Professional Documents

Culture Documents

Filled Composite Column

Uploaded by

AlphaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Filled Composite Column

Uploaded by

AlphaCopyright:

Available Formats

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

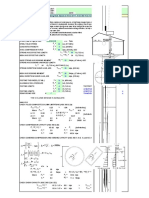

Filled Composite Column Design Based on AISC 360-10 & ACI 318-11

INPUT DATA & DESIGN SUMMARY

STEEL SHAPE (Tube or Pipe) & SIZE HSS10X8X1/2 < == Tube

STEEL YIELD STRESS Fy = 46 ksi

CONCRETE STRENGTH fc' = 4 ksi

AXIAL COMPRESSION FORCE Pr = 100 kips, ASD

STRONG AXIS EFFECTIVE LENGTH kLx = 40 ft

WEAK AXIS EFFECTIVE LENGTH kLy = 3 ft

STRONG AXIS BENDING MOMENT Mrx = 15 ft-kips, ASD

STRONG AXIS BENDING UNBRACED LENGTH Lb = 40 ft, (AISC 360-10 F2.2.c)

STRONG DIRECTION SHEAR LOAD, ASD Vstrong = 50 kips

WEAK AXIS BENDING MOMENT Mry = 20 ft-kips, ASD

WEAK DIRECTION SHEAR LOAD, ASD Vweak = 30 kips

THE DESIGN IS ADEQUATE.

ANALYSIS

CHECK FILLED COMPOSITE COLUMN LIMITATIONS (AISC 360-10, I2.2a)

Asteel / Atotal = 0.20 > 1.0% [Satisfactory]

Where Asteel = 15.3 in2

Atotal = 78.3 in2

b/t= 16.00 < 2.26 (E / Fy)0.5 = 56.75

[Satisfactory]

D/t= N/A 0.15 E / Fy = 94.57

Where b= 8.0 in

D= N/A E= 29000 ksi

t= 0.5 in

CHECK COMPRESSION CAPACITY (AISC 360-10, I2.2b)

Pc = P n / c = 142.77 kips > Pr [Satisfactory]

Where c = 2.0 Pn = 285.54254 kips

C2 = 0.85 P0 = 918 kips

C3 = 0.90 Pe = 325.59012 kips

CHECK COMBINED COMPRESSION AND BENDING CAPACITY (AISC 360-10 I1.1b & I4, and ACI 318-11 Chapter 9 & 10)

2 0.85 f '

C '

o , E c 57 f C , E s 29000 ksi

Ec

c c 2

0.85 f '

C

2 , for 0 c o

f C

o o

'

0.85 f C

, for c o

s E s , for s t

f

S

f y , for s t

C= 5.45 in

Pc = Pn / b = 100 kips

Mc = Mn / b = 86 ft-kips > Mu / (b / b) = (Mrx2 + Mry2)0.5 = 25.0 ft-kips

Where b = 1.67 Pn = 167 kips [Satisfactory]

b = 0.9 Mn = 143.1 ft-kips

CHECK SHEAR CAPACITY (AISC 360-10, I2.2d & G2)

Vn,strong / v = 184.0 / 1.67 = 110.2 kips > Vstrong = 50.0 kips [Satisfactory]

Vn,weak / v = 147.2 / 1.67 = 88.1 kips > Vweak = 30.0 kips [Satisfactory]

You might also like

- 3 - Flush End Plate Moment Conn To Beam WebDocument11 pages3 - Flush End Plate Moment Conn To Beam Webabdul khaderNo ratings yet

- Construction Inspection ManualDocument261 pagesConstruction Inspection ManualMetalloy97% (33)

- φ - Vc b f ' c Vu b Tu - P: Design for Torsion and Shear According to ACI-318-99Document2 pagesφ - Vc b f ' c Vu b Tu - P: Design for Torsion and Shear According to ACI-318-99mahmoud IbrahemNo ratings yet

- SITE/10/20 Checklist for Screeding ProjectDocument5 pagesSITE/10/20 Checklist for Screeding ProjectAlphaNo ratings yet

- Design of Corbel Shear Reinforcement (ACI 318-08Document2 pagesDesign of Corbel Shear Reinforcement (ACI 318-08Shamim Ahsan ZuberyNo ratings yet

- Steel Structure Construction Inspection Course Guide PDFDocument274 pagesSteel Structure Construction Inspection Course Guide PDFladhytiaputraNo ratings yet

- MAS Assessment Exam Answer Key SolutionDocument7 pagesMAS Assessment Exam Answer Key SolutionJonalyn JavierNo ratings yet

- Plastering Work ChecklistDocument1 pagePlastering Work ChecklistAlphaNo ratings yet

- 1 Input Data: Hilti PROFIS Engineering 3.1.1Document10 pages1 Input Data: Hilti PROFIS Engineering 3.1.1Zaido Al HalabiNo ratings yet

- Design of Raft FoundationDocument9 pagesDesign of Raft FoundationAnonymous ciKyr0tNo ratings yet

- Double Angle CapacityDocument2 pagesDouble Angle CapacityAlphaNo ratings yet

- Uplift With Moment CalculationDocument4 pagesUplift With Moment CalculationdennykvgNo ratings yet

- Tower Crane FoundationDocument65 pagesTower Crane FoundationHayder Hasan100% (2)

- Chap 7 Foundation DesignDocument36 pagesChap 7 Foundation DesignZulhasri WahapNo ratings yet

- Best Practice Guidelines For Concrete Placement Planning, Field Testing, and Sample Collection PDFDocument48 pagesBest Practice Guidelines For Concrete Placement Planning, Field Testing, and Sample Collection PDFandriessebastia9395No ratings yet

- Slab Surface Prevention RepairDocument16 pagesSlab Surface Prevention Repairambryx2001No ratings yet

- Workability and Quality Control of Concrete PDFDocument268 pagesWorkability and Quality Control of Concrete PDFFernando González100% (1)

- Workability and Quality Control of Concrete PDFDocument268 pagesWorkability and Quality Control of Concrete PDFFernando González100% (1)

- BW - Calculation Sheet - Rev01Document15 pagesBW - Calculation Sheet - Rev01Ernest NavarroNo ratings yet

- DoubleAngleCapacityDocument2 pagesDoubleAngleCapacityIsprotec IngenieriaNo ratings yet

- Unique Solutions in Bored PilesDocument72 pagesUnique Solutions in Bored PilesAlphaNo ratings yet

- Design of Reinforced Concrete Shear WallDocument15 pagesDesign of Reinforced Concrete Shear WallAnonymous nwByj9L0% (1)

- Pile Cap Design For 3-Piles Pattern Based On ACI 318-14Document18 pagesPile Cap Design For 3-Piles Pattern Based On ACI 318-14VikasVarmaNo ratings yet

- Column W10x49 2L6x4x1/2 BraceDocument4 pagesColumn W10x49 2L6x4x1/2 BraceDario Federico Noguez GonzalézNo ratings yet

- History of The Indian Caste System and Its Impact Today MA ThesisDocument35 pagesHistory of The Indian Caste System and Its Impact Today MA Thesisjupiterjjrm100% (1)

- Moment Connection Using Mathcad PDFDocument11 pagesMoment Connection Using Mathcad PDFbong2rmNo ratings yet

- CorbelDocument2 pagesCorbelAbdullah Al MamunNo ratings yet

- 6-Bracing Connection - TDocument2 pages6-Bracing Connection - TMUTHUKKUMARAMNo ratings yet

- BP2Document3 pagesBP2insane88No ratings yet

- PRYING9.xls AISC Prying Action AnalysisDocument5 pagesPRYING9.xls AISC Prying Action AnalysisCarlos Valverde PortillaNo ratings yet

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionDocument11 pagesRean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionrbalmodalNo ratings yet

- Concrete Vibrators 1003 HandbookDocument8 pagesConcrete Vibrators 1003 HandbookMohammad Saleem ZahidiNo ratings yet

- Filled Composite ColumnDocument1 pageFilled Composite ColumnLloyd R. PonceNo ratings yet

- Flitch Plate BeamDocument1 pageFlitch Plate Beamdnl_vicarsNo ratings yet

- T-Shape Member Capacity Based on AISC 360-10Document1 pageT-Shape Member Capacity Based on AISC 360-10Amey GudigarNo ratings yet

- Construction Site Best Management Practices HandbookDocument326 pagesConstruction Site Best Management Practices HandbookAlphaNo ratings yet

- Wind ASCE 7-10 V 1.02-2Document188 pagesWind ASCE 7-10 V 1.02-2Dass DassNo ratings yet

- Double Angle CapacityDocument2 pagesDouble Angle CapacityAmey GudigarNo ratings yet

- RV Design of Column Base PlateDocument2 pagesRV Design of Column Base Plateapi-190618655No ratings yet

- Strap Footing TheoryDocument4 pagesStrap Footing TheorySwopnilOjhaNo ratings yet

- Composite BeamDocument7 pagesComposite Beamsaif.mullaNo ratings yet

- Wind Load Calculation 29-08-2018Document4 pagesWind Load Calculation 29-08-2018mbhanusagar.keynesNo ratings yet

- Anchorage To ConcreteDocument10 pagesAnchorage To ConcretemakakkNo ratings yet

- Structural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Document39 pagesStructural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Henj MirasolNo ratings yet

- Drop Panel CalculationDocument2 pagesDrop Panel Calculationsandiok86No ratings yet

- Reference Output Calculations & FormulasDocument4 pagesReference Output Calculations & FormulasAddrien DanielNo ratings yet

- "EMBEDPL2" - Embedment Strength of Stud Plate: Program DescriptionDocument23 pages"EMBEDPL2" - Embedment Strength of Stud Plate: Program DescriptionBolarinwaNo ratings yet

- ACI 209R-92 - Effects of creep, shrinkage, and temperature in concreteDocument15 pagesACI 209R-92 - Effects of creep, shrinkage, and temperature in concreteHussein BeqaiNo ratings yet

- ASCE7 Wind For Cladding CN8 Block BDocument4 pagesASCE7 Wind For Cladding CN8 Block BCheng KoNo ratings yet

- HSS8X6X1/2: The Column Design Is AdequateDocument24 pagesHSS8X6X1/2: The Column Design Is AdequateSehna SerajNo ratings yet

- Mathcad - 21-Design of StairDocument3 pagesMathcad - 21-Design of StairMrAlittle FingerNo ratings yet

- C4-Interier Composite Beam PerpendicularDocument10 pagesC4-Interier Composite Beam PerpendicularvpjagannaathNo ratings yet

- Super Composite ColumnDocument2 pagesSuper Composite ColumnCheng Por EngNo ratings yet

- Corbel BS8110Document3 pagesCorbel BS8110Nugraha BintangNo ratings yet

- ACI Moment Coefficient Design AID PDFDocument13 pagesACI Moment Coefficient Design AID PDFSufian Ahmad50% (4)

- Composite Slab Deck ACI318Document4 pagesComposite Slab Deck ACI318jflttwNo ratings yet

- Repport Steel Structure PDFDocument111 pagesRepport Steel Structure PDFAnonymous fxqnhfKNo ratings yet

- Airbus Reference Language AbbreviationsDocument66 pagesAirbus Reference Language Abbreviations862405No ratings yet

- ACI 305.1-06 Specification For Hot Weather Concreting PDFDocument12 pagesACI 305.1-06 Specification For Hot Weather Concreting PDFNafnaf TroopNo ratings yet

- 5.2.7.4 Concrete Contractor Control PlanDocument5 pages5.2.7.4 Concrete Contractor Control PlanwinasharNo ratings yet

- Cellular BeamDocument14 pagesCellular BeamAlphaNo ratings yet

- Check Crack Width in Beam As Per IS 456Document4 pagesCheck Crack Width in Beam As Per IS 456Rupali ChadhaNo ratings yet

- ACCA P1 Governance, Risk, and Ethics - Revision QuestionsDocument2 pagesACCA P1 Governance, Risk, and Ethics - Revision QuestionsChan Tsu ChongNo ratings yet

- SOF IEO Sample Paper Class 4Document2 pagesSOF IEO Sample Paper Class 4Rajesh RNo ratings yet

- Method Statement For Pile Integrity Test ProcedureDocument3 pagesMethod Statement For Pile Integrity Test ProcedureDeny Cahyo N100% (2)

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionDocument6 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionVenu GopalNo ratings yet

- Software Verification: Example 17Document8 pagesSoftware Verification: Example 17sancloudNo ratings yet

- Beam DesignDocument7 pagesBeam DesignKasi ViswanathanNo ratings yet

- RC Stair SlabsDocument3 pagesRC Stair SlabsAssad Mohammed AliNo ratings yet

- Nib CalculationDocument1 pageNib CalculationKen LuuNo ratings yet

- Sway Frame Steel Column DesignDocument1 pageSway Frame Steel Column DesignChirianu MarianNo ratings yet

- BNBC 2015 Earthquake LoadingDocument2 pagesBNBC 2015 Earthquake LoadingSA023100% (1)

- Members With Combined Bending and Axial ForceDocument32 pagesMembers With Combined Bending and Axial ForceJohn RomanusNo ratings yet

- Steel Building Brace Connection DesignDocument4 pagesSteel Building Brace Connection Designmoganna73No ratings yet

- Openwell StaircaseDocument8 pagesOpenwell StaircaseAbdul AzeemNo ratings yet

- Wall Design ACI318M-02 Bearing Designed by ACI Section 14.5Document2 pagesWall Design ACI318M-02 Bearing Designed by ACI Section 14.5EngDbtNo ratings yet

- TSS 35 / 205 sheet thickness & load data for aluminium & steel roofingDocument1 pageTSS 35 / 205 sheet thickness & load data for aluminium & steel roofingAkhil VNNo ratings yet

- Shear Wall Design-ACI-318-14Document30 pagesShear Wall Design-ACI-318-14Christian ReedNo ratings yet

- Filled Composite Column Design Based On AISC 360-10/16 & ACI 318-19Document1 pageFilled Composite Column Design Based On AISC 360-10/16 & ACI 318-19Prolay MannaNo ratings yet

- The Design Is Adequate.: Ksi, (290 Mpa) FT, (4.27 M) Kips, (27 KN) W KLF, (2 KN / M) F (0.4 KN) (3.66 M) F H PDocument8 pagesThe Design Is Adequate.: Ksi, (290 Mpa) FT, (4.27 M) Kips, (27 KN) W KLF, (2 KN / M) F (0.4 KN) (3.66 M) F H PSureshbabu NarayanasamyNo ratings yet

- PD Pipe Support Drawing ExamplesDocument16 pagesPD Pipe Support Drawing ExamplesAlphaNo ratings yet

- RISK ASSESSMENT - Use of Grinders: S Severity Rating L Likelyhood RR Risk RatingDocument4 pagesRISK ASSESSMENT - Use of Grinders: S Severity Rating L Likelyhood RR Risk RatingAlphaNo ratings yet

- Procedure For Concrete Compression TestDocument6 pagesProcedure For Concrete Compression TestAlphaNo ratings yet

- AAADocument7 pagesAAAAlphaNo ratings yet

- Truss Terminology PDFDocument3 pagesTruss Terminology PDFNerinel CoronadoNo ratings yet

- Welding Qualityplansample PDFDocument20 pagesWelding Qualityplansample PDFAlphaNo ratings yet

- Best Practice Guide - Compaction & Backfill: Photograph Site On ArrivalDocument2 pagesBest Practice Guide - Compaction & Backfill: Photograph Site On ArrivalAlphaNo ratings yet

- Methodstm Leanconcrete 141120013214 Conversion Gate01Document7 pagesMethodstm Leanconcrete 141120013214 Conversion Gate01Zitheeq UmarNo ratings yet

- Concrete Construction Article PDF - Checklist For Safe Construction of Formwork PDFDocument3 pagesConcrete Construction Article PDF - Checklist For Safe Construction of Formwork PDFrony1346No ratings yet

- Concrete Construction Article PDF - Checklist For Safe Construction of Formwork PDFDocument3 pagesConcrete Construction Article PDF - Checklist For Safe Construction of Formwork PDFrony1346No ratings yet

- Basic Formwork & Concreting Checklist For Builders and Building Trades ContractorsDocument2 pagesBasic Formwork & Concreting Checklist For Builders and Building Trades ContractorsAlphaNo ratings yet

- 2008 2 2 3 15 A Study On Construction Management Contract For Construction Project PDFDocument6 pages2008 2 2 3 15 A Study On Construction Management Contract For Construction Project PDFAlphaNo ratings yet

- The Effects of Drilling Slurry On Reinforcement in Drilled Shaft PDFDocument163 pagesThe Effects of Drilling Slurry On Reinforcement in Drilled Shaft PDFGibral MaulanaNo ratings yet

- AAADocument7 pagesAAAAlphaNo ratings yet

- 3.6 God Provides Water and Food MaryDocument22 pages3.6 God Provides Water and Food MaryHadassa ArzagaNo ratings yet

- Course Code: Hrm353 L1Document26 pagesCourse Code: Hrm353 L1Jaskiran KaurNo ratings yet

- On-Chip ESD Protection Design For IcsDocument14 pagesOn-Chip ESD Protection Design For IcsMK BricksNo ratings yet

- DISADVANTAGESDocument3 pagesDISADVANTAGESMhd MiranNo ratings yet

- Mediclaim - ChecklistDocument4 pagesMediclaim - ChecklistKarthi KeyanNo ratings yet

- IPIECA - IOGP - The Global Distribution and Assessment of Major Oil Spill Response ResourcesDocument40 pagesIPIECA - IOGP - The Global Distribution and Assessment of Major Oil Spill Response ResourcesОлегNo ratings yet

- Axis Bank Placement Paper Interview Questions 48072Document3 pagesAxis Bank Placement Paper Interview Questions 48072Ravi RanjanNo ratings yet

- Effects of Zero Moment of Truth On Consumer Behavior For FMCGDocument14 pagesEffects of Zero Moment of Truth On Consumer Behavior For FMCGBoogii EnkhboldNo ratings yet

- Attribute Achievement FormDocument15 pagesAttribute Achievement FormMiguel MenesesNo ratings yet

- Move Over G7, It's Time For A New and Improved G11: Long ShadowDocument16 pagesMove Over G7, It's Time For A New and Improved G11: Long ShadowVidhi SharmaNo ratings yet

- Pantone and K100 Reverse White MedicineDocument16 pagesPantone and K100 Reverse White MedicinepaanarNo ratings yet

- Uvas CaractDocument10 pagesUvas CaractgondeluNo ratings yet

- REVISION OF INTEREST RATES ON DEPOSITS IN SANGAREDDYDocument3 pagesREVISION OF INTEREST RATES ON DEPOSITS IN SANGAREDDYSRINIVASARAO JONNALANo ratings yet

- Duet Embedded Memories and Logic Libraries For TSMC 28HP: HighlightsDocument5 pagesDuet Embedded Memories and Logic Libraries For TSMC 28HP: HighlightsmanojkumarNo ratings yet

- Investigation Report on Engine Room Fire on Ferry BerlinDocument63 pagesInvestigation Report on Engine Room Fire on Ferry Berlin卓文翔No ratings yet

- FILM STUDIES CORE COURSE GUIDEDocument230 pagesFILM STUDIES CORE COURSE GUIDEAmaldevvsNo ratings yet

- Eurapipe ABS Pipe - Fittings ManualDocument52 pagesEurapipe ABS Pipe - Fittings ManualLê Minh ĐứcNo ratings yet

- Communication in Application: WhatsappDocument18 pagesCommunication in Application: WhatsappNurul SuhanaNo ratings yet

- Wicks Angela, Roethlein Christopher - A Satisfaction - Based Definition of QualityDocument1 pageWicks Angela, Roethlein Christopher - A Satisfaction - Based Definition of Qualityalfdjole0% (1)

- Arts and Culture An Introduction To The Humanities Combined Volume 4th Edition Benton Test Bank Full Chapter PDFDocument22 pagesArts and Culture An Introduction To The Humanities Combined Volume 4th Edition Benton Test Bank Full Chapter PDFoutscoutumbellar.2e8na100% (15)

- A-00 IndexDocument10 pagesA-00 IndexNizarHamrouniNo ratings yet

- UEME 1143 - Dynamics: AssignmentDocument4 pagesUEME 1143 - Dynamics: Assignmentshikai towNo ratings yet

- Ecma L1221BR3 PD02 05172016Document2 pagesEcma L1221BR3 PD02 05172016Anil JindalNo ratings yet

- CVCITC Smoke-Free Workplace Policy & ProgramDocument2 pagesCVCITC Smoke-Free Workplace Policy & ProgramKristine Joy CabujatNo ratings yet

- Long Standoff Demolition Warheads For Armor, Masonry and Concrete TargetsDocument27 pagesLong Standoff Demolition Warheads For Armor, Masonry and Concrete Targetsahky7No ratings yet