Professional Documents

Culture Documents

AN6204

Uploaded by

CTN2010Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AN6204

Uploaded by

CTN2010Copyright:

Available Formats

INCH-POUND

AN6204L

4 November 2013

SUPERSEDING

AN6204K

25 January 2006

DETAIL SPECIFICATION SHEET

VALVE, HYDRAULIC BLEEDER

This specification is approved for use by all Departments and

Agencies of the Department of Defense.

The requirements for acquiring the product described herein shall consist of this specification sheet.

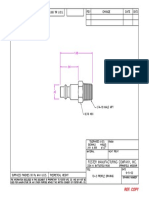

FIGURE 1. Valve dimensions and configuration.

AMSC N/A FSC 4820

Source: https://assist.dla.mil -- Downloaded: 2017-04-01T18:21Z

Check the source to verify that this is the current version before use.

AN6204L

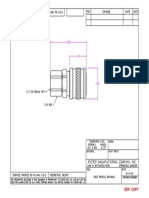

AN6204 Thread A B C D E F J L

G

Dash number T Dia .016 .016 .016 .016 .005 .016 .016

.3750-24

1 .278 .906

UNF-2A .188 .563 .656 .734 .159 --- ---

(see note 7) .005 .016

(see note 8)

.2500-28 +.000 +.000

2

UNF-2A .190 .430 .406 .453 .531 .0781 .922 .344 .313

(see note 7)

(see note 8) -.005 -.010

.3750-24

3 .278 .906

UNJF-3A .188 .563 .656 .734 .159 --- ---

(see note 9) .005 .016

(see note 10)

.2500-28 +.000 +.000

4

UNJF-3A .190 .430 .406 .453 .531 .0781 .922 .344 .313

(see note 9)

(see note 10) -.005 -.010

Inches mm Inches mm

.003 0.08 .2500 6.350

.004 0.10 .278 7.06

.005 0.13 .313 7.95

.010 0.25 .344 8.74

.016 0.41 .375 9.53

.031 0.79 .3750 9.525

.063 1.60 .406 10.31

.065 1.65 .430 10.92

.075 1.91 .531 13.49

.0781 1.984 .563 14.30

.159 4.04 .734 18.64

.188 4.78 .906 23.01

.190 4.83 .922 23.42

1.063 27.00

NOTES:

1. Dimensions are in inches.

2. Metric equivalents are given for information only.

3. Unless otherwise specified, tolerances .005 (0.13 mm), angles .5.

4. Dimensioning and tolerancing in accordance with ASME Y14.5.

5. Break edges .003 to .015 inch (0.08 to 0.38 mm) unless otherwise specified. Remove all hanging

burrs and slivers.

6. Surface texture shall be 250 in Ra for unmachined surfaces, except forging parting lines and

500in Ra for forging parting planes in accordance with ASME B46.1.

7 Inactive for new design.

8 Thread right hand in accordance with ASME B1.1.

9 Recommended for new design.

10 Threads shall be in accordance with SAE-AS8879.

FIGURE 1. Valve dimensions and configuration - Continued.

Source: https://assist.dla.mil -- Downloaded: 2017-04-01T18:21Z

Check the source to verify that this is the current version before use.

AN6204L

REQUIREMENTS:

Materials:

Steel alloy 4140 in accordance with SAE-AMS6349 or SAE-AMS6382.

Corrosion resistant steel (CRES) in accordance with one of the following:

321 CRES in accordance with SAE-AMS5645.

15-5 PH CRES (UNS 15500) in accordance with SAE-AMS5862, SAE-AMS5659,

or ASTM A693.

Age hardening CRES in accordance with ASTM A705/A705M

Heat treat to 155,000 psi (1069 MPa) tensile strength.

Finish: See table I.

TABLE I. Material and plating designators.

Material and

Material alloy and plating finish

plating designator

Steel alloy 4140 with cadmium finish in accordance with SAE-AMS-QQ-P-416, type

A

II, class 2, dyed black.

B CRES no finish.

R Steel alloy 4140 with zinc plate in accordance with ASTM B633; type VI, Fe/Zn 5.

Finish. Finishes shall be as specified in table I. All platings shall be capable of meeting a minimum

of 96 hours salt spray test in accordance with ASTM B117. The valve shall show no evidence of

corrosion after 96 hours of salt spray. Fluid passages, other openings, and internal threads shall not

be subject to the plating thickness requirement and may have bare areas provided they are protected

with a light film of oil.

