Professional Documents

Culture Documents

How To Tell If A Pump Is Working Well

Uploaded by

4gen_3Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Tell If A Pump Is Working Well

Uploaded by

4gen_3Copyright:

Available Formats

How to tell if a pump is working well

From experience we can say that in general, the hydraulic component on which the

greatest responsibility for the functioning of the hydraulic system of a machin

e is the bomb, or bombs. This does not mean it is the most important, is general

ly working for longer, and its form of construction depends heavily on a good fi

ltration and care of the oil. All hydraulic systems follow a logical sequence of

operations determined by the type of components within the circuit and how they

are interconnected. Without going into details of how it was the fault detectio

n of the machine, say we have a suspicion that the pump may be malfunctioning. B

efore you begin, you should obtain as much information about the system and in p

articular the pump: Type of engine that drives the pump (electric, hydraulic, di

esel, gasoline, etc.), Power and rotation speed or RPM. The temperature at which

the system works type pump (gear, vane, piston, etc.) Flow that must be supplie

d without pressure, flow to the working pressure, maximum allowable pressure. Di

ameter recommended by the manufacturer for suction and discharge, to compare wit

h the actual. There are suction filter? , What type (internal, external, microns

), bypass (valve opens when the filter is clogged). Height of the tank with resp

ect to the pump (top level or below). Oil level in the tank. Needless to say, al

l this information will help you interpret the test results, to avoid doubt. Usi

ng a flowmeter, a pressure gauge and a relief valve, must do the following arran

gement:

RELIEF VALVE

FLOWMETERS GAUGE

ELECTRIC MOTOR 4.8 H.P. 1800 RPM

100 LITRE TANK

Isolating the pump discharge from the rest of the system, run the engine and let

the pump sent the flow through the flowmeter, while keeping open the relief val

ve to the tank. In this way we can take the pump flow without pressure, which mu

st be equal to that suggested by the manufacturer without pressure. Then we must

begin to close the relief valve and pressure we see on the gauge rises. When we

reach the working pressure, we take flow reading is then compared with that sug

gested by the manufacturer. The flux difference between the pressure and flow pr

essure gives us an idea of the volumetric efficiency of the pump. Values below 8

0% are considered low and the pump should be replaced. Now let's look at other f

actors. If at the time of taking the first flow, the value is less than the assu

mption made without pressure, we take into account that this may be because the

pump is sucking air through the suction or through the shaft seal. From the amou

nt of air that sucking will depend how low the flow will be. Another problem tha

t can make reading flux pressure is lower is due to a restriction in the suction

of the pump, causing an excessive vacuum suction generated by the phenomenon kn

own as cavitation. This phenomenon can be confirmed with a vacuum gauge placed a

t the entrance to the pump as close as possible. Abstract. If the pump has no su

ction related problems, such as aeration or cavitation, with the flowmeter have

100% certainty on the status of the pump. If we have doubts with the suction, yo

u have to solve these problems before measuring the flow at the pump for maximum

certainty.

RELIEF VALVE

FLOWMETERS GAUGE

ELECTRIC MOTOR 4.8 H.P. 1800 RPM

100 LITRE TANK

You might also like

- Working Methodology in The School of Football. Author: Emanuele Aquilani Att Cisco Calcio RomaDocument4 pagesWorking Methodology in The School of Football. Author: Emanuele Aquilani Att Cisco Calcio Roma4gen_3No ratings yet

- CCB - Suggested Methods For MusiciansDocument2 pagesCCB - Suggested Methods For Musicians4gen_3No ratings yet

- SociologyDocument9 pagesSociology4gen_3No ratings yet

- Guides Clinical Protocols Revisionists Were SystematicallyDocument5 pagesGuides Clinical Protocols Revisionists Were Systematically4gen_3No ratings yet

- What Should Be A Written GFS?Document3 pagesWhat Should Be A Written GFS?4gen_3No ratings yet

- UntitledDocument6 pagesUntitled4gen_3No ratings yet

- All About BPM - Step by Step Process To Begin WithDocument8 pagesAll About BPM - Step by Step Process To Begin With4gen_3No ratings yet

- Model CurriculumDocument1 pageModel Curriculum4gen_3No ratings yet

- OSegredoDocument14 pagesOSegredo4gen_3No ratings yet

- Conference PackagesDocument17 pagesConference Packages4gen_3No ratings yet

- Disclosure of Information Technology For SchoolsDocument4 pagesDisclosure of Information Technology For Schools4gen_3No ratings yet

- JazzAscona Official Flyer - Programme 2010Document15 pagesJazzAscona Official Flyer - Programme 20104gen_3No ratings yet

- Apostila - FiberglassDocument9 pagesApostila - Fiberglass4gen_3No ratings yet

- Windows OriginalDocument1 pageWindows Original4gen_3No ratings yet

- Pensions: The Government's Guidance Document (May 16, 2010)Document10 pagesPensions: The Government's Guidance Document (May 16, 2010)4gen_3No ratings yet

- The Journal of FreetownDocument9 pagesThe Journal of Freetown4gen_3No ratings yet

- Tuscany Exclusive Program 2010Document8 pagesTuscany Exclusive Program 20104gen_3No ratings yet

- Do Neurons Play?Document2 pagesDo Neurons Play?4gen_3No ratings yet

- Educaparty ScribbDocument5 pagesEducaparty Scribb4gen_3No ratings yet

- No Secret Mouth 26Document17 pagesNo Secret Mouth 264gen_3No ratings yet

- The Guide Ablution and Prayer of The Muslim From (MC ISLAM SUNNA)Document4 pagesThe Guide Ablution and Prayer of The Muslim From (MC ISLAM SUNNA)4gen_3No ratings yet

