Professional Documents

Culture Documents

Bentwood Box With Snap-Fit Lid: Walnut, Hard Maple

Uploaded by

khunchaiyai0 ratings0% found this document useful (0 votes)

1K views4 pagesA bentwood box with a snap-fit lid can be made from a stack of spruce 2 X 4's laminated together. A bending form is used to shape the main body of the box. The box's lid is made from the same material as the bending form.

Original Description:

Original Title

Bentwood Box

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA bentwood box with a snap-fit lid can be made from a stack of spruce 2 X 4's laminated together. A bending form is used to shape the main body of the box. The box's lid is made from the same material as the bending form.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1K views4 pagesBentwood Box With Snap-Fit Lid: Walnut, Hard Maple

Uploaded by

khunchaiyaiA bentwood box with a snap-fit lid can be made from a stack of spruce 2 X 4's laminated together. A bending form is used to shape the main body of the box. The box's lid is made from the same material as the bending form.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

29

BENTWOOD BOX WITH

SNAP-FIT LID

Walnut, Hard Maple

Copyright 2004 Martian Auctions 117

MAKING THE

BENTWOOD BOX

Work begins with the construction of a bending form for

the main body of the box. Mine consists of a stack of

spruce 2 X 4's laminated together and band-sawn and

sanded to the box's inside profile. On the side of the form

that will shape the front of the box, the face of the form

is undercut for the lap of material beneath the box's glue

joint. A thin strip of metal (in my case, aluminum siding)

is screwed to the form creating an opening into which the

end of the sidewall material can be slipped as that material

is wrapped around the form.

material. Profile the inside and outside of the sidewalls.

The next step is acquiring material for the sidewalls of

On the band saw, cut the bottom profile, keeping the saw

the box (see chapter two for a detailed discussion).

kerf approximately 1/16" outside the pencil line that marked

After the sidewall material has been soaked (for twenty-

the outside circumference of the sidewalls. Then, clamping

four hours in cool water, followed by ten minutes in warm

the bottom in a vise, cut away the extra 1/16" of material

water), wrapped around the form, and clamped in place,

with a block plane, to remove the saw marks.

it should dry for four or five days. At that time, remove

Mark the rabbet around the bottom circumference with

it from the form and cut the lap joint. For this particular

a line 5/16" from the top surface of the bottom. Next, with

example, I drilled three holes in the joint, sandwiching in

a dovetail saw, make a shallow cut along that line. This

three bits of peacock feather between the lapping lamina-

saw kerf represents the bottom of the rabbet. With a chisel,

tions so that the feather was visible through the holes. The

cut the rabbet to the depth marked by the line traced

joint is then glued and clamped using the bending form

around the inside face of the sidewalls. Once the bottom

and the caul both to protect the material from the clamps

has been fit, sand the parts and assemble the box using 1/8"

and to preserve the box's oval shape while the glue cures.

wooden pegs to both fasten the walls to the bottom and

(this process is described in some detail in chapter two).

the clasps to the walls.

Cut out the clasps and the handle next. Thicknesses can

vary, but the thickness of the clasps must be accurately

transferred to the stock that will later become the lid so

that the walls of the notches fit snugly against the clasps.

When you have selected the lid material, place the box's OPENING THE BOX

bentwood sidewalls on that material and draw a line around

its circumference. Next, establish a centerline running from

one end of the box to the other. This centerline is necessary

in order to lay out the notches that will house the clasps.

Next, sketch the outside profile of the lid. There is

considerable freedom in establishing this profile since the

notch placements are the only critical locations on the lid.

Then cut the lid's outside profile on the band saw.

Once the lid has been shaped, the handle is affixed. I

taped the handle in place, turned the lid over, and drove

a couple of wood screws up through the lid and into the

handle.

Make the bottom next. After thicknessing the stock to

1 Place your thumbs on the tops of the box's clasps while your

fingers grasp the fishtail ends of the lid. Spread open the

clasps and lift the lid. To close, press the lid down against the

7/16”, place the box's bentwood sidewalls on the bottom clasps until it snaps into place.

