Professional Documents

Culture Documents

Vessels Manhours Estimate

Uploaded by

ruponline1Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vessels Manhours Estimate

Uploaded by

ruponline1Copyright:

Available Formats

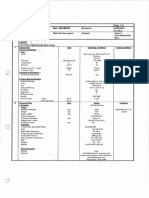

MANHOUR ESTIMATE (VESSELS)

CLIENT : REF DOC :

PRODUCT : PLANT SECTION : PRODN. CAP.: PROJECT TYPE STATUS PREPD. BY : SHEET NO. 1 OF 1

& DATE : Rev 00

NO. OF INTERNAL

NO. OF DELIVERABLES MAN-HOURS

ACTIVITIES

TAG NO./ QTY

SPECIFICATION TITLE

SR. NO. Nos. Spec. Data Drg TBC Spec. Design Vendor Client-Vendor

(Enq) Sheets (Enq.) (Bid Ev.) (Order) Calc. Drawing meeting TOTAL

Review (No. of days)

1 Pressure Vessels : Normal 3 60 180

: Critical 10 80 800

2 Shell & Tube Heat Exchanger : Normal 4 90 360

: Critical 5 130 650

3 Column : Normal 1 100 100

: Critical 2 150 300

4 Column Internal Modifications 3 30 90

5 Plate Heat Exchanger 2 35 70

6 Agitator 1 60 60

7 Insulation, Painting & Holding down Bolt schedule 60 60

8 Meeting & Co-ordination 200 200

Total 2870

ASSUMPTIONS

1) ASME/TEMA codes to be utilized for design of equipment.

2) ASME code stamp requirement is not considered for pressure vessels.

EXCLUSIONS

1) Design drawings / Fabrication drawings of any equipment will not be prepared by Vessels (Except for Vessels with volume less than 15 m3).

2) FEA work for the geometry/size falling outside the ASME code limit and for the nozzle local loads where geometry basis exceeds code

limit. (If required to be done at actual)

3) Vendor drawing review for Vessels with volume less than 15 m3.

SCOPE OF WORK

1) Preparation of MDS, Design Drawings (For Vessels with volume less than 15 m3), MR, Offer review, TQ/TBA, PR, Vendor drawing

review.

INPUTS REQUIRED

1) Process data sheets duely complete for all above equipment.

You might also like

- Cost Centers Vs ManhoursDocument166 pagesCost Centers Vs Manhoursguy88100% (1)

- 2a Piping Estimate & Summary ExampleDocument29 pages2a Piping Estimate & Summary ExampleTutu RohanaNo ratings yet

- Estimation Man HourDocument422 pagesEstimation Man HourEngFaisal Alrai50% (2)

- Cost and Estimate Pressure TankDocument8 pagesCost and Estimate Pressure TankLester MuscaNo ratings yet

- Man Hour Estimate ProgramDocument15 pagesMan Hour Estimate ProgramnbnbNo ratings yet

- Piping ManhoursDocument32 pagesPiping ManhoursNejat Ababay75% (16)

- Welding Cost Estimator PubDocument8 pagesWelding Cost Estimator Pubrockufool100% (4)

- CS Pipe Fab & Erect CostsDocument6 pagesCS Pipe Fab & Erect Costswally55bear69% (16)

- Piping CostingDocument10 pagesPiping CostingShankar CoolNo ratings yet

- 2 A Piping Estimate Summary ExampleDocument23 pages2 A Piping Estimate Summary Exampleans99No ratings yet

- Piping Manhours (Weight)Document25 pagesPiping Manhours (Weight)Nejat AbabayNo ratings yet

- CS Pipes Installation CostDocument12 pagesCS Pipes Installation Costrajkamal_e100% (2)

- Piping Manhour Costing Estimate SampleDocument24 pagesPiping Manhour Costing Estimate SampleMethosalem Haincadto85% (34)

- Typical Piping DeliverablesDocument4 pagesTypical Piping DeliverablesShyam Prasad K S100% (1)

