Professional Documents

Culture Documents

Excavation and Back Filling Works Jsa

Uploaded by

rashid zamanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Excavation and Back Filling Works Jsa

Uploaded by

rashid zamanCopyright:

Available Formats

9.

0 HEALTH, SAFETY AND RISK ASSESSMENT:

SAFETY

9.1 The Safety Manager is responsible for the overall safety of the

construction site. His responsibilities include site inductions ensuring work

permits are valid, accident reports, number of man-

hours worked and ensuring all works are carried out in the safest possible

manner consistent with good construction practices. In case of imminent

danger the site supervisor/superintendent has to stop the work

immediately. The Safety officer at site is equally responsible for stopping the

work in the above case.

All required and necessary safety measures shall be taken during the

execution of this section of

work as shown and not limited to the following: -

a. Proper use of Personal Protective equipment.

b. Place necessary warning signs as required.

c. Safety harness shall be used by all workers who are working on elevated

area.

d. Provide flickering lights and reflectors while working in the night time.

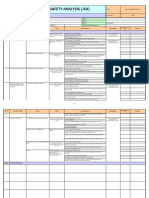

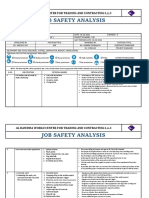

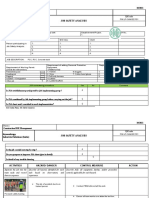

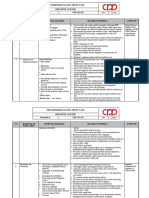

9.2 The Job Safety Analysis (JSA) for General Excavation and

Backfilling Works are as follows:

Item Activity Hazards / Risks Control Measures

No. Identified

01 Survey of the job Slip and trip Implement housekeeping

site procedures.

Wearing of the required PPEs

particularly safety harness in deep

excavated area..

02 Excavation of earth Slip and trip of Secure approved excavation work

and trenching workers. permit prior to the start of the work.

Fall of workers and Excavation plan and excavation

equipments. work checklist must be available at

the work site.

Cave-in of excavation

walls. Assign licensed and experienced

operators.

Excavation site must be cordoned

with safety warning tapes and / or

hard barricades painted with red &

white whichever is applicable

including provision of sufficient

lightings & blinker lights during

PORT TANK FARM &

LOADING FACILITIES

(PACKAGE-9)

nighttime.

Install adequate safety signs such

as excavation in-progress, keep out

- deep excavation, etc.

Assign experienced and trained

personnel / workers.

Provide spoil area away at least 2

meters from the edge of the

excavation to avoid cave-in or

collapse in case excavated

materials will not be hauled or

disposed at once.

Provide sufficient shoring system,

sloping of ground or other

equivalent means such as sheeting,

crossing bracings, trench shield or

box and jacks, benching,

underpinning, etc. whichever is

applicable.

Prohibit movement of vehicles and

equipments near the edge of the

excavation that may result to side

wall excavation cave-in or collapse

due to severe ground movement.

03 Backfilling works Slip and trip of Implement method statement /

workers. procedures on safe backfilling

works.

Fall of workers and

tools / equipments. Strict supervision during backfilling

works.

Wearing of the required PPEs.

Assign licensed and experienced

operators.

Assign experienced and trained

personnel / workers.

04 Trenches Falling from height Earth excavated to be stored 2

and cave' in meters away from excavation

site.

Earth excavated in "V" shape.

Vehicle to be kept in 2 meters

from edge of excavation.

Experienced and trained

workers.

Doc No: Title:

Page 2 of 10

SA-JER-PIAAA-PIJQ-502543 Rev 00 METHOD OF STATEMENT FOR GENERAL

EXCAVATION AND BACKFILLING

PORT TANK FARM &

LOADING FACILITIES

(PACKAGE-9)

Essential PPE in use.

Method Statement in place.

05 Environmental Extreme Implement safety procedures &

conditions during environmental guidelines on heat stress.

excavation works. condition such as high

temperature & Inspect excavation and adjacent

humidity and strong areas for possible hazardous

wind. atmosphere and any other condition

that may present a hazard.

Suspend / stop all operations during

extreme temperature & humidity

and high wind of more than 25

knots.

