Professional Documents

Culture Documents

FlowSciV9.3Features WEB

Uploaded by

easy_astronautCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FlowSciV9.3Features WEB

Uploaded by

easy_astronautCopyright:

Available Formats

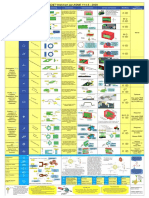

FLOW-3D Version 9.

3 Features

Meshing & Geometry Numerical Modeling Options Physical Modeling Options

Structured finite difference/control Volume-of-Fluid (VOF) method for fluid Scour & erosion/deposition

volume interfaces-TruVOF Cavitation

Multi-Block Gridding with: First, second or third order advection Phase change (liquid-vapor, liquid-solid

Nested blocks Sharp fluid interface tracking & liquid-gas)

Linked blocks Implicit & explicit modeling options Surface tension

Fractional areas/volumes (FAVORTM) Point, line relaxation & GMRES pressure Thermocapillary effects

for efficient & accurate geometry solvers Wall adhesion

definition User-defined variables, subroutines & Wall roughness

Solids Modeler output Vapor & gas bubbles

Imports most CAD files Utilities for runtime interaction during Solidification & melting (heat-of-

execution transformation table)

Flow Type Options Mass/momentum/energy sources

Flow Definition Options Shear, density & temperature-

dependent viscosity

Internal, external & free-surface flows Thixotropic viscosity

Three, two & one dimensional General initial conditions

problems Symmetry Elastic stress

Transient flows Rigid walls Electric field

Cartesian or cylindrical coordinates Continuative Elastic membranes & walls

Inviscid, viscous, laminar & turbulent Periodic Evaporation residue

flows Specified pressure Dielectric phenomena

Non-inertial reference frames Specified velocity Electro-osmosis

Multiple scalar species Outflow Electrostatic particles

Two-phase flows Grid overlay Electro-mechanical effects

Heat transfer with phase change Hydrostatic Joule heating

Saturated & unsaturated porous media Custom Air entrainment

Volume flow rate Molecular & turbulent diffusion

Thermal Modeling Options Surface waves

Restart previous simulation Metal Casting Models

Natural convection Continuation of a simulation

Forced convection Overlay boundary conditions from a Solidification & melting

Conduction in fluid & solid previous simulation Solidification shrinkage

Fluid-solid heat transfer Change mesh Microporosity

Conduction Add, delete or change model Binary segregation during solidification

Specified heat flux parameters Solid-fraction dependent latent heat

release

Specified solid temperature Thermal die cycling

Heat transfer to voids from fluid/ Fluid Modeling Options

obstacles

Thermal stress & deformations

Distributed energy sources/sinks in One incompressible fluid confined or Defect tracking

fluids or solids with free surfaces Cavitation potential model

Radiation by emissivity Two incompressible fluids miscible or Lost-Foam casting model

Viscous heating with sharp interfaces Semi-solid material model

Compressible fluid subsonic, Moisture in sand & molds

transonic, supersonic Back pressure & vents

Stratified fluid Shot sleeves

Acoustic phenomena

Mass particles with variable density or

diameter

Improving the world through accurate flow modeling

FLOW-3D Version 9.3 Features

Turbulence Models Special Physical Models Coupling with Other Programs

Prandtl mixing length General Moving Object model with 6 Geometry input from Stereolithography

One-equation transport Degrees of Freedomuser specified (STL) files binary or ASCII

Two-equation - model motion or fully-coupled with fluid flow Geometry input from ANSYS or IDEAS

RNG - model Rotating/spinning obstacles tetrahedral data

Large eddy simulation Porous baffles & obstacles with linear & Direct interfaces with EnSight,

quadratic flow losses FieldView & Tecplot visualization

Porous Media Models Collision model programs

Moving object assemblies PLOT3D output

Variable porosity Neutral file output

Directional porosity Discrete Particle Models Extensive customization possibilities

General flow losses (linear & quadratic) Topographic data

Capillary pressure Massless marker particles

Unsaturated flow Mass particles of variable size/mass Supported Platforms

Heat transfer in porous media Linear & quadratic fluid-dynamic drag

Monte-Carlo diffusion Processors

Two-phase & Particle-Fluid momentum coupling x86/x86-32 (Intel Pentium/Xeon,

Coefficient of restitution or sticky

Two-component Models particles

AMD Athlon/Opteron)

x86/x86-64 (Intel Pentium/Xeon/Core,

Point or volumetric particle sources

Liquid/liquid & gas/liquid interfaces Charged particles

AMD Athlon/Opteron)

Two-fluid mixtures Probe particles Operating Systems

One compressible fluid with a dispersed 32-bit Windows XP/Vista

incompressible component

Two-component drift-flux User Conveniences 64-bit Windows XP/Vista & Server 2003

Two-component, vapor/non- 32-bit Redhat Enterprise 3.0+

condensible gases Mesh & initial condition generators 64-bit Redhat Enterprise 3.0+

Phase transformations for gas-liquid & Time-step control for accuracy & & SUSE Enterprise 9.0+

liquid-solid stability

Automatic limited compressibility Hardware Requirements

Adiabatic bubbles

Bubbles with phase change Convergence control

Mentor help to optimize efficiency The hardware requirements to run

Continuum fluid with discrete particles FLOW-3D depend on the number

Scalar transport Change solution parameters as solver

runs of physical models active during the

Manage & launch multiple simulations simulation. An iso-thermal, inviscid

Shallow Flow Models simulation requires roughly 1GB of

memory for 2.5 million computational

Shallow water model Data Processing Options cells in double precision. Activating

General topography turbulence & heat transfer increases the

Wetting & drying Automatic or custom graph requests memory requirements by about 30%.

