04900 SPO Woo Pik

TriRZTOTEROA ZOANG 04920.SPO-Yi0 Yalow

20AWG Ci520-SPOTO Yoon q

—s ANE 32926 SP0FI0 Yalow

o aoANG 420 SOKO Teiow

o 20 ANG 4520-SPONTO Yalow

ag BOAWG 24320 SPORT Tete |

© Replacement terminals are not available. Inst

pigtail terminal applications.

00-099

lead, refer to the Honda Electrical Connector Catalog for proper

11 of 12

CHECKING FOR POOR FIT OF TERMINALS

Loose terminal fit can cause a number of intermittent

problems in electrical circuits. By using the Terminal

Inspection Feeier Tool Set T/N 07XAJ-001000A. you

‘can inspect the terminal ft between the two matching

Connectors without removing the terminals from the

connector body.

1, Find the terminal tool that best matches the male

terminal in the mating connector.

2. Insert the terminal tool into the female terminal, and

then remove the terminal too.

NOTE: Make sure you do net select a terminal tool

that is larger than the mating male terminal

because it would spread the female terminal and

cause a loose fit

ei,

Tmorxasgoioooa/ ZA\

La)

N

TYPICAL FEMALE:

CONNECTOR

3. Compare the drag to the other terminals in the

connector. If the drag is less, replace the terminal

with a replacement terminal from the appropriate

terminal repair kt

120f12

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Service Cabinet and Transformer Breaker Sizing 1082004Document49 pagesService Cabinet and Transformer Breaker Sizing 1082004Hazem HassanNo ratings yet

- FR3 LV Insulation CoordinationDocument43 pagesFR3 LV Insulation CoordinationRihlesh ParlNo ratings yet

- Malaysia StdsDocument78 pagesMalaysia StdsSherwin J. Dela CruzNo ratings yet

- Bus Fault Loc - CommentedDocument1 pageBus Fault Loc - CommentedSherwin J. Dela CruzNo ratings yet

- EE 306 Lecture Notes v4Document462 pagesEE 306 Lecture Notes v4Linh TranNo ratings yet

- Protective Relay SettingsDocument2 pagesProtective Relay SettingsShashiraj ShettigarNo ratings yet

- Basic Nec Code Rules and Design PracticeDocument13 pagesBasic Nec Code Rules and Design PracticeSiswoyo Suwidji100% (1)

- Principles of Electrical GroundingDocument43 pagesPrinciples of Electrical GroundingSaber HussainiNo ratings yet

- Basic Nec Code Rules and Design PracticeDocument13 pagesBasic Nec Code Rules and Design PracticeSiswoyo Suwidji100% (1)

- ICAO Figure 6-2Document1 pageICAO Figure 6-2Sherwin J. Dela CruzNo ratings yet

- Sizing The Circuit Breakers: Using The Specification StickerDocument1 pageSizing The Circuit Breakers: Using The Specification Stickershaan19No ratings yet

- Auto Wiring TipsDocument3 pagesAuto Wiring TipsSherwin J. Dela CruzNo ratings yet

- Sizing The Circuit Breakers: Using The Specification StickerDocument1 pageSizing The Circuit Breakers: Using The Specification Stickershaan19No ratings yet

- The Basics of PF Correction On Single Induction MotorsDocument8 pagesThe Basics of PF Correction On Single Induction MotorsSherwin J. Dela CruzNo ratings yet

- Zone ClassificationDocument9 pagesZone ClassificationibrahimkhansahilNo ratings yet

- Fault Analysis NotesDocument26 pagesFault Analysis NotesJohn Don88% (8)

- Researchpaper/Load Flow Analysis of 132 KV Substation Using ETAP SoftwareDocument5 pagesResearchpaper/Load Flow Analysis of 132 KV Substation Using ETAP SoftwareBattinapati ShivaNo ratings yet

- Electricity Regulation in Argentina - Overview - Practical LawDocument15 pagesElectricity Regulation in Argentina - Overview - Practical LawSherwin J. Dela CruzNo ratings yet

- UL ArgentineDocument17 pagesUL ArgentineSherwin J. Dela CruzNo ratings yet

- Three Phase Load CalculatorDocument1 pageThree Phase Load CalculatorSherwin J. Dela CruzNo ratings yet

- Key Technical Changes in 3 Edition of IP 15Document10 pagesKey Technical Changes in 3 Edition of IP 15indhumathibabusenanNo ratings yet

- RIB Swing Gate OperatorDocument4 pagesRIB Swing Gate OperatorSherwin J. Dela CruzNo ratings yet

- RIB Parking BarrierDocument1 pageRIB Parking BarrierSherwin J. Dela CruzNo ratings yet

- TransformersDocument2 pagesTransformersSherwin J. Dela CruzNo ratings yet

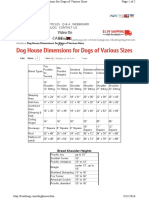

- Dog House Dimensions For Dogs of Various Sizes: Online Courses Video On DemandDocument2 pagesDog House Dimensions For Dogs of Various Sizes: Online Courses Video On DemandSherwin J. Dela CruzNo ratings yet

- Open Your Garage Door and House Lights Through Mobile App: Optional AccessoriesDocument2 pagesOpen Your Garage Door and House Lights Through Mobile App: Optional AccessoriesSherwin J. Dela CruzNo ratings yet

- FR CatalogueDocument44 pagesFR CatalogueSherwin J. Dela CruzNo ratings yet

- PEE-Proposed OutlineDocument3 pagesPEE-Proposed OutlineSherwin J. Dela CruzNo ratings yet

- PEE-Proposed Title FormatDocument1 pagePEE-Proposed Title FormatSherwin J. Dela CruzNo ratings yet