Professional Documents

Culture Documents

Eng PRD Maitrise Operationelle

Uploaded by

Adel AliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eng PRD Maitrise Operationelle

Uploaded by

Adel AliCopyright:

Available Formats

Ref.

: PRD-SST-07

OPERATIONAL CONTROL TOOLS

Index : 01

Page 1 /3

1) OBJECTIVES :

This procedure allows the identification of activities and operations that require operational

control (significant risk-related activities) to establish instructions, guidelines and recommendations

for safe use of products, equipment and services in order to limit their impact on health and safety of

personnel and installations.

2) SCOPE :

This procedure applies to all operations and activities conducted by the SOSEM Company

concerned by significant risks.

3) DEFINITION & ABREVIATIONS :

Hazard: Source, situation or act with a potential for harm in terms of personal injury or damage to health,

or a combination of these.

Risk: combination of the probability of the occurrence of one or more hazardous events or exposures to

or from such events and the severity of personal injury or damage to health (3.8) that this event or this /

these exposure (s) can cause.

Risk assessment: estimation process of one or more risk (arising from one or more hazards, taking into

account the adequacy of any existing controls, and deciding whether or risk (s) is (are) acceptable (s) or

not.

Location: any physical location in which work activities are carried out under the control of the

organization.

QSM: Quality and Safety Manager

QSA: Quality and Safety Assistant

GR: Manager;

Dir. / Chief: Executive / Head concerned

OHSR: Occupational Health and Safety Responsible

OHS: Occupational Health and Safety

HRM: Human Resource Manager.

4) DOCUMENTS DE REFERENCE :

PRD-SST-01= Hazard identification, assessment and control of risks

PRD-SST-15 = Hazard identification, assessment and control of risks

PRD-SST-12= EPI process management (personal protective equipment)

PRD-SMI-01 = Subcontractors and suppliers Procedure

PRD-SST-06= Lock out / Tag out Procedure

PRD-SST-05 = Procedure during travel and actions

PRD-SST-13 = HSE signaling procedure

DOC-SST-31= HSE basic operating criteria

INS-SST-19= Use of electrical charts

CON-SST-18= special requirement to the attention of teammates 1st response

INS-SST-15= Local maintenance

Ref.: PRD-SST-07

OPERATIONAL CONTROL TOOLS

Index : 01

Page 2 /3

INS-SST-13= Health and Safety

INS-SST-12= Transshipments with forklift

INS-SST-11= Evacuation Instructions

INS-SST-10= Fire safety, extinguishing means

INS-SST-09= Safety Instruction for SOSEM park and workshops

INS-SST-08= Specific safety instruction to chemical products storage

INS-SST-01= intervention on plant and electrical equipment

INS-SST-20= Handling equipment Traffic

INS-SST-07= Access prohibition

FOR-SST-35= HSE Program

INS-SST-22= Introduction to visitors safety

INS-SST-21= Visitors reception

INS-SST-02= Safety instructions in case of fire

INS-SST-05= Instructions on gestures and postures

CON-SST-03= General instructions on internal rules

FOR-SST-23= Risk Analysis Data Sheet

FOR-SST-07= Action plan to improve regulatory requirements

FOR-SST-29= Risk Analysis improvement action Plan

5) MODIFICATION :

Date Index Reason for modification

08/10/2010 00 Creation

Document review:

19/10/2011 01

Change HSE Program Action Plan of step # 2

6) VALIDATION:

Elaborated by Checcked by Approved by

Name Ahmed Bredai Moez GHARBI Ihsen FERSI

Position HSE Responsible QS Manager General Manager

Date & signature

Ref.: PRD-SST-07

OPERATIONAL CONTROL TOOLS

Index : 01

Page 3 /3

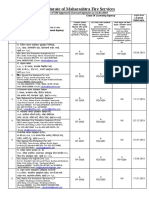

7) DOCUMENTS CONTROL:

7.1 Arrangements Description:

WHO WHAT HOW RECORD

1-

Identification of Significant risks are identified according to

Steering activities or operations the scoring method motioned in the hazard PRD-SST-01

Committe associated with identification and analysis procedures and FOR-SST-23

significant risks risk mastery

2-

Objectives and action plan will be FOR-SST-07

QSM Setting objectives and action

established on the basis of risk analysis, FOR SST-29

+ plan FOR-MQA-13

assessment of regulatory compliance

HSER FOR-SST-35

3-

Implementation of operational

control

4-

Documentation No

necessity

HSER

Following

according to steps

yes 6, 7, 8 et 9

5-

To reduce the high risk in significant risk

QSM Drafting or updating of operations, mastery documents are

+ "control documents" developed

HSER (procedures, instructions and safety

guidelines ...).

6- Training programs are held, safety posters

HRR Awareness, training and

+ are developed and displayed for the

display of elaborated

HSER persons concerned.

instructions

7- Preventive and

An improvement task sheet will be established

Method / instructions corrective actions

HSER in the event of non-compliance and mastery of

Verification documents verification. procedures

8-

Periodic audits will be planned to check Internal audit

QSM Audit

the conformity of this operational procedure

approach.

9- Management

review account

Management Review

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Admin Building Risk AssessmentDocument3 pagesAdmin Building Risk AssessmentAdel AliNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Cambridge ScaleDocument9 pagesCambridge Scalemartina curcurutoNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Celta: Syllabus and Assessment GuidelinesDocument20 pagesCelta: Syllabus and Assessment GuidelinesAlexandra AntonNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Preliminary Colloquium Schedule 07.2016Document4 pagesPreliminary Colloquium Schedule 07.2016Adel AliNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Course Syllabus: TOEIC Preparation Class: GLID 3 Year Trainer: MR Adel ALI Number of Hours: 38 HoursDocument2 pagesCourse Syllabus: TOEIC Preparation Class: GLID 3 Year Trainer: MR Adel ALI Number of Hours: 38 HoursAdel AliNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Final Exam of English For Bba 3 Answer SheetDocument1 pageFinal Exam of English For Bba 3 Answer SheetAdel AliNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Guidelines For Designing Effective English Language Teaching Materials-HowardDocument9 pagesGuidelines For Designing Effective English Language Teaching Materials-HowardSussanRooNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Conference and Summer School Program-2Document10 pagesConference and Summer School Program-2Adel AliNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Grad 3 Dogoriti PDFDocument11 pagesGrad 3 Dogoriti PDFAdel AliNo ratings yet

- ChoiceDocument7 pagesChoiceAdel AliNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Reading Part 4Document2 pagesReading Part 4Adel AliNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Eng Circulation Des Engins de ManutentionDocument1 pageEng Circulation Des Engins de ManutentionAdel AliNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Test Predictiv Engleza Multiple ChoiceDocument3 pagesTest Predictiv Engleza Multiple ChoiceDana ZamfirNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Anglais Technique Aéronotique - 18Document3 pagesAnglais Technique Aéronotique - 18Adel AliNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Eng - PRD Identification Et Gestions Des Situations D'urgence v01Document2 pagesEng - PRD Identification Et Gestions Des Situations D'urgence v01Adel AliNo ratings yet

- ChoiceDocument7 pagesChoiceAdel AliNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Eng Circulation Des Engins de ManutentionDocument1 pageEng Circulation Des Engins de ManutentionAdel AliNo ratings yet

- Guidelines For Designing Effective English Language Teaching Materials-HowardDocument9 pagesGuidelines For Designing Effective English Language Teaching Materials-HowardSussanRooNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Creativity in EducationDocument8 pagesCreativity in EducationElena Paslaru HubatiNo ratings yet

- IELTS PreparationDocument50 pagesIELTS PreparationAdel AliNo ratings yet

- ARCHIVO 2yle Starters Word ListDocument5 pagesARCHIVO 2yle Starters Word ListAndy Garcia PeñaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Game Like Activities FINALDocument44 pagesGame Like Activities FINALrevathipushNo ratings yet

- IELTS Speaking Criteria Public Version PDFDocument1 pageIELTS Speaking Criteria Public Version PDFDiana Laura Durán Chablé100% (1)

- Advice On Writing A CV Lesson PlanDocument2 pagesAdvice On Writing A CV Lesson PlanAdel AliNo ratings yet

- General Guidelines 3Document10 pagesGeneral Guidelines 3Adel AliNo ratings yet

- Ielts Secrets: Enhance Your VocabularyDocument4 pagesIelts Secrets: Enhance Your VocabularyAdel AliNo ratings yet

- Ielts FaqDocument8 pagesIelts FaqAdel AliNo ratings yet

- British Council Seminar Series - Call For Proposals 2015 - 16Document4 pagesBritish Council Seminar Series - Call For Proposals 2015 - 16Adel AliNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Affiche British Council - InddDocument1 pageAffiche British Council - InddAdel AliNo ratings yet

- 08 RTK-Chemical Safety PDFDocument13 pages08 RTK-Chemical Safety PDFsiva sakthiNo ratings yet

- Pyro AnswersDocument4 pagesPyro AnswersPaul RoblingNo ratings yet

- ESD Valve SILDocument8 pagesESD Valve SILmgkvprNo ratings yet

- Hazard Communication: 29 CFR 1910.1200 Compliance Training PresentationDocument25 pagesHazard Communication: 29 CFR 1910.1200 Compliance Training PresentationMonzurNo ratings yet

- Risk Register Rumah SakitDocument12 pagesRisk Register Rumah SakitBagus Kusuma WardhanaNo ratings yet

- Annexure 3 - Medical CertificateDocument1 pageAnnexure 3 - Medical CertificateJMZ de Wet100% (2)

- Data Center Audit ChecklistDocument2 pagesData Center Audit ChecklistGajendra.Kanse84% (58)

- Aqua Clear PFD Material Safety Data Sheet PDFDocument6 pagesAqua Clear PFD Material Safety Data Sheet PDFlimaduaNo ratings yet

- NEBOSH Assignment 2 - 30th April 2016Document1 pageNEBOSH Assignment 2 - 30th April 2016Nazneen AliNo ratings yet

- General Laboratory Safety TrainingDocument33 pagesGeneral Laboratory Safety TrainingLouis Fetilo FabunanNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 3 Candle ReversalDocument32 pages3 Candle Reversaltotok100% (1)

- WSH Guidelines On Laboratories Handling Chemicals PDFDocument57 pagesWSH Guidelines On Laboratories Handling Chemicals PDFGerard GovinNo ratings yet

- MCQ On Safety ManagementDocument5 pagesMCQ On Safety ManagementKishor Patil71% (31)

- 5 - Process Flow Diagram and Onsite Verification of Flow Diagram - SedresDocument3 pages5 - Process Flow Diagram and Onsite Verification of Flow Diagram - Sedreskamran100% (1)

- Hospital Safety ManualDocument9 pagesHospital Safety Manualfairus100% (4)

- Safety Data Sheet: 1. IdentificationDocument7 pagesSafety Data Sheet: 1. IdentificationPubcrawlNo ratings yet

- Prepared By: Amiya Ray Sandeep SidhuDocument29 pagesPrepared By: Amiya Ray Sandeep SidhuHarpreet Sutdhar89% (18)

- Biological EffectDocument10 pagesBiological EffectCedric MercadoNo ratings yet

- Hand Hygiene Awareness (5 Moments+ Steps of Handwashing)Document15 pagesHand Hygiene Awareness (5 Moments+ Steps of Handwashing)ManpreetNo ratings yet

- RA-LBC-007 Risk Assessment Drilling Operations and WorkDocument5 pagesRA-LBC-007 Risk Assessment Drilling Operations and Workjones100% (1)

- 28th February, 2023Document4 pages28th February, 2023Syed Adnan AliNo ratings yet

- Chapter 10 Risk Management PlanDocument23 pagesChapter 10 Risk Management PlanPrabath Nilan Gunasekara100% (1)

- OshaDocument2 pagesOshachapisha incNo ratings yet

- List of Approved Licensed AgenciesDocument77 pagesList of Approved Licensed AgenciesAshish Mishra60% (5)

- Hazard Identification, Risk Assessment and Risk Control FormDocument1 pageHazard Identification, Risk Assessment and Risk Control Formusman4428No ratings yet

- Ra 11058Document69 pagesRa 11058Art Corbe0% (1)

- Hazard Identification and Risk Assessment Criteria Form Hazard Identification and Risk Assessment Criteria FormDocument21 pagesHazard Identification and Risk Assessment Criteria Form Hazard Identification and Risk Assessment Criteria FormElvyn Fabellore HerreraNo ratings yet

- KeselamatankerjaDocument214 pagesKeselamatankerjaKorinto PrilusworoNo ratings yet

- Emergency - Plans - Sample Emergency Preparedness WorksheetDocument3 pagesEmergency - Plans - Sample Emergency Preparedness WorksheetMianNo ratings yet