Wind shear Interactive OpenGL-based graphics (grid A single precision solver reduces the

Ground roughness effects overlay optional) memory requirements by roughly 40%.

Color or B/W vector, contour, 3D surface

& particle plots

Chemistry Models Moving history & probe data

Force & moment computations

Stiff equation solver for chemical rate Animation output

equations PostScript, JPEG & Bitmap output

Stationary or advected species Streamlines FLOW-3D & TruVOF are registered

STL geometry viewer in the US Patent & Trademark Office.

www.flow3d.com | sales@flow3d.com | 505.982.0088

You might also like

- Transactions of The Association For COmputational Linguistics PDFDocument14 pagesTransactions of The Association For COmputational Linguistics PDFeasy_astronautNo ratings yet

- Appleton Right BrainDocument13 pagesAppleton Right Braineasy_astronautNo ratings yet

- Information Theory: Information Theory and The Digital Age A, C, K, T, YDocument27 pagesInformation Theory: Information Theory and The Digital Age A, C, K, T, YidayacgNo ratings yet

- How To Take Yourself Lightly PDFDocument2 pagesHow To Take Yourself Lightly PDFeasy_astronautNo ratings yet

- Ipfs p2p File SystemDocument11 pagesIpfs p2p File Systemeasy_astronautNo ratings yet

- A Comparison of Five Business PhilosophiesDocument13 pagesA Comparison of Five Business PhilosophiesCK LimNo ratings yet

- The Human Side of Enterprise PDFDocument11 pagesThe Human Side of Enterprise PDFeasy_astronautNo ratings yet

- Min Os BookDocument78 pagesMin Os BookstevenjaganNo ratings yet

- 75 Things To Do With Your MenteesDocument16 pages75 Things To Do With Your Menteeseasy_astronautNo ratings yet

- Systems Leadership IntroDocument9 pagesSystems Leadership Introeasy_astronautNo ratings yet

- The Philosophy of Creativity - GautDocument13 pagesThe Philosophy of Creativity - GautDavid Chak100% (3)

- Using Custom Classes in Scripts - CATIA V5 AutomationDocument9 pagesUsing Custom Classes in Scripts - CATIA V5 Automationeasy_astronautNo ratings yet

- Being A Mentee - How To Get The Most From MentoringDocument17 pagesBeing A Mentee - How To Get The Most From Mentoringeasy_astronautNo ratings yet

- A Comparison of Five Business PhilosophiesDocument13 pagesA Comparison of Five Business PhilosophiesCK LimNo ratings yet

- GDT Wall Chart 2009 Arch - D PDFDocument1 pageGDT Wall Chart 2009 Arch - D PDFeasy_astronautNo ratings yet

- The Characteristics of Mathematical Creativity PDFDocument16 pagesThe Characteristics of Mathematical Creativity PDFeasy_astronautNo ratings yet

- Being A Mentee - How To Get The Most From MentoringDocument17 pagesBeing A Mentee - How To Get The Most From Mentoringeasy_astronautNo ratings yet

- Supercritical Power Generation-Experiences, Issues & ChallengesDocument85 pagesSupercritical Power Generation-Experiences, Issues & ChallengesVeda SiddharthNo ratings yet

- Study of Manufacturing of Steam Turbine Blade PDFDocument54 pagesStudy of Manufacturing of Steam Turbine Blade PDFeasy_astronaut67% (6)

- Steam Turbine Blade DesignDocument7 pagesSteam Turbine Blade Designeasy_astronaut100% (1)

- Trig Cheat SheetDocument4 pagesTrig Cheat Sheetapi-284574585No ratings yet

- Brief, Horrible MomentsDocument51 pagesBrief, Horrible Momentseasy_astronaut100% (1)

- Groupthink - WikipediaDocument13 pagesGroupthink - Wikipediaeasy_astronautNo ratings yet

- The Philosophy of Creativity - GautDocument13 pagesThe Philosophy of Creativity - GautDavid Chak100% (3)

- GDand TDocument0 pagesGDand TKaliya PerumalNo ratings yet

- GDT Wall Chart 2009 Arch - D PDFDocument1 pageGDT Wall Chart 2009 Arch - D PDFeasy_astronautNo ratings yet

