Professional Documents

Culture Documents

330C Excavator Hydraulic System

Uploaded by

john ayengah100%(1)100% found this document useful (1 vote)

47 views8 pagesuo

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentuo

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

47 views8 pages330C Excavator Hydraulic System

Uploaded by

john ayengahuo

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 8

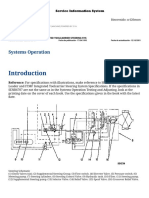

330C Excavator Hydraulic System-Travel Counterbalance Valve

Travel Counterbalance Valve

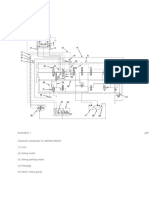

Left travel motor and travel counterbalance valve

(1) Crossover relief valve (reverse travel)

(16) Crossover relief valve (forward travel)

(24) Port (supply port for forward travel)

(27) Port (supply port for reverse travel)

(33) Counterbalance valve

(35) Travel counterbalance valve(36) Left travel motor

Travel counterbalance valve (35) consists of counterbalance valve (33), crossover relief valve (1)

and crossover relief valve (16). The travel counterbalance valve is bolted to the travel motor. The

travel counterbalance valve has the following four functions.

The travel counterbalance valve prevents a shock load when travel is stopped.

The travel counterbalance valve prevents overspeed while the machine is travelling down

a slope.

The travel counterbalance valve prevents cavitation.

The travel counterbalance valve routes a portion of the oil to the travel parking brake in

order to release the brake.

Counterbalance Valve Operation During Level Travel

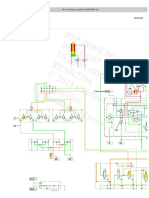

Travel counterbalance valve (level travel)

(1) Crossover relief valve (reverse travel)

(2) Passage

(3) Valve

(4) Passage

(5) Passage

(6) Passage

(7) Passage

(8) Valve

(9) Spool

(10) Spring

(11) Passage

(12) Spring

(13) Spring

(14) Damper Spool

(15) Ball

(16) Crossover relief valve (forward travel)

(17) Passage

(18) Spring chamber

(19) Passage

(20) Damper Chamber

(21) Orifice

(22) Passage

(23) Check valve

(24) Port (supply port for forward travel)

(25) Passage

(26) Passage

(27) Port (supply port for reverse travel)

(28) Check valve

(29) Passage

(30) Spring

(32) Passage

(33) Counterbalance valve(35) Travel counterbalance valve

Counterbalance valve (33) consists of spool (9), check valve (23), check valve (28), spring (13)

and spring (30). During forward travel on level ground, pump oil is supplied to port (24). The oil

flows through port (24), passage (25), and check valve (23). The oil flow forces check valve (23)

to open. This allows oil to flow through port (24), passage (25), check valve (23), passage (2),

and the port to the rotary group of the travel motor.

A portion of the oil delivery from the drive pump in port (24) flows through passage (22) and

passage (17) against ball (15). Ball (15) moves to the right against the force of spring (12) in

damper spool (14). The oil delivery then flows through passage (19) into spring chamber (18).

The oil pressure in damper chamber (20) acts on the end of spool (9). Spool (9) shifts to the right

against the force of spring (30). Passage (7) opens.

As spool (9) shifts to the right, return oil from the travel motor flows through the port, passage

(7), passage (26), and port (27) to the hydraulic tank.

When the oil flow from port (24) is blocked, the pressure in damper chamber (20) decreases. The

force of spring (30) shifts spool (9) to the left. Passage (7) closes. Return oil from the travel

motor is blocked and the rotation of the travel motor stops.

When the direction of travel is reversed, pump oil flows to spool (9) through port (27). Spool (9)

shifts to the left. The return oil flows through port (24). During reverse travel, the travel

counterbalance valve operates in the same manner as the forward travel operation.