OPERATING CHARACTERISTICS

The valve shall be able to function at operating pressure at 3,000 PSI and shall withstand and seal

2,250 psi (16 Mpa) minimum pressure.

Part or Identifying Number (PIN):

AN 6204 -1 A

Material plating designator,

see table I

Dash number from figure 1

Basic specification number

AN prefix

PIN example: AN6204-1A is for a hydraulic bleeder valve steel alloy 4140 with cadmium finish for a

.3750-24UNF-2A taped hole.

Source: https://assist.dla.mil -- Downloaded: 2017-04-01T18:21Z

Check the source to verify that this is the current version before use.

AN6204L

Guidance on use of alternative parts with less hazardous or non-hazardous materials. This

specification provides for a number of alternative plating materials via the PIN. Users should select

the PIN with the least hazardous material that meets the form, fit, and function requirements of their

application.

Order of precedence. Unless otherwise noted herein or in the contract, in the event of a conflict

between the text of this document and the references cited herein, the text of this document takes

precedence. Nothing in this document, however, supersedes applicable laws and regulations unless a

specific exemption has been obtained.

Referenced documents shall be of the issue in effect on date of invitations for bid.

Changes from previous issues. Marginal notations are not used in this revision to identify changes

with respect to the previous issue due to the extent of the changes.

Referenced document. This document references the following:

ASME B1.1 SAE-AMS-QQ-P-416

ASME B46.1 SAE-AMS5645

ASME Y14.5 SAE-AMS5659

ASTM A693 SAE-AMS5862

ASTM A705/A705M SAE-AMS6349

ASTM B633 SAE-AMS6382

ASTM B117 SAE-AS8879

CONCLUDING MATERIAL

Custodians: Preparing activity:

Army - AV DLA - CC

Navy - AS

Air Force - 99 (Project 4820-2013-011)

DLA - CC

Review activities:

Army - MI

Navy - CG, MC, SA, SH

Air Force - 11, 70, 71

NOTE: The activities listed above were interested in this document as of the date of this document.

Since organizations and responsibilities can change, you should verify the currency of the information

above using the ASSIST Online database at https://assist.dla.mil.

Source: https://assist.dla.mil -- Downloaded: 2017-04-01T18:21Z

Check the source to verify that this is the current version before use.

You might also like

- AN807 Rev7Document5 pagesAN807 Rev7MAI_QualityNo ratings yet

- An805 8Document3 pagesAn805 8jcNo ratings yet

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet

- Resistance and Deformation of Solid Media: Pergamon Unified Engineering SeriesFrom EverandResistance and Deformation of Solid Media: Pergamon Unified Engineering SeriesNo ratings yet

- Advances in Engineering Plasticity and its ApplicationsFrom EverandAdvances in Engineering Plasticity and its ApplicationsW.B. LeeNo ratings yet

- Source: Https://assist - Dla.mil - Downloaded: 2017-12-05T21:08Z Check The Source To Verify That This Is The Current Version Before UseDocument6 pagesSource: Https://assist - Dla.mil - Downloaded: 2017-12-05T21:08Z Check The Source To Verify That This Is The Current Version Before UseJoey ThomannNo ratings yet

- Strain-stress relation for cubic materialsDocument11 pagesStrain-stress relation for cubic materialsgordan100% (1)

- Guide to Load Analysis for Durability in Vehicle EngineeringFrom EverandGuide to Load Analysis for Durability in Vehicle EngineeringP. JohannessonRating: 4 out of 5 stars4/5 (1)

- Aluminium Alloy 6061-T651 WeldedDocument9 pagesAluminium Alloy 6061-T651 WeldedBagandi ManurungNo ratings yet

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysFrom EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysRating: 1 out of 5 stars1/5 (1)

- Nonlinear Finite Element Analysis and Adina: Proceedings of the 4th ADINA ConferenceFrom EverandNonlinear Finite Element Analysis and Adina: Proceedings of the 4th ADINA ConferenceNo ratings yet

- Modelling of Frictional Joints in Dynamically LoadDocument26 pagesModelling of Frictional Joints in Dynamically LoadAaron GalvezNo ratings yet

- Modern Practice in Stress and Vibration Analysis: Proceedings of the Conference Held at the University of Liverpool, 3–5 April 1989From EverandModern Practice in Stress and Vibration Analysis: Proceedings of the Conference Held at the University of Liverpool, 3–5 April 1989J. E. MottersheadNo ratings yet

- ASMEY14.5M Geometric Dimensioning and TolerancingDocument239 pagesASMEY14.5M Geometric Dimensioning and TolerancingVicente Pañol VNo ratings yet