- Museum NightDocument13 pagesMuseum Night4gen_3No ratings yet

- General OphthalmologyDocument24 pagesGeneral Ophthalmology4gen_3No ratings yet

- Products Filling of Wrinkles - Afssaps Recommendations For The ConsumerDocument1 pageProducts Filling of Wrinkles - Afssaps Recommendations For The Consumer4gen_3No ratings yet

- Lemon TherapyDocument1 pageLemon Therapy4gen_3No ratings yet

- Multi OrgasmusDocument29 pagesMulti Orgasmus4gen_30% (1)

- Whitepaper Facebook Privatsphaere 05 2010Document16 pagesWhitepaper Facebook Privatsphaere 05 20104gen_3No ratings yet

- ItineraryDocument4 pagesItinerary4gen_3No ratings yet

- Systems of Equations ExercisesDocument2 pagesSystems of Equations Exercises4gen_3No ratings yet

- 080 525 in The WombDocument2 pages080 525 in The Womb4gen_3No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- E-Tivity 4.1 Tutorials On GovernorsDocument1 pageE-Tivity 4.1 Tutorials On GovernorsMugisha OlivierNo ratings yet

- ControlDocument59 pagesControlTuan Anh Nguyen HuuNo ratings yet

- Curvilinear Motion and ProjectilesDocument15 pagesCurvilinear Motion and ProjectilesAltammar1367% (3)

- Heat Transfer - K. A. GavhaneDocument175 pagesHeat Transfer - K. A. GavhaneHussainNo ratings yet

- Dynamic Model of a Two-Cylinder Four-Stroke Engine for Vibration AnalysisDocument12 pagesDynamic Model of a Two-Cylinder Four-Stroke Engine for Vibration AnalysisrajmNo ratings yet

- Newco Product Line BrochureDocument8 pagesNewco Product Line BrochureshahganNo ratings yet

- Slide Valves - Flachschieber - Klizni Ventili - Valvole A GhigliottinaDocument54 pagesSlide Valves - Flachschieber - Klizni Ventili - Valvole A GhigliottinaTiberiu PalNo ratings yet

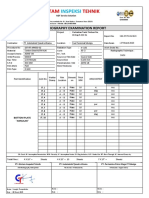

- Pt. Gintam Tehnik: InspeksiDocument5 pagesPt. Gintam Tehnik: Inspeksirizky youlandaNo ratings yet

- Tractor Operator AgricultureDocument9 pagesTractor Operator AgricultureConstantin CarpenNo ratings yet

- Manual Flowpacks Ensamble InstitucionalDocument32 pagesManual Flowpacks Ensamble InstitucionalhaynerNo ratings yet

- Mould Ejection OptDocument50 pagesMould Ejection OptMohamed HassanNo ratings yet

- Injectors. Adaptations. Coding - Bimmerprofs - Com - NOx Emulator NOXEM 129 - 130 - 402 Developed For BMW N43 & N53 Series EnginesDocument27 pagesInjectors. Adaptations. Coding - Bimmerprofs - Com - NOx Emulator NOXEM 129 - 130 - 402 Developed For BMW N43 & N53 Series EnginesMiguelNo ratings yet

- PA66 Ultramid A4H BASFDocument2 pagesPA66 Ultramid A4H BASFAlan MoraisNo ratings yet

- Lecture 15 Plane Strain and Axisymmetric Structural Elements CommentaryDocument2 pagesLecture 15 Plane Strain and Axisymmetric Structural Elements CommentaryHenry AbrahamNo ratings yet

- How Carburetors Work: Understanding the Six Main SystemsDocument7 pagesHow Carburetors Work: Understanding the Six Main Systemssaithea25No ratings yet

- Group Assignment Q1Document2 pagesGroup Assignment Q1Muhdhadi SajariNo ratings yet

- CYTJ45-2 Specification - KAMACH 18UDocument8 pagesCYTJ45-2 Specification - KAMACH 18UJhonatan rincon martinezNo ratings yet

- Getting A Good Fit: Selecting The Right Shaft and Housing ToleranceDocument2 pagesGetting A Good Fit: Selecting The Right Shaft and Housing Toleranceeng13No ratings yet

- RoofBolter - Technical Specification-FinalDocument5 pagesRoofBolter - Technical Specification-FinalSushantNo ratings yet

- Electronics 18 E0306Document9 pagesElectronics 18 E0306GiangDoNo ratings yet

- DIB - Generators & MotorsDocument6 pagesDIB - Generators & MotorsDeepen SharmaNo ratings yet

- Floating Head Heat ExchangerDocument5 pagesFloating Head Heat ExchangerniralNo ratings yet

- Die Casting Machines Core Pins & Ejector PinsDocument1 pageDie Casting Machines Core Pins & Ejector PinsJayden BarnesNo ratings yet

- W90 WHEEL LOADER Service ManualDocument321 pagesW90 WHEEL LOADER Service Manualelshind88% (8)

- AhadDocument88 pagesAhadAhmad NNo ratings yet

- NQR 87-80-190 CREW - ARK0953 - v03Document4 pagesNQR 87-80-190 CREW - ARK0953 - v03LEON AGUILAR PEDRO RONALDNo ratings yet

- pc200 7 Main Pump Test MethodDocument26 pagespc200 7 Main Pump Test Methodalfred100% (1)

- An Introduction To Boiler Maintenance EditedDocument7 pagesAn Introduction To Boiler Maintenance EditedPritv SavalagiNo ratings yet

- 5 Steps To A 5 AP Physics C 2017 - McGraw-HillDocument299 pages5 Steps To A 5 AP Physics C 2017 - McGraw-HillRishit Kalra100% (1)

- Composite Filled Composite Circular Column DesignDocument1 pageComposite Filled Composite Circular Column DesignAli SamaniNo ratings yet