Counterbalance Valve Operation During Slope Travel

Travel counterbalance valve (slope travel)

(1) Crossover relief valve (reverse travel)

(2) Passage

(3) Valve

(4) Passage

(5) Passage

(6) Passage

(7) Passage

(8) Valve

(9) Spool

(10) Spring

(11) Passage

(12) Spring

(13) Spring

(14) Damper Spool

(15) Ball

(16) Crossover relief valve (forward travel)

(17) Passage

(18) Spring chamber

(19) Passage

(20) Damper Chamber

(21) Orifice

(22) Passage

(23) Check valve

(24) Port (supply port for forward travel)

(25) Passage

(26) Passage

(27) Port (supply port for reverse travel)

(28) Check valve

(29) Passage

(30) Spring

(32) Passage

(33) Counterbalance valve(35) Travel counterbalance valve

When the machine travels down a slope, the travel motors rotate at a higher speed. The higher

speed is due to the mass (weight and size) of the machine. When this condition occurs, the

pumps cannot maintain the oil supply to the travel motors. The lack of oil supply will cause

cavitation in the travel motor. A pressure decrease occurs at port (24). A pressure decrease occurs

in spring chamber (18) as well.

The force of spring (30) moves spool (9) to the left. Passage (7) begins to close. This blocks oil

flow between passage (7) and passage (26). The return oil from the travel motor and the oil flow

to the suction port of the travel motor are restricted. The rotation of the travel motor slows down.

The pressure of the oil delivery from the drive pump at port (24) increases. Part of the oil flows

through passage (17). Spool (9) shifts to the right. Passage (7) opens. Return oil from the travel

motor flows through port (27). The modulation of spool (9) maintains the proper opening of

passage (7) when the machine travels down a slope. The travel motor begins to rotate in

accordance with the amount of pump oil supply. This prevents cavitation in the travel motors.

When the machine is travelling down a slope, or the machine is suddenly stopped, spool (9)

suddenly closes passage (7). This causes a hydraulic pressure spike to occur. A damper is

provided at both ends of spool (9) in order to prevent hydraulic pressure spikes. As spool (9)

shifts to the left, the oil in damper chamber (20) is pressurized. Ball (15) moves to the left. The

oil in spring chamber (18) flows through orifice (21) and into passage (22). Spool (9) slowly

moves to the left. Passage (7) slowly closes. The size and the position of orifice (21) maintains

the proper shock damper.

Operation Of Travel Crossover Relief Valves During

Machine Stop

Travel counterbalance valve (travel stop)

(1) Crossover relief valve (reverse travel)

(2) Passage

(3) Valve

(4) Passage

(5) Passage

(6) Passage

(7) Passage

(8) Valve

(9) Spool

(10) Spring

(11) Passage

(12) Spring

(13) Spring

(14) Damper Spool

(15) Ball

(16) Crossover relief valve (forward travel)

(17) Passage

(18) Spring chamber

(19) Passage

(20) Damper Chamber

(21) Orifice

(22) Passage

(23) Check valve

(24) Port (supply port for forward travel)

(25) Passage

(26) Passage

(27) Port (supply port for reverse travel)

(28) Check valve

(29) Passage

(30) Spring

(32) Passage

(33) Counterbalance valve(35) Travel counterbalance valve

If the travel levers/pedals are returned to the NEUTRAL position during machine movement, the

oil delivery from the pumps is blocked from the travel motors. The pressure at port (24) of the

travel counterbalance valve decreases. The force of spring (30) moves spool (9) to the left to the

neutral position. The mass (weight and size) of the machine causes the travel motor to continue

to rotate. Passage (7) is closed and the flow of return oil is blocked. A sudden pressure increase

occurs in passage (11). The return oil in passage (11) flows through passage (6) to crossover

relief valve (1). Valve (3) shifts to the left. The return oil in passage (6) flows past the open valve

(3) into suction passage (2) of the travel motor.

Travel crossover relief valve

(3) Valve

(2) Passage

(6) Passage

(39) Body

(40) Orifice

(41) Orifice

(42) Orifice

(43) Stem

(44) Passage(45) Shock reducing piston

The return oil pressure in passage (6) flows through orifice (41) in valve (3). The oil then flows

through orifices (40) and (42) in stem (43). The return oil now flows through passage (44).

Shock reducing piston (45) shifts to the right. The travel crossover relief valve maintains the

circuit pressure at a lower pressure until the right end of shock reducing piston (45) contacts stem

(43). When the shock reducing piston is fully shifted to the right, the oil pressure in passage (6)

increases to the pressure setting of the crossover relief valve. All of the oil flow in passage (6)

now flows past valve (3) into return passage (2) .

The oil pressure gradually increases until the shock reducing piston shifts fully to the right.

Pressure spikes in the travel circuit are eliminated. This is called a two-stage relief operation. The

two-stage relief operation absorbs the shock load at the stop of a travel operation.