- The Commercial Vehicle: An IntroductionDocument24 pagesThe Commercial Vehicle: An IntroductionPawan Kumar Gupta100% (1)

- 2012-005 RWG-WEB RodEnd SphericalBearingsDocument14 pages2012-005 RWG-WEB RodEnd SphericalBearingskamaleshaiahNo ratings yet

- SAE AMS4772K-2015 Silver Alloy, Brazing Filler MetalDocument6 pagesSAE AMS4772K-2015 Silver Alloy, Brazing Filler MetalraulNo ratings yet

- NAS StandardDocument2 pagesNAS StandardtamaranmNo ratings yet

- Guide For Bolted Join Design and Analysis PernosDocument47 pagesGuide For Bolted Join Design and Analysis PernosjeremiasNo ratings yet

- NDIA Fundamentals Engineering Drawing PracticesDocument25 pagesNDIA Fundamentals Engineering Drawing PracticesPaul MatquisNo ratings yet

- Fatigue Curve - S235JR ExperimantalDocument9 pagesFatigue Curve - S235JR ExperimantalPrabath MadusankaNo ratings yet

- Analysis of The Yokeless and Segmented Armature MachineDocument7 pagesAnalysis of The Yokeless and Segmented Armature MachineSeksan KhamkaewNo ratings yet

- ASTM E9 CompresionDocument9 pagesASTM E9 CompresionChris Matías YezNo ratings yet

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- AMS4016MDocument5 pagesAMS4016M黄当甲No ratings yet

- Is 2610Document8 pagesIs 2610kamalkraj4002No ratings yet

- MMPDS 11 PreviewDocument24 pagesMMPDS 11 Previewmfregeau3654No ratings yet

- Engineering Deisgn With PolymersDocument39 pagesEngineering Deisgn With Polymerschristopher_kephart1100% (1)

- FF S 85DDocument20 pagesFF S 85DmshNo ratings yet

- Behaviour of Sleeved Bolt Connections in Precast Concrete FramesDocument246 pagesBehaviour of Sleeved Bolt Connections in Precast Concrete Framespavan2deepuakiNo ratings yet

- IFI 100 Prevailing Torque LocknutsDocument7 pagesIFI 100 Prevailing Torque LocknutsMarceloGonçalvesNo ratings yet

- The Strength of Materials: A Treatise on the Theory of Stress Calculations for EngineersFrom EverandThe Strength of Materials: A Treatise on the Theory of Stress Calculations for EngineersNo ratings yet

- 17-7 PH Data BulletinDocument16 pages17-7 PH Data Bulletinmeckup123No ratings yet

- 3.4. Stress StiffeningDocument12 pages3.4. Stress StiffeningLe Anh TuanNo ratings yet

- Deformation Geometry for Materials Scientists: International Series on Materials Science and TechnologyFrom EverandDeformation Geometry for Materials Scientists: International Series on Materials Science and TechnologyRating: 5 out of 5 stars5/5 (1)

- Bossard Taptite Self Tapping Screw CatalogueDocument10 pagesBossard Taptite Self Tapping Screw CataloguepmlmkpNo ratings yet

- Material Specification: Specification: Revision Date: Revision LevelDocument2 pagesMaterial Specification: Specification: Revision Date: Revision LevelReginaldo Santos100% (1)

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- Ms33537e PDFDocument11 pagesMs33537e PDFstaedtlerpNo ratings yet

- Aerospace Material Specification: Tolerances Corrosion and Heat-Resistant Steel TubingDocument3 pagesAerospace Material Specification: Tolerances Corrosion and Heat-Resistant Steel TubingTetianaNo ratings yet

- Nas 1581Document1 pageNas 1581tangyuNo ratings yet

- NAS1102 Series Screw SpecsDocument1 pageNAS1102 Series Screw Specsscribd8341100% (1)

- Surface Vehicle Recommended Practice: Reaf. MAY1998Document5 pagesSurface Vehicle Recommended Practice: Reaf. MAY1998anupthattaNo ratings yet

- Sae As 81820-4B 2007 (En)Document4 pagesSae As 81820-4B 2007 (En)Oh No PotatoNo ratings yet

- AMS5688Document7 pagesAMS5688Federica FiorentiniNo ratings yet

- Handbook PDFDocument48 pagesHandbook PDFbhaskarjalanNo ratings yet

- SKF Filament Wound BushingsDocument8 pagesSKF Filament Wound BushingsWes VendrigNo ratings yet