06 Confined Space

07 Equipment

08 Shoring

Doc No: Title:

Page 3 of 10

SA-JER-PIAAA-PIJQ-502543 Rev 00 METHOD OF STATEMENT FOR GENERAL

EXCAVATION AND BACKFILLING

You might also like

- Job Safety Analysis - : Installing Wall Frames and Roof Trusses On-SiteDocument6 pagesJob Safety Analysis - : Installing Wall Frames and Roof Trusses On-SiteNaz ッ Wany100% (1)

- 02-JSA For ExcavationDocument4 pages02-JSA For Excavationpraveen nair80% (20)

- Jsa For Tile FixingDocument4 pagesJsa For Tile FixingMohammed Minhaj100% (1)

- Hazard Analysis of Painting Work at Sussen Asia Pvt. Ltd. ProjectDocument2 pagesHazard Analysis of Painting Work at Sussen Asia Pvt. Ltd. ProjectEka100% (1)

- NWC Corporate Projects Risk Assessment Forms: Job / TaskDocument3 pagesNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebNo ratings yet

- Job Safety Analysis For Pressure TestingDocument2 pagesJob Safety Analysis For Pressure TestingPerwez2192% (37)

- Jsa For Road WorksDocument11 pagesJsa For Road Worksyc safety75% (12)

- JSA For Asphalt Concrete PavingDocument10 pagesJSA For Asphalt Concrete PavingRAMIL75% (4)

- JSA For Brick WorkDocument3 pagesJSA For Brick Workwahyu nugroho83% (6)

- JSA - Fire Proofing WorksDocument5 pagesJSA - Fire Proofing WorksAnis Uddin100% (3)

- JOB HAZARD ANALYSIS (Pipe Laying)Document9 pagesJOB HAZARD ANALYSIS (Pipe Laying)jay R100% (3)

- Job Safety Tips for Backfilling & CompactionDocument2 pagesJob Safety Tips for Backfilling & Compactionrashid zaman84% (25)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingJayendra Patel89% (9)

- Job Safety Analysis for Concrete WorksDocument8 pagesJob Safety Analysis for Concrete Worksfrancis_e_tan93% (27)

- Manual Excavation JSADocument1 pageManual Excavation JSATausif Khan100% (2)

- JSA-Manual Lifting of MaterialsDocument3 pagesJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- Civil JSA Form Block WorkDocument3 pagesCivil JSA Form Block Workdrmuhsin86% (7)

- JOB SAFETY ANALYSIS FOR CARPENTRY AND WOOD WORKDocument3 pagesJOB SAFETY ANALYSIS FOR CARPENTRY AND WOOD WORKba ratnaparkheNo ratings yet

- JHA For Concreting WorkDocument2 pagesJHA For Concreting WorkTigor GurningNo ratings yet

- Job Safety Analysis for Shuttering and Deshuttering Form WorkDocument3 pagesJob Safety Analysis for Shuttering and Deshuttering Form Workba ratnaparkhe83% (12)

- JSA of Glass FixingDocument5 pagesJSA of Glass FixingPAVANKUMAR50% (2)

- JSA-Construction Right of WayDocument3 pagesJSA-Construction Right of Wayfrancis_e_tan100% (5)

- JSA For Floor & Wall TilingDocument2 pagesJSA For Floor & Wall TilingSatya Naidu91% (11)

- Lifting Plan GuidelinesDocument45 pagesLifting Plan GuidelinesFerry H. Sitohang100% (5)

- Concreting Job Safety Analysis (JSA)Document2 pagesConcreting Job Safety Analysis (JSA)sudam kumar raut95% (19)

- HSE Plan 001 PDFDocument49 pagesHSE Plan 001 PDFrashid zaman100% (1)

- Jsa For ScaffoldingDocument3 pagesJsa For Scaffoldingsoubhagya100% (4)

- Concreting and ShutteringDocument3 pagesConcreting and ShutteringAnuj Kjoy0% (1)

- Applied Statics and Strength of Materials 6th Edition Ebook PDFDocument61 pagesApplied Statics and Strength of Materials 6th Edition Ebook PDFteri.sanborn87695% (44)