During forward travel of the left travel motor, oil flow opens crossover relief valve (1) when the

machine is stopping. During reverse travel of the left travel motor, crossover relief valve (16) is

activated when the machine is stopping.

Crossover relief valves (1) and (16) protect the travel motor by releasing the high pressure oil.

Crossover relief valves (1) and (16) also provide makeup oil from the outlet side of the travel

motor to the inlet side of the travel motor. This makeup oil prevents a vacuum condition in the

travel motor.

In order to adjust the pressure setting of the crossover relief valves, refer to the crossover relief

valves by the functions of the travel control levers. Refer to crossover relief valve (16) as left

travel (forward). Refer to crossover relief valve (1) as left travel (reverse).

Reference: For more information concerning the pressure settings of the travel crossover relief

valves, refer to Testing and Adjusting, "Relief Valve (Crossover) - Test and Adjust".

Travel Parking Brake Operation

When the oil delivery from the drive pump at port (24) of the travel counterbalance valve is

blocked, spool (9) moves to the right. Passage (4) opens. A portion of the oil delivery in passage

(25) flows through passage (4) and passage (32) in order to release the travel parking brake.

Since passage (4) opens before passage (7), the rotation of the motor rotary group does not start

until the travel parking brake is released.

When the oil delivery to port (24) is blocked in order to stop the rotation of the travel motor,

spool (9) returns to the NEUTRAL position. Passage (4) closes after passage (7) closes. This

allows the movement of the machine to stop before the travel parking brake is engaged.

Reference: For more information concerning the operation of the travel parking brake, refer

toSystems Operation, "Travel Parking Brake".

You might also like

- Travel Counterbalance Valve: Systems OperationDocument10 pagesTravel Counterbalance Valve: Systems OperationRainer Lopez E100% (3)

- HOLD Position For The Swing ValveDocument6 pagesHOLD Position For The Swing ValveBrankoNo ratings yet

- 330C Excavator Hydraulic System Travel Counterbalance ValveDocument10 pages330C Excavator Hydraulic System Travel Counterbalance ValveRkert torresNo ratings yet

- Hydraulic System-Swing SystemDocument5 pagesHydraulic System-Swing Systemjohn ayengah100% (3)

- Swing Hydraulic System: Systems OperationDocument12 pagesSwing Hydraulic System: Systems OperationRainer Lopez ENo ratings yet

- 994D Wheel Loader Steering Pilot Valve OperationDocument3 pages994D Wheel Loader Steering Pilot Valve OperationBraulio BracamontesNo ratings yet

- SwingDocument9 pagesSwingAdamNo ratings yet

- 320dl Swing SystemDocument10 pages320dl Swing SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- Excavator Hydraulic System-Bucket SystemDocument3 pagesExcavator Hydraulic System-Bucket Systemjohn ayengahNo ratings yet

- Steering Control ValveDocument12 pagesSteering Control Valvehidekel crafort vinicioNo ratings yet

- Relief Valve (Cushion Crossover) Relief Valve Operation: SMCS Code: 5111 5454Document15 pagesRelief Valve (Cushion Crossover) Relief Valve Operation: SMCS Code: 5111 5454Sam SungNo ratings yet

- 320dl Pilot Valve Travel SystemDocument3 pages320dl Pilot Valve Travel SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- Embruague Luc 994Document4 pagesEmbruague Luc 994sergio toroNo ratings yet

- Pilot Valve (Command Control Steering) 966Document16 pagesPilot Valve (Command Control Steering) 966Ahmed RezkNo ratings yet

- 330C Excavator Hydraulic Syste1Document4 pages330C Excavator Hydraulic Syste1john ayengahNo ratings yet

- Displacement Change ValveDocument5 pagesDisplacement Change ValveJuan Daniel Martinez Montoya100% (1)

- Stick Hydraulic SystemDocument9 pagesStick Hydraulic SystemWaridi RidiNo ratings yet

- Boom Hydraulic System CAT 330Document17 pagesBoom Hydraulic System CAT 330hector100% (1)

- Boom Hydraulic System CAT 330Document17 pagesBoom Hydraulic System CAT 330hectorNo ratings yet

- Bucket Hydraulic SystemDocument3 pagesBucket Hydraulic Systemjuan david loyola100% (1)