- Y14 32 1M 1994Document72 pagesY14 32 1M 1994deepdreamx6400No ratings yet

- Failure Analysis of A Car Suspension System Ball JointDocument8 pagesFailure Analysis of A Car Suspension System Ball Jointsubha_aeroNo ratings yet

- AISI 440 Martensit PDFDocument4 pagesAISI 440 Martensit PDFJimmyVargasNo ratings yet

- GS52Document3 pagesGS52S.Hasan MirasadiNo ratings yet

- Mil STD 810h HumidityDocument22 pagesMil STD 810h Humiditymariela baigorriaNo ratings yet

- Build Your Own Magneto TimerDocument1 pageBuild Your Own Magneto TimerCTN2010No ratings yet

- Cce - LB - B Series - 580B - Specs - 06-26-2009Document6 pagesCce - LB - B Series - 580B - Specs - 06-26-2009CTN2010No ratings yet

- Build Your Owner LeakDocument2 pagesBuild Your Owner LeakCTN2010No ratings yet

- Cce LB Historic 580 Specs 06-26-2009Document4 pagesCce LB Historic 580 Specs 06-26-2009CTN2010100% (1)

- Easa Sib 2008-54 1Document2 pagesEasa Sib 2008-54 1CTN2010No ratings yet

- BendixMagnetoFilterInstall PDFDocument1 pageBendixMagnetoFilterInstall PDFCTN2010No ratings yet

- Wheel Parts Cross ReferenceDocument2 pagesWheel Parts Cross ReferenceCTN2010No ratings yet

- CMI Current Publication Listing - Jan-2017Document8 pagesCMI Current Publication Listing - Jan-2017CTN2010No ratings yet

- Bendix Magneto Filter InstallDocument1 pageBendix Magneto Filter InstallCTN2010No ratings yet

- Stahovaky 2Document27 pagesStahovaky 2CTN2010No ratings yet

- Is 21 010B e PDFDocument12 pagesIs 21 010B e PDFCTN2010No ratings yet

- EATON Togle Switches Vol11 - Tab04Document35 pagesEATON Togle Switches Vol11 - Tab04CTN2010No ratings yet

- Aerospace Fasteners and Supplier GuideDocument2 pagesAerospace Fasteners and Supplier GuideCTN2010No ratings yet

- 10-3 Profile DrawingDocument1 page10-3 Profile DrawingCTN2010No ratings yet

- 3003 Profile DrawingDocument1 page3003 Profile DrawingCTN2010No ratings yet

- Is 21 010B e PDFDocument12 pagesIs 21 010B e PDFCTN2010No ratings yet

- Is 21 010B eDocument12 pagesIs 21 010B eCTN2010No ratings yet

- 3103 Profile DrawingDocument1 page3103 Profile DrawingCTN2010No ratings yet

- Air Conditioning Compressor/Clutch Service ManualDocument2 pagesAir Conditioning Compressor/Clutch Service ManualromulofcarreraNo ratings yet

- EATON Catalog IntroductionDocument2 pagesEATON Catalog IntroductionCTN2010No ratings yet

- Portfolio LAGUNADocument6 pagesPortfolio LAGUNACTN2010No ratings yet

- DTP Amg 2015Document108 pagesDTP Amg 2015CTN2010No ratings yet

- 5310 2Document11 pages5310 2CTN2010No ratings yet

- Visteon AutomotiveDocument4 pagesVisteon AutomotiveCTN2010No ratings yet

- Air Conditioning Compressor/Clutch Service ManualDocument2 pagesAir Conditioning Compressor/Clutch Service ManualromulofcarreraNo ratings yet

- 5305 Service Manual Model 44 Front Hub LokDocument6 pages5305 Service Manual Model 44 Front Hub LokCTN2010No ratings yet

- CT Pag Oil Reference Chart 05Document2 pagesCT Pag Oil Reference Chart 05jldamascenoNo ratings yet

- Periodic Table of ElementsDocument1 pagePeriodic Table of ElementsMonte Carlo PaladoNo ratings yet

- OrbitalsDocument1 pageOrbitalshttp://spmchem.blogspot.com/No ratings yet

- Jabatan Bomba StandardsDocument21 pagesJabatan Bomba Standardsredisme09No ratings yet

- Standards For RehabilitationDocument55 pagesStandards For RehabilitationJuan Carlos Ryan ValdezNo ratings yet

- Weight Calculations Specific Weight (G/CM)Document15 pagesWeight Calculations Specific Weight (G/CM)Ranjeet Kumar ThakurNo ratings yet