- Standard Manhour Estimation: Fabrication & WeldingDocument3 pagesStandard Manhour Estimation: Fabrication & WeldingPratik Desai100% (7)

- Weight Factor Plan: Project Work Package Contractor Revision DateDocument4 pagesWeight Factor Plan: Project Work Package Contractor Revision DatescottigiancarloNo ratings yet

- Labor Manhours PDFDocument8 pagesLabor Manhours PDFadon97100% (1)

- Sharafco Man Hour Estimation (Pipeline)Document6 pagesSharafco Man Hour Estimation (Pipeline)Prasad67% (3)

- Project Management Man-Hour Cost Analysis: Case: Wärtsilä Energy SolutionsDocument32 pagesProject Management Man-Hour Cost Analysis: Case: Wärtsilä Energy SolutionsAziz EL100% (1)

- Estimating Labor Productivity Manhours PDFDocument24 pagesEstimating Labor Productivity Manhours PDFBench LaxamanaNo ratings yet

- Imperial Piping Weight Load Calculation WorkbookDocument13 pagesImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- Saddle AnalysisDocument17 pagesSaddle AnalysisPEJU0007No ratings yet

- Daily Progress ReportDocument3 pagesDaily Progress ReportManoranjan sharmaNo ratings yet

- Typical Piping Project SequenceDocument13 pagesTypical Piping Project SequenceZoebairNo ratings yet

- Awareness Training EstimateDocument16 pagesAwareness Training EstimatekamlNo ratings yet

- RIL Constn NormDocument29 pagesRIL Constn NormSubhojit Adhikary100% (3)

- Technical Calculation and Estimator's Man Hour Manual - Marko Bulic's 20031Document107 pagesTechnical Calculation and Estimator's Man Hour Manual - Marko Bulic's 20031Rezza Aditya47% (17)

- Standard Unit Work HoursDocument312 pagesStandard Unit Work HoursGino Alessandro PiazzaNo ratings yet

- Nozzle Load AnalysisDocument2 pagesNozzle Load Analysisvm153748763No ratings yet

- Pipe Stress Manhours Estimation (Node Wise)Document7 pagesPipe Stress Manhours Estimation (Node Wise)pipestressNo ratings yet

- Steam Drum CalulationDocument85 pagesSteam Drum Calulationsibi_s_rajNo ratings yet

- Checklist For Nozzle OrientationDocument4 pagesChecklist For Nozzle OrientationPhilippe LAVOISIERNo ratings yet

- Wave GuidesDocument141 pagesWave GuidesVamshi Krishna100% (1)

- 2b Piping Estimate & Summary FormDocument14 pages2b Piping Estimate & Summary FormEK63100% (1)

- Max Allowable Pressure of Pipes and Pipellines CER 04022013 1 (V. S. Kumar Unprotected)Document106 pagesMax Allowable Pressure of Pipes and Pipellines CER 04022013 1 (V. S. Kumar Unprotected)Vashish Ramrecha100% (1)

- SS Pipe Fab & Erect CostsDocument5 pagesSS Pipe Fab & Erect Costswally55bear67% (3)

- PID Check ListDocument6 pagesPID Check ListArunachalam KaliyaperumalNo ratings yet

- Piping BOQ (13 Jul)Document25 pagesPiping BOQ (13 Jul)Mubashir100% (2)

- FinalDocument12 pagesFinalchompink6900No ratings yet

- Piping Training - Typical Project TypesDocument12 pagesPiping Training - Typical Project TypesDinesh Hande100% (2)

- In-Service Monitoring of Lubricating Oil For Auxiliary Power Plant EquipmentDocument20 pagesIn-Service Monitoring of Lubricating Oil For Auxiliary Power Plant Equipmentمحمد نصیریNo ratings yet

- Cost Estimation of Storage TankDocument2 pagesCost Estimation of Storage Tankmiteshmayur84% (19)

- CAESAR II Training Overview PDFDocument5 pagesCAESAR II Training Overview PDFJesus MaestreNo ratings yet