- 320dl Bucket Hydraulic SystemDocument3 pages320dl Bucket Hydraulic SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- 32odl Swing Oil Makeup SystemDocument4 pages32odl Swing Oil Makeup SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- 966H Wheel Loader Steering System OverviewDocument9 pages966H Wheel Loader Steering System OverviewAhmed RezkNo ratings yet

- Piston Pump (Brake, Hydraulic Fan)Document7 pagesPiston Pump (Brake, Hydraulic Fan)EVER DAVID SAAVEDRA HUAYHUANo ratings yet

- 320dl Stick SystemDocument8 pages320dl Stick SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- 11 Main Hydraulic PumpDocument4 pages11 Main Hydraulic PumpZawminhtun100% (1)

- 330C Excavator Hydraulic System/ Travel MotorDocument4 pages330C Excavator Hydraulic System/ Travel Motorjohn ayengahNo ratings yet

- Quick-Drop Valve: Previous ScreenDocument9 pagesQuick-Drop Valve: Previous ScreenBroCactusNo ratings yet

- 446D Valvula de Prioridad. Operacion de SistemaDocument8 pages446D Valvula de Prioridad. Operacion de SistemaCarlos IrabedraNo ratings yet

- Relief Valve CrossoverDocument5 pagesRelief Valve CrossoverSherlock HolmesNo ratings yet

- Torque Converter With The Impeller Clutch and The Lockup ClutchDocument10 pagesTorque Converter With The Impeller Clutch and The Lockup ClutchrickcyNo ratings yet

- Travel Hydraulic SystemDocument10 pagesTravel Hydraulic SystemAllan LariosaNo ratings yet

- Hydraulic Shematic FonctionDocument10 pagesHydraulic Shematic FonctionatelierNo ratings yet

- Control Valve (Straight Travel)Document5 pagesControl Valve (Straight Travel)Steven ManuputtyNo ratings yet

- 160m Hyd Pump Control Valve SysDocument8 pages160m Hyd Pump Control Valve SysDaniel Rhasty-ghee AhmanorNo ratings yet

- Control Valve Straight TravelDocument5 pagesControl Valve Straight TravelSteven Y.MNo ratings yet

- Operación de Sistema2nfnDocument14 pagesOperación de Sistema2nfnroqueNo ratings yet

- Wednesday, April 9, 2014: Travel Hydraulic SystemDocument7 pagesWednesday, April 9, 2014: Travel Hydraulic Systemjohn ayengahNo ratings yet

- Att System OperationDocument41 pagesAtt System OperationchanlinNo ratings yet

- Travel Motor System OperationDocument9 pagesTravel Motor System OperationAllan Lariosa100% (1)

- 938F Wheel Loader 7SN00001-UP (MACHINE) POWERED BY 3116 Engine (SEBP2374 - 53) - Sistemas y ComponentesDocument15 pages938F Wheel Loader 7SN00001-UP (MACHINE) POWERED BY 3116 Engine (SEBP2374 - 53) - Sistemas y ComponentesCarlos Andres Campos TorresNo ratings yet

- D6C Power Shift OperationDocument40 pagesD6C Power Shift OperationJhon AschNo ratings yet

- Valvula Selectora Trans.Document4 pagesValvula Selectora Trans.enriqueNo ratings yet

- Stick Hydraulic System: Systems OperationDocument11 pagesStick Hydraulic System: Systems OperationKusharyantoNo ratings yet

- Stick Hydraulic SystemDocument11 pagesStick Hydraulic SystemAllan LariosaNo ratings yet

- 13 Main Control ValveDocument13 pages13 Main Control ValveZawminhtunNo ratings yet

- 320D2 and 323D2 Excavator Bucket Hydraulic SystemDocument4 pages320D2 and 323D2 Excavator Bucket Hydraulic SystemvidalNo ratings yet

- Piston Pump (Brake, Hydraulic Fan)Document7 pagesPiston Pump (Brake, Hydraulic Fan)kiddrix gamerNo ratings yet

- Hydraulic System Operation for D11N Track-Type TractorDocument43 pagesHydraulic System Operation for D11N Track-Type Tractormiguel_catNo ratings yet

- Sis 2.2Document7 pagesSis 2.2Mohamed OmarNo ratings yet

- Fuel Inject 1Document13 pagesFuel Inject 1caterpillar971No ratings yet

- Retro 11Document52 pagesRetro 11Henry MonteagudoNo ratings yet

- 980c Especificaciones InglesDocument19 pages980c Especificaciones InglesEdgar TorresNo ratings yet