- JHA - Installation of Pipe & Support For Fire Protection 1Document7 pagesJHA - Installation of Pipe & Support For Fire Protection 1Ralph Castillo100% (2)

- 7 - Civil WorkDocument12 pages7 - Civil WorkPerwez21100% (1)

- 4 JSA For Structural Fabrication and Erection WorkDocument4 pages4 JSA For Structural Fabrication and Erection WorkHappy Prajapat67% (3)

- Cement Plaster JSADocument4 pagesCement Plaster JSAMohammed Minhaj50% (2)

- Jsa For Gypsum Fixing & DismentlingDocument5 pagesJsa For Gypsum Fixing & DismentlingSushil Kumar YadavNo ratings yet

- JSA Ladders Working at Heights 001Document2 pagesJSA Ladders Working at Heights 001Raman SawNo ratings yet

- Job Safety Analysis (JSA) : Description Hazard ControlDocument2 pagesJob Safety Analysis (JSA) : Description Hazard ControlRidha Bennasr100% (2)

- Composite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Document2 pagesComposite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Bhargav BbvsNo ratings yet

- Job Safety Analysis: 1 Confined Space Entry JSA ExampleDocument7 pagesJob Safety Analysis: 1 Confined Space Entry JSA Examplerashid zamanNo ratings yet

- JSA Wall and Ceiling PanelsDocument5 pagesJSA Wall and Ceiling PanelsPAVANKUMAR67% (6)

- 3S HSE MS Docs ContentDocument85 pages3S HSE MS Docs Contentrashid zamanNo ratings yet

- Job Safety Analysis for Rohan Builders Construction ProjectsDocument9 pagesJob Safety Analysis for Rohan Builders Construction Projectsradeep100% (1)

- Pamphlet On Safety Precautions in ExcavationDocument4 pagesPamphlet On Safety Precautions in ExcavationasdadNo ratings yet

- Risk Assessment Tables: Risk Rating & Rating Number Remedial Action and TimescaleDocument6 pagesRisk Assessment Tables: Risk Rating & Rating Number Remedial Action and Timescalerashid zaman100% (1)

- JSA For Concrete, Brecking, ExavationDocument6 pagesJSA For Concrete, Brecking, ExavationBinay0% (1)

- SASO Standards ListDocument72 pagesSASO Standards Listrashid zaman50% (2)

- SASO Catalogue Standards Part TwoDocument73 pagesSASO Catalogue Standards Part TwoLloyd R. Ponce50% (4)

- SASO Catalogue Standards Part TwoDocument73 pagesSASO Catalogue Standards Part TwoLloyd R. Ponce50% (4)

- CHIPPING CONCRETE HAMMER DRILLDocument2 pagesCHIPPING CONCRETE HAMMER DRILLidigiti75% (12)

- Concrete & Form Work: Job Safety Analysis Pouring ConcreteDocument1 pageConcrete & Form Work: Job Safety Analysis Pouring ConcreteHortencio Samuel100% (4)

- BYDP-JHA-05 Erection of ScaffoldingDocument4 pagesBYDP-JHA-05 Erection of ScaffoldingAhmad Shauqi100% (6)

- 9.JSA For Night Work Activity - Rev 01Document7 pages9.JSA For Night Work Activity - Rev 01ibrahim80% (10)

- JHA For Excavation Backfilling and Compaction R 01Document6 pagesJHA For Excavation Backfilling and Compaction R 01Sreekumar100% (2)

- Excavation and Back Filling Works JsaDocument3 pagesExcavation and Back Filling Works JsaNazir Hussain67% (12)

- 003 JSA All Civil WorksDocument5 pages003 JSA All Civil WorksMohammed Minhaj100% (11)

- WMS-02 - Material Unloading & Shifting by Farana & MannuallyDocument5 pagesWMS-02 - Material Unloading & Shifting by Farana & MannuallySufiyan Khedekar100% (2)

- Safety MNGT Sys Audit ReportDocument10 pagesSafety MNGT Sys Audit Reportrashid zamanNo ratings yet

- Safe Work Procedure - Sample 1Document4 pagesSafe Work Procedure - Sample 1Sn AhsanNo ratings yet

