Professional Documents

Culture Documents

TDS-PLC 118 ST

Uploaded by

rowatersCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS-PLC 118 ST

Uploaded by

rowatersCopyright:

Available Formats

Technical Data Sheet

PLC 118 ST

PRODUCT

SELF - PRIMING EPOXY MASTIC PHYSICAL DATA

Finish : semi-gloss

DESCRIPTION No. of Components : Two

PLC 118 ST is a two-component surface tolerant anti- Volume Solids : 85%

corrosion epoxy coating for steel and concrete surfaces. Mixing Ratio : 1 part A to 1 part B

It is a self-priming coating for old and painted steel by volume

surfaces. It is highly recommended as a maintenance Recommended Thickness : 100 - 300 microns DFT

coating on rusty or painted surface where abrasive per coat

blasting is not possible. PLC 118 ST can be top-coated Theoretical Coverage : 8.5 m2/litre @ 100

with alkyd, acrylic, polyurethane, vinyl and other top- microns DFT

coats. (WFT = 118 microns)

No. of coats recommended : One or Two.

RECOMMENDED USES Drying Time : Touch dry - 3 hours

PLC 118 ST is particularly recommended for new Open for traffic - 24

construction as well as maintenance painting of rusty hours

steel or upgrading old coatings. Ideal for steel buildings, Full cure - 7 days

piping, machinery, equipment, bridges, tank and Pot life : 2 hours (varies with

exposed structural steel. Excellent for waste water tank temperature)

lining and corrosion protection for re-bars in structure Packing Size : 5 litres & 20 litres.

repair works. One or two coats is required for most

applications. Hand or power tool cleaning is acceptable APPLICATION INSTRUCTIONS

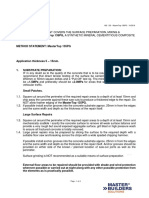

for rusty surface. SURFACE PREPARATION :

Steel : The most recommended surface preparation

ADVANTAGES method for anti-corrosion applications is abrasive

blasting to SSPC-SP10 near white metal finish but for

Easy application - Applied by roller or spray.

areas where abrasive blasting is not practical, PLC

Chemical resistant - resistant to wide range of

118 ST can be applied on power tool prepared

industrial chemicals.

surfaces.

High build - can build up to 300 microns DFT in one

coat. MIXING : Mix component A thoroughly then mix in

Anti-corrosion - excellent protection properties for component B and mix till homogeneous. Do not mix

steel surfaces. more materials than the quantity to be consumed

Surface tolerant adhere well to surface with within the pot life.

minimum surface preparation and old coatings.

Good adhesion - Adhere very well to almost any THINNING : Thin not more than 10% by volume with

surface. PLC Thinner #3 only when necessary for Workability.

Self-priming - No primer required.

APPLICATION : PLC 118 ST can be applied by

roller, brush, conventional spray and airless spray.

For steel surfaces, do not apply when the surface

temperature is less than 3C above the dew point.

Apply by roller using parallel passes in one direction.

For detailed application procedures, please contact

PLC Laboratory Technical Division.

CLEANING : Clean all application tools with PLC

Cleaner #2 immediately after use.

Tel : 603-80604584 Fax : 603-80604676 Email : email@plc.com.my Website : www.plc.com.my Rev.6/12.11

You might also like

- Structural Steel ErectionDocument7 pagesStructural Steel Erectionzaki fadlNo ratings yet

- Periodic Structural Inspection of Existing BuildingDocument14 pagesPeriodic Structural Inspection of Existing BuildingSarah SullivanNo ratings yet

- Anchored Piled Retaining Wall 24-06-2016Document9 pagesAnchored Piled Retaining Wall 24-06-2016rowatersNo ratings yet

- AW60-41SN Vac Test LocationsDocument5 pagesAW60-41SN Vac Test Locations2791957No ratings yet

- Work Program GuidelinesDocument29 pagesWork Program Guidelinesrowaters100% (3)

- NAAMM NOMMA Finishes Manual PDFDocument116 pagesNAAMM NOMMA Finishes Manual PDFMichaelTorresNo ratings yet

- Particular Specification Plastering Work: (For Building & Area Development Work) Indian StandardsDocument15 pagesParticular Specification Plastering Work: (For Building & Area Development Work) Indian StandardsRamesh KomiriNo ratings yet

- MS - MasterTop 135PGDocument4 pagesMS - MasterTop 135PGAzhar Shaikh100% (1)

- Method Statement Repairing Honey OmbDocument3 pagesMethod Statement Repairing Honey Ombmamat hamzahNo ratings yet

- Asian Paints (Technical Details) PDFDocument2 pagesAsian Paints (Technical Details) PDFanon_87010987350% (2)

- Silver Schmidt ManualDocument47 pagesSilver Schmidt ManualEl LlacunaNo ratings yet

- MS - Sikadur-732 (Application of Epoxy Bonding Agent) (Ver.01)Document4 pagesMS - Sikadur-732 (Application of Epoxy Bonding Agent) (Ver.01)Jerome Li100% (2)

- Structured Method Statement For Concrete Repair - 6Document15 pagesStructured Method Statement For Concrete Repair - 6m.umarNo ratings yet

- Construction Method Statement For ApplicDocument5 pagesConstruction Method Statement For ApplicKhasan MustofaNo ratings yet

- 29 Method Statement BRICK WORKDocument6 pages29 Method Statement BRICK WORKSusil Kumar SahooNo ratings yet

- Construction material list and diagramDocument1 pageConstruction material list and diagramDexter Lex F. SatanaNo ratings yet

- 0 - Sika Grout With Sikadur 732 Epoxy Bonding AgentDocument4 pages0 - Sika Grout With Sikadur 732 Epoxy Bonding AgentRA SamsonNo ratings yet

- 4 Cement Slurries AdditivesDocument71 pages4 Cement Slurries AdditivesLenin Diaz100% (1)

- Probable Maximum Precipitation Analysis BakunDocument7 pagesProbable Maximum Precipitation Analysis BakunrowatersNo ratings yet

- TeleStacker® ConveyorDocument4 pagesTeleStacker® ConveyorSuperior IndustriesNo ratings yet

- Method of StatementDocument8 pagesMethod of StatementHisham BerrasaliNo ratings yet

- Niessen, Walter R.-Combustion and Incineration Processes - Applications in Environmental Engineering, Fourth Edition-CRC Press (2010)Document800 pagesNiessen, Walter R.-Combustion and Incineration Processes - Applications in Environmental Engineering, Fourth Edition-CRC Press (2010)Mohamed Tarek KamarNo ratings yet

- Underground Cable System Design Manual Laying Cables Pipes DuctsDocument6 pagesUnderground Cable System Design Manual Laying Cables Pipes Ductsmajorabs100% (3)

- D Internet Myiemorgmy Intranet Assets Doc Alldoc Document 13074 SPJ S11-LuarDocument41 pagesD Internet Myiemorgmy Intranet Assets Doc Alldoc Document 13074 SPJ S11-LuarMuhammad Hafizuddin100% (1)

- Scope of Work-UnipoleDocument2 pagesScope of Work-UnipoleAnonymous ikcpefzUXtNo ratings yet

- Inspection, Good Construction Practices, Workmanship and Codal ProvisionsDocument31 pagesInspection, Good Construction Practices, Workmanship and Codal ProvisionsThiyagarajan TiguNo ratings yet

- Cem Tec White PuDocument2 pagesCem Tec White Pupravi3434No ratings yet

- Corrosion KING HBE (Primer All User) Tech. DataDocument2 pagesCorrosion KING HBE (Primer All User) Tech. Datamuhamadrafie1975No ratings yet

- Birla Aerocon AAC Blocks - Literature V01 PDFDocument4 pagesBirla Aerocon AAC Blocks - Literature V01 PDFdhruvNo ratings yet

- Fosroc Nitocote EM 300 protects concrete from corrosionDocument2 pagesFosroc Nitocote EM 300 protects concrete from corrosionAarish Khan100% (1)

- 187 NanoGrout EGDocument2 pages187 NanoGrout EGTristan Irvin Asi100% (3)

- Setseal B - TDSDocument4 pagesSetseal B - TDShussam jumah100% (1)

- Crystalline waterproofing for concrete structuresDocument2 pagesCrystalline waterproofing for concrete structuresRuel Buntog100% (1)

- Nitoproof 600PFDocument3 pagesNitoproof 600PFshyamsundar_ceNo ratings yet

- Methodology For PQC (00) Toll Plaza L&TDocument4 pagesMethodology For PQC (00) Toll Plaza L&TDeven PatleNo ratings yet

- Fenomastic Pure Colours Enamel MattDocument4 pagesFenomastic Pure Colours Enamel MattAslam KhanNo ratings yet

- Cebex 100 PDFDocument2 pagesCebex 100 PDFBijaya RaulaNo ratings yet

- Recron 3S GuideDocument11 pagesRecron 3S GuideJay BhayaniNo ratings yet

- UltraTech FixoBlock Thin Joint MortarDocument2 pagesUltraTech FixoBlock Thin Joint MortarRohan BagadiyaNo ratings yet

- Apron Concrete Repair Method R01Document19 pagesApron Concrete Repair Method R01ayhanarmanNo ratings yet

- Method Statement ConbextraGPDocument7 pagesMethod Statement ConbextraGPsinambeladavidNo ratings yet

- GP209 - Method Statement For Soil Preparation and Natural Grass InstallationDocument5 pagesGP209 - Method Statement For Soil Preparation and Natural Grass Installationatef ghazyNo ratings yet

- TDS - Bronco Cemgrout SP75Document4 pagesTDS - Bronco Cemgrout SP75Jignessh JoshiNo ratings yet

- PDS - Boscoseal AdmixDocument2 pagesPDS - Boscoseal AdmixKaren Grace DumangcasNo ratings yet

- pdfPlumbingLicenceApplication ShahidDocument2 pagespdfPlumbingLicenceApplication ShahidAKASH shrivastava50% (2)

- Sls 855-1Document28 pagesSls 855-1AnushkaNo ratings yet

- Checklist For Terrace WaterproofingDocument2 pagesChecklist For Terrace WaterproofingSantosh YadavNo ratings yet

- Renderoc TGDocument4 pagesRenderoc TGBalasubramanian Ananth100% (1)

- Install Geocell GuidelinesDocument3 pagesInstall Geocell GuidelinesDaniel MartinezNo ratings yet

- Construction Stage Wise Payment ScheduleDocument1 pageConstruction Stage Wise Payment SchedulePushpendra ShaktawatNo ratings yet

- Quotation For CG Kerbstone 165 MM PDFDocument1 pageQuotation For CG Kerbstone 165 MM PDFGovind GyawaliNo ratings yet

- Lysaght Klip-Lok OptimaDocument12 pagesLysaght Klip-Lok OptimaZaid AzmiNo ratings yet

- WMS-POP Punning PDFDocument1 pageWMS-POP Punning PDFRobin DahiyaNo ratings yet

- Vetonit Spatter Dash-MC SDM212Document2 pagesVetonit Spatter Dash-MC SDM212toni mujiyonoNo ratings yet

- Ac-Pqc-Injecto: Low Viscous Epoxy Injection ResinDocument2 pagesAc-Pqc-Injecto: Low Viscous Epoxy Injection ResinDeven PatleNo ratings yet

- Waterproof Planiseal 288Document3 pagesWaterproof Planiseal 288Chezy629No ratings yet

- Quality Assurance ManualDocument6 pagesQuality Assurance ManualEdgarDavidDiazCamposNo ratings yet

- Datasheet File - Conbextra GPDocument3 pagesDatasheet File - Conbextra GPmuraliNo ratings yet

- Hycrete Data Sheet - Hycrete W1000Document2 pagesHycrete Data Sheet - Hycrete W1000Anthony AjuloNo ratings yet

- Pumpable cementitious grout for filling voidsDocument4 pagesPumpable cementitious grout for filling voidsIqbal Muhammad100% (1)

- MTC For ThermocolDocument2 pagesMTC For ThermocolhariprasadNo ratings yet

- 131 - 1.9.1.2-85T - 316 Stainless SteelDocument4 pages131 - 1.9.1.2-85T - 316 Stainless SteelFtg WwfdfNo ratings yet

- MasterSeal 550Document2 pagesMasterSeal 550Muhammad Abdul Wajid RaiNo ratings yet

- Fosroc Auramix 300 AdmixtureDocument2 pagesFosroc Auramix 300 Admixture892513822950% (2)

- Concure WBDocument2 pagesConcure WBR.ThangarajNo ratings yet

- MS - CHRYSO Tapelastic Premia (Kalpitiya)Document3 pagesMS - CHRYSO Tapelastic Premia (Kalpitiya)Kasun HewagamaNo ratings yet

- Cicobond SBRDocument2 pagesCicobond SBRmud444100% (1)

- Epoxy and ESD FlooringDocument4 pagesEpoxy and ESD Flooringdox4printNo ratings yet

- Structured Method Statement For Concrete Repair - 1Document15 pagesStructured Method Statement For Concrete Repair - 1m.umar100% (1)

- Plinth ProtectionDocument3 pagesPlinth ProtectionSanjeev kumarNo ratings yet

- Ul Ul Ul Ultracote Tracote Tracote TracoteDocument3 pagesUl Ul Ul Ultracote Tracote Tracote TracoteJenniferValleNo ratings yet

- Epoxy Zinc Rich Primer Technical Data SheetDocument1 pageEpoxy Zinc Rich Primer Technical Data SheetDzulNo ratings yet

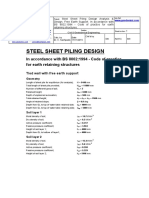

- Sachpazis Cantilever Steel Sheetpile Retaining Wall Analysis Design Free Earth Support To Eurocode 7Document14 pagesSachpazis Cantilever Steel Sheetpile Retaining Wall Analysis Design Free Earth Support To Eurocode 7rowatersNo ratings yet

- Steel Sheet Piling Design: in Accordance With BS 8002:1994 - Code of Practice For Earth Retaining StructuresDocument5 pagesSteel Sheet Piling Design: in Accordance With BS 8002:1994 - Code of Practice For Earth Retaining StructuresrowatersNo ratings yet

- Amer - Final Format Approved 04-18-13Document166 pagesAmer - Final Format Approved 04-18-13rowatersNo ratings yet

- The Rational Method-David B.thompson 2006Document7 pagesThe Rational Method-David B.thompson 2006Dani Tun TunNo ratings yet

- New Doc 21Document1 pageNew Doc 21rowatersNo ratings yet

- Tropical Residual Soil Properties On Slopes: M.F.Ishak, M.F. Zolkepli and M.AffendyDocument9 pagesTropical Residual Soil Properties On Slopes: M.F.Ishak, M.F. Zolkepli and M.AffendyrowatersNo ratings yet

- 3 PBDocument7 pages3 PBrowatersNo ratings yet

- 06 (86-87)Document3 pages06 (86-87)rowatersNo ratings yet

- Lasermap Asia: Your Lasermapping TeamDocument2 pagesLasermap Asia: Your Lasermapping TeamrowatersNo ratings yet

- 2017 Tekla Steel Fabrication Ebook Part1 enDocument10 pages2017 Tekla Steel Fabrication Ebook Part1 enrowatersNo ratings yet

- PDFDocument20 pagesPDFrowatersNo ratings yet

- Esy FenceDocument6 pagesEsy FencerowatersNo ratings yet

- Access For Appliances and Fire-Fighting Facilities For Fire & Rescue Service UseDocument9 pagesAccess For Appliances and Fire-Fighting Facilities For Fire & Rescue Service UserowatersNo ratings yet

- 2 PDFDocument10 pages2 PDFrowatersNo ratings yet

- PL7040 FDocument6 pagesPL7040 FrowatersNo ratings yet

- PL7040 FSI SUMP DESIGN 1 Model PDFDocument1 pagePL7040 FSI SUMP DESIGN 1 Model PDFrowatersNo ratings yet

- Technical Specification and Performance Curve for PL 7040 PumpDocument7 pagesTechnical Specification and Performance Curve for PL 7040 PumprowatersNo ratings yet

- RTS 18 New Zealand On-Road Tracking Curves For Heavy Motor VehiclesDocument20 pagesRTS 18 New Zealand On-Road Tracking Curves For Heavy Motor VehiclesRipper RipperripperNo ratings yet

- Wind-Resistant Design of High Mast Structures: Journal of The Chinese Institute of Engineers, Vol 33, No 4 (2010)Document1 pageWind-Resistant Design of High Mast Structures: Journal of The Chinese Institute of Engineers, Vol 33, No 4 (2010)rowatersNo ratings yet

- Pl7040 Fsi Sump Design 1 ModelDocument1 pagePl7040 Fsi Sump Design 1 ModelrowatersNo ratings yet

- Turn Pathsem1Document1 pageTurn Pathsem1rowatersNo ratings yet

- Freak Downpour, Winds Wreck Havoc in PenangDocument2 pagesFreak Downpour, Winds Wreck Havoc in PenangrowatersNo ratings yet

- Frequently Asked Questions ON Scale of FeesDocument2 pagesFrequently Asked Questions ON Scale of FeesrowatersNo ratings yet

- Life-Cycle Assessment Is A Technique Use To Analyse The Environmental ImpactsDocument15 pagesLife-Cycle Assessment Is A Technique Use To Analyse The Environmental ImpactskrutikaNo ratings yet

- CortadorDocument7 pagesCortadorMarco DiazNo ratings yet

- Bending - Wikipedia, The Free EncyclopediaDocument12 pagesBending - Wikipedia, The Free EncyclopediajazzclubNo ratings yet

- Electronic Thermostat Circuit Using TransistorsDocument2 pagesElectronic Thermostat Circuit Using Transistorstim schroderNo ratings yet

- Catalog Water Purifier 2016 YOUTHFULDocument5 pagesCatalog Water Purifier 2016 YOUTHFULhamadalami2007No ratings yet

- Henry Cat ENG 2013Document100 pagesHenry Cat ENG 2013strelbNo ratings yet

- ACPSB 380P Rooftop PackageDocument28 pagesACPSB 380P Rooftop Package6PakNo ratings yet

- Hawai Chappal: - SpecificationDocument28 pagesHawai Chappal: - SpecificationAvinash MishraNo ratings yet

- Ungerol Les 3 70 Spec 2018Document1 pageUngerol Les 3 70 Spec 2018Emmarold OdwongosNo ratings yet

- CAT6 Modular Plug Installation GuideDocument2 pagesCAT6 Modular Plug Installation GuideAndrés CisnerosNo ratings yet

- List of Steel TradersDocument2 pagesList of Steel TraderspreanandNo ratings yet

- Zintek® 300 HP + Techseal® Glossy Black SLDocument9 pagesZintek® 300 HP + Techseal® Glossy Black SLSyedMazharAliShahNo ratings yet

- MBSA1523 Managerial Economics Group 4 Presentation 1 ReportDocument12 pagesMBSA1523 Managerial Economics Group 4 Presentation 1 ReportPIONG MENG ZIAN MBS211233No ratings yet

- FM 306: Size Reduction and Sieving: ObjectiveDocument6 pagesFM 306: Size Reduction and Sieving: ObjectiveErcille Mae Oraiz PacamoNo ratings yet

- Petrolchimico Eng Ita PDFDocument28 pagesPetrolchimico Eng Ita PDFJavier TrujillanoNo ratings yet

- Calpeda MXP Multistage Horizontal PumpDocument2 pagesCalpeda MXP Multistage Horizontal PumpWayne SeamanNo ratings yet

- Renewable Energy Resources - Lecture 5Document29 pagesRenewable Energy Resources - Lecture 5Kifayat UllahNo ratings yet

- SmagDocument28 pagesSmagcsvasukiNo ratings yet

- Lift Truck Gear From DTAUTO - CADocument32 pagesLift Truck Gear From DTAUTO - CAGregGGHNo ratings yet

- Design and Optimization of A Formula SAE VehicleDocument163 pagesDesign and Optimization of A Formula SAE VehiclesadsdNo ratings yet

- HMT Assignment1Document8 pagesHMT Assignment1Navya IshaNo ratings yet

- T-600 Series ManualDocument15 pagesT-600 Series ManualJaime RichardsonNo ratings yet

- Tower Signal BoqDocument2 pagesTower Signal Boqrafael velardeNo ratings yet

- W4-SCIENCE Grade 5Document56 pagesW4-SCIENCE Grade 5Gladish AnsubanNo ratings yet