- CAT 3412 Lubrication SystemDocument5 pagesCAT 3412 Lubrication SystemCEVegaONo ratings yet

- Bucket Hydraulic SystemDocument4 pagesBucket Hydraulic SystemNay SoeNo ratings yet

- 2013/10/06 Lockup Clutch and Solenoid Valve (Torque Converter) (UENR1447-02)Document3 pages2013/10/06 Lockup Clutch and Solenoid Valve (Torque Converter) (UENR1447-02)Luis Lopez PaucarNo ratings yet

- Hydraulic System: Systems OperationDocument28 pagesHydraulic System: Systems OperationRoberto BaierNo ratings yet

- Transmission Hydraulic SystemDocument4 pagesTransmission Hydraulic SystemA Ramos Gaby100% (4)

- PPL Exam Secrets Guide: Aircraft General & Principles of FlightFrom EverandPPL Exam Secrets Guide: Aircraft General & Principles of FlightRating: 5 out of 5 stars5/5 (2)

- Business PlanDocument1 pageBusiness Planjohn ayengahNo ratings yet

- GroupsDocument1 pageGroupsjohn ayengahNo ratings yet

- Adventures in Automotive Networks ADocument206 pagesAdventures in Automotive Networks Ajohn ayengahNo ratings yet

- Bible verses about God's sovereignty and authorityDocument1 pageBible verses about God's sovereignty and authorityjohn ayengahNo ratings yet

- Oil ViscosityDocument2 pagesOil Viscosityjohn ayengahNo ratings yet

- 2444Document28 pages2444john ayengahNo ratings yet

- Sensors Book 2Document17 pagesSensors Book 2john ayengahNo ratings yet

- ProductDocument3 pagesProductjohn ayengahNo ratings yet

- 244Document28 pages244john ayengahNo ratings yet

- Parts list for operation device and fuel/cooling systemsDocument208 pagesParts list for operation device and fuel/cooling systemsjohn ayengahNo ratings yet

- 24444Document27 pages24444john ayengahNo ratings yet

- Solar BatteryyyDocument51 pagesSolar Batteryyyjohn ayengahNo ratings yet

- 12-Volt Alternator Installation & Operation ManualDocument12 pages12-Volt Alternator Installation & Operation Manualzzsq35No ratings yet

- International BridgeDocument45 pagesInternational Bridgejohn ayengahNo ratings yet

- HeuiDocument1 pageHeuijohn ayengahNo ratings yet

- Sample Resignation Letter - Notice PeriodDocument2 pagesSample Resignation Letter - Notice PeriodRenren MedranoNo ratings yet

- DiagnosticDocument29 pagesDiagnosticjohn ayengahNo ratings yet

- 12-Volt Alternator Installation & Operation ManualDocument12 pages12-Volt Alternator Installation & Operation Manualzzsq35No ratings yet

- The SpiritDocument2 pagesThe Spiritjohn ayengahNo ratings yet

- Parts list for operation device and fuel/cooling systemsDocument208 pagesParts list for operation device and fuel/cooling systemsjohn ayengahNo ratings yet

- Sample Resignation Letter - Notice PeriodDocument2 pagesSample Resignation Letter - Notice PeriodRenren MedranoNo ratings yet

- DiagnosticDocument29 pagesDiagnosticjohn ayengahNo ratings yet

- Sensors BookDocument18 pagesSensors Bookjohn ayengah100% (1)

- HeavyDocument346 pagesHeavyjohn ayengahNo ratings yet

- The Spirit 2Document3 pagesThe Spirit 2john ayengahNo ratings yet

- Adventures in Automotive Networks andDocument206 pagesAdventures in Automotive Networks andjohn ayengah100% (1)

- 40 Sins That WILL Send You To HellDocument7 pages40 Sins That WILL Send You To Helljohn ayengahNo ratings yet

- Oil Viscosity Is Measured Several WaysDocument2 pagesOil Viscosity Is Measured Several Waysjohn ayengahNo ratings yet

- P.O. Box MG 1471 Kumasi, Adum: John AyengahDocument1 pageP.O. Box MG 1471 Kumasi, Adum: John Ayengahjohn ayengahNo ratings yet