Copyright 2004 Martian Auctions 118

Copyright 2004 Martian Auctions 119

BENDING FORM

1 A block at the base

of the bending form

allows a vise to hold

it. After wrapping the

soaked, resawn stock

around the form,

clamp the caul to the

form to hold it in

place. Cut an opening

in the top of the form

for the clamp head.

This close up of the box side reveals peacock feather inlay in the

holes, a very unique design element.

MAKING THE LID

1The layout of the

2If the surface of the

lid is shown. lid is to be shaped,

Careful planning at flat surfaces must

this stage will ensure be left for the base

a lid that snaps of the handle.

cleanly into place.

MAKING THE BOTTOM

1 Define the bot-

2Cut the rabbet

tom of the rabbet with a chisel. Here,

that will receive the the chisel is cutting

sidewalls by a across end grain.

shallow saw cut After cutting

made all around the another 3/4" of the

bottom. rabbet, reverse the

bottom in the vise in

order to cut back to

that point from the

other side.

3 PEGS

The various parts

have been cut and

fit and are ready for

1 This shows the

ends of two pegs

assembly. Notice driven through the

the widened section sidewall into the

of the rabbet which clasp. Below, to the

will receive the left, is one of the

lapped section of the pegs holding the

sidewalls. Notice, bottom and sidewall

too, the notches for together. Drill a

Copyright 2004 Martian Auctions

the bottoms of the 120 inserting

hole before

clasps. these pegs.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Rudiment Control: Clinic Edition!Document28 pagesRudiment Control: Clinic Edition!USER58679100% (2)

- The Misterious Power of Xingyi QuanDocument353 pagesThe Misterious Power of Xingyi Quannajwa latifah96% (27)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Crotch-Grained Chess Table: Walnut, PoplarDocument5 pagesCrotch-Grained Chess Table: Walnut, Poplarkhunchaiyai100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Artists EaselDocument13 pagesArtists Easelkhunchaiyai100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Adjustable Plant ShelvesDocument3 pagesAdjustable Plant Shelves- yAy3e -No ratings yet

- Flute - All GradesDocument32 pagesFlute - All GradesRubanDuraisinghNo ratings yet

- Bow SawDocument6 pagesBow Sawkhunchaiyai100% (2)

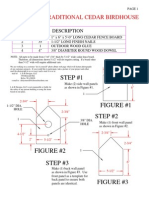

- Bird HouseDocument3 pagesBird Housekhunchaiyai100% (3)

- 1999 An Exposition of The Book of Revelation - LECTURE NOTESDocument364 pages1999 An Exposition of The Book of Revelation - LECTURE NOTESSimon Devram100% (2)

- Myth of SisyphusDocument3 pagesMyth of SisyphusPaliwalharsh8No ratings yet

- The Master and The SlaveDocument330 pagesThe Master and The SlaveRalph Ellectual100% (5)

- Corbin - On The Meaning of Music in Persian MysticismDocument3 pagesCorbin - On The Meaning of Music in Persian MysticismKeith BroughNo ratings yet

- Book Case (Mission Style)Document8 pagesBook Case (Mission Style)khunchaiyai100% (3)

- Build A Toy BoxDocument10 pagesBuild A Toy BoxkhunchaiyaiNo ratings yet

- New Covenant Theology and Futuristic PremillennialismDocument12 pagesNew Covenant Theology and Futuristic Premillennialismsizquier66No ratings yet

- SOAL PTS 1 BAHASA INGGRIS Kelas 8Document7 pagesSOAL PTS 1 BAHASA INGGRIS Kelas 8Ricky Berlian100% (2)

- Bookcase PlansDocument7 pagesBookcase PlansBrenda LeeNo ratings yet

- Case StudyDocument4 pagesCase StudyNATASHA SINGHANIANo ratings yet

- Biography Review Angela MerkelDocument2 pagesBiography Review Angela Merkelxaskar epNo ratings yet

- Cappucino BarDocument3 pagesCappucino Bar- yAy3e -100% (1)

- Chest of Drawers 2Document6 pagesChest of Drawers 2khunchaiyai100% (3)

- Candle BoxDocument4 pagesCandle Box- yAy3e -No ratings yet

- Arts and Crafts ChairDocument9 pagesArts and Crafts ChairlaniNo ratings yet

- Bird House2Document3 pagesBird House2khunchaiyai100% (1)

- Bathroom Mirror PDFDocument3 pagesBathroom Mirror PDFBenivaldo Do Nascimento JuniorNo ratings yet

- Adirondack Chair: Overview: Adirondack Chairs Can Be Made From A Variety of Woods. The Most CommonDocument4 pagesAdirondack Chair: Overview: Adirondack Chairs Can Be Made From A Variety of Woods. The Most CommonkhunchaiyaiNo ratings yet

- Group 2 BSN 2D Module 2 Workshop 2Document1 pageGroup 2 BSN 2D Module 2 Workshop 2Jashtine JingcoNo ratings yet

- AMC Weekly Report 02-21-2020Document23 pagesAMC Weekly Report 02-21-2020Sebastian AbordoNo ratings yet

- House BlessingDocument5 pagesHouse Blessingapi-202192344No ratings yet

- Quantus Project Status & Schedule Update - 1.6.18Document46 pagesQuantus Project Status & Schedule Update - 1.6.18Froilan EspinosaNo ratings yet

- Adjust Global App Trends 2019Document35 pagesAdjust Global App Trends 2019MetropolesNo ratings yet

- MCSL 054 Section 2Document36 pagesMCSL 054 Section 2Jeevi BrkNo ratings yet

- Quotes About Poetry PDFDocument3 pagesQuotes About Poetry PDFDA10000No ratings yet

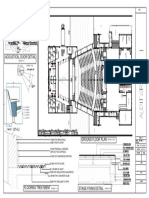

- Auditorium SH1 PDFDocument1 pageAuditorium SH1 PDFPRATIMA MAHADIKNo ratings yet

- Critical LensDocument2 pagesCritical LensSakib100% (1)

- Amelia Spokes Warwick Primary School Wellingborough NorthamptonshireDocument4 pagesAmelia Spokes Warwick Primary School Wellingborough NorthamptonshireDiamonds Study CentreNo ratings yet

- God of Our Yesterdays Matt Redman (Key of G)Document2 pagesGod of Our Yesterdays Matt Redman (Key of G)api-6040319No ratings yet

- GMB Sor Effect 11112013 Notifications PDFDocument243 pagesGMB Sor Effect 11112013 Notifications PDFJalpesh PatelNo ratings yet

- Tragic Hero (Combined Version)Document18 pagesTragic Hero (Combined Version)107590No ratings yet

- Lista Preturi Alfaparf RO 2010 IanDocument7 pagesLista Preturi Alfaparf RO 2010 Ianmilogu69No ratings yet

- May 15 1863 Paris S Salon Des Refuses Op PDFDocument3 pagesMay 15 1863 Paris S Salon Des Refuses Op PDFendlessdaylight6863No ratings yet

- Cerruti HistoryDocument4 pagesCerruti HistoryPhan LeNo ratings yet

- He Is LordDocument1 pageHe Is Lordapi-219593609No ratings yet

- Tum Haseen Main JawaanDocument3 pagesTum Haseen Main Jawaanrishisap2No ratings yet

- Seiwoong Oh - Encyclopedia of Asian-American Literature (Encyclopedia of American Ethnic Literature) - Facts On File (2007)Document401 pagesSeiwoong Oh - Encyclopedia of Asian-American Literature (Encyclopedia of American Ethnic Literature) - Facts On File (2007)Juan MNo ratings yet