Professional Documents

Culture Documents

Risk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DB

Uploaded by

nsadnanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DB

Uploaded by

nsadnanCopyright:

Available Formats

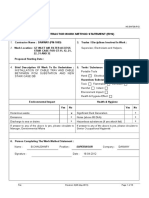

HS.SAF.09.

F12

CONTRACTOR WORK METHOD STATEMENT (EHS)

1. Contractor Name : DANWAY (PM-1009) 3. Trades / Disciplines Involved In Work :

2. Work Location : GT INLET AIR FILTER ACCESS Supervisor, Electricians and Helpers.

STAIR CASE FOR GT-11, 12, 21,

22, 31 AND 32

Proposed Starting Date :

4. Brief Description Of Work To Be Undertaken : 5. Tools / Substance

INSTALLATION OF CABLE TRAY/CABLE FROM

Portable Tools

EXISTING LIGHTING DB IN PCM TO NEW DB FOR

LIGHTING OF ACCESS STAIRCASE FOR GT Hand Electrical Pneumatic

INLET AIR FILTERS (ALL GT UNITS).GLANDING &

Hazardous Substances

TERMINATION.

Toxic Flammable Corrosive

Harmful Irritant

Environment Impact

Health & Hygiene Effect

Environmental Impact Health & Hygiene

Yes No Yes No

Hazardous waste x Significant Dust Generation x

Emissions x Noise (above 85 DbA) x

Discharge to sea or drains x Hazardous substances (if yes attach list) x

If answer to any of the above is yes, please circulate to If answer to any of the above is yes, please circulate to

Manager, Environmental Affairs Senior Occupational Hygienist

6. Person Completing The Work Method Statement :

Name : B.CHAUDHARY Position : SUPERVISOR Company : DANWAY

Signature : Date : 16-04-2012

File: Revision: 0(26-May-2011) Page 1 of 13

HS.SAF.09.F12

7. Approvals

Contractors Site Rep. Name PRAVEENKUMAR Signature : Date :

EMAL Representative Name Signature : Date :

Area Owner Name Signature : Date :

Name Signature: Date:

EMAL EHS Department

The completed Work Method Statement must be submitted at least seven full working days prior to the

commencement of activities.

Where the Work Method Statement indicates the use of Hazardous Substances, a Material Hazard Data

Sheet must be attached.

After the Area Owners approval the Work Method Statement shall be forwarded to EHS department for

approval

The approved Work Method Statement must be attached to the permit(s) to work and all persons involved

in the job instructed in its requirements.

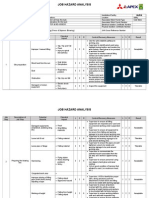

2. RISK ESTIMATOR CHART

The Risk Estimator chart should be used as an assistant for filling out the work

method statement.

Severity

Probability Low x1 Medium x 2 High x3

Low x1 Low Probability x Low Severity LP x MS LP x HS

1x1=1 1x2 = 2 1x3 =3

Medium x2 MP x LS MP X MS MP x HS

2x1 =2 2x2 =4

2x3 =6

High x3 HP x LS HP X HS HP x HS

3 x 1 =3 3x2 = 6 3x3=9

Significant Risk = High Risk (6-9) or Medium Risk (3-4) in terms of probability and severity

Tolerable Risk = Risk reduced to an acceptable level = Low Risk (1-2)

Residual Risk = Risk remaining after implementing recommended control actions (usually very minor).

File: Revision: 0(26-May-2011) Page 2 of 13

HS.SAF.09.F12

8. Safety Analysis

Severity x Probability =

Risk

Individual Activities To Identified Hazard(s) Persons Exposed To Precautions and Plan of actions To Be Taken

Complete Work. List In Residual Risk

Associated With Activity Hazard To Remove / Control Hazards

Sequence of Activity (Use Risk Estimator

Chart)

6.1 PREPARATION. Slips, trips and fall at Maintain housekeeping around in the

the same level. working area.

Hot environment All personnel involve in the activity must

Emal, Engr., Supv.

Manual handling be aware of heat stress, supervisor to 2x2=4

Elec, and helpers

hazards ensure drinking cold water is available.

Supervisor to give tool box talk

regarding proper manual handling.

File: Revision: 0(26-May-2011) Page 3 of

13

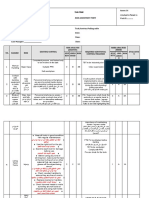

HS.SAF.09.F12

APPROVAL(Permit to Client coordination Emal , Engr., Supv. Verify isolations.

work from EMAL) fails, job stopped, Elec, helpers

Start work after getting permit from

work unapproved.

Emal.

Operatives should

Engineer / supervisor must ensure that

be aware of

emergency the work permit is valid for the date and

procedure of EMAL tine

All work force are inducted by EMAL

All personnel involve in the activities

must wear the required PPEs at all

times(eg.hard hat, appropriate safety 2x2=4

glass, safety shoe, hand gloves, dust

mask, disposable coverall)

Advance planning by contractor

considering the time consumption to

recive the permit from EMAL

Emergency procedure must be

displayed at prominent location and

cascade to operatives on regular

interval and recorded.

Ensure the operatives must be go

through EMAL and DANWAY safety

induction.

File: Revision: 0(26-May-2011) Page 4 of

13

HS.SAF.09.F12

All hand tools to be used must be

Using damaged in good condition.

6.2 INSTALLATION OF

hand tools. Electricians & Inspect before use, periodically

CABLE SUPPORT, 2 x 1 =2

CABLE TRAY & Sharp edges of Helpers maintained.

CABLE LADDER. cable support / tray & Extra care to be taken while

ladder. installing cable support / tray & ladder,

use hand gloves.

Electricians & Competent workers to be deployed,

Incompetent workers. 2 x 1 =2

Helpers supervisor to check the competency of

the workers.

Electricians ,

Slips, trips and fall at supervisor & Maintain housekeeping around the 2 x 1 =2

the same level. Helpers working area.

Using of bad Hand power tools must be in good

condition of hand condition with color coding inspection

power tools. tag.

Drilling without clear Electricians & Use clear safety glass inside control

3x1=3

safety glass, dust Helpers room, dust masks & ear plug.

mask & ear plug Drilling to be done in phase manner if

Dust from electric the fire alarm system is close to the

drill may cause of drilling point.

fire alarm activation.

Electricians & 3x1=3

Unauthorized Helpers Only competent and authorized worker

for the using of power tools.

File: Revision: 0(26-May-2011) Page 5 of

13

HS.SAF.09.F12

using of hand power

tools.

Supervisor to ensure all power source

to be connected with ELCB and only

Electricians , 110V industrial socket to be used at

supervisor & site. 3x1=3

Electrocution / Fire.

Helpers

Appropriate fire extinguisher to be

provided if necessary.

Do not use metal step ladder.

Inspect ladder before use, assign

one man to hold the ladder on the

ground while in used.

Using of bad Always climb up and down facing

condition step ladder. Electricians & the ladder.

3x1=3

Fall from height Helpers Don't carry tools or materials in

scaffold or from your hand while climbing up and down

ladder ladder.

Ensure workers on top of

Scaffolders must wear their safety

harness and 100% tie off.

All workers near by 2x2=4

Fall of materials may Do not keep unwanted materials

injure workers below on top of the scaffold or ladder.

Materials to be removed should

be in safe manner one by one--,

File: Revision: 0(26-May-2011) Page 6 of

13

HS.SAF.09.F12

ensure no materials to be dropped.

Barricade the working area by

using warning tape and sign boards.

Electricians &

Manual handling Supervisor to give toolbox talk 2 x 1 =2

Helpers

hazards. regarding proper manual handling.

Wear P.P.E.'s at all times ( e.g. hard hat,

Not using proper Electricians &

appropriate safety glass, safety shoes, 2x1=2

P.PE.s Helpers

hand gloves, dust mask, long sleeve

shirt & reflective vest.)

BY MAIN CONTRACTOR

A separate method statement will be

6.3 INSTALLATION OF submitted by the main contractor for 2x1=2

SCAFFOLDING approval of EMAL & PTW will be

approved by main contractor for

scaffold erection

6.5 CABLE LAYING /

Sharp edges from

PULLING Extra care to be taken while pulling the

existing cable Cable pulling group 2x1=2

BETWEENLIGHTING cable on cable tray & ladder, use hand

support / tray &

DB TO NEW gloves.

ladder.

STAIRCASE DB.

Extra care to be taken while pulling

Damaged existing

Cable pulling group cable to the existing cable tray / ladder, 2x1=2

cable.

if necessary protects the existing cable

with polyethylene sheet.

File: Revision: 0(26-May-2011) Page 7 of

13

HS.SAF.09.F12

Slips, trips and fall at Cable pulling group Maintain housekeeping around the 2x1=2

the same level. working area.

Do not use aluminium ladders.

Dont stack unnecessary

materials inside PCM Substation.

Dont leave cut cable inside the

building & top of panels.

Inspect ladder before use, assign

Using of bad

condition step ladder. one man to hold the ladder on the

Cable pulling group ground while in used. 3x1=3

Fall from height

Always climb up and down facing

scaffold or from

the ladder.

ladder.

Don't carry tools or materials in

your hand while climbing up and down

ladder.

Ensure workers on top of

Scaffolders must wear their safety

harness and 100% tie off.

Communication

Cable pulling group Good communication measures / 2x1=2

barriers among

devices shall be used.

workers.

Manual handling Cable pulling group Supervisor to give toolbox talk 2x1=2

hazards. regarding proper manual handling.

File: Revision: 0(26-May-2011) Page 8 of

13

HS.SAF.09.F12

6.5.4.2 ISOLATION Attach EMAL isolation permit.

Barricade the area with proper warning

signages.

Use only standard danger tags likes

DANGER NOT USE or DO NOT

OPERATE

All workers involve

Electrocution Do not operate any device with danger 3x2=6

in the activity

tag

Only the person who place the lock and

tag shall remove it

Do not use conductive articles of

jewelry and clothing(eg. watch,

bracelets rings etc)

Use appropriate PPE,s

CABLE DRESSING Manual handling

Elec., & helpers Close supervision will be implemented. 2x1=2

Hand injury

Supervisor to give tool box talk

regarding proper manual handling.

Incompetent Verify isolations

electrician.

Competent workers to be deployed,

Use of sharp hand

CABLE GLANDING & Electricians & supervisor to check the competency of

tools. 2x1=2

TERMINATIONS. Helpers the workers.

Use damaged hand

tools may slip and All hand tools to be used must be

injure electrician or in good condition, inspect before use.

damage property.

File: Revision: 0(26-May-2011) Page 9 of

13

HS.SAF.09.F12

Unauthorized Electricians & Only competent and authorized worker

3x1=3

using of hand power Helpers for the using of power tools.

tools.

Supervisor to ensure all power source

to be connected with ELCB and only

Electricians & 110V industrial socket to be used at

3x1=3

Electrocution / Fire. Helpers site.

Appropriate fire extinguisher to be

provided if necessary.

Do not use metal step ladder.

Electricians &

Slips, trips and fall at Maintain housekeeping around the 2 x1=3

Helpers

the same level. working area.

Only Emal Big 5 trained

personnel to do the job.

If required safety bulletin needs

TESTING Slip / Trip / Fall Testing group to be issued. 2x1=2

- same level Maintain good housekeeping

around the area.

All temporary cable should be properly

organized.

Unauthorized Testing group 3x1=3

person Access towards to the testing

Electricity / Fire area to be barricaded and watchman

File: Revision: 0(26-May-2011) Page 10 of

13

HS.SAF.09.F12

to be posted.

Testing area to be barricaded and

proper sign boards to be placed which

read "TESTING IN PROGRESS

KEEP AWAY".

Avoid cable joint.

Clear everybody from the area

where testing is in progress.

All testing equipments must be in good

conditioned and with valid calibration

Testing

Testing group test certificates. 3x1=3

equipment

All testing equipments must be

approved by client prior to utilize at

site.

Only competent and authorized person

INSPECTION Supv,Elect & to do the inspection, ensure notified

Unauthorized 2x1=2

helpers the client with all necessary

workers

documents.

Slip / Trip / Fall - Emal, Engr., Supv. Maintain good housekeeping around

2x1=2

same level Elec, and helpers the area.

Working without Emal, Engr., Supv. 2x1=2

proper PPEs Wear P.P.E.'s at all times (hard

Elec, and helpers

hat, appropriate safety glass, safety

File: Revision: 0(26-May-2011) Page 11 of

13

HS.SAF.09.F12

shoes, hand gloves, dust mask, fire

retardant long sleeve shirt / pants.

This sheet must be properly completed detailing all of the steps required to complete the job along with the sequence of events and each of the hazards

arising. Failure to properly complete the form will result in non-approval.

(Additional sheets to be used as required)

9. Chemical Analysis (This form to be used as required)

Product Name

MSDS supplied Yes / No

Dangerous Goods Class

Hazardous Material Yes / No

Nature of Hazard Irritation / Carcinogen / Corrosive / Toxic / Other

Form Solid /Liquid / Gas / Dust / Vapour / Mist

Exposure Route Inhalation / Skin / Eye / Ingestion

Number of People Exposed

Duration of Exposure

Frequency of Exposure

File: Revision: 0(26-May-2011) Page 12 of

13

HS.SAF.09.F12

Controls to be implemented

Estimate of Exposure Negligible / Marginal / High

This sheet must be properly completed detailing all the necessary information. Failure to properly complete the form will result in non-approval.

File: Revision: 0(26-May-2011) Page 13 of

13

You might also like

- Risk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPDocument20 pagesRisk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPnsadnanNo ratings yet

- Risk Assessment For GIS Preparation For HV Cable TestDocument11 pagesRisk Assessment For GIS Preparation For HV Cable Testnsadnan100% (3)

- Risk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatDocument6 pagesRisk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatnsadnanNo ratings yet

- Risk Ass - INSTALLATION OF PLC CABINET IN SECTION ELECTRICAL ROOMDocument8 pagesRisk Ass - INSTALLATION OF PLC CABINET IN SECTION ELECTRICAL ROOMnsadnan100% (1)

- PM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBDocument16 pagesPM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBnsadnanNo ratings yet

- Risk Ass. - AD 417 - Installation of SocketDocument6 pagesRisk Ass. - AD 417 - Installation of SocketnsadnanNo ratings yet

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Document3 pagesRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocument6 pagesRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Changing Faulty Flood Light JSA (BoomLift)Document2 pagesChanging Faulty Flood Light JSA (BoomLift)black_3289No ratings yet

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- 012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2Document11 pages012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2nsadnanNo ratings yet

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Document3 pagesRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- SOP SOP0022 Concrete Core DrillDocument3 pagesSOP SOP0022 Concrete Core Drillkristian08No ratings yet

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Document3 pages(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisNo ratings yet

- Rmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)Document2 pagesRmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)myn maliQueNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagya100% (1)

- Mie-Hse-Jha-007 - Cable Pulling, Laying, Dressing Work, TerminationDocument6 pagesMie-Hse-Jha-007 - Cable Pulling, Laying, Dressing Work, TerminationLuqman Osman100% (3)

- Risk Assessment - Placing of Transformer - TTSDocument6 pagesRisk Assessment - Placing of Transformer - TTSnsadnan100% (2)

- 007 - Risk Ass. - CE-0994-MEP WorksDocument9 pages007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- JSA For Electrical Work TCF3-HaradhDocument6 pagesJSA For Electrical Work TCF3-HaradhShaikh Abu bakarNo ratings yet

- JSA Erection of Gathering TentDocument12 pagesJSA Erection of Gathering TentMuhammad Tariq100% (2)

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDocument12 pagesRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- JHA For Steam PipingDocument17 pagesJHA For Steam PipingM8Rskn6wcNo ratings yet

- 6-Steel Work Risk Assessment ReportDocument7 pages6-Steel Work Risk Assessment ReportSyed Ali Hassan67% (3)

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 pagesJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNo ratings yet

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocument9 pagesRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajNo ratings yet

- RISK ASSES-106-Erection of Steel Structure BuildinDocument4 pagesRISK ASSES-106-Erection of Steel Structure BuildinRochdi Bahiri50% (2)

- Jha New - PWHTDocument6 pagesJha New - PWHTSalam AlkataluniNo ratings yet

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- Risk Assessment For Cable LayingDocument5 pagesRisk Assessment For Cable Layingpopamino50% (2)

- Skillbuild Risk Assessment: Competition Organising Partner: Citb /skillbuild Competition Skills: BricklayingDocument6 pagesSkillbuild Risk Assessment: Competition Organising Partner: Citb /skillbuild Competition Skills: BricklayinguknandiNo ratings yet

- Installation of Chain Link FenceDocument2 pagesInstallation of Chain Link FenceMohd Hafiz MuhamedNo ratings yet

- JSA For RCC, Foundation & Generator Installation (R-00)Document14 pagesJSA For RCC, Foundation & Generator Installation (R-00)Suju RajanNo ratings yet

- Risk Assessment Rib Erection & FabricationDocument2 pagesRisk Assessment Rib Erection & FabricationAkash SharmaNo ratings yet

- Risk Assessment Analysis (Safety & Health) :-Earth MatDocument1 pageRisk Assessment Analysis (Safety & Health) :-Earth Matakshaf10No ratings yet

- Job Safety Assessment (Jsa)Document19 pagesJob Safety Assessment (Jsa)Saravanan Sara0% (1)

- JHA Blowing PressDocument5 pagesJHA Blowing PressLuqman OsmanNo ratings yet

- Job Safety Analysis For Civil WorkDocument9 pagesJob Safety Analysis For Civil Worksakthi venkatNo ratings yet

- jesa-INSTALLATION OF Toilet Cubicle PartitionDocument5 pagesjesa-INSTALLATION OF Toilet Cubicle PartitionLeo PascualNo ratings yet

- JHA For Loop CheckDocument8 pagesJHA For Loop CheckFrancis Enriquez Tan83% (6)

- 2 - Pulling CablesDocument5 pages2 - Pulling CablesAhmed KhaledNo ratings yet

- Installation and Repair of Fibre Optic Cable PDFDocument3 pagesInstallation and Repair of Fibre Optic Cable PDFBento BoxNo ratings yet

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocument6 pagesRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanNo ratings yet

- JSA Manual Excavation and Cable LayingDocument3 pagesJSA Manual Excavation and Cable Layingimran100% (1)

- One Direct Method Statement: Preventative MeasuresDocument4 pagesOne Direct Method Statement: Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Deshuttering WorkDocument2 pagesDeshuttering WorkChandru100% (1)

- Sharjah Waterfront City-Sector 2 & Sun IslandDocument2 pagesSharjah Waterfront City-Sector 2 & Sun IslandCaptainNo ratings yet

- 011 Duct Lifter SWMSDocument2 pages011 Duct Lifter SWMSJ JohnsonNo ratings yet

- Risk Assessment - Removing Existing Septic Tank and Connection of Live Foul Sewer To ManholeDocument14 pagesRisk Assessment - Removing Existing Septic Tank and Connection of Live Foul Sewer To Manholeloveson70971% (7)

- Risk Assessment-Instllation & Fabrication of Steel Structural WorkDocument3 pagesRisk Assessment-Instllation & Fabrication of Steel Structural WorkKono Nor AtanNo ratings yet

- # 20 Installation of Cable Tray Trunking (SWP)Document5 pages# 20 Installation of Cable Tray Trunking (SWP)Anonymous kWfNFbNo ratings yet

- HSF-PR-0063 Work at HeightDocument32 pagesHSF-PR-0063 Work at HeightChris Bonnington0% (1)

- Chipping Work (Manually)Document1 pageChipping Work (Manually)ChandruNo ratings yet

- JSA For Fire Water LineDocument4 pagesJSA For Fire Water Linemyo lwinNo ratings yet

- Risk Ass. - INSTALLATION OF 25 MM G.I. PIPE WITH EXISTING LINEDocument12 pagesRisk Ass. - INSTALLATION OF 25 MM G.I. PIPE WITH EXISTING LINEnsadnanNo ratings yet

- Risk Ass. - RELOCATION OF 11 KV CABLE FROM EXISTING ROUTE TO NEW LOCATIONDocument6 pagesRisk Ass. - RELOCATION OF 11 KV CABLE FROM EXISTING ROUTE TO NEW LOCATIONnsadnan100% (1)

- Risk Ass. - INSTALLATION OF CBCT IN SUBSTATION 4730-ESS-001Document12 pagesRisk Ass. - INSTALLATION OF CBCT IN SUBSTATION 4730-ESS-001nsadnanNo ratings yet

- Contractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingDocument8 pagesContractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingnsadnanNo ratings yet

- ONVIF Profile Feature Overview v2-2Document6 pagesONVIF Profile Feature Overview v2-2nsadnanNo ratings yet

- BSIA Cyber Secure It January 2019Document16 pagesBSIA Cyber Secure It January 2019nsadnanNo ratings yet

- ONVIF Profile T Specification v1-0Document77 pagesONVIF Profile T Specification v1-0nsadnanNo ratings yet

- Checklist For Access Control System InstallationDocument6 pagesChecklist For Access Control System Installationnsadnan71% (7)

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDocument5 pagesPeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanNo ratings yet

- ONVIF Profile - S Specification v1-2Document42 pagesONVIF Profile - S Specification v1-2nsadnan0% (1)

- DDC Systems2Document28 pagesDDC Systems2nsadnan100% (1)

- Checklist For Pre Commissioning of CCTV SystemDocument1 pageChecklist For Pre Commissioning of CCTV Systemnsadnan67% (6)

- 1 45Document3 pages1 45nsadnan0% (1)

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Document1 pageCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan67% (3)

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocument6 pagesRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanNo ratings yet

- Checklist For Commissioning of CCTV SystemDocument2 pagesChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- Testing and Commissioning Pre-Check List (ID 1506)Document1 pageTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- Excel Intelligent Pdu User InstructionsDocument2 pagesExcel Intelligent Pdu User InstructionsnsadnanNo ratings yet

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocument10 pagesRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Risk Assessment - Installation of Ventilation FanDocument6 pagesRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- Risk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control BuildingDocument14 pagesRisk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control Buildingnsadnan91% (82)

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Document3 pagesRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (2)

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Document3 pagesRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocument9 pagesRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- Risk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and TestingDocument12 pagesRisk Assessment - Ad-417 - Installation of Do Meter, Cable Trench Excavation, Cable Installation and Testingnsadnan100% (1)

- RISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The MaterialsDocument6 pagesRISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The Materialsnsadnan100% (5)

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocument6 pagesRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDocument6 pagesRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- Risk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light FittingsDocument6 pagesRisk Assessment - Cg-4750-Installation of Lighting Protection Pole, Street Lighting Pole and Light Fittingsnsadnan86% (21)

- Tutorial 4.2Document4 pagesTutorial 4.2Rosa FinizioNo ratings yet

- Freud - TheoryDocument29 pagesFreud - TheoryNirmal Raj100% (1)

- Agricultural Issues HyperdocDocument13 pagesAgricultural Issues Hyperdocapi-291123127No ratings yet

- Sexual QigongDocument3 pagesSexual Qigongfahim100% (1)

- Nursing Education InpakistanDocument32 pagesNursing Education InpakistanIrfan AliNo ratings yet

- My Abilities First: Positive Language in Health Care: Disruptive EducationDocument3 pagesMy Abilities First: Positive Language in Health Care: Disruptive EducationVe SaNo ratings yet

- REGULATIONS AND CURRICULUM1.0 - CompressedDocument50 pagesREGULATIONS AND CURRICULUM1.0 - CompressedneethuNo ratings yet

- Ch11 - Performance AppraisalsDocument35 pagesCh11 - Performance AppraisalsGreggi RizkyNo ratings yet

- AAP January 2024 Complete Issue NeoReviewsDocument71 pagesAAP January 2024 Complete Issue NeoReviewshabibfmNo ratings yet

- A Quantitative Study About Time Management and Its Relation To Procrastination Among Senior High School Students of Our Lady of Fatima UniversityDocument20 pagesA Quantitative Study About Time Management and Its Relation To Procrastination Among Senior High School Students of Our Lady of Fatima UniversityClaire GonoNo ratings yet

- New Years Resolutions Are Bad For You Reading Comprehension Exercises - 75675Document2 pagesNew Years Resolutions Are Bad For You Reading Comprehension Exercises - 75675Настя ИваненковаNo ratings yet

- Krok 1 Stomatology 2006Document21 pagesKrok 1 Stomatology 2006helloNo ratings yet

- Breathe OlogyDocument59 pagesBreathe OlogyPere Ureña Bartrina73% (22)

- A Case of Sheehan's Syndrome: A Rare But Life - Threatening ComplicationDocument2 pagesA Case of Sheehan's Syndrome: A Rare But Life - Threatening ComplicationEditor IJTSRDNo ratings yet

- DIS Project Proforma 2015 PDFDocument7 pagesDIS Project Proforma 2015 PDFVidyesh Nair100% (2)

- Project: Author:Cernopischi ArtiomDocument6 pagesProject: Author:Cernopischi ArtiomTwitch KappaNo ratings yet

- 07 Aromatherapy Questionnaire PDFDocument1 page07 Aromatherapy Questionnaire PDFAgnesNo ratings yet

- RPT DCRVisitDocument6 pagesRPT DCRVisitPinku JaiswalNo ratings yet

- Tidal Model of Mental Health RecoveryDocument3 pagesTidal Model of Mental Health RecoveryMary BurgosNo ratings yet

- LESSON 1 EED Spec 322Document5 pagesLESSON 1 EED Spec 322Jhezmae Rose Pasion AlonzoNo ratings yet

- PsychopathologyDocument14 pagesPsychopathologyKrinjal KapoorNo ratings yet

- What's New at BrightRockDocument2 pagesWhat's New at BrightRockB MthembuNo ratings yet

- Turning A Product Into A Brand: Adeo Health ScienceDocument11 pagesTurning A Product Into A Brand: Adeo Health ScienceHarshit KumarNo ratings yet

- Part IDocument8 pagesPart IMj Ong Pierson GarboNo ratings yet

- APA Research Proposal 2021Document14 pagesAPA Research Proposal 2021med wardNo ratings yet

- Personality Test Guide For Job ApplicationsDocument44 pagesPersonality Test Guide For Job Applicationsdoppler_No ratings yet

- ACOG Practice Bulletin No 202Document25 pagesACOG Practice Bulletin No 202Berri RahmadhoniNo ratings yet

- Review Mcqs For 2016 Systemic PathologyDocument8 pagesReview Mcqs For 2016 Systemic PathologySameer100% (1)

- Ai Paper 1 - Analysis InterpretationDocument7 pagesAi Paper 1 - Analysis Interpretationapi-687427075No ratings yet

- HEMP Training PDFDocument3 pagesHEMP Training PDFMuhammad.SaimNo ratings yet