- Fault SimulatorDocument112 pagesFault Simulatorjohn ayengahNo ratings yet

- Foundry Technology GuideDocument34 pagesFoundry Technology GuidePranav Pandey100% (1)

- 4 DiscussionDocument2 pages4 DiscussiondreiNo ratings yet

- Lay Out New PL Press QltyDocument68 pagesLay Out New PL Press QltyDadan Hendra KurniawanNo ratings yet

- Special Proceedings Case DigestDocument14 pagesSpecial Proceedings Case DigestDyan Corpuz-Suresca100% (1)

- Data Sheet FC SIDocument2 pagesData Sheet FC SIAndrea AtzeniNo ratings yet

- Siegfried Kracauer - Photography (1927)Document17 pagesSiegfried Kracauer - Photography (1927)Paul NadeauNo ratings yet

- Plumbing Arithmetic RefresherDocument80 pagesPlumbing Arithmetic RefresherGigi AguasNo ratings yet

- Newton Raphson Method MCQDocument15 pagesNewton Raphson Method MCQmd junaidNo ratings yet

- Maturity Mode Agile BookDocument110 pagesMaturity Mode Agile BookSai VenkatNo ratings yet

- JTIL Purchase Requisition for Plasma Machine SparesDocument3 pagesJTIL Purchase Requisition for Plasma Machine Sparesshivam soniNo ratings yet

- Describing An Object - PPTDocument17 pagesDescribing An Object - PPThanzqanif azqaNo ratings yet

- 2020 - Audcap1 - 2.3 RCCM - BunagDocument1 page2020 - Audcap1 - 2.3 RCCM - BunagSherilyn BunagNo ratings yet

- Alpha Phi Omega National Service Fraternity Strategic PlanDocument1 pageAlpha Phi Omega National Service Fraternity Strategic Planlafay3tteNo ratings yet

- Minimum Fees To Be Taken by CADocument8 pagesMinimum Fees To Be Taken by CACA Sanjay BhatiaNo ratings yet

- Bargaining Power of SuppliersDocument9 pagesBargaining Power of SuppliersPiyumi VitharanaNo ratings yet

- Buyers FancyFoodDocument6 pagesBuyers FancyFoodvanNo ratings yet

- Research of William Wells at HarvardDocument10 pagesResearch of William Wells at HarvardARGHA MANNANo ratings yet

- The Top 10 Strategic Technology Trends For 2020: Tomas Huseby Executive PartnerDocument31 pagesThe Top 10 Strategic Technology Trends For 2020: Tomas Huseby Executive PartnerCarlos Stuars Echeandia CastilloNo ratings yet

- Impression Techniques in Complete Denture Patients: A ReviewDocument6 pagesImpression Techniques in Complete Denture Patients: A ReviewRoja AllampallyNo ratings yet

- What Is Inventory Management?Document31 pagesWhat Is Inventory Management?Naina SobtiNo ratings yet

- AP World History: Islamic Empires and Scientific AdvancementDocument55 pagesAP World History: Islamic Empires and Scientific AdvancementJa'TasiaNo ratings yet

- SWOT AnalysisDocument6 pagesSWOT Analysishananshahid96No ratings yet

- Ericsson 3G Chapter 5 (Service Integrity) - WCDMA RAN OptDocument61 pagesEricsson 3G Chapter 5 (Service Integrity) - WCDMA RAN OptMehmet Can KahramanNo ratings yet

- Gamma World Character SheetDocument1 pageGamma World Character SheetDr8chNo ratings yet

- Primary Homework Help Food ChainsDocument7 pagesPrimary Homework Help Food Chainsafnaxdxtloexll100% (1)

- Cost Systems: TermsDocument19 pagesCost Systems: TermsJames BarzoNo ratings yet

- Opamp TIDocument5 pagesOpamp TIAmogh Gajaré100% (1)

- Skype Sex - Date of Birth - Nationality: Curriculum VitaeDocument4 pagesSkype Sex - Date of Birth - Nationality: Curriculum VitaeSasa DjurasNo ratings yet

- Chapter 2 Literature ReviewDocument10 pagesChapter 2 Literature ReviewSharan BvpNo ratings yet

- Hilton 5-29 Case SolutionDocument4 pagesHilton 5-29 Case SolutionPebbles RobblesNo ratings yet