- 2a Piping Estimate & Summary ExampleDocument15 pages2a Piping Estimate & Summary ExampleRaymond MetselaarNo ratings yet

- Technical Calculation and Estimator's Man Hour Manual - Marko Bulic's 20033Document3 pagesTechnical Calculation and Estimator's Man Hour Manual - Marko Bulic's 20033Rezza Aditya0% (1)

- Manhours For CS Piping Erection Including FitupDocument1 pageManhours For CS Piping Erection Including FitupSoham BanerjeeNo ratings yet

- Check List For Piping GADDocument3 pagesCheck List For Piping GADkaruna100% (2)

- Vessel Data SheetDocument1 pageVessel Data SheetMichael HaiseNo ratings yet

- Piping-Progress-Measurement - (In Dia and in Meter)Document7 pagesPiping-Progress-Measurement - (In Dia and in Meter)RohimNo ratings yet

- Pipe Support As Per Asme 31.1Document1 pagePipe Support As Per Asme 31.1udaysaichand kollipara100% (1)

- Exam Style Answers 20 Asal Physics CBDocument2 pagesExam Style Answers 20 Asal Physics CBAnshul ShahNo ratings yet

- Two-Stage Ball Milling of Recycled Machining Chips To Create An Alternative Feedstock Powder For Metal Additive ManufacturingDocument40 pagesTwo-Stage Ball Milling of Recycled Machining Chips To Create An Alternative Feedstock Powder For Metal Additive ManufacturingJazmínARNo ratings yet

- PipeFlowModelLibraryManual PDFDocument132 pagesPipeFlowModelLibraryManual PDFalspeer1905100% (1)

- Strength Calcul SheetDocument379 pagesStrength Calcul Sheetmustufa akolawalaNo ratings yet

- Mathcad - C05-C2Document6 pagesMathcad - C05-C2Krish ChandNo ratings yet

- Job Card Check Impeller & Bearing PompaDocument1 pageJob Card Check Impeller & Bearing PompaIkhsanAbdillahNo ratings yet

- Daily Progress Report: Mtr. 4690 Mtr. Mtr. 4690Document3 pagesDaily Progress Report: Mtr. 4690 Mtr. Mtr. 4690Manoranjan sharmaNo ratings yet

- Gen PNG STD 001 - 02Document40 pagesGen PNG STD 001 - 02Jose C. MelendezNo ratings yet

- CM0202, Compressor DWGDocument17 pagesCM0202, Compressor DWGansariiqbal9570No ratings yet

- Report Generation: Gajendhiran.V M.E-Cad/CamDocument6 pagesReport Generation: Gajendhiran.V M.E-Cad/CamGajendhar KVK100% (1)

- Technical Specification PTP Ennore Part2-2024-02!19!06!07!41Document239 pagesTechnical Specification PTP Ennore Part2-2024-02!19!06!07!41trilokNo ratings yet

- Mathcad - C06-C10 PDFDocument7 pagesMathcad - C06-C10 PDFKrish ChandNo ratings yet

- SA-6416 Shaft OutputDocument4 pagesSA-6416 Shaft OutputEngineering ProductionNo ratings yet

- PALL FILTER - Process Data SheetDocument2 pagesPALL FILTER - Process Data SheetThirukkumaranBalasubramanianNo ratings yet

- UW-2 OutDocument48 pagesUW-2 Out966571016208No ratings yet

- Certificados - Mtc-Po 23040-Req 14989Document98 pagesCertificados - Mtc-Po 23040-Req 14989MissionPetroleum InfoNo ratings yet

- Ujjain: The City of TemplesDocument2 pagesUjjain: The City of Templesruponline1No ratings yet

- Tubesheet As Per ASME Sec. VIII-Div.1 UHXDocument1 pageTubesheet As Per ASME Sec. VIII-Div.1 UHXruponline1No ratings yet

- Nozzle StressDocument25 pagesNozzle StressvamsiNo ratings yet

- 1-9 and 1-10 Diff PDFDocument3 pages1-9 and 1-10 Diff PDFsumedh444No ratings yet