- Jsa For Operating A BobcatDocument2 pagesJsa For Operating A Bobcatsoubhagya100% (2)

- Structure Dismantling JSADocument2 pagesStructure Dismantling JSAtnssbhaskar69% (13)

- Camp Cleaning ScheduleDocument4 pagesCamp Cleaning Schedulerashid zamanNo ratings yet

- JSA For False CeilingDocument4 pagesJSA For False CeilingJaved100% (3)

- JSA For Installation of Precast SlabDocument4 pagesJSA For Installation of Precast Slabyc safety100% (3)

- GL 01 Welfare Facilities at Labour CampDocument3 pagesGL 01 Welfare Facilities at Labour Camptp101267100% (1)

- Job Safety Analysis - Cement SiloDocument9 pagesJob Safety Analysis - Cement SiloMohammed Minhaj100% (1)

- Job Safety Analysis for Reinforcement WorkDocument2 pagesJob Safety Analysis for Reinforcement Workba ratnaparkhe50% (2)

- Job Safety Analysis (Hydro Jetting)Document4 pagesJob Safety Analysis (Hydro Jetting)rashid zaman57% (7)

- JSA Earthpit Construction GeneralDocument4 pagesJSA Earthpit Construction Generalmukka88No ratings yet

- Excavation Job Safety AnalysisDocument1 pageExcavation Job Safety AnalysisVishal Upadhyay100% (3)

- Hot Tap ProcedureDocument7 pagesHot Tap Procedurerashid zamanNo ratings yet

- Osl Camp Rules Be2db2fc 6e88 4403 Ab94 7dac1ef89e09Document4 pagesOsl Camp Rules Be2db2fc 6e88 4403 Ab94 7dac1ef89e09rashid zaman100% (1)

- Osl Camp Rules Be2db2fc 6e88 4403 Ab94 7dac1ef89e09Document4 pagesOsl Camp Rules Be2db2fc 6e88 4403 Ab94 7dac1ef89e09rashid zaman100% (1)

- Job Hazard Analysis DemolitionDocument2 pagesJob Hazard Analysis DemolitionvinothNo ratings yet

- Ovr IbDocument27 pagesOvr IbAriel CaresNo ratings yet

- 02concreting & Block Bricks Work JSADocument3 pages02concreting & Block Bricks Work JSAJayendra Patel100% (1)

- GFS Tank Quotation C20210514Document4 pagesGFS Tank Quotation C20210514Francisco ManriquezNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument5 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNo ratings yet

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document7 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson Escamillan100% (1)

- JHSA for Temporary Plastic Septic TankDocument4 pagesJHSA for Temporary Plastic Septic TankAnna JisabaNo ratings yet

- JOB HAZARD SAFETY ANALYSISDocument5 pagesJOB HAZARD SAFETY ANALYSISShamel Jen FacundoNo ratings yet

- Job Description For Camp Staff 15Document7 pagesJob Description For Camp Staff 15rashid zamanNo ratings yet

- Template AccommodationDocument7 pagesTemplate Accommodationrashid zamanNo ratings yet

- Accomodation Inspection (Internal)Document2 pagesAccomodation Inspection (Internal)rashid zamanNo ratings yet

- Job Safety Analysis FormDocument1 pageJob Safety Analysis Formrashid zamanNo ratings yet

- NEBOSH PracticalDocument15 pagesNEBOSH Practicalrashid zaman100% (1)

- Iso 9001-2008Document40 pagesIso 9001-2008rashid zamanNo ratings yet

- Consequences 0 A B C: Low Risk Medium Risk High RiskDocument3 pagesConsequences 0 A B C: Low Risk Medium Risk High Riskrashid zamanNo ratings yet

- Safety Objectives SettingDocument12 pagesSafety Objectives Settingrashid zamanNo ratings yet

- Table of ContentsDocument2 pagesTable of Contentsrashid zamanNo ratings yet

- Accomodation Inspection (Internal)Document2 pagesAccomodation Inspection (Internal)rashid zamanNo ratings yet

- SWP4 - StepladdersDocument1 pageSWP4 - Stepladdersrashid zamanNo ratings yet

- Fundamentals of A Workplace First-Aid Program: Best Practices GuideDocument28 pagesFundamentals of A Workplace First-Aid Program: Best Practices Guidefsixteen5070No ratings yet