- Study of Manufacturing of Steam Turbine Blade PDFDocument54 pagesStudy of Manufacturing of Steam Turbine Blade PDFeasy_astronaut67% (6)

- NEi L1Document4 pagesNEi L1easy_astronautNo ratings yet

- GD&T Symbols Reference GuideDocument2 pagesGD&T Symbols Reference Guidecreating_24No ratings yet

- GDand TDocument0 pagesGDand TKaliya PerumalNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Alphabetic KnowledgeDocument8 pagesAlphabetic KnowledgejsdgjdNo ratings yet

- 160kW SOFT STARTER - TAP HOLE 1Document20 pages160kW SOFT STARTER - TAP HOLE 1Ankit Uttam0% (1)

- Group 2 ITI Consensus Report: Prosthodontics and Implant DentistryDocument9 pagesGroup 2 ITI Consensus Report: Prosthodontics and Implant DentistryEsme ValenciaNo ratings yet

- Caradol sc48 08Document2 pagesCaradol sc48 08GİZEM DEMİRNo ratings yet

- Sheltered 2 Item Recycle ListDocument5 pagesSheltered 2 Item Recycle ListRachel GNo ratings yet

- Microfinance Ass 1Document15 pagesMicrofinance Ass 1Willard MusengeyiNo ratings yet

- All India Civil Services Coaching Centre, Chennai - 28Document4 pagesAll India Civil Services Coaching Centre, Chennai - 28prakashNo ratings yet

- Akilas Mebrahtom ResumeDocument1 pageAkilas Mebrahtom ResumeAnonymous lLpBfQNo ratings yet

- William Hallett - BiographyDocument2 pagesWilliam Hallett - Biographyapi-215611511No ratings yet

- ET4254 Communications and Networking 1 - Tutorial Sheet 3 Short QuestionsDocument5 pagesET4254 Communications and Networking 1 - Tutorial Sheet 3 Short QuestionsMichael LeungNo ratings yet

- UFO Yukon Spring 2010Document8 pagesUFO Yukon Spring 2010Joy SimsNo ratings yet

- The Body Shop Case Analysis. The Challenges of Managing Business As Holistic ConfigurationDocument28 pagesThe Body Shop Case Analysis. The Challenges of Managing Business As Holistic ConfigurationHanna AbejoNo ratings yet

- Masoneilan - 78 Series Air Filter Regulators IOMDocument8 pagesMasoneilan - 78 Series Air Filter Regulators IOMNithyANo ratings yet

- LPS 1131-Issue 1.2-Requirements and Testing Methods For Pumps For Automatic Sprinkler Installation Pump Sets PDFDocument19 pagesLPS 1131-Issue 1.2-Requirements and Testing Methods For Pumps For Automatic Sprinkler Installation Pump Sets PDFHazem HabibNo ratings yet

- The First Voyage Round The World by MageDocument405 pagesThe First Voyage Round The World by MageGift Marieneth LopezNo ratings yet

- Inventions Over The Last 100 YearsDocument3 pagesInventions Over The Last 100 YearsHombreMorado GamerYTNo ratings yet

- I Pmtea 2020 HandoutDocument94 pagesI Pmtea 2020 HandoutAbhijeet Dutta100% (1)

- DAA UNIT 1 - FinalDocument38 pagesDAA UNIT 1 - FinalkarthickamsecNo ratings yet

- Calculus For The Life Sciences 2nd Edition Greenwell Solutions ManualDocument26 pagesCalculus For The Life Sciences 2nd Edition Greenwell Solutions ManualSharonPerezozqy100% (56)

- Refutation EssayDocument6 pagesRefutation Essayapi-314826327No ratings yet

- Oceanarium: Welcome To The Museum Press ReleaseDocument2 pagesOceanarium: Welcome To The Museum Press ReleaseCandlewick PressNo ratings yet

- Procter and Gamble - MarketingDocument10 pagesProcter and Gamble - MarketingIvana Panovska100% (5)

- Acetylcysteine 200mg (Siran, Reolin)Document5 pagesAcetylcysteine 200mg (Siran, Reolin)ddandan_2No ratings yet

- Chapter 5 - CheerdanceDocument10 pagesChapter 5 - CheerdanceJoana CampoNo ratings yet

- Newsletter 1-2021 Nordic-Baltic RegionDocument30 pagesNewsletter 1-2021 Nordic-Baltic Regionapi-206643591100% (1)

- Data Network Unit 6 - UCDocument15 pagesData Network Unit 6 - UCANISHA DONDENo ratings yet

- WBCS 2023 Preli - Booklet CDocument8 pagesWBCS 2023 Preli - Booklet CSurajit DasNo ratings yet

- 1.161000 702010 New Perspectives 2ndedDocument43 pages1.161000 702010 New Perspectives 2ndedbimobimoprabowoNo ratings yet

- KundaliniDocument3 pagesKundaliniAlfred IDunnoNo ratings yet

- Ti05001 PDFDocument1 pageTi05001 PDFanggieNo ratings yet