- ULMA Technical HandbookDocument132 pagesULMA Technical HandbookcaponelyNo ratings yet

- ULMA Technical HandbookDocument132 pagesULMA Technical HandbookcaponelyNo ratings yet

- Comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFDocument13 pagesComparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFruponline1No ratings yet

- Duplex SS in Refining API 938C PDFDocument7 pagesDuplex SS in Refining API 938C PDFruponline1No ratings yet

- He3488lsw TdsDocument2 pagesHe3488lsw TdsVi TrầnNo ratings yet

- klx250 h6fh7f Parts List PDFDocument91 pagesklx250 h6fh7f Parts List PDFOliverNo ratings yet

- C4 BMobile RobotsDocument114 pagesC4 BMobile RobotsMichael DavisNo ratings yet

- Module 3Document28 pagesModule 3Carms GameNo ratings yet

- The Drain System Design Is Based On Segregated SystemsDocument1 pageThe Drain System Design Is Based On Segregated Systemsjoenediath9345No ratings yet

- Battery Check VoltageDocument42 pagesBattery Check VoltageAlief NewNo ratings yet

- Revision Worksheet Numericals SA2Document2 pagesRevision Worksheet Numericals SA2Chinmaya NagpalNo ratings yet

- Theories of FailureDocument77 pagesTheories of FailureAnonymous 6HADGUEXDNo ratings yet

- D2060-M - Medical Vacuum and Gas SystemsDocument7 pagesD2060-M - Medical Vacuum and Gas Systemspaintbrush793053No ratings yet

- Sirius Timer Relay ManualDocument28 pagesSirius Timer Relay ManualVinoth MahendranNo ratings yet

- XI-Chemistry-DOE Support Material 2019-20 - 2Document22 pagesXI-Chemistry-DOE Support Material 2019-20 - 2MeersNo ratings yet

- Sizing and Cost Estimation Methodology For Stand Alone Residential PV Power SystemDocument20 pagesSizing and Cost Estimation Methodology For Stand Alone Residential PV Power SystemvenvettyNo ratings yet

- @perkins: 4000 Series 4016TAG2 4016TAG2ADocument2 pages@perkins: 4000 Series 4016TAG2 4016TAG2AIman AkbariNo ratings yet

- Basic Principal of Electrical CircuitryDocument19 pagesBasic Principal of Electrical CircuitryAreeba ParvezNo ratings yet

- NT7 Practical Guide For Using CFW-09 and CFW-11 Inverters and Weg Motors With Long Motor Cables-R01 PDFDocument2 pagesNT7 Practical Guide For Using CFW-09 and CFW-11 Inverters and Weg Motors With Long Motor Cables-R01 PDFfelipeNo ratings yet

- Final Version - Impulse Testing and Insulation Deterioration in Electric MotorsDocument6 pagesFinal Version - Impulse Testing and Insulation Deterioration in Electric MotorsJoseph ChamiNo ratings yet

- 2016 Zapata Hincapie John Alexander ThesisDocument84 pages2016 Zapata Hincapie John Alexander ThesisbetelgueseNo ratings yet

- Diamer Basha DamDocument6 pagesDiamer Basha DamKashif Ali Hasnain0% (1)

- Water and Energy Efficient Showers: Project ReportDocument54 pagesWater and Energy Efficient Showers: Project ReportMurali Krishna KakaraparthiNo ratings yet

- Pab 10Document6 pagesPab 10MelvinDapitanonNo ratings yet

- Instruction Manual Fisher 4200 Electronic Position Transmitters en 124158Document44 pagesInstruction Manual Fisher 4200 Electronic Position Transmitters en 124158Peter RhoadsNo ratings yet

- Quantum Mechanics Tunneling & Harmonic OscillatorDocument33 pagesQuantum Mechanics Tunneling & Harmonic Oscillatorvivek patelNo ratings yet

- 006 Cluster BondingDocument16 pages006 Cluster Bondingmaaz aliNo ratings yet

- BlakeDocument19 pagesBlakeDeanneLaylayNo ratings yet