- About UsDocument19 pagesAbout UsworkisgodNo ratings yet

- NH-Armaflex SpecificationDocument2 pagesNH-Armaflex SpecificationPanya PurahongNo ratings yet

- For Better Building: Diamond Cements (Prop. Heidelbergcement India LTD) Damoh UnitDocument1 pageFor Better Building: Diamond Cements (Prop. Heidelbergcement India LTD) Damoh UnitAjay SinghNo ratings yet

- Cec 313 Lect NoteDocument10 pagesCec 313 Lect NoteSamson Mide FolorunshoNo ratings yet

- (Effects of Fly Ash in Cement Properties)Document9 pages(Effects of Fly Ash in Cement Properties)ShowvikNo ratings yet

- Exibitor List - As of 28nov08Document6 pagesExibitor List - As of 28nov08Soldier MayNo ratings yet

- CASHCLA DESIGN DRAWINGS FOR CALIFORNIA GOLD PROPERTIES RESIDENCEDocument7 pagesCASHCLA DESIGN DRAWINGS FOR CALIFORNIA GOLD PROPERTIES RESIDENCEAngelo MoralNo ratings yet

- Uniclass2015 Ss v1 18 RevisionsDocument7 pagesUniclass2015 Ss v1 18 Revisionsabdullah sahibNo ratings yet

- A29A29M-12e1 Standard Specification For General Requirements For Steel Bars, Carbon and Alloy, Hot-Wrought 000Document16 pagesA29A29M-12e1 Standard Specification For General Requirements For Steel Bars, Carbon and Alloy, Hot-Wrought 000Moongil oodagamNo ratings yet

- BOQ SummaryDocument4 pagesBOQ SummaryTijoNo ratings yet

- Astm A312-A312m-05Document11 pagesAstm A312-A312m-05NadhiraNo ratings yet

- Scrapzone Price ListDocument2 pagesScrapzone Price Listshantanukulkarni007No ratings yet

- Strength and Shrinkage Properties of Mortar Containing A Nonstandard High-Calcium Fly AshDocument4 pagesStrength and Shrinkage Properties of Mortar Containing A Nonstandard High-Calcium Fly AshTarek ChikerNo ratings yet

- 8.19.3 Laying: 8.20 Curtain W T T ALL W W With Aluminium Composite Panels (Acp) Cladding P P 8.20.1 GeneralDocument5 pages8.19.3 Laying: 8.20 Curtain W T T ALL W W With Aluminium Composite Panels (Acp) Cladding P P 8.20.1 GeneralAnshuman RathNo ratings yet

- SN3148 - Use of Limestone in Cements PDFDocument78 pagesSN3148 - Use of Limestone in Cements PDFKalindaMadusankaDasanayakaNo ratings yet

- Surface Preparation and Protective CoatingDocument19 pagesSurface Preparation and Protective CoatingnitinNo ratings yet

- Catalogo Burndy Telecommunications ProductsDocument66 pagesCatalogo Burndy Telecommunications ProductsGregor RojasNo ratings yet

- Accurex Hood SpecsDocument42 pagesAccurex Hood SpecsaudithanNo ratings yet

- SMR System DataSheetDocument4 pagesSMR System DataSheetTracyNo ratings yet

- Estimate SampleDocument26 pagesEstimate Sampleesg2917305No ratings yet

- ICSSES 2024 (Sample Template)Document9 pagesICSSES 2024 (Sample Template)Naveen ShankarNo ratings yet

- Catawissa BrochureDocument12 pagesCatawissa Brochurepacho916No ratings yet

- Standard VCS 5737,: Volvo Car CorporationDocument9 pagesStandard VCS 5737,: Volvo Car CorporationWei Yue ZhuanNo ratings yet

- Snag List-Hyatt House Hvac and Chiller System Valve Pakage CD Fa Duct Rooms or Areas Fcu and Duct ConnectionDocument10 pagesSnag List-Hyatt House Hvac and Chiller System Valve Pakage CD Fa Duct Rooms or Areas Fcu and Duct ConnectionriyasudheenmhNo ratings yet

- Intro to Concrete Structures DesignDocument42 pagesIntro to Concrete Structures DesignTanvirH.ChowdhuryNo ratings yet

- PCC and Technique UsedDocument13 pagesPCC and Technique UsedashnaNo ratings yet

- Level Flat No.: Cold & Hot Water Services Feed Pipe Calculation ScheduleDocument2 pagesLevel Flat No.: Cold & Hot Water Services Feed Pipe Calculation ScheduleMario B. DaluNo ratings yet