- HSSC English Model PaperDocument32 pagesHSSC English Model PaperMaryam Abdus SalamNo ratings yet

- Grading System The Inconvenient Use of The Computing Grades in PortalDocument5 pagesGrading System The Inconvenient Use of The Computing Grades in PortalJm WhoooNo ratings yet

- Galaxy Owners Manual Dx98vhpDocument10 pagesGalaxy Owners Manual Dx98vhpbellscbNo ratings yet

- ITP Exam SuggetionDocument252 pagesITP Exam SuggetionNurul AminNo ratings yet

- MQC Lab Manual 2021-2022-AutonomyDocument39 pagesMQC Lab Manual 2021-2022-AutonomyAniket YadavNo ratings yet

- CDI-AOS-CX 10.4 Switching Portfolio Launch - Lab V4.01Document152 pagesCDI-AOS-CX 10.4 Switching Portfolio Launch - Lab V4.01Gilles DellaccioNo ratings yet

- DOE Tank Safety Workshop Presentation on Hydrogen Tank TestingDocument36 pagesDOE Tank Safety Workshop Presentation on Hydrogen Tank TestingAlex AbakumovNo ratings yet

- CTR Ball JointDocument19 pagesCTR Ball JointTan JaiNo ratings yet

- I Will Be Here TABSDocument7 pagesI Will Be Here TABSEric JaoNo ratings yet

- Kate Elizabeth Bokan-Smith ThesisDocument262 pagesKate Elizabeth Bokan-Smith ThesisOlyaGumenNo ratings yet

- Mpu 2312Document15 pagesMpu 2312Sherly TanNo ratings yet

- MCQ Ch16solDocument4 pagesMCQ Ch16solandiswahlongwa870No ratings yet

- Process Financial Transactions and Extract Interim Reports - 025735Document37 pagesProcess Financial Transactions and Extract Interim Reports - 025735l2557206No ratings yet

- Methods to estimate stakeholder views of sustainabilityDocument7 pagesMethods to estimate stakeholder views of sustainabilityAlireza FatemiNo ratings yet

- Efaverenz p1Document4 pagesEfaverenz p1Pragat KumarNo ratings yet

- Excel Solver Optimization ReportDocument9 pagesExcel Solver Optimization ReportMy Duyen NguyenNo ratings yet

- CBSE Class 6 Whole Numbers WorksheetDocument2 pagesCBSE Class 6 Whole Numbers WorksheetPriyaprasad PandaNo ratings yet

- Damcos Mas2600 Installation UsermanualDocument26 pagesDamcos Mas2600 Installation Usermanualair1111No ratings yet

- Test Bank For Fundamental Financial Accounting Concepts 10th by EdmondsDocument18 pagesTest Bank For Fundamental Financial Accounting Concepts 10th by Edmondsooezoapunitory.xkgyo4100% (47)

- France Winckler Final Rev 1Document14 pagesFrance Winckler Final Rev 1Luciano Junior100% (1)

- LSMW With Rfbibl00Document14 pagesLSMW With Rfbibl00abbasx0% (1)

- ERIKS Dynamic SealsDocument28 pagesERIKS Dynamic Sealsdd82ddNo ratings yet

- AVR Instruction Set Addressing ModesDocument4 pagesAVR Instruction Set Addressing ModesSundari Devi BodasinghNo ratings yet

- Chapter 19 - 20 Continuous Change - Transorganizational ChangeDocument12 pagesChapter 19 - 20 Continuous Change - Transorganizational ChangeGreen AvatarNo ratings yet

- Use Visual Control So No Problems Are Hidden.: TPS Principle - 7Document8 pagesUse Visual Control So No Problems Are Hidden.: TPS Principle - 7Oscar PinillosNo ratings yet

- Journals OREF Vs ORIF D3rd RadiusDocument9 pagesJournals OREF Vs ORIF D3rd RadiusironNo ratings yet

- Basic Features of The Microcredit Regulatory Authority Act, 2006Document10 pagesBasic Features of The Microcredit Regulatory Authority Act, 2006Asif Hasan DhimanNo ratings yet