Professional Documents

Culture Documents

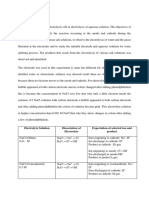

Adsoprtion

Uploaded by

SanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adsoprtion

Uploaded by

SanaCopyright:

Available Formats

CHAPTER 17

Adsorption

17.1. INTRODUCTION

Although adsorption has been used as a physical-chemical process for many years, it is

only over the last four decades that the process has developed to a stage where it is now

a major industrial separation technique. In adsorption, molecules distribute themselves

between two phases, one of which is a solid whilst the other may be a liquid or a gas.

The only exception is in adsorption on to foams, a topic which is not considered in this

chapter.

Unlike absorption, in which solute molecules diffuse from the bulk of a gas phase to

the bulk of a liquid phase, in adsorption, molecules diffuse from the bulk of the uid to

the surface of the solid adsorbent forming a distinct adsorbed phase.

Typically, gas adsorbers are used for removing trace components from gas mixtures.

The commonest example is the drying of gases in order to prevent corrosion, condensation

or an unwanted side reaction. For items as diverse as electronic instruments and biscuits,

sachets of adsorbent may be included in the packaging in order to keep the relative

humidity low. In processes using volatile solvents, it is necessary to guard against the

incidental loss of solvent carried away with the ventilating air and recovery may be

effected by passing the air through a packed bed of adsorbent.

Adsorption may be equally effective in removing trace components from a liquid phase

and may be used either to recover the component or simply to remove a noxious substance

from an industrial efuent.

Any potential application of adsorption has to be considered along with alternatives

such as distillation, absorption and liquid extraction. Each separation process exploits

a difference between a property of the components to be separated. In distillation, it

is volatility. In absorption, it is solubility. In extraction, it is a distribution coefcient.

Separation by adsorption depends on one component being more readily adsorbed than

another. The selection of a suitable process may also depend on the ease with which the

separated components can be recovered. Separating n- and iso-parafns by distillation

requires a large number of stages because of the low relative volatility of the components.

It may be economic, however, to use a selective adsorbent which separates on the basis

of slight differences in mean molecular diameters, where for example, n- and iso-pentane

have diameters of 0.489 and 0.558 nm respectively. When an adsorbent with pore size of

0.5 nm is exposed to a mixture of the gases, the smaller molecules diffuse to the adsorbent

surface and are retained whilst the larger molecules are excluded. In another stage of the

process, the retained molecules are desorbed by reducing the total pressure or increasing

the temperature.

970

You might also like

- Allagtah2015 PDFDocument15 pagesAllagtah2015 PDFSanaNo ratings yet

- Carniti NeDocument3 pagesCarniti NeSanaNo ratings yet

- 1 s2.0 S1876610214008881 Main PDFDocument10 pages1 s2.0 S1876610214008881 Main PDFSanaNo ratings yet

- Comparison of Three Methods For Natural Gas Dehydration PDFDocument6 pagesComparison of Three Methods For Natural Gas Dehydration PDFSanaNo ratings yet

- Ahmad I 2017Document49 pagesAhmad I 2017SanaNo ratings yet

- Samanta 2011Document8 pagesSamanta 2011SanaNo ratings yet

- Caffeine Is A Xanthine Alkaloid Compound That Acts As A Stimulant in Humans. Caffeine Is SometimesDocument1 pageCaffeine Is A Xanthine Alkaloid Compound That Acts As A Stimulant in Humans. Caffeine Is SometimesSanaNo ratings yet

- Sub-Chronic Nandrolone Treatment Modifies Neurochemical and Behavioral Effects of Amphetamine and 3,4-Methylenedioxymethamphetamine (MDMA) in RatsDocument11 pagesSub-Chronic Nandrolone Treatment Modifies Neurochemical and Behavioral Effects of Amphetamine and 3,4-Methylenedioxymethamphetamine (MDMA) in RatsSanaNo ratings yet

- Tsai 2017Document10 pagesTsai 2017SanaNo ratings yet

- Zhang 2016Document7 pagesZhang 2016SanaNo ratings yet

- CaféineDocument11 pagesCaféineSanaNo ratings yet

- Wang 2016Document11 pagesWang 2016SanaNo ratings yet

- Safety Science: Riccardo TommasiniDocument6 pagesSafety Science: Riccardo TommasiniSanaNo ratings yet

- UVCE (Roberts1982)Document17 pagesUVCE (Roberts1982)SanaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Air Suspension Benefits Over Steel SpringsDocument3 pagesAir Suspension Benefits Over Steel SpringsBejoy G NairNo ratings yet

- Reservoir Modelling & Simulation GuideDocument96 pagesReservoir Modelling & Simulation GuideyouungNo ratings yet

- CBCS StatisticsDocument79 pagesCBCS StatisticsXING XINGNo ratings yet

- SUMMATIVE EXAM (G11) 2023 ExamDocument3 pagesSUMMATIVE EXAM (G11) 2023 ExamDens Lister Mahilum100% (1)

- Propeller Model Tests GuideDocument12 pagesPropeller Model Tests GuideOdpewğw RlelelwNo ratings yet

- 4PH0 1P Que 20160119 PDFDocument28 pages4PH0 1P Que 20160119 PDFschlemielzNo ratings yet

- 978402applied Math Test Paper - Xi Set 2 - Sem 2Document4 pages978402applied Math Test Paper - Xi Set 2 - Sem 2MehulNo ratings yet

- P18 Probability in The CourtroomDocument14 pagesP18 Probability in The CourtroomYehiaNo ratings yet

- Quasi VarianceDocument2 pagesQuasi Varianceharrison9No ratings yet

- MK-PPT Chapter 1Document37 pagesMK-PPT Chapter 1Nicolás SánchezNo ratings yet

- Template 8dDocument165 pagesTemplate 8dLuis Alberto Quiroz GranadosNo ratings yet

- Association of Genetic Variant Linked To Hemochromatosis With Brain Magnetic Resonance Imaging Measures of Iron and Movement DisordersDocument10 pagesAssociation of Genetic Variant Linked To Hemochromatosis With Brain Magnetic Resonance Imaging Measures of Iron and Movement DisordersavinNo ratings yet

- Flow MeterDocument9 pagesFlow MeterShin BoNo ratings yet

- Migrating Your SQL Server Workloads To PostgreSQL - Part 3 - CodeProjectDocument6 pagesMigrating Your SQL Server Workloads To PostgreSQL - Part 3 - CodeProjectgfgomesNo ratings yet

- VHDL ExperimentsDocument55 pagesVHDL Experimentssandeepsingh93No ratings yet

- TIPS ON MEASUREMENT UNCERTAINTIESDocument2 pagesTIPS ON MEASUREMENT UNCERTAINTIESrahmaNo ratings yet

- Electrical Plant Load AnalysisDocument36 pagesElectrical Plant Load AnalysisJesus EspinozaNo ratings yet

- Digital Techniques/Electronic Instrument SystemsDocument29 pagesDigital Techniques/Electronic Instrument SystemsE DNo ratings yet

- Chapter 11 - MatricesDocument39 pagesChapter 11 - MatricesJhagantini Palanivelu0% (1)

- Astm E1588.1207649 GSRDocument5 pagesAstm E1588.1207649 GSRjoao carlos100% (1)

- PHY 107 Force and Motion 1 NotesDocument14 pagesPHY 107 Force and Motion 1 Notessojib yeasinNo ratings yet

- MP Lab3Document4 pagesMP Lab3kawish420No ratings yet

- CADAM - Model Parameters: General InformationDocument4 pagesCADAM - Model Parameters: General InformationmyapmisNo ratings yet

- Sampling, Testing, and Analysis of Asphalt Roll Roofing, Cap Sheets, and Shingles Used in Roofing and WaterproofingDocument13 pagesSampling, Testing, and Analysis of Asphalt Roll Roofing, Cap Sheets, and Shingles Used in Roofing and WaterproofingLuigi HernándezNo ratings yet

- 4th Form Scheme of WorkDocument6 pages4th Form Scheme of WorkEustace DavorenNo ratings yet

- Discussion Exp 2 Chm674Document4 pagesDiscussion Exp 2 Chm674Eva Lizwina MatinNo ratings yet

- Synopsis On Cyber Cafe Management SystemDocument22 pagesSynopsis On Cyber Cafe Management Systemyadavdhaval9No ratings yet

- Sky Telescope 201304Document90 pagesSky Telescope 201304Haydn BassarathNo ratings yet

- Exp 5-SteamPowerPlantDocument11 pagesExp 5-SteamPowerPlantFirst LastNo ratings yet