Professional Documents

Culture Documents

Fuel UST-Double Wall Drawing

Uploaded by

Abu Anas M.SalaheldinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel UST-Double Wall Drawing

Uploaded by

Abu Anas M.SalaheldinCopyright:

Available Formats

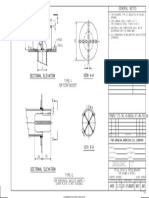

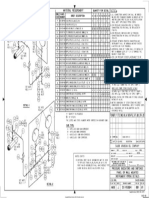

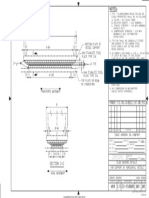

General Notes

Tan-to-Tan 8076 1. All dimensions are in (mm) unless otherwise indicated;

B Primary Tank: ID 3000, Thk 10 2. All bolt holes shall straddle the tank main axis;

3. All shell, heads and nozzles welding shall be full pentetration

7100

7750

Sampling/Guage Hatch

(N5)

(N4)

Seondary Tank: ID 3150, Thk 10

weld;

4. Striker plates are installed under each group of nozzles.

Collar Plate 5. All sharp corners shall be grounded off.

1990 1990 6. Pressure Pneumatic test procedure:

Datum

After completion of the primary tank, and before

7000

(MH)

1000

6750

4500

5000

5500

7350

(HH)

(N3)

(N1)

(N2)

(N6)

assembling the secondary tank, the primary tank shall

1 be checked for leakage by applying internal air pressure

SF 38 and using soap suds, linseed oil or equivalent material

Covered Hinged Manway for detection of leaks. The test pressure is not to be less

2 Lifting Lugs, Mesh Screen than a gauge pressure of 3 psi (20.7 kPa) nor more than

Thk 20 mm, 5 psi (34.5 kPa).

with repad 10 mm Upon completion of the finished tank, the primary tank

Collar Plate shall again be pressurized to a gauge pressure of 5 psi

(34.5 kPa) and held for 1 hour to check for leakage. A

continuous drop in pressure is considered evidence of

leakage.

While maintaining a gauge pressure of 5 psi (34.5 kPa)

on the primary tank, the space bounded by the primary

and secondary tank shall be pressurized to a gauge

pressure of 5 psi (34.5 kPa). The secondary tank shall

be checked for leakage by applying a soap suds

Secondary Dished Flanged Head solution.

Thk 8 (MAF) 7. The tanks shall be erected in accordance with the Standard for the

Installation of Oil Burning Equipment, NFPA 31 & STI P3

Primary Dished Flanged Head Requirements;

Thk 8 (MAF) 8. Galvanic reaction protection anodes as per requirements of

STI P3 shall be installed on the tank.

1 9. Tank shall be supported to the ground using:

Turnbuckles Crosby HG-226, HG-227 or HG-228 (or equivalent)

with rated capacity higher than 6.0 ton & impact capcity not less

CG

than 1.5.

Chains (if necessary) Crosby Spectrum 10 Grade 100 Alloy

Chain 1/2" (13 mm), or Crosby Spectrum 8 Grade 80 Alloy

Chain 5/8" (16 mm) .

Min. lifting angle with the horizontal axis is 60

INSTALLATION SITE:

DRAWN BY: DESIGNED BY: CHECKED BY: APPROVED BY: DATE:

(dd/mm/yyyy)

MSA MSA 2017.01.17

ARCH CIVIL STRC PAVN ELEC MECH ETLN DATE

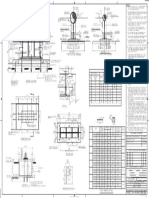

Striker Plate Striker Plate APPROVED AS SUBMITTED

Internal Ladder Interstitial Nozzle APPROVED WITH IND. CHANGES

(Galvanized) SECTION A-A Striker Plate (Leak Monitoring Nozzle) DISAPPROVED RESUBMIT

B

Secondary Steel Tank 3829

Primery Steel Tank

1

1 Steel Tank Mansory Supports

(150x150x10)

CLIENT:

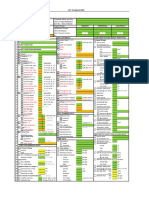

OPERATING/DESIGN DATA

Hold down Lugs

(Thk 20 mm) ITEM NO. KT-D100

TYPE OF TANK DOUBLE WALL UST (Horizontal)

OPERATING PRESSURE ATMOSPHERIC

OPERATING TEMP. (C) 50

PRODUCT STORED FUEL OIL

60 SP. GRAVITY OF LIQUID 1.1

FLASH POINT OF LIQUID (C) --

Total 5 x 2 Turnbuckles

(more than 6.0 ton Capacity) WORKING CAPACITY (Ltr) 6700

WORKING CAPACITY (Ltr) 6700

PUMP RATE (in/out) (m/Hr.) --

CONSTRUCTION MANAGER:

15 BURIAL HIEGHT (m) TBA

UPN 80 Welded to Primary Tank (Typ) DESIGN CODE & STANDARDS: UL-142 9 Edition/ STI-P3

th

(Qty 13)

ASME BPVC Section VIII, Div. 1 2015 (No Stamp)

Standoffs Detail

SECTION B-B DESIGN INT. PRESSURE (kPa) ATM + FULL OF LIQUID

CONTRACTOR:

DESIGN TEMPERATURE (C) 66

MDMT (ASME VIII-1) (C) 0

MATERIAL OF CONSTRUCTION NOZZLE SCHEDULE TANKS DETAILS

TOTAL CORR. ALL. (mm) 1.6

SHELL, HEADS (PRIM & SCONDARY TANKS) A 36 NOZZLE SIZE NECK FLANGE RE-PAD

TOTAL Qty. ONE (1) TANK NDT (ASME VIII-1) RT ( None ), UT PHASE & DISCIPLINE:

SERVICE QTY. REMARKS

NECK & FLANGES FROM PLATE A 36 MARK DN SCH./THK. RATING TYPE DIA. THK TAG No. Mnfg. S/N PWHT (ASME VIII-1) NO SHOP DRAWING

80 KT-J100 (TBL) IMPACT TEST (ASME VIII-1) Exempted UG-20 (f)

NOZZLE STANDARD FLANGES A 105 N1 INLET 1 Sch XS/80 150# WNRF - - WITH DIP PIPE STEEL STRUCTURE

NOZZLE NECKS < NPS 12 A 53 B N2 OUTLET 80 1 Sch XS/80 150# WNRF - - WITH DIP PIPE & FOOT VALVE

CERTIFICATION TESTING DRAWING TITLE:

PIPE FITTINGS A 234 WPB N3 SPARE 80 1 Sch XS/80 150# WNRF - - WITH B/F & DIP PIPE

INSPECTION Mnfg./Client/TPI (TBL) General Arrangement Drawing

BOLTS & NUTS (OUTSIDE) A 193 B7 / A 194 2H N4 VENT 80 1 Sch XS/80 150# WNRF - - WITH GOOSE NECK HOLD LIST: 1 HYDROTEST (ASME VIII-1, UL 58) (bar) N/A for

BOLTS & NUTS (INSIDE) A 193 B8M / A 194 8M N5 LEVEL TRANSMITTER 80 1 Sch XS/80 150# WNRF - - WITH PERFORATED DIP PIPE

GASKET CNAF N6 LEAK DETECTION / VENT 80 1 Sch XS/80 150# WNRF - - WITH INTERSTITIAL PIPE 1. All Nozzles sizes & location based on Piping & Instrumentation PNUMATIC TEST (UL58 Para 20.1) (psi) 3 - 5 for Fuel Oil Tank

design; EXTERNAL PRESSURE TEST (UL 58) (bar) N/A (UL58 Para.5.1.1)

EXTERNAL ATTACHMENTS A 36 HH GAUGE & SAMPLING HATCH 200 1 Sch XS/80 150# WNRF - - QUICK CLAMP HATCH 2. Spare Nozzle; 56800 Ltr Capacity

INTERNAL ATTACHMENTS A 36 / A 53 B MH MANHOLE ID 600 1 Thk 10 API 650 FLAT FACE 850 10 mm WTIH HINGED COVER

3. Cathodic Protection Anodes quantity, location and fixing detail; WEIGHT SUMMARY

4. DELETED

INTERNAL LADDER A 36 (GALVANIZED) 5. DELETED TRANSPORTATION/LIFTING (kg) TBL PROJECT NUMBER DRAWING NUMBER SHEET REV.

6. DELETED 001

NAME PLATE / BRACKET SS 304 / A 36 OPERATING (FULL OF LIQUID) (kg) TBL

7.

8.

Painting

Operating Data & Fluid Properties.

PAPER SIZE: (A1) 01

GALVANIC PROTECTION ANODES (TBL) FULL OF WATER (kg) TBL NTS 001

You might also like

- Double Wall TankDocument1 pageDouble Wall TankFerry Triyana AnirunNo ratings yet

- 2WallTank NFPA ULDocument1 page2WallTank NFPA ULPolo VarsanNo ratings yet

- ETL Pressure Relief Valves Datasheet PDFDocument6 pagesETL Pressure Relief Valves Datasheet PDFNanasaheb PatilNo ratings yet

- Storage Tanks Nozzle Orientation GuideDocument5 pagesStorage Tanks Nozzle Orientation GuideragulNo ratings yet

- STD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureDocument27 pagesSTD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureNikunj KNo ratings yet

- Customer pipe design and pulsation guidelinesDocument2 pagesCustomer pipe design and pulsation guidelinesdigecaNo ratings yet

- DC 950045 001Document1 pageDC 950045 001Abu Anas M.SalaheldinNo ratings yet

- Api 650Document42 pagesApi 650samvendan100% (1)

- IFC Series Y-Strainers: NotesDocument30 pagesIFC Series Y-Strainers: Notesmarsha.fsdNo ratings yet

- Breather Valve - PV Valve - CNC380Document2 pagesBreather Valve - PV Valve - CNC380mhidayat108No ratings yet

- Lifting Lug DesignDocument7 pagesLifting Lug DesignJens SøndergaardNo ratings yet

- Nozzle Loads As Per Shell DEPDocument4 pagesNozzle Loads As Per Shell DEPSarfaraz KhanNo ratings yet

- API 682 4th Ed DatasheetDocument2 pagesAPI 682 4th Ed DatasheetMuhammad Ghufran KhanNo ratings yet

- Requirement in EN ISO 1442 2017Document6 pagesRequirement in EN ISO 1442 2017Sơn Nguyễn TháiNo ratings yet

- Design and Analysis of Spherical Pressure Vessel UsingDocument14 pagesDesign and Analysis of Spherical Pressure Vessel UsingADitya JenaNo ratings yet

- Truck Loading Arms (D 32)Document7 pagesTruck Loading Arms (D 32)Elias EliasNo ratings yet

- 2013 SECTION IX GUIDANCE FOR USING CUSTOMARY AND SI UNITSDocument3 pages2013 SECTION IX GUIDANCE FOR USING CUSTOMARY AND SI UNITSMohdBadruddinKarimNo ratings yet

- HT Aboveground Horizontal PDFDocument4 pagesHT Aboveground Horizontal PDFSenthil KumarNo ratings yet

- FVC Catalog - UnlockedDocument80 pagesFVC Catalog - UnlockedhumbubbleNo ratings yet

- 1013 - Spec For Storage TanksDocument17 pages1013 - Spec For Storage TanksAli Hajirassouliha100% (2)

- Anchor ChairDocument3 pagesAnchor ChairrsubramaniNo ratings yet

- Anaerobic Digester CoversDocument2 pagesAnaerobic Digester CoversChris QueroNo ratings yet

- MS Data Sheet TanqueDocument2 pagesMS Data Sheet TanqueLION_FIRENo ratings yet

- Emergency Vent Cover Installation ManualDocument16 pagesEmergency Vent Cover Installation ManualandyNo ratings yet

- Pressure-Temp Chart for Materials 4 Spec-GradeDocument5 pagesPressure-Temp Chart for Materials 4 Spec-GradeWilson Ramirez ZuniniNo ratings yet

- ISO 15614-1 0 Bilfinger Salamis 19.11.2018. ISO 15614-1 N/A BIS-DK Form Number: BIS-DK-F 108Document1 pageISO 15614-1 0 Bilfinger Salamis 19.11.2018. ISO 15614-1 N/A BIS-DK Form Number: BIS-DK-F 108TomasPavlovicNo ratings yet

- CCME-PN-1180 - Environmental Guidelines For Controlling Emissions of Volatile Organic Compounds From Aboveground Storage TanksDocument38 pagesCCME-PN-1180 - Environmental Guidelines For Controlling Emissions of Volatile Organic Compounds From Aboveground Storage TanksPubcrawlNo ratings yet

- Floating Roof DesinDocument5 pagesFloating Roof Desindimdaliak_985662241No ratings yet

- Frangible Roof To Shell JointDocument1 pageFrangible Roof To Shell JointSAGARNo ratings yet

- 30 m3 LCo2 Storage Tank GA DrawingDocument1 page30 m3 LCo2 Storage Tank GA DrawingKabona FistonNo ratings yet

- Garlock - Gasket Dimensions - Catalog - Segun ASME Y DINDocument24 pagesGarlock - Gasket Dimensions - Catalog - Segun ASME Y DINkevin15vhNo ratings yet

- AWWA D100 Tension TableDocument1 pageAWWA D100 Tension Tablejojo_323No ratings yet

- Vent Silencer Specification SheetDocument2 pagesVent Silencer Specification SheetAqeel Bisma100% (1)

- Annex F Design of Tanks For Small Internal PressuresDocument9 pagesAnnex F Design of Tanks For Small Internal PressuresJamir Diaz MechanNo ratings yet

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocument5 pagesASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNo ratings yet

- Ansi Ul 142 TanksDocument1 pageAnsi Ul 142 TanksGabo Montaño MendozaNo ratings yet

- AST - Fixed Roof DesignDocument23 pagesAST - Fixed Roof DesignAntony Bruno Genewin100% (2)

- vs1 DatasheetDocument22 pagesvs1 DatasheetMojtabaNo ratings yet

- Nord Lock Washers InfoDocument8 pagesNord Lock Washers InfoMaclean ArthurNo ratings yet

- Guide FOR Asme Review Teams FOR Review of Applicants FOR Asme Certificates of Authorization (A, M, PP, S, E, H, HLW, U, UM, U2, U3, PRT and T)Document16 pagesGuide FOR Asme Review Teams FOR Review of Applicants FOR Asme Certificates of Authorization (A, M, PP, S, E, H, HLW, U, UM, U2, U3, PRT and T)Adam GrajewskiNo ratings yet

- CFD ApplicationsDocument5 pagesCFD ApplicationsavailmeNo ratings yet

- Astm F436.04 PDFDocument6 pagesAstm F436.04 PDFWelington Volpatto MoraisNo ratings yet

- 10 30 Deck DocumentationDocument93 pages10 30 Deck DocumentationDejan Deki MaticNo ratings yet

- Frangible roof joints allow emergency venting in tanksDocument2 pagesFrangible roof joints allow emergency venting in tanksShane HancockNo ratings yet

- Pressure Vessel Design Safety in Gas ProcessingDocument7 pagesPressure Vessel Design Safety in Gas ProcessingTeuku Muhammad ArrahmanNo ratings yet

- Type AB Air Gaps - Practical ExamplesDocument3 pagesType AB Air Gaps - Practical ExamplesZack ZakariaNo ratings yet

- Jack Bolt StandardDocument2 pagesJack Bolt Standard7761430No ratings yet

- Pump Selection Guide GouldsDocument24 pagesPump Selection Guide Gouldsjayaramanrathnam100% (2)

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFDocument8 pagesTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4No ratings yet

- Tank Jet MixersDocument2 pagesTank Jet MixersGabriela Axinte100% (1)

- Emergency Release Coupling: For Marine Loading ArmDocument11 pagesEmergency Release Coupling: For Marine Loading ArmShamsul Azhar SulaimanNo ratings yet

- Rectangular Tank DesignDocument9 pagesRectangular Tank DesignMiguel EspañolNo ratings yet

- Russian Codes (9.11)Document55 pagesRussian Codes (9.11)bruce lianNo ratings yet

- Installation, Operation & Maintenance Manual: Virgo Engineers LimitedDocument47 pagesInstallation, Operation & Maintenance Manual: Virgo Engineers LimitedSreenivasNo ratings yet

- JERMS-D-3205 Manufacture of Atmospheric TanksDocument39 pagesJERMS-D-3205 Manufacture of Atmospheric TanksHari BabuNo ratings yet

- Breather Valves2Document12 pagesBreather Valves2prashant_dc_in100% (1)

- Profile of the International Pump Industry: Market Prospects to 2010From EverandProfile of the International Pump Industry: Market Prospects to 2010Rating: 1 out of 5 stars1/5 (1)

- SieyuanDocument4 pagesSieyuandanny maciasNo ratings yet

- Top View: Resultant Consulting EnginersDocument1 pageTop View: Resultant Consulting EnginersEnrique RafaelNo ratings yet

- ELECTRIC LAYOUT-ModelDocument1 pageELECTRIC LAYOUT-Modelmanasa manasaNo ratings yet

- Special-2 Stainless Steel EnclosureDocument1 pageSpecial-2 Stainless Steel EnclosureAbu Anas M.SalaheldinNo ratings yet

- Plasite 7159 PDSDocument4 pagesPlasite 7159 PDSAbu Anas M.SalaheldinNo ratings yet

- Iso 10423-2022Document12 pagesIso 10423-2022Abu Anas M.SalaheldinNo ratings yet

- 2014 Yang MaterialEffectonShrinkage WJ 2014 11 s421Document11 pages2014 Yang MaterialEffectonShrinkage WJ 2014 11 s421Abu Anas M.SalaheldinNo ratings yet

- DD 950008 001Document1 pageDD 950008 001Abu Anas M.SalaheldinNo ratings yet

- Comparative Tracking Index of Electrical Insulating MaterialsDocument6 pagesComparative Tracking Index of Electrical Insulating MaterialsAbu Anas M.SalaheldinNo ratings yet

- BGAS QustionDocument47 pagesBGAS QustionAbu Anas M.SalaheldinNo ratings yet

- Esab Xpert 7018 Low Hydrogen ElectrodeDocument1 pageEsab Xpert 7018 Low Hydrogen ElectrodeAbu Anas M.SalaheldinNo ratings yet

- Hydraulics - Offshore SuppliesDocument1,214 pagesHydraulics - Offshore SuppliesAbu Anas M.SalaheldinNo ratings yet

- Stauffenberg RBW5RUL PDFDocument172 pagesStauffenberg RBW5RUL PDFErikas AbepaNo ratings yet

- HEAVY WALLED PV MANUFACTURINGDocument28 pagesHEAVY WALLED PV MANUFACTURINGAbu Anas M.SalaheldinNo ratings yet

- Buttweldshrinkagepaper BasavarajuDocument9 pagesButtweldshrinkagepaper BasavarajuAbu Anas M.SalaheldinNo ratings yet

- DD-950005, Rev 00, SHT 001, 05.31.1985 PDFDocument1 pageDD-950005, Rev 00, SHT 001, 05.31.1985 PDFRami ELLOUMINo ratings yet

- DC 950042 001Document1 pageDC 950042 001Abu Anas M.SalaheldinNo ratings yet

- Metals 11 00568 v2Document18 pagesMetals 11 00568 v2Abu Anas M.SalaheldinNo ratings yet

- Aa 036025 001Document1 pageAa 036025 001Abu Anas M.SalaheldinNo ratings yet

- DD-950005, Rev 00, SHT 001, 05.31.1985 PDFDocument1 pageDD-950005, Rev 00, SHT 001, 05.31.1985 PDFRami ELLOUMINo ratings yet

- DC 950041 001Document1 pageDC 950041 001Abu Anas M.SalaheldinNo ratings yet

- Notes:: List of Material Detail Qty. ForDocument1 pageNotes:: List of Material Detail Qty. ForAbu Anas M.SalaheldinNo ratings yet

- DC 950042 001Document1 pageDC 950042 001Abu Anas M.SalaheldinNo ratings yet

- DC 950045 001Document1 pageDC 950045 001Abu Anas M.SalaheldinNo ratings yet

- DD 950008 001Document1 pageDD 950008 001Abu Anas M.SalaheldinNo ratings yet

- DC 950041 001Document1 pageDC 950041 001Abu Anas M.SalaheldinNo ratings yet

- Aa 036025 002Document1 pageAa 036025 002Abu Anas M.SalaheldinNo ratings yet

- DD 950008 001Document1 pageDD 950008 001Abu Anas M.SalaheldinNo ratings yet

- Aa 036007 002Document1 pageAa 036007 002Abu Anas M.SalaheldinNo ratings yet

- Notes:: List of Material Detail Qty. ForDocument1 pageNotes:: List of Material Detail Qty. ForAbu Anas M.SalaheldinNo ratings yet

- Aa 036015 001Document1 pageAa 036015 001narutothunderjet216No ratings yet

- AC-036413-001 Orifice Flange AssemblyDocument1 pageAC-036413-001 Orifice Flange Assemblynarutothunderjet216No ratings yet

- Notes:: Typical Installation DrawingDocument1 pageNotes:: Typical Installation DrawingAbu Anas M.SalaheldinNo ratings yet

- Division of WorkDocument19 pagesDivision of WorkBharadwaj KwcNo ratings yet

- Introduction To Asset Pricing ModelDocument8 pagesIntroduction To Asset Pricing ModelHannah NazirNo ratings yet

- MBA Capstone Module GuideDocument25 pagesMBA Capstone Module GuideGennelyn Grace PenaredondoNo ratings yet

- Variety July 19 2017Document130 pagesVariety July 19 2017jcramirezfigueroaNo ratings yet

- Human Rights Violations in North KoreaDocument340 pagesHuman Rights Violations in North KoreaKorea Pscore100% (3)

- Samuel Johnson Short Fiction Analysis - EssayDocument2 pagesSamuel Johnson Short Fiction Analysis - EssayATRI BHATTACHARYYANo ratings yet

- 8D6N Europe WonderDocument2 pages8D6N Europe WonderEthan ExpressivoNo ratings yet

- Civil Air Patrol News - Mar 2007Document60 pagesCivil Air Patrol News - Mar 2007CAP History LibraryNo ratings yet

- Finals ReviewerDocument4 pagesFinals ReviewerElmer Dela CruzNo ratings yet

- Phone, PTCs, Pots, and Delay LinesDocument1 pagePhone, PTCs, Pots, and Delay LinesamjadalisyedNo ratings yet

- Judgment at Nuremberg - Robert ShnayersonDocument6 pagesJudgment at Nuremberg - Robert ShnayersonroalegianiNo ratings yet

- Montaner Vs Sharia District Court - G.R. No. 174975. January 20, 2009Document6 pagesMontaner Vs Sharia District Court - G.R. No. 174975. January 20, 2009Ebbe DyNo ratings yet

- Volume 42, Issue 52 - December 30, 2011Document44 pagesVolume 42, Issue 52 - December 30, 2011BladeNo ratings yet

- Audio Script + Key (Updated)Document6 pagesAudio Script + Key (Updated)khoareviewNo ratings yet

- VA Response On Home Loans For Veterans Working in Marijuana IndustryDocument1 pageVA Response On Home Loans For Veterans Working in Marijuana IndustryMarijuana MomentNo ratings yet

- The Christian WalkDocument4 pagesThe Christian Walkapi-3805388No ratings yet

- Uttara ClubDocument16 pagesUttara ClubAccounts Dhaka Office75% (4)

- Ecommerce Product: Why People Should Buy Your Product?Document3 pagesEcommerce Product: Why People Should Buy Your Product?khanh nguyenNo ratings yet

- Ra 4136Document12 pagesRa 4136Rizaida DiestoNo ratings yet

- Accounting Time Allowed - 2 Hours Total Marks - 100: You Are Required To Calculate TheDocument3 pagesAccounting Time Allowed - 2 Hours Total Marks - 100: You Are Required To Calculate TheNew IdNo ratings yet

- Installation and repair of fibre optic cable SWMSDocument3 pagesInstallation and repair of fibre optic cable SWMSBento Box100% (1)

- The Call of CthulhuDocument15 pagesThe Call of CthulhuCerrüter LaudeNo ratings yet

- 50Document3 pages50sv03No ratings yet

- AC4301 FinalExam 2020-21 SemA AnsDocument9 pagesAC4301 FinalExam 2020-21 SemA AnslawlokyiNo ratings yet

- Effectiveness of Environmental Impact Assessment Process in The MDocument136 pagesEffectiveness of Environmental Impact Assessment Process in The MJoel AntonyNo ratings yet

- SPY-1 Family Brochure 6-PagerDocument6 pagesSPY-1 Family Brochure 6-Pagerfox40No ratings yet

- Emergency Loan Pawnshop v. Court of Appeals, G.R. No. 129184, February 28Document3 pagesEmergency Loan Pawnshop v. Court of Appeals, G.R. No. 129184, February 28Alan Vincent FontanosaNo ratings yet

- Noli Me TangereDocument26 pagesNoli Me TangereJocelyn GrandezNo ratings yet

- Civil Unrest in Eswatini. Commission On Human Rights 2021Document15 pagesCivil Unrest in Eswatini. Commission On Human Rights 2021Richard RooneyNo ratings yet

- Supply Chain Management PepsiDocument25 pagesSupply Chain Management PepsivenkateshNo ratings yet