Professional Documents

Culture Documents

Imm D-h7x Tfi95gb

Uploaded by

Anonymous A55PY1bCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Imm D-h7x Tfi95gb

Uploaded by

Anonymous A55PY1bCopyright:

Available Formats

017A/ENGD-#S-TFI95GB

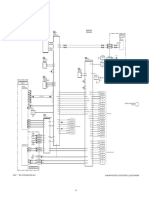

Installation and Maintenance Manual 3 wire type NPN output 3 wire type PNP output

Solid State Auto-Switch Series D-H7A1, D-H7A2, DC(+) DC(+)

D-H7BA, D-H7B, D-H7BW, D-H7NW, D-H7PW Brown (Red) Brown (Red)

For future reference, please keep this manual in a safe place OUT OUT

Problem Switch Load Switch Load

Power Black (White) Power

This manual should be read in conjunction with the current product catalogue Black (White) source

source DC(-)

DC(-)

Safety Instructions 2. Only trained personnel should operate pneumatically Stay ON

operated machinery and equipment. Condition (sometimes OFF) Blue (Black) Blue (Black)

These safety instructions are intended to prevent a hazardous situa- Compressed air can be dangerous if an operator is unfamiliar

tion and/or equipment damage. These instructions indicate the level with it. Assembly, handling or repair of pneumatic systems should 2 wire type (Sink output) 2 wire type (Source output)

of potential hazard by label of Caution, Warning or Danger. be performed by trained and experienced operators. Indicator Stay ON

Stay OFF OUT(+)

To ensure safety, be sure to observe ISO4414 (Note1), JIS B 8370 (Note2) lamp lights OUT(+)

(sometimes ON) Load

and other safety practices. 3. Do not service machinery/equipment or attempt to Power

Stay OFF Brown (Red) Brown (Red) source

Note 1: ISO 4414: Pneumatic fluid power Recommendations for the remove component until safety is confirmed. Switch

application of equipment to transmission and control systems. 1) Inspection and maintenance of machinery/equipment should Switch Power

Indicator Normal OUT(-) source OUT(-)

Note 2: JIS B 8370: Pneumatic system axiom. only be performed after confirmation of safe locked-out Stay OFF Load

control positions. lamp lights

Blue (Black) Blue (Black)

CAUTION : Operator error could result in injury or 2) When equipment is to be removed, confirm the safety process

equipment damage. as mentioned above. Switch off air and electrical supplies and Normal

exhaust all residual compressed air in the system. Source voltage 2 wires/ Fig 4

3) Before machinery/equipment is re-started, ensure all safety or load voltage 3 wires

WARNING : Operator error could result in serious measures to prevent sudden movement of cylinders etc.

injury or loss of life. (Bleed air into the system gradually to create back-pressure, Normal Abnormal Exterior dimensions Appropriate tightening torque

2 wires/ 3 wires 2 wires

i.e. incorporate a soft-start valve). 2 wires

DANGER : In extreme conditions, there is a 3 wires

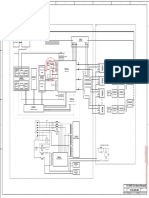

D-H7A1/H7A2/H7B

possible result of serious injury or loss of life. 4. Contact SMC if the product is to be used in any of the

following conditions: 3 wires Load spec. Replace the Load spec. Indicator lamp Autoswitch

1) Conditions and environments beyond the given specifica- check 1 switch check 2

Autoswitch set screw

WARNING tions, or if product is used outdoors.

Normal Abnormal Normal Abnormal Normal Abnormal M3X0. 5x14l

2) Installations in conjunction with atomic energy, railway, air

6. 5

Wiring

8

1. The compatibility of pneumatic equipment is the respon- navigation, vehicles, medical equipment, food and beverage, (output) check

sibility of the person who designs the pneumatic system recreation equipment, emergency stop circuits, press 9

or decides its specifications. applications, or safety equipment. Normal Abnormal 29 4. 6

Since the products specified here are used in various operating 3) An application which has the possibility of having negative Autoswitch mounting band

conditions, their compatibility for the specific pneumatic system effects on people, property, or animals, requiring special (with bracket)

must be based on specifications or after analysis and/or tests to safety analysis. 4. 3 3. 5

3. 4

meet your specific requirements. Fig 5

CAUTION A B A C D E B B A A F D

M3 mounting screw correct tightening torque is 0.8~1.0 Nm

11. 5

8

Ensure that the air supply system is filtered to 5 micron. (8.2~10.2 kgf.cm)S

10. 5 Most sensitive position

1. Product specification Setting the switch detection position

Load spec. check 1 . . .ON voltage > Load voltage - Internal voltage drop

Load spec. check 2 . . .OFF current > Leak current Position the actuator at its stroke end.

D-H7BW

Model number D-H7A1 D-H7NW D-H7A2 D-H7PW D-H7B

D-H7BA

A . . .Switch output parts failure (replace) D . . . .Switch failure Single colour display

Wiring style Three wire type Two wire type D-H7BW/H7NW/H7PW/H7BA Move the auto-switch into the centre of the operating range and

B . . .Correct wiring E . . . .Replace cylinder. Detectable magnet field inadequate (No magnet)

Output style NPN type PNP type ensure that the red LED is ON.

Application IC, Relay, PLC 24V DC Relay, PLC C . . .Replace switch 2 wires R 3 wires F . . . .Replace PLC input board or replace switch 2 wire R3 wires

Source voltage DC51224V (DC4.5~28V) Indicator lamp Two colour display

Current consumption 10mA or less Move the Auto-switch into the centre of the operating range and

Load voltage DC28V or less DC24V (DC10~28V) Fig 1 ensure that the green LED is ON.

Load current 40mA or less 80mA or less 5~40mA or less

6. 5

8

Internal voltage drop 1.5V or less 0.8V or less 4V or less not start. Do not use this switch in conditions where temperatures are outside

Leak current 100A or less at DC24V 0.8mA or less at DC24V Ensure that, if using a load that can generate a surge voltage ie. Relay of the switch operating Spec. 9 ON

Operating time 1ms or less or Solenoid valve, a built-in surge protection circuit is installed. Protect the switch from weld spatter and accumulation of iron dust etc. 29 4. 6

Operating OFF

One colour Two colour One colour Two colour One colour Two colour Red Green Red

indicator lamp* If an auto-switch is to be used to generate an inter-lock signal, which Maintenance

Proof impact 1000m/s2 requires high reliability, then instigate mechanical protection, or place 4. 3 3. 5

3. 4

Operating range

Insulation resistance 50M or more at DC500V mega another switch, double inter-lock style, together. Ensure the correct To avoid incorrect operation periodic maintenance should be carried out.

Proof voltage AC1000V for 1 minute (lead wire, between cases) operation of this Inter-lock frequently. Check tightness of mounting screw regularly to prevent possible

11. 5

Ambient temperature -10~60C Ensure, when installing this product, that enough space is movement of the switch from its set position.

8

Protection structure IEC529 standard IP67, JISC0920 available for maintenance to be carried out. Regularly check condition of the wiring. Repair insulation damage

immediately or replace the switch.

* One colour: Red diode lights when ON CAUTION If a red LED is showing this indicates that the switch has moved Fig 6

Two colour: Operating positionRed diode lights from the set position. Re-adjust the switch until the green LED is

Optimum operating positionGreen diode lights Do not subject this product to any form of impact damage. showing (this is the optimum position).

Do not lift an actuator, fitted with an auto-switch, by the switch lead, Detecting actuator stroke end

Installation lowing conditions before operation, and note that the internal voltage as stress may be applied to the inside of the switch. CAUTION

drop and leak current have a considerable influence on the serial and Ensure auto-switch mounting screw is tightened to the correct torque Refer to dimensions A & B in the actuator catalogue.

Actuators parallel connection of the 2-wire solid state switch. (see Mounting of switch bracket). If detection failure occurs i.e. LED remains ON follow the faultfinding Fig 3

Adjust the auto-switch so that the ON position coincides with the cen- chart above (Fig 1). CAUTION

WARNING Leak current influence tre of the operating area. If the switch is set to one side or the other Basic wiring (Fig 4)

I.E Voltage generated to the load when the power is turned off. of this centre position then inconsistent operation will occur. For applications involving contact with water, elasticity, and welding, D-H7BA (Improved water resistant type)

To eliminate the possibility of magnetic interference between switch- contact your nearest SMC Office. (See at the end of this Manual.) Lead wire colour in brackets indicates products complying with IEC. Although this switch has improved properties with regard to oil and

es, please ensure that, when two or more actuators are used, in Voltage generated = Auto-switch leak current x load resistance. If this Wiring water resistance, it should not be exposed to cutting oil, which con-

parallel, they are kept at least 40mm apart. voltage exceeds the OFF voltage of the load, it is possible that the load If the hysteresis, between the ON and OFF position of the switch is Connection with PLC (sequence controller) tains additives, high-pressure water jets or extremes of temperature.

may stay ON. In order to match the condition of the controller-input Do not apply repeated bending or tensile forces to the incorrect please consult SMC. Depending on the PLC input specification, the output design of 3 wire

Mid-stoke position sensing unit and leak current, then auto-switch leak current must be less than connecting wiring as this may cause disconnection. Bend radius is type switches and 2 wire type switches differ. (See below) CAUTION

Exercise caution when attempting to detect the piston at mid-position, input unit OFF current. approximately R40mm or more. Hysteresis

without stopping, as the switch detection time may be too short, Connect the load before applying power to the switch, failure to do so PLC input specification 3 wire output type 2 wire connecting type In all cases do not clean with a solvent solution.

particularly at relatively high actuator speeds. Detectable max. piston Internal voltage drop may cause excess current to damage the switch. Sink input NPN output Sink output mode

Piston moving When you enquire about the product, please contact the following

speed can be obtained by the following formula: Should an internal voltage drop occur, then the load supply voltage Ensure wiring is carried out correctly. Not all wiring modes have pro- ON position Source input PNP output Source output mode

direction SMC Corporation:

will also drop as the switch operates. (Load supply voltage = Source tection and the switch may be damaged.

ENGLAND Phone 01908-563888 TURKEY Phone 212-2211512

V (mm/s) = Auto switch operating range (mm) voltage Internal voltage drop). Separate signal lines from power/high voltage lines to prevent 'noise'. Mounting of switch bracket

ITALY Phone 02-92711 GERMANY Phone 6103-402-0

Load operating time (m/s) When the load supply voltage becomes lower than the switch ON Ensure all wiring is correctly and fully insulated.

Hysteresis HOLLAND Phone 020-5318888 FRANCE Phone 01-64-76-10-00

voltage, the load may not operate correctly. Piston moving Each actuator has a specified mounting bracket to mount the switch

SWITZERLAND Phone 052-34-0022 SWEDEN Phone 08-603 07 00

Where possible keep all wiring as short as possible. WARNING direction to the actuator. The type of bracket depends on the following:

SPAIN Phone 945-184100 AUSTRIA Phone 02262-62-280

WARNING Type of actuator, and tube O.D. Please consult the current

Phone 902-255255 IRELAND Phone 01-4501822

CAUTION DO NOT USE THIS SWITCH IN AN EXPLOSIVE ATMOSPHERE. actuator catalogue for details.

GREECE Phone 01-3426076 DENMARK Phone 8738-0800

Incorrect load voltage Do not use this switch in high magnetic fields, as this will damage the OFF position When fitting an auto-switch for the first time please ensure that the

FINLAND Phone 09-68 10 21 NORWAY Phone 67-12 90 20

If the 2-wire type solid state auto-switch has a large internal voltage Although the switch will operate correctly, even if the load current is switch and actuator magnet. actuator is fitted with a magnet and that the brackets are correct for

BELGIUM Phone 03-3551464 POLAND Phone 48-22-6131847

drop, and leakage current is also high, it is possible that the load may below the limit of the specification, the indicator light will be Do not use this switch in water-laden atmospheres, oil or chemical the actuator type.

not operate correctly due to incorrect load spec. Please confirm the fol- 'dimmed'. If the load current falls to 3mA, or lower, the operation may laden atmospheres. Fig 2

You might also like

- N9 and N10 With SCR (2014 - 2016) : Engine Wiring Diagram Engine Control Module (ECM)Document4 pagesN9 and N10 With SCR (2014 - 2016) : Engine Wiring Diagram Engine Control Module (ECM)Phil B.No ratings yet

- 0000003221Document3 pages0000003221Ael Ch100% (2)

- Protection Guide enDocument74 pagesProtection Guide enEmad100% (28)

- Piper Lance II - Turbo Lance II-Maintenance - smv1986Document568 pagesPiper Lance II - Turbo Lance II-Maintenance - smv1986willkobiNo ratings yet

- TTNFC EN 00 - CircuitDocument18 pagesTTNFC EN 00 - CircuitRoseller SumonodNo ratings yet

- Wiring Diagram DSE 7320 AMFDocument1 pageWiring Diagram DSE 7320 AMFAbdulrehman SoomroNo ratings yet

- 2017 09Document164 pages2017 09sowabar100% (1)

- TW Ycm01265958803Document62 pagesTW Ycm0126595880313239563No ratings yet

- Wiring Diagram DSE 7320 AMF PDFDocument1 pageWiring Diagram DSE 7320 AMF PDFAgung Prasetyo83% (6)

- Conflict MangementDocument35 pagesConflict Mangementmadhuri_bind100% (1)

- Jtm-1 Handmades Version: by MatecDocument16 pagesJtm-1 Handmades Version: by MatecRodrigo Amaral100% (1)

- Wiring Diagram DSE 7320 AMF PDFDocument1 pageWiring Diagram DSE 7320 AMF PDFKo Thet100% (5)

- Wiring Diagram DSE 7320 AMFDocument1 pageWiring Diagram DSE 7320 AMFLizardo Astudillo Cruz100% (1)

- Classic Text Messages Morning GreetingsDocument2 pagesClassic Text Messages Morning GreetingsDhamukarthikeyanNo ratings yet

- Merlin Gerin Technical Guide Medium VoltageDocument80 pagesMerlin Gerin Technical Guide Medium Voltagepavlovicg100% (1)

- Typical wiring diagram for generator control panelDocument1 pageTypical wiring diagram for generator control panelIPS RSSK0% (1)

- Wiring Diagram DSE 7320 AMFDocument1 pageWiring Diagram DSE 7320 AMFIvan Alves100% (1)

- Soft Starter HandbookDocument94 pagesSoft Starter Handbookapi-3844354100% (6)

- EM150-12WS - (LCR 600 E3708-3709 Series Wiring Schematic)Document1 pageEM150-12WS - (LCR 600 E3708-3709 Series Wiring Schematic)Rizky Andriansyah OmardaniNo ratings yet

- Output Circuit Wiring Graph Ordering InformationDocument2 pagesOutput Circuit Wiring Graph Ordering InformationNikolas Kolasni Lakenir Ckerde DockosNo ratings yet

- Panasonic Dp-100 Series Instruction ManualDocument4 pagesPanasonic Dp-100 Series Instruction ManualMarco Antonio ReyesNo ratings yet

- Block Diagram: 5.1 Main BoardDocument8 pagesBlock Diagram: 5.1 Main BoardFRANCISCO ALVARADO VERGARANo ratings yet

- ES2020 InimDocument1 pageES2020 InimmohammadNo ratings yet

- Schematics Laptop Lenovo b490 La4801126410106Document103 pagesSchematics Laptop Lenovo b490 La4801126410106Nirmal JithNo ratings yet

- Electrical Specifications 注意事項: Power Input WiringDocument2 pagesElectrical Specifications 注意事項: Power Input WiringAmmar AlkindyNo ratings yet

- 2SB1587 PDFDocument1 page2SB1587 PDFisaiasvaNo ratings yet

- EN AC-CNC2019-1D-Mega R1.x Diagram OVERVIEWDocument2 pagesEN AC-CNC2019-1D-Mega R1.x Diagram OVERVIEWLionel SebertNo ratings yet

- Changeover Switch Base Mounting: CCF CCPDocument1 pageChangeover Switch Base Mounting: CCF CCPAhmed MoharramNo ratings yet

- 2SB1647Document1 page2SB1647Julio barriosNo ratings yet

- Automatic meter testing system diagramDocument1 pageAutomatic meter testing system diagramBach MaiNo ratings yet

- 12 Block Diagram: 12.1. Servo & System ControlDocument18 pages12 Block Diagram: 12.1. Servo & System ControlPaulo Roberto s freireNo ratings yet

- DYNC3005 Manual ENDocument2 pagesDYNC3005 Manual ENRiccardo GentilettiNo ratings yet

- Data bus and control interfaces for clinical analyzer componentsDocument1 pageData bus and control interfaces for clinical analyzer componentsIbrahimMoussaM7No ratings yet

- FN1016 2SD2390Document1 pageFN1016 2SD2390jcarlos1960No ratings yet

- Honda PCX 2014-More Electrical WiringDocument1 pageHonda PCX 2014-More Electrical WiringTACOMPUTER33% (3)

- RGBW/RGB/CCT/Dimming 4 Channel LED RF Controller: Model No.: C4 (150-500ma) / C4 (350-1200ma)Document2 pagesRGBW/RGB/CCT/Dimming 4 Channel LED RF Controller: Model No.: C4 (150-500ma) / C4 (350-1200ma)justfanloveNo ratings yet

- Ena Enc en Drw171375aa 20180118 He 20180122Document1 pageEna Enc en Drw171375aa 20180118 He 20180122Umar faroukNo ratings yet

- LG 50PJ350 Block Diagram (SCH) 2 PDFDocument3 pagesLG 50PJ350 Block Diagram (SCH) 2 PDFMahmoud Digital-DigitalNo ratings yet

- Net2 PSU With Trigger Disconnect: OverviewDocument4 pagesNet2 PSU With Trigger Disconnect: OverviewBoris MaldonadoNo ratings yet

- (Esquema) P22D 11281-1 Ot5vj SchematicsDocument104 pages(Esquema) P22D 11281-1 Ot5vj SchematicsVictor Arguello GonzalezNo ratings yet

- 24 Urban Cruiser (Cont. Next Page) : Abs (W/ VSC), TRC and VSCDocument2 pages24 Urban Cruiser (Cont. Next Page) : Abs (W/ VSC), TRC and VSCHEMIL ROBERTO RODRIGUEZ HERRERANo ratings yet

- To Do YC01-003-001 (A2)Document1 pageTo Do YC01-003-001 (A2)Bach MaiNo ratings yet

- sg3400 3125 2500HV MV 20 - DatasheetDocument1 pagesg3400 3125 2500HV MV 20 - DatasheetAnindio PrabuNo ratings yet

- Touchworx Flatscreen Lane Pair Wiring DiagramDocument1 pageTouchworx Flatscreen Lane Pair Wiring DiagramNathan BukoskiNo ratings yet

- 2P162816-1 Dcs302ca61Document1 page2P162816-1 Dcs302ca61Ruan FernandesNo ratings yet

- J7-c USB Tester English Manual (SZB)Document1 pageJ7-c USB Tester English Manual (SZB)GT S5360No ratings yet

- Darlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2439)Document1 pageDarlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2439)Elcio BrembattiNo ratings yet

- Typical wiring diagram for generator control panelDocument1 pageTypical wiring diagram for generator control panelMamadou djibril Ba100% (1)

- Wiring Diagram DSE 7320 AMFDocument1 pageWiring Diagram DSE 7320 AMFFlorent A. d'Agoué CADETENo ratings yet

- Wiring Diagram KompressorDocument1 pageWiring Diagram KompressorIPS RSSKNo ratings yet

- Wiring Diagram Dse 7320 Amf PDF FreeDocument1 pageWiring Diagram Dse 7320 Amf PDF FreeSemih GençNo ratings yet

- Wiring Diagram DSE 7320 AMF PDFDocument1 pageWiring Diagram DSE 7320 AMF PDFBTS PowerStation100% (1)

- Wiring Diagram Dse 7320 Amf PDF FreeDocument1 pageWiring Diagram Dse 7320 Amf PDF FreeSemih GençNo ratings yet

- Wiring Diagram Dse 7320 Amf PDF FreeDocument1 pageWiring Diagram Dse 7320 Amf PDF FreeSemih GençNo ratings yet

- Muxless Schematics DocumentDocument104 pagesMuxless Schematics DocumentFernanda Ferreira de FreitasNo ratings yet

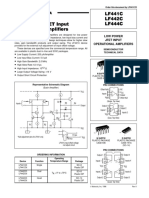

- LF441CNDocument10 pagesLF441CNingucvNo ratings yet

- Ti 20221115 Sg320hx and Sg350hx System Diagram v2 enDocument2 pagesTi 20221115 Sg320hx and Sg350hx System Diagram v2 en2D EngenhariaNo ratings yet

- CONTROLLINO MAXI PinoutDocument1 pageCONTROLLINO MAXI PinoutAVRNATORNo ratings yet

- KV-27FS320 Block Diagram and SchematicsDocument9 pagesKV-27FS320 Block Diagram and SchematicsMilly ContrerasNo ratings yet

- Gateway NV54 NV58 (Wistron SJV50-MV)Document59 pagesGateway NV54 NV58 (Wistron SJV50-MV)German ValenciaNo ratings yet

- Darlington: Silicon PNP Epitaxial Planar TransistorDocument1 pageDarlington: Silicon PNP Epitaxial Planar Transistorroberto carlos martinez narvaezNo ratings yet

- Darlington: Silicon PNP Epitaxial Planar TransistorDocument1 pageDarlington: Silicon PNP Epitaxial Planar Transistormarcelo giussaniNo ratings yet

- TSL1401Document8 pagesTSL1401Chế ThiệnNo ratings yet

- Darlington: Silicon NPN Triple Diffused Planar Transistor (Complement To Type 2SB1687)Document1 pageDarlington: Silicon NPN Triple Diffused Planar Transistor (Complement To Type 2SB1687)mundomusicalmeriaNo ratings yet

- High voltage disconnect circuit breaker warningDocument1 pageHigh voltage disconnect circuit breaker warningDražen ĐukićNo ratings yet

- QuickStartGuide - 10U For Shoei J-Cruise (RC4) - 2.0.0 - en - 181025 - MP0501656Document2 pagesQuickStartGuide - 10U For Shoei J-Cruise (RC4) - 2.0.0 - en - 181025 - MP0501656Aditya IyerNo ratings yet

- GTU102.2 ING - Vers 2011Document90 pagesGTU102.2 ING - Vers 2011Anonymous A55PY1bNo ratings yet

- CB FuseDocument31 pagesCB FuseAnonymous A55PY1bNo ratings yet

- Catalogue Lamps and Gears 2014Document312 pagesCatalogue Lamps and Gears 2014Anonymous A55PY1bNo ratings yet

- Catalogue Lamps and Gears 2014Document312 pagesCatalogue Lamps and Gears 2014Anonymous A55PY1bNo ratings yet

- Catalogue Lamps and Gears 2014Document312 pagesCatalogue Lamps and Gears 2014Anonymous A55PY1bNo ratings yet

- Imm D-h7x Tfi95gbDocument1 pageImm D-h7x Tfi95gbAnonymous A55PY1bNo ratings yet

- VAMP - IEC 60870-5-103 Interoperability ListDocument19 pagesVAMP - IEC 60870-5-103 Interoperability ListAnonymous A55PY1bNo ratings yet

- Imm D-h7x Tfi95gbDocument1 pageImm D-h7x Tfi95gbAnonymous A55PY1bNo ratings yet

- Series: Dual Rod CylinderDocument22 pagesSeries: Dual Rod CylinderAnonymous A55PY1bNo ratings yet

- Cooperating Sequential Processes (Dijkstra) - PaperDocument74 pagesCooperating Sequential Processes (Dijkstra) - PaperCole AroraNo ratings yet

- Lecture 3Document16 pagesLecture 3Awil MohamedNo ratings yet

- Electric Current and Ohm's LawDocument2 pagesElectric Current and Ohm's LawSheldon MillerNo ratings yet

- Name: Keatlaretse Bridgette Surname: Macucwa Module Name: Social Work Practice Module Code: BSW 2605 Assessment No: 2 Due Date: 14 August 2020Document6 pagesName: Keatlaretse Bridgette Surname: Macucwa Module Name: Social Work Practice Module Code: BSW 2605 Assessment No: 2 Due Date: 14 August 2020keatlaretse macucwaNo ratings yet

- Phase-Field Models For The Evolution of Complex SystemsDocument37 pagesPhase-Field Models For The Evolution of Complex SystemsMathis PlappNo ratings yet

- Filters in GeneralDocument3 pagesFilters in GeneralJoseGarciaRuizNo ratings yet

- Calibration Procedure Crowcon Xgard Gas Detectors - 5720273 - 01Document16 pagesCalibration Procedure Crowcon Xgard Gas Detectors - 5720273 - 01Daniel Rolando Gutierrez FuentesNo ratings yet

- Screen 2014 Nettleton 5 28 PDFDocument24 pagesScreen 2014 Nettleton 5 28 PDFtaroefNo ratings yet

- Standards List July2019Document8 pagesStandards List July2019Richard PNo ratings yet

- 2004 Level 3 Questions: Newham Bulk LEADocument18 pages2004 Level 3 Questions: Newham Bulk LEAPatience NgundeNo ratings yet

- Nb7040 - Rules For Pipe Connections and Spools: Acc. Building Specification. Rev. 2, November 2016Document4 pagesNb7040 - Rules For Pipe Connections and Spools: Acc. Building Specification. Rev. 2, November 201624142414No ratings yet

- ICN Question Bank Unit-1, 2 and 3 (Upto GSM Identifier)Document1 pageICN Question Bank Unit-1, 2 and 3 (Upto GSM Identifier)Snehal PatelNo ratings yet

- The Jambeli Culture of South Coastal Ecuador Estrada Meggers y EvansDocument93 pagesThe Jambeli Culture of South Coastal Ecuador Estrada Meggers y EvansMarco VargasNo ratings yet

- Module 4 NotesDocument20 pagesModule 4 NotesvijaykumaryadavNo ratings yet

- PNR Status. - Train Details: Number Name Class QuotaDocument1 pagePNR Status. - Train Details: Number Name Class QuotaPranshuNo ratings yet

- M & E Eyerusalem TesfayeDocument12 pagesM & E Eyerusalem Tesfayeeyerusalem tesfayeNo ratings yet

- Openroads Designer User ManualDocument112 pagesOpenroads Designer User ManualNilay BhavsarNo ratings yet

- Disaster Readiness Exam SpecificationsDocument2 pagesDisaster Readiness Exam SpecificationsRICHARD CORTEZNo ratings yet

- t-030f Spanish p35-48Document4 pagest-030f Spanish p35-48Juan ContrerasNo ratings yet

- Iso 9712 2012 PDFDocument19 pagesIso 9712 2012 PDFBala KrishnanNo ratings yet

- ISSAQ: An Integrated Sensing Systems For Real-Time Indoor Air Quality MonitoringDocument15 pagesISSAQ: An Integrated Sensing Systems For Real-Time Indoor Air Quality MonitoringKemHuyềnNo ratings yet

- Brochure GM IM Roller Mill Antares MDDR MDDT en LowDocument8 pagesBrochure GM IM Roller Mill Antares MDDR MDDT en Lowahmed shomanNo ratings yet

- SBC For Toll PlazaDocument6 pagesSBC For Toll PlazaruchitaNo ratings yet

- NumericalsDocument6 pagesNumericalsaditya dhapodkarNo ratings yet

- Katie Nelson PDFDocument3 pagesKatie Nelson PDFKatie